Omni-directional wheels for full range of motion

An omnidirectional, omnidirectional wheel technology, applied in the field of omnidirectional wheels, can solve the problems of limiting the moving ability of omnidirectional wheels, unable to realize the left and right autonomous movement of the wheels, etc., and achieve the effect of reducing additional unbalanced torque and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

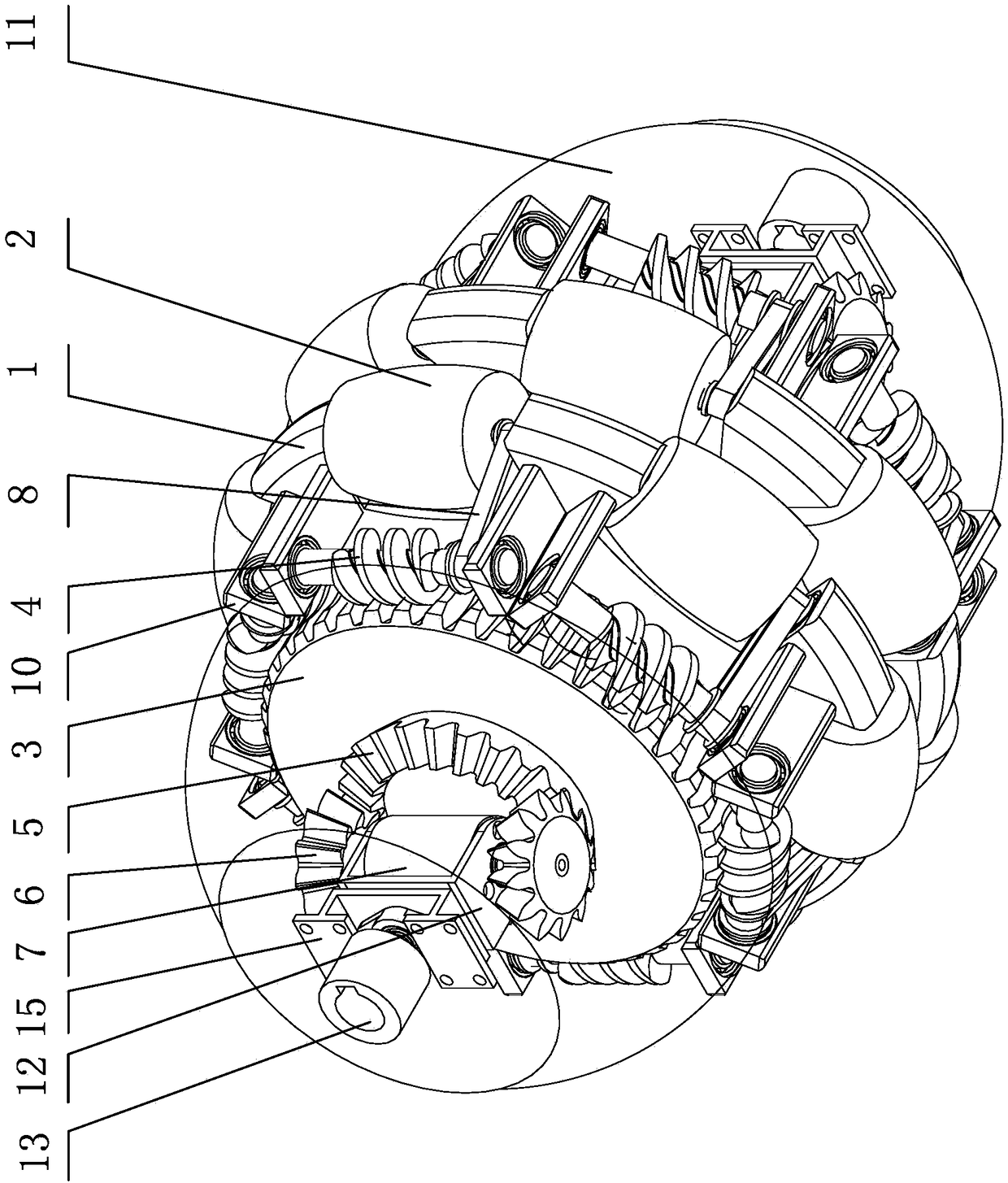

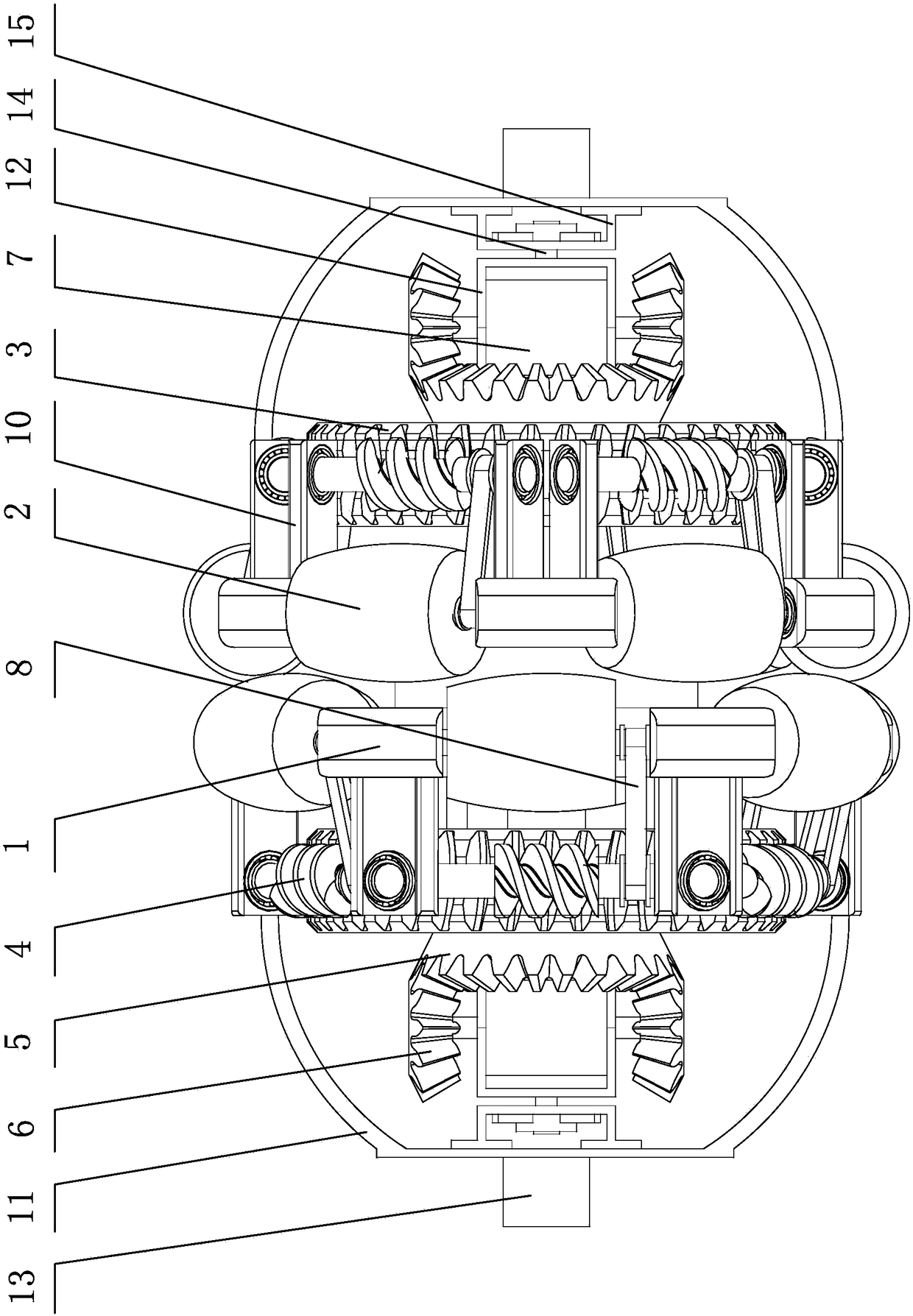

