Wade extruder device capable of adjusting extruding force

A technology of extrusion force and extruder, which is applied in the field of Wade extruder device, can solve the problems of unable to adjust the extrusion force, affect the accuracy of 3D printing, and difficult to control the distance, etc., to achieve convenient adjustment of extrusion force and cost Reduced, good installation integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

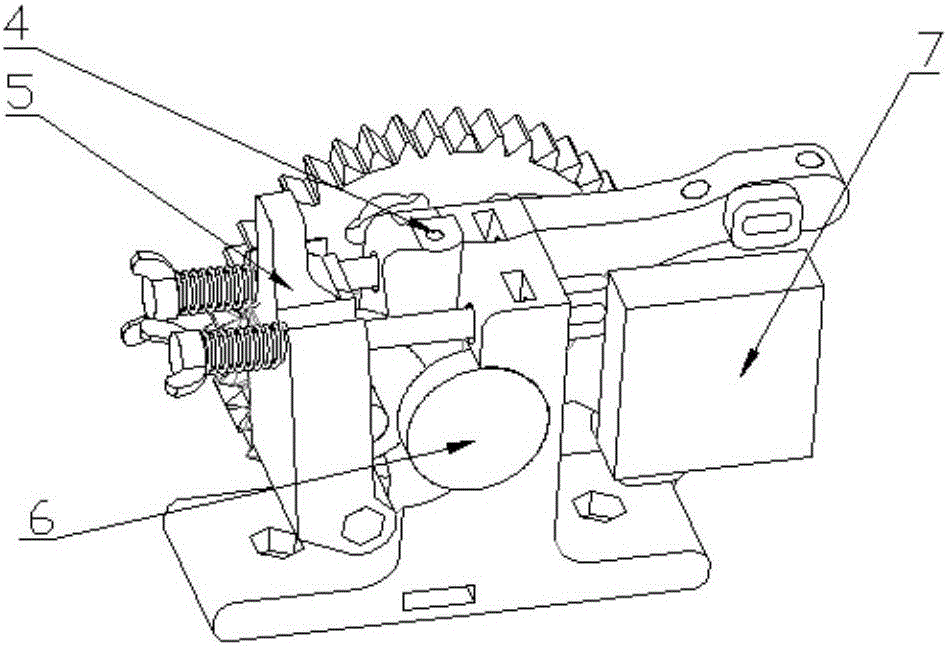

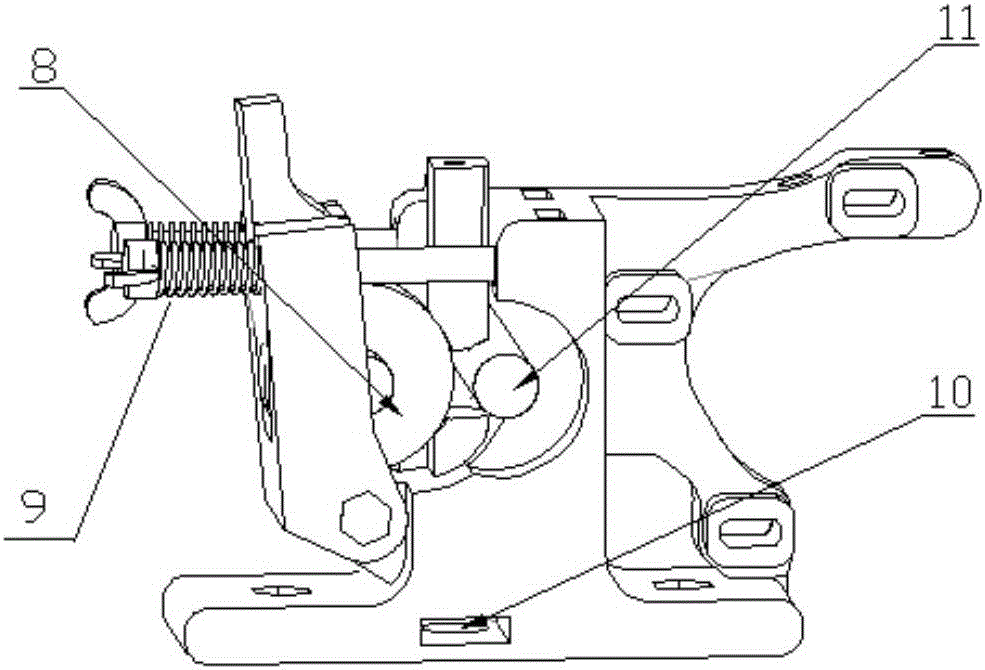

[0030] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

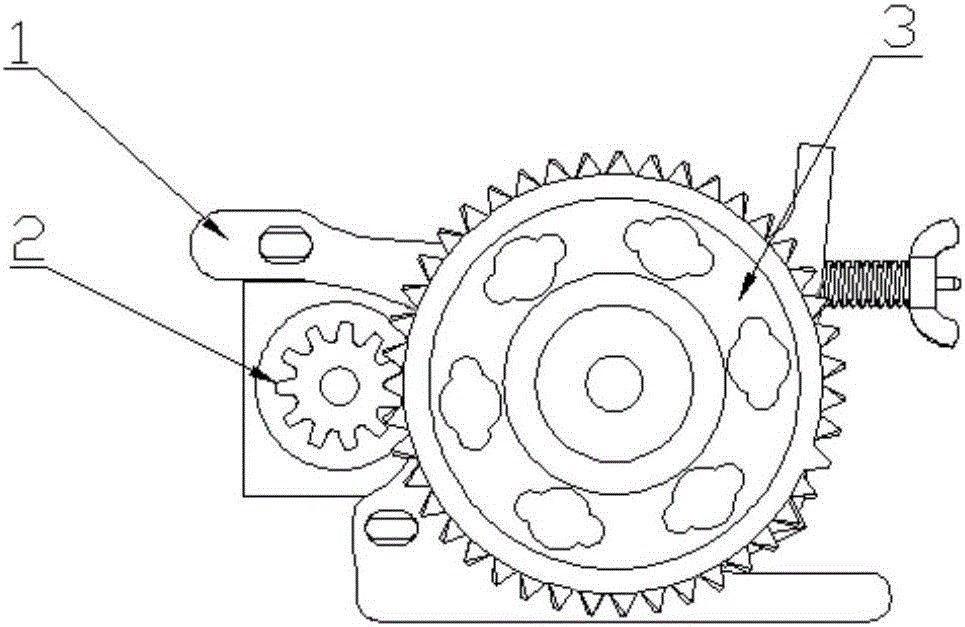

[0031] Such as figure 1 , figure 2 , image 3 As shown, the present invention discloses a Wade extruder device with adjustable extrusion force, which includes an extrusion arm, a support arm, a stepping motor, a driving gear, a driven gear, a driven wheel, and an extrusion force adjustment device;

[0032] The stepping motor is arranged on the support arm, and its output shaft is fixedly connected with the shaft center of the driving gear;

[0033] The driven gear and the bearing are respectively arranged on both sides of the support arm; one end of the extrusion shaft is fixedly connected to the axis of the driven gear, and the other end is connected to the bearing; the bearing is fixedly connected to the support arm;

[0034] The driven gear meshes with the driving gear;

[0035] The inner wall of the extrusion arm is provided with a groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com