Label casing method

A sleeve labeling and labeling technology, applied in the field of sleeve labeling, can solve problems such as occupation of human resources, disadvantageous enterprise automation production, etc., and achieve the effect of high sleeve setting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

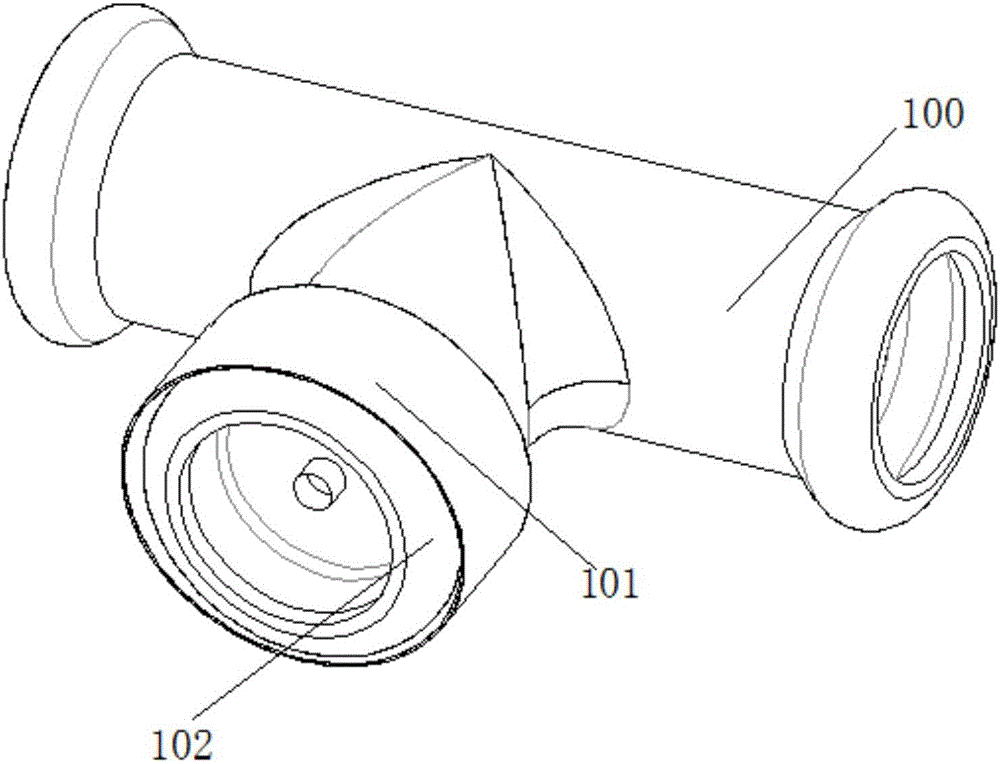

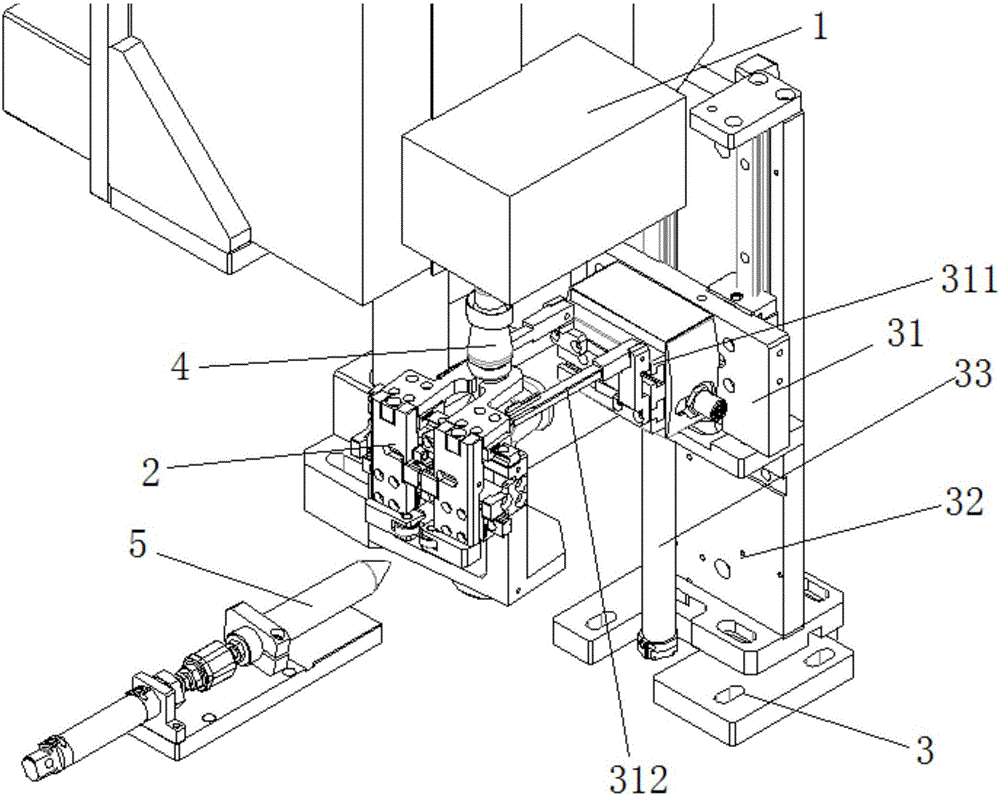

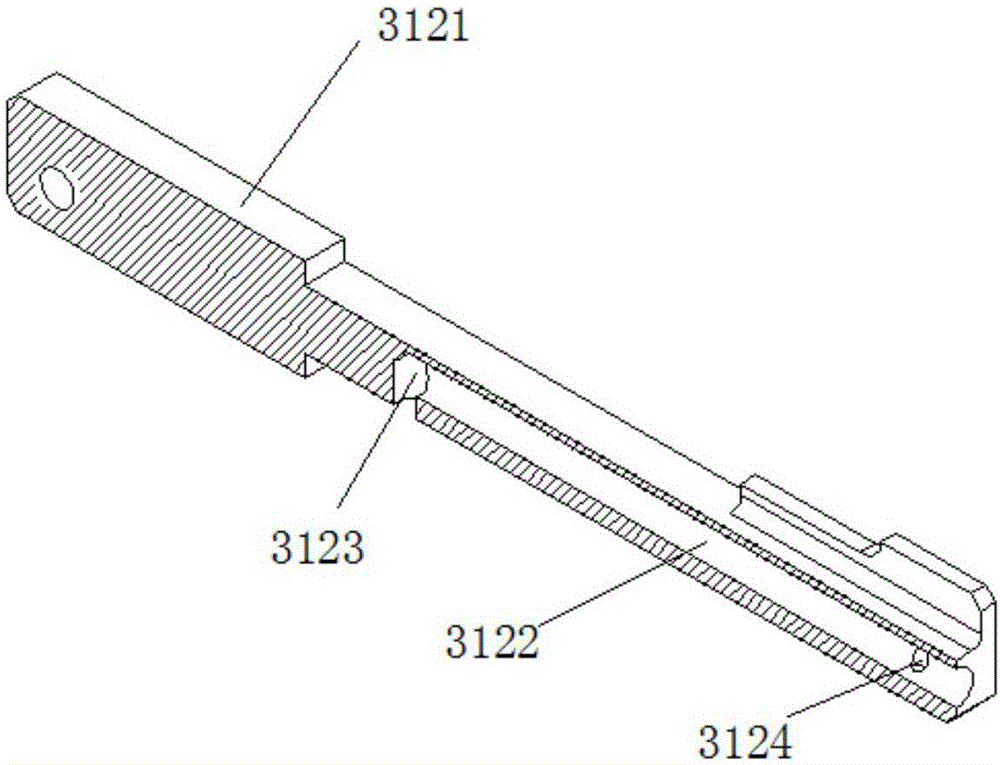

[0046] see Figure 1 to Figure 7 , which shows a labeling mechanism including a label cutting machine 1, a product holding carrier 2 arranged below the label cutting machine 1 for holding a three-way pipe fitting 100, and a product holding carrier 2 corresponding to the product and with the The label cutting machine 1 is used in conjunction with the sleeve label assembly 3 on which the liftable sleeve module 31 is arranged, and the sleeve film fixture 4 corresponding to the three-way pipe fitting 100 .

[0047] The mantle jig 4 includes a jig body 41 in the shape of a tapered cylinder, and a jig insert 43 connected to the lower end of the jig body 41 and provided with a limit step 42 matching the tee pipe 102 .

[0048] The label cutting machine 1 can be a common label cutting machine on the market. The taper of the jig body 41 of the mantle jig 4 can be set according to the size of the tee pipe 102. At the same time, a plurality of limit steps 42 can be set to accommodate T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com