Exhaust device

A technology for exhaust devices and jackets, which is applied in the automotive field and can solve problems such as difficult cleaning and easy sticking of rubber materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

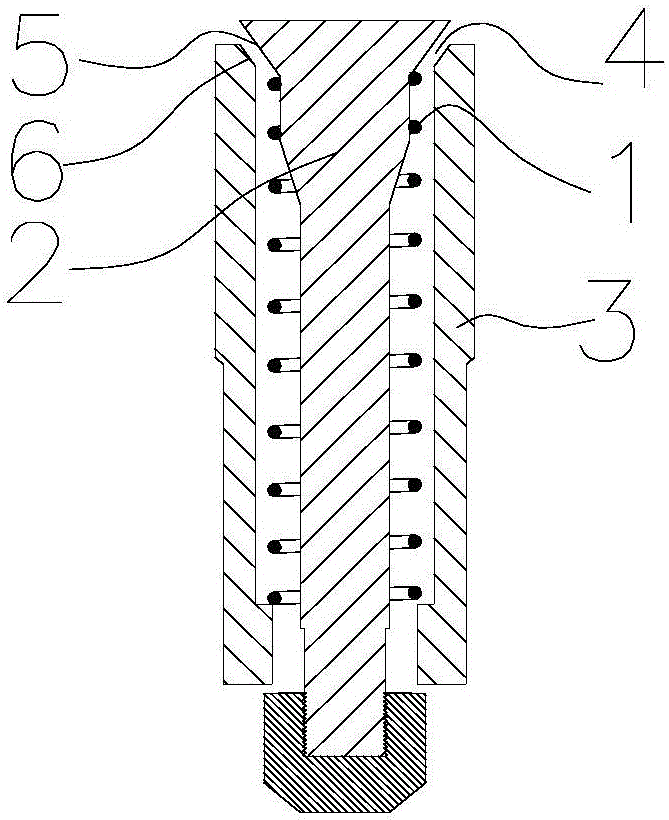

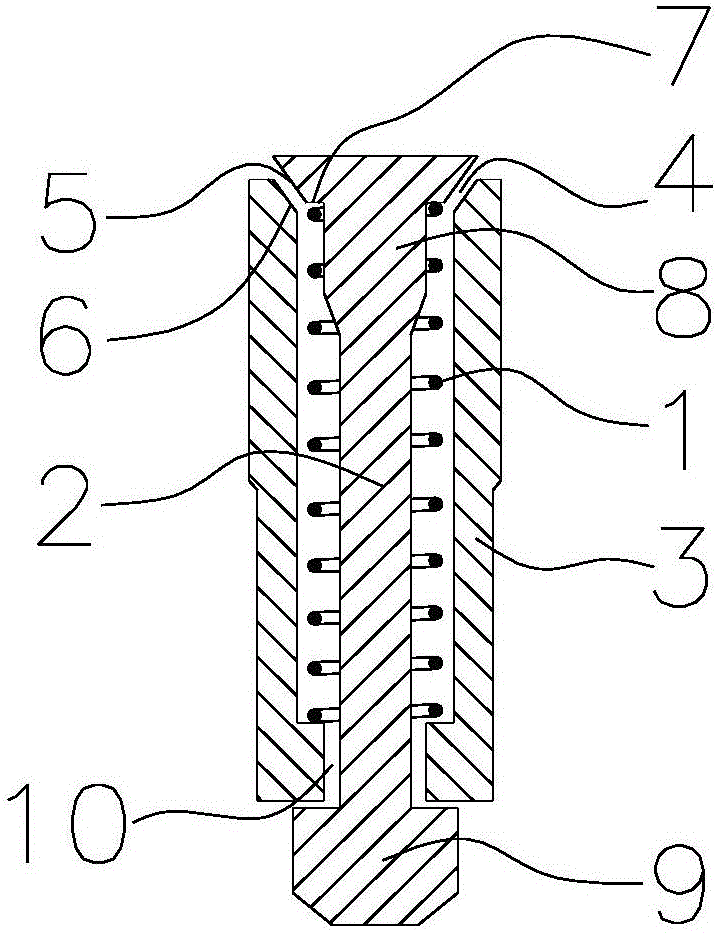

[0034] An exhaust device, comprising: an inner core, a spring and an outer jacket, the spring is located between the inner core and the outer jacket, and is placed outside the inner core, and a row is arranged between the outer jacket and the inner core. Air cavity;

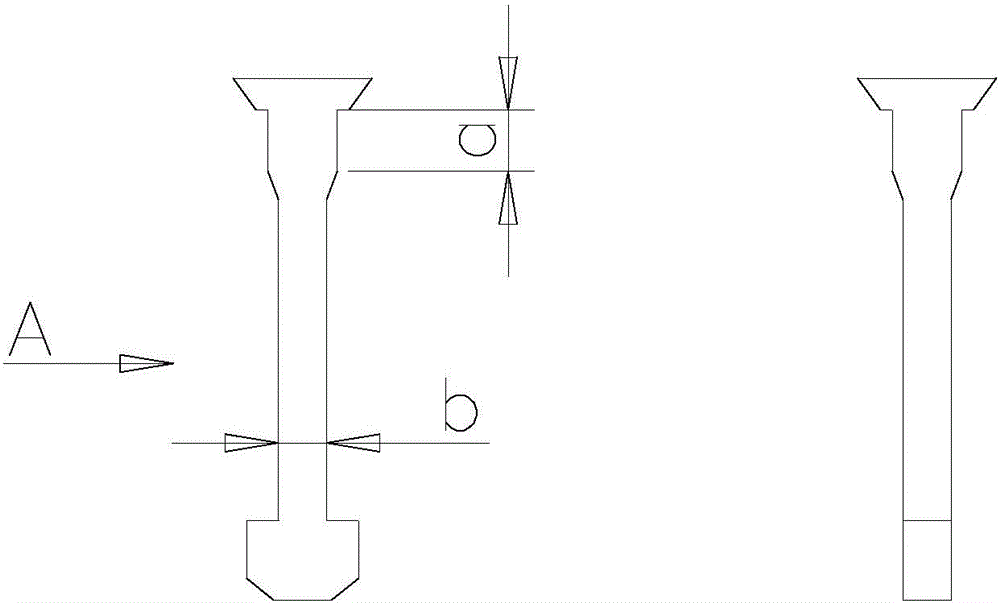

[0035] The inner core includes a core head, a core rod and a core tail, the core head is arranged at one end of the inner core close to the inner cavity of the tire molding mold, and the core head and the outer jacket are respectively provided with mutually matching core heads The sealing surface and the sealing surface of the jacket, the sealing surface of the core head and the top surface of the core head form an acute angle conical surface, so that the sealing surface of the core head and the sealing surface of the jacket form a seal when the raw tire is vulcanized; the sealing surface of the core head and the core There is a stepped surface between the rod sections, the width of the bottom surface of the core...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com