Prefabricated pcf exterior wall panel with window frame and its installation method

A technology for exterior wall panels and window frames, which is applied in the processing of walls, building materials, and building components. It can solve the problems of complex construction, poor waterproof performance of window frames, and long construction time, and achieve simplified on-site construction procedures, reliable connections, and lesser number of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

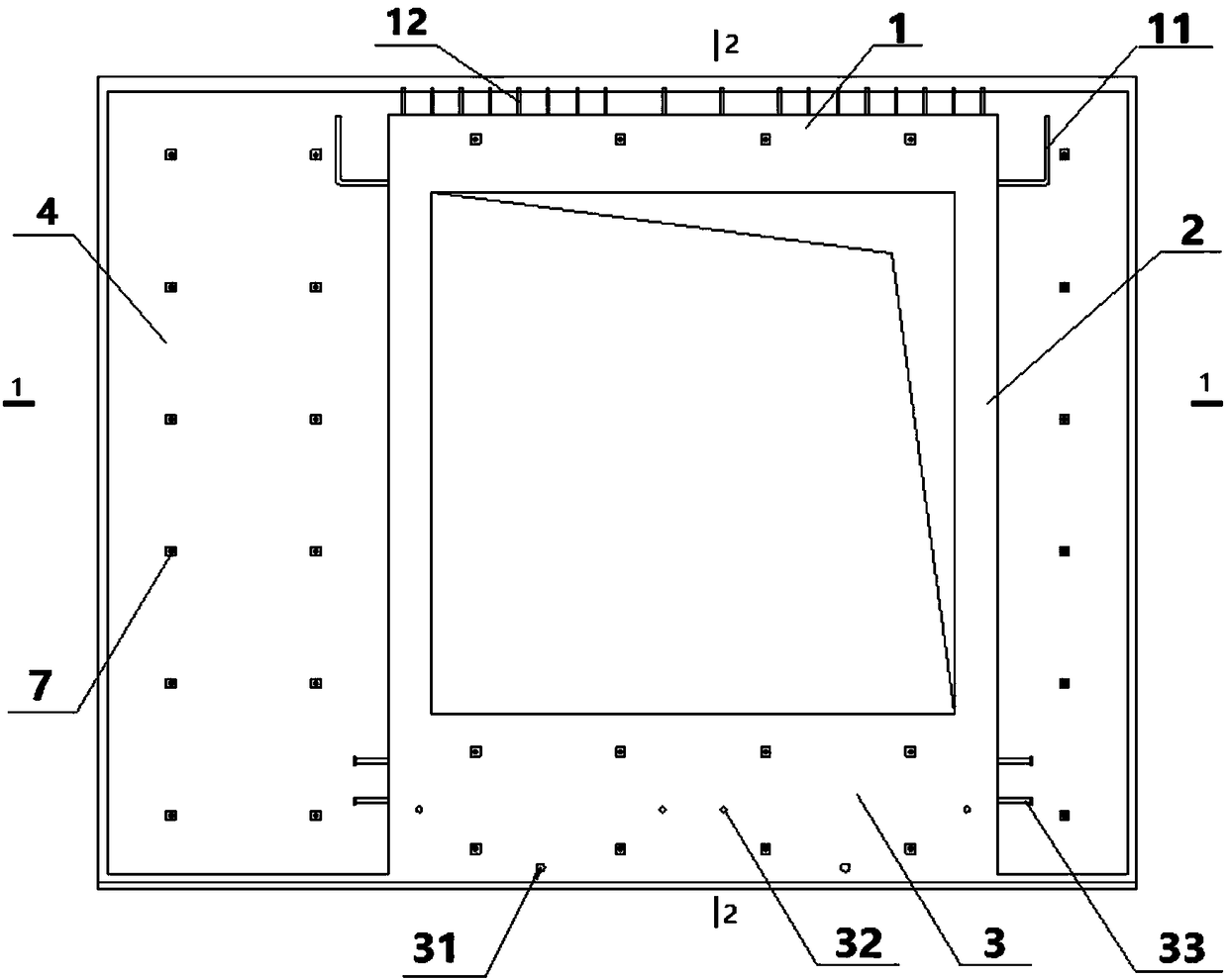

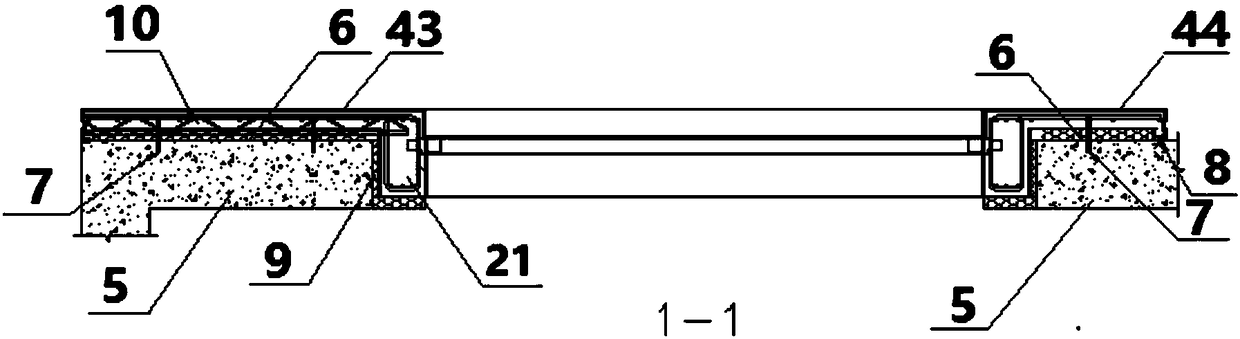

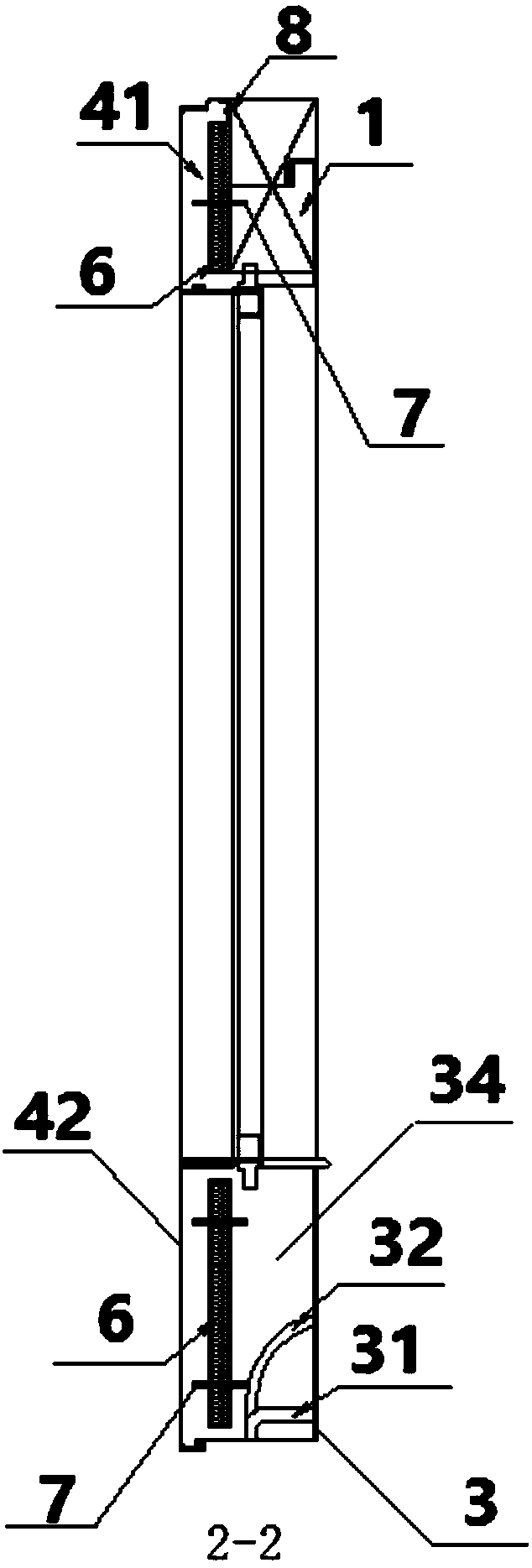

[0029] Such as figure 1 As shown, it includes composite beam prefabricated part 1, window frame 2, window lower wall 3 and PCF outer leaf plate 4 extending from the window frame to the surroundings; the PCF outer leaf plate 4 extending to the surroundings of the window frame includes the upward extending PCF outer blades 41, PCF outer blades 42 extending downward from the window frame, PCF outer blades 43 extending leftward from the window frame, PCF outer blades 44 extending rightward from the window frame; the left and right sides of the window frame Window side panels 21 are arranged on the sides; The top of the prefabricated part 1 of the composite beam is provided with a closed stirrup 12, the bottom of the prefabricated part 1 of the composite beam is provided with the longitudinal reinforcement 11 of the lower part of the beam, and the longitudinal reinforcement 11 of the lower part of the beam is bent upward; Bolt 33. In this embodiment, the thickness of the PCF oute...

Embodiment 2

[0040] The installation method step of embodiment 1 product is:

[0041] First, fix the prefabricated PCF exterior wall panels with window frames: hoist the prefabricated PCF exterior wall panels with window frames in place, adjust the vertical elevation and verticality of the prefabricated PCF exterior wall panels with window frames, and use Temporary supports fix the prefabricated PCF exterior wall panels with window frames;

[0042] Secondly, pour the concrete of the edge components on both sides of the window frame and the composite layer concrete of the composite beam on the upper part of the window frame, specifically including 1. Binding the steel bars of the edge components on both sides of the window frame, and installing the connecting bolts on both sides of the lower wall of the window. The connecting bolts are interlaced with the steel bars of the edge members on both sides of the window frame; 2. The longitudinal bars of the beam lower part of the prefabricated pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com