Self-locking type ring-shaped buckle for scaffold

A self-locking, ring buckle technology, applied in the field of scaffolding, can solve the problems of construction personnel's personal safety hazards, easy sliding, large fastening force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] To make the objectives, technical solutions, and advantages of the embodiments of the present invention clearer, the specific embodiments will be described in detail below in conjunction with the accompanying drawings.

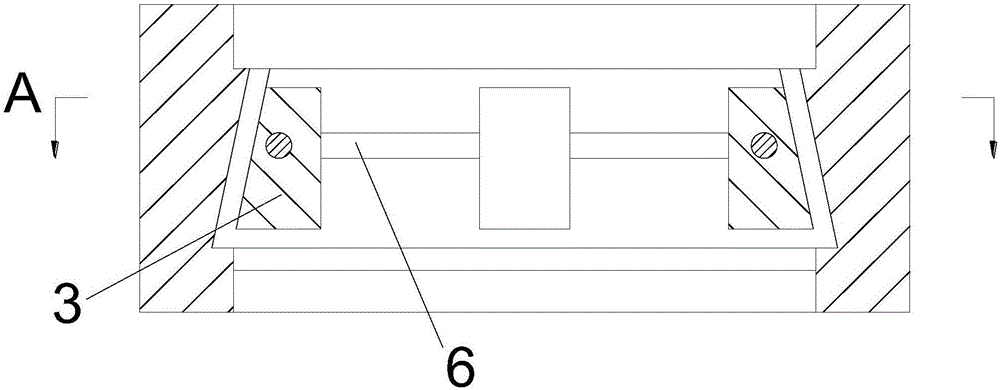

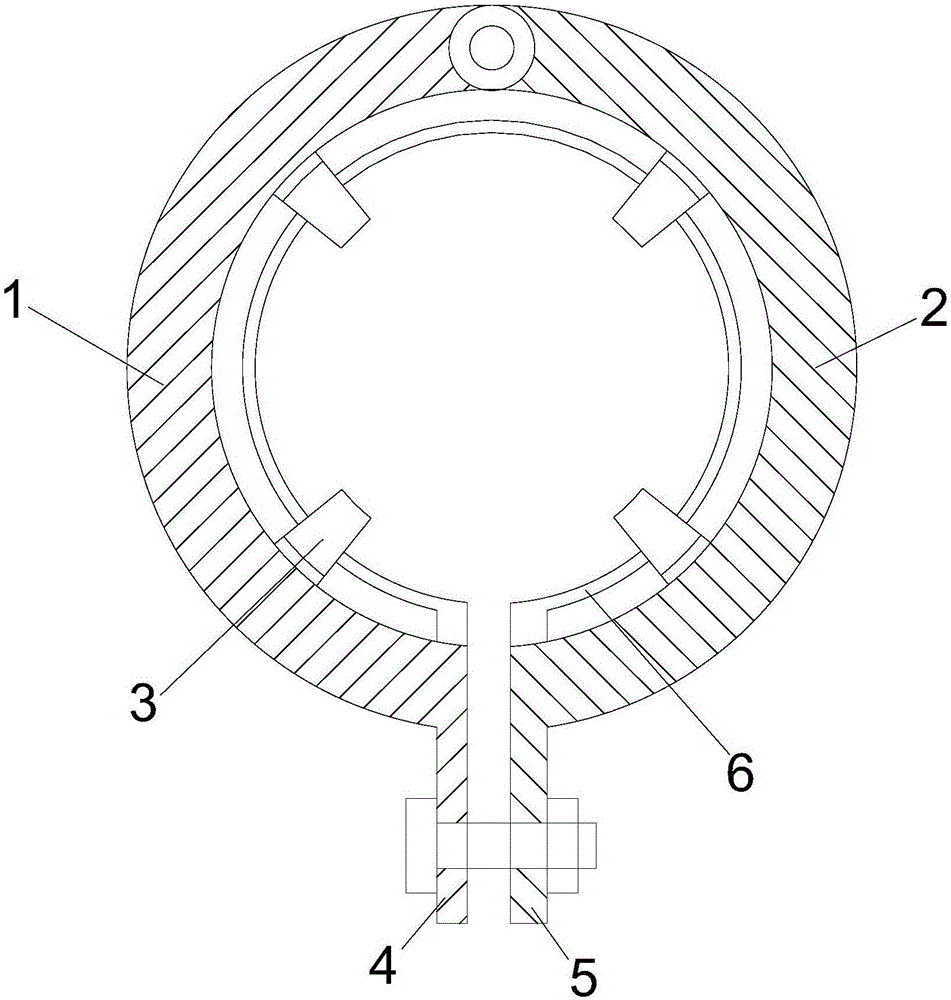

[0020] Such as Figure 1-2 As shown, figure 1 Is a schematic diagram of the structure of the present invention, figure 2 for figure 1 A cross-sectional view of A includes the first buckle body 1, the second buckle body 2, the anti-skid block 3 and the mounting ring 6.

[0021] Both the first buckle body 1 and the second buckle body 2 have a semi-annular structure, the first end of the first buckle body 1 and the first end of the second buckle body 2 are hinged, the first buckle body 1 and the second buckle body 2 The inner walls of both are tapered structures, and the two cooperate to form a tapered cavity. In specific implementation, the second end of the first buckle body 1 is provided with a first connecting ear 4, and the second end of the second buckl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com