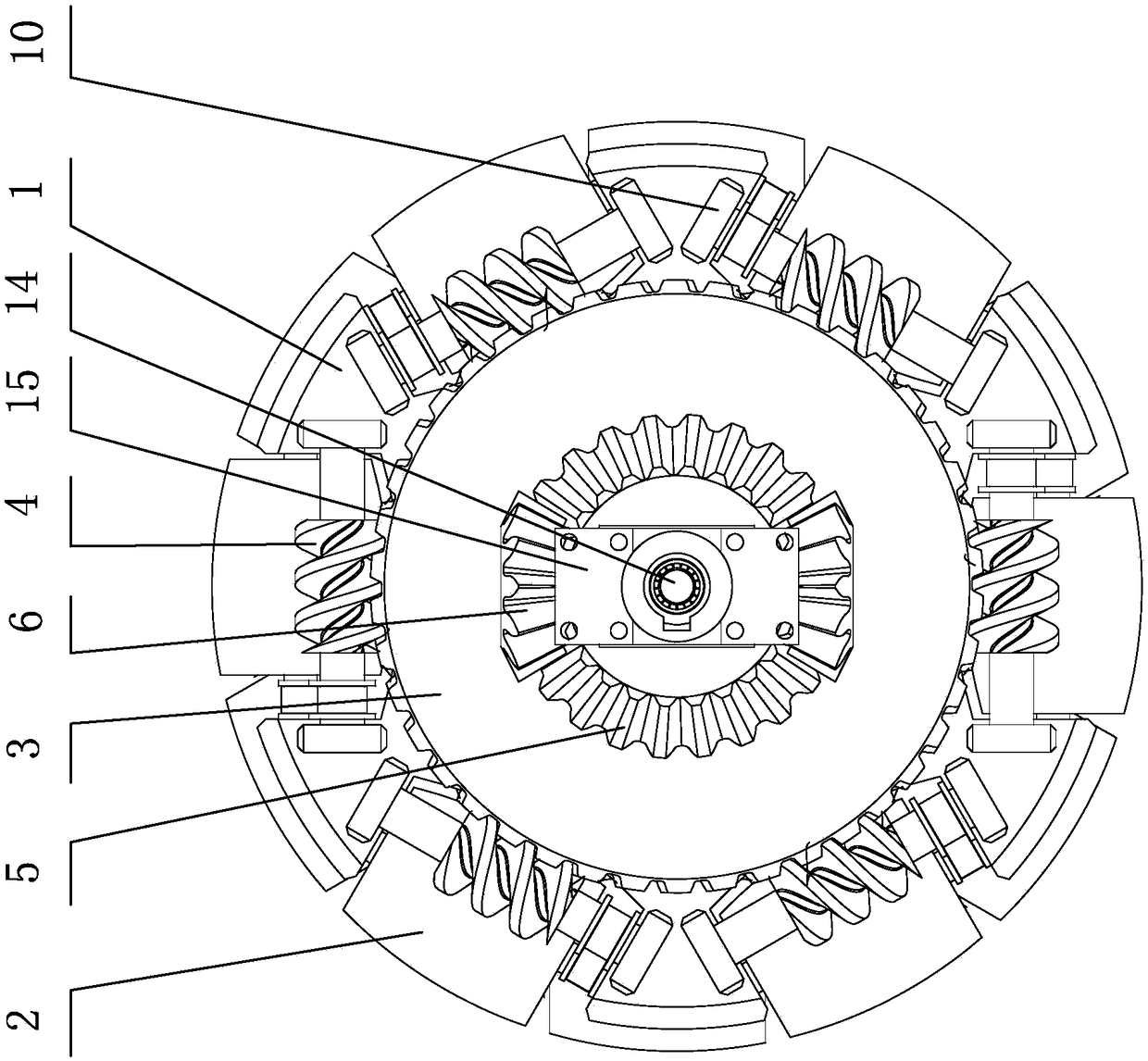

[0021] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0022] The omni-directional wheel capable of omnidirectional movement of the present invention comprises hub 1, joint wheel 2, joint wheel driving mechanism, wheel cover 11 and other components.

[0023] The two hubs 1 (rolling forward and backward) are coaxially connected to the left and right, and there are a plurality of joint wheels 2 (short rollers that rotate left and right) evenly distributed on the upper circumference of each hub 1, and the joints on the left and right hubs 1 The wheels 2 are dislocated relative to each other, and a plurality of worm support frames 10 uniformly distributed on the circumference are horizontally arranged on the outer edge of each wheel hub 1, and the left and right wheel covers 11 are respectively installed and connected on the end faces of the left and right worm support frames ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com