Photosensitive resin composition for isolator

A photosensitive resin and spacer technology, which is applied to photosensitive materials, optics, and opto-mechanical equipment for opto-mechanical equipment. Retention rate, sufficient liquid crystal orientation, and effect of reducing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] 30% by weight of an alkali-soluble acrylate resin, 5% by weight of a urethane resin represented by the above chemical formula 4, and 5% by weight of a crosslinkable monomer having at least two ethylenic double bonds represented by the above chemical formula 5 The indicated urethane monomer, 0.5% by weight of Irgacure 907 (manufactured by Ciba Chemical Specialty Products Co., Ltd.) as a photopolymerization initiator, 0.2% by weight of 4,4-bisdiethylaminobenzophenone, 37% by weight of As a solvent, propylene glycol methyl ether acetate, 17% by weight of ethyl 3-ethoxypropionate, and 5.3% by weight of butyl acetate were uniformly mixed to manufacture a liquid photosensitive resin composition for spacers.

Embodiment 2~4 and comparative example 1~3

[0067] Except having used the component and composition ratio shown in following Table 1 in said Example 1, it implemented by the method similar to said Example 1, and manufactured the liquid photosensitive resin composition for spacers. In this case, the unit in Table 1 is "% by weight".

[0068] differentiate

[0069] Table 1 will be described below.

[0070] Alkali-soluble acrylate resin:

[0071] Benzyl methacrylate: methacrylic acid: methyl methacrylate = 60: 20: 20

[0072] Molecular weight: 20,000.

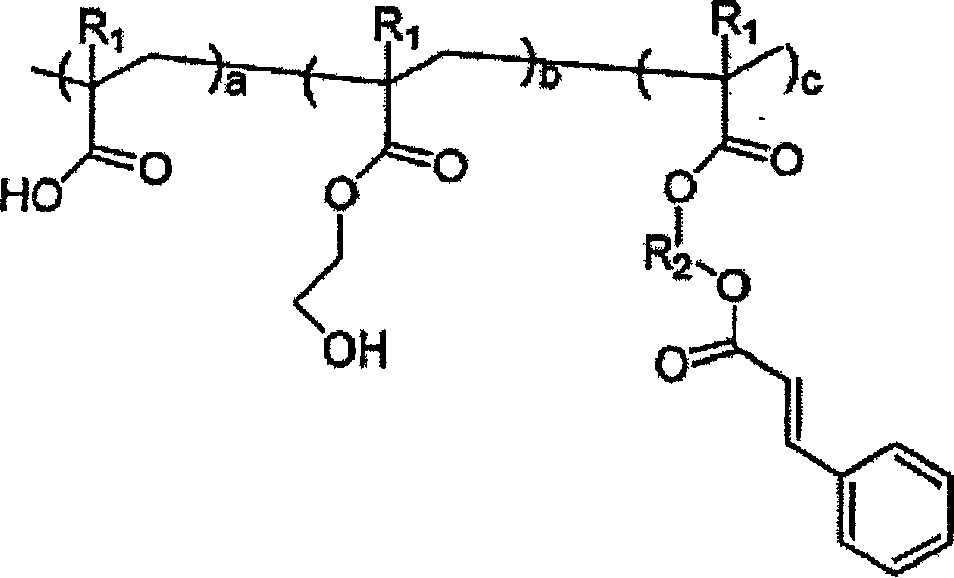

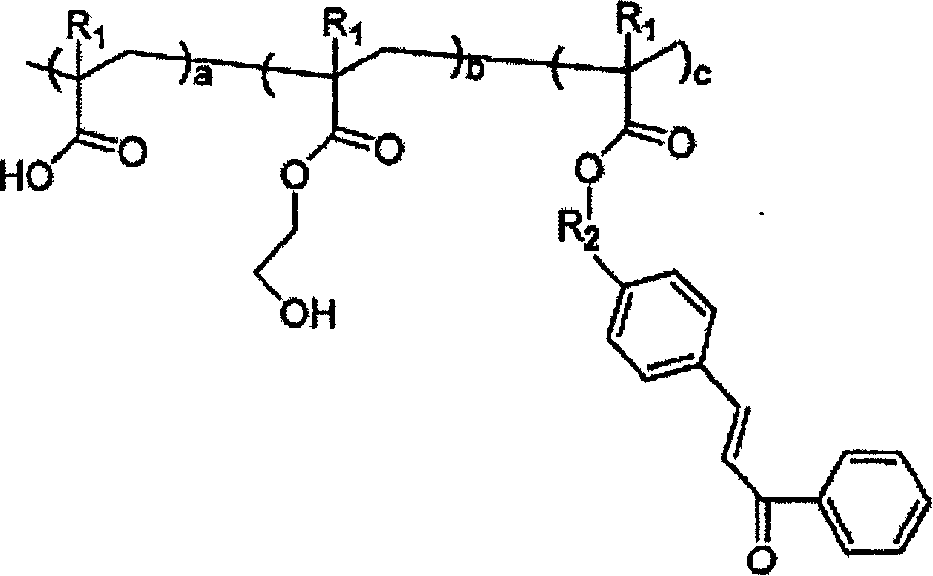

[0073] In chemical formula 1 and chemical formula 2:

[0074] R 1 = methyl, R 2 =methylene, a:b:c=20:20:60, molecular weight: 20,000.

[0075] In chemical formula 4:

[0076] R 3 = 1,6-hexylene, R 4 , R 5 =Methyl group, molecular weight: 3,000.

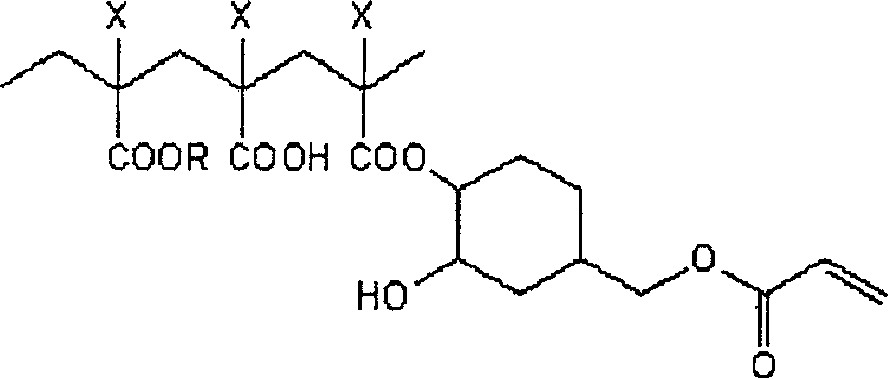

[0077] In chemical formula 5:

[0078] R 6 = methylene, R 7 =-C(CH 3 ) 2 C 6 h 4 C(CH 3 )=CH 2 , y=6, z=2.

[0079] Using the photosensitive resin compositions for spacers produced i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com