Optimal Control Method of Air Knife Distance in Galvanizing Production

An air knife distance, optimization control technology, applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problems of air knife pressure adjustment saturation, front and rear coating deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

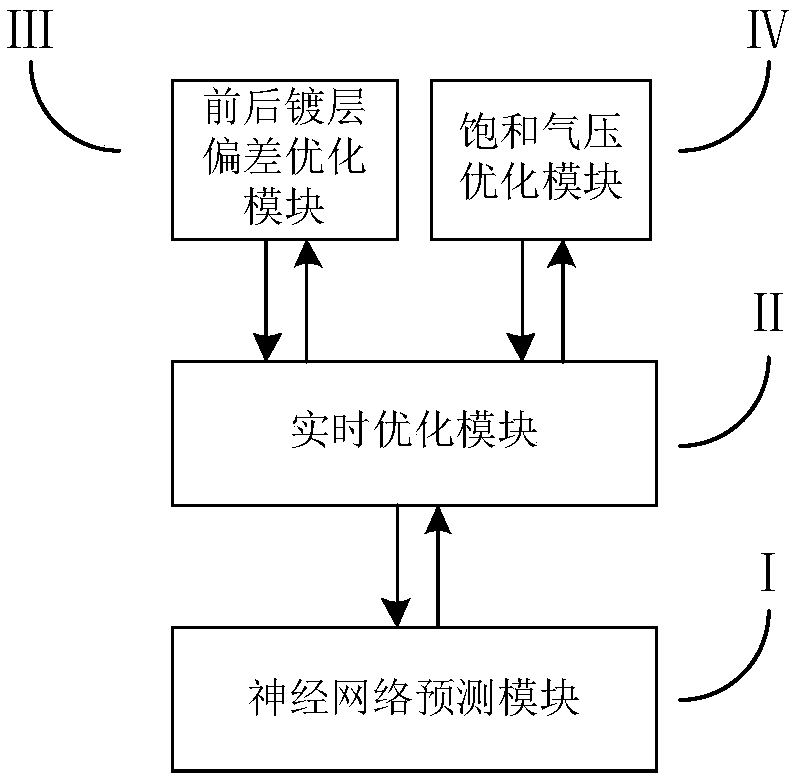

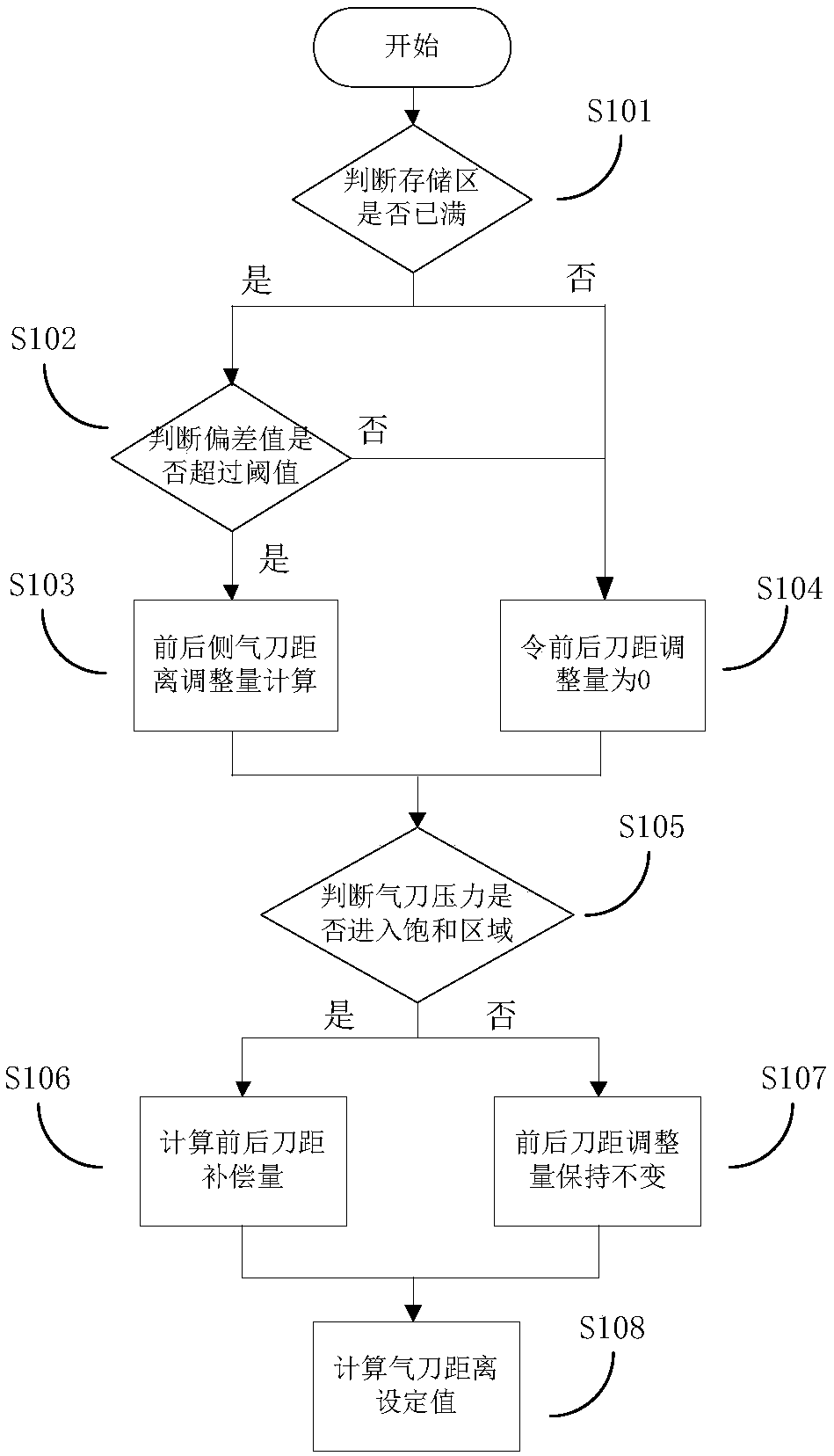

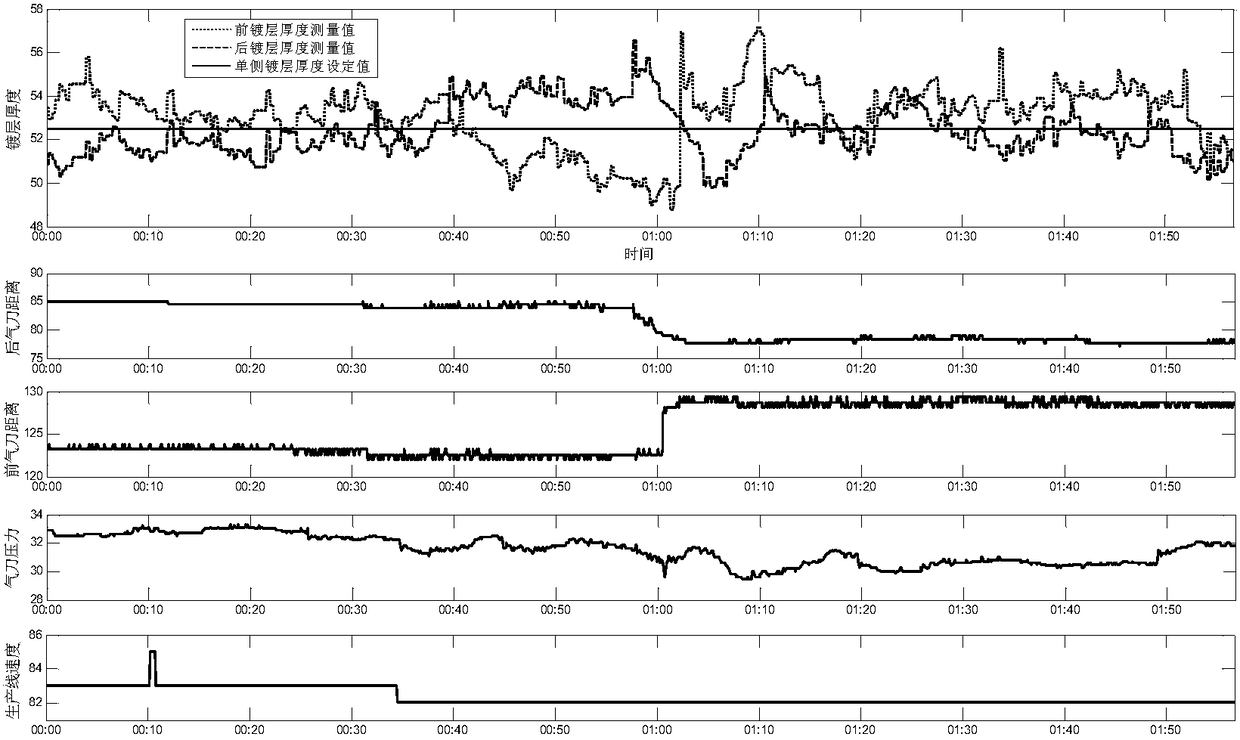

[0047] The following will combine Figure 1 to Figure 4 The air knife distance optimization control method for galvanizing production provided by the present invention is described in detail, which is an optional embodiment of the present invention, and it can be considered that those skilled in the art can make it within the scope of not changing the spirit and content of the present invention. Make revisions and polish.

[0048] First of all, the relevant problems and solutions in the prior art are described first:

[0049] Galvanized products are widely used in construction, home appliances, automobiles and other industries due to their good corrosion resistance. Too thick a coating will not only waste raw materials such as zinc ingots, but also affect the spot weldability, adhesion, and anti-powdering of the coating. Properties such as resistance, but too thin coating will affect the corrosion resistance of the product, and the product quality cannot meet the standard. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com