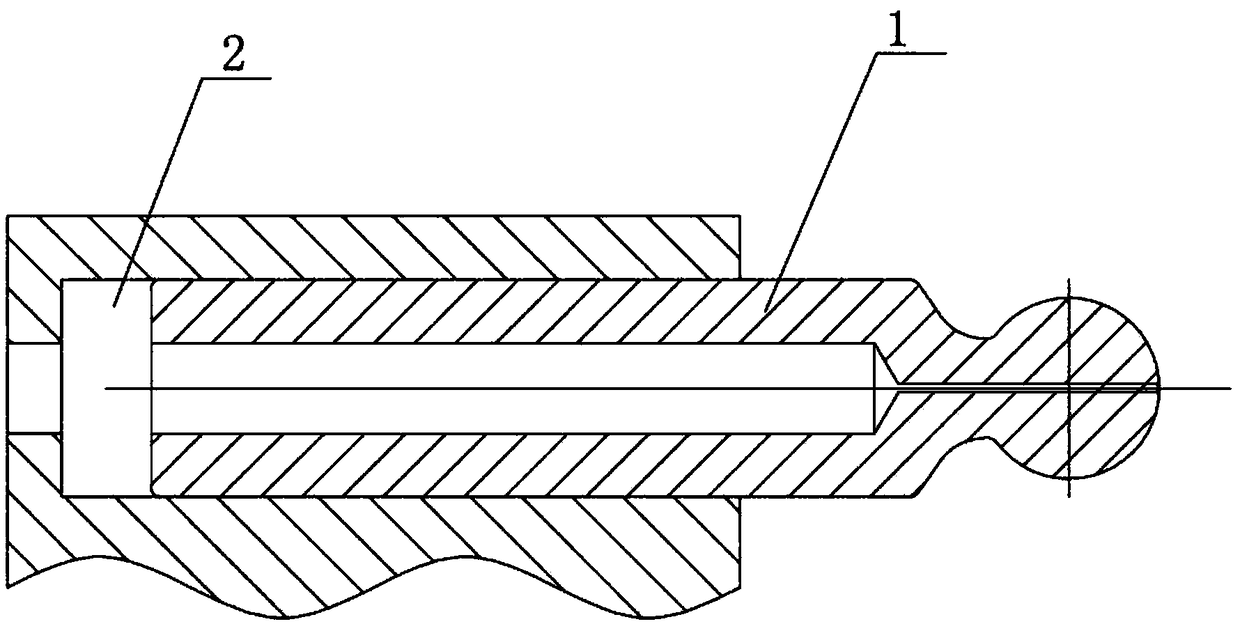

A plunger pair structure for ultra-high pressure axial swash plate plunger pump

A swash plate plunger pump and plunger pair technology, which is applied to the components of the pumping device for elastic fluids, pump components, variable displacement pump components, etc. , reduce the volume efficiency of the pump, etc., to achieve the effect of simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described below.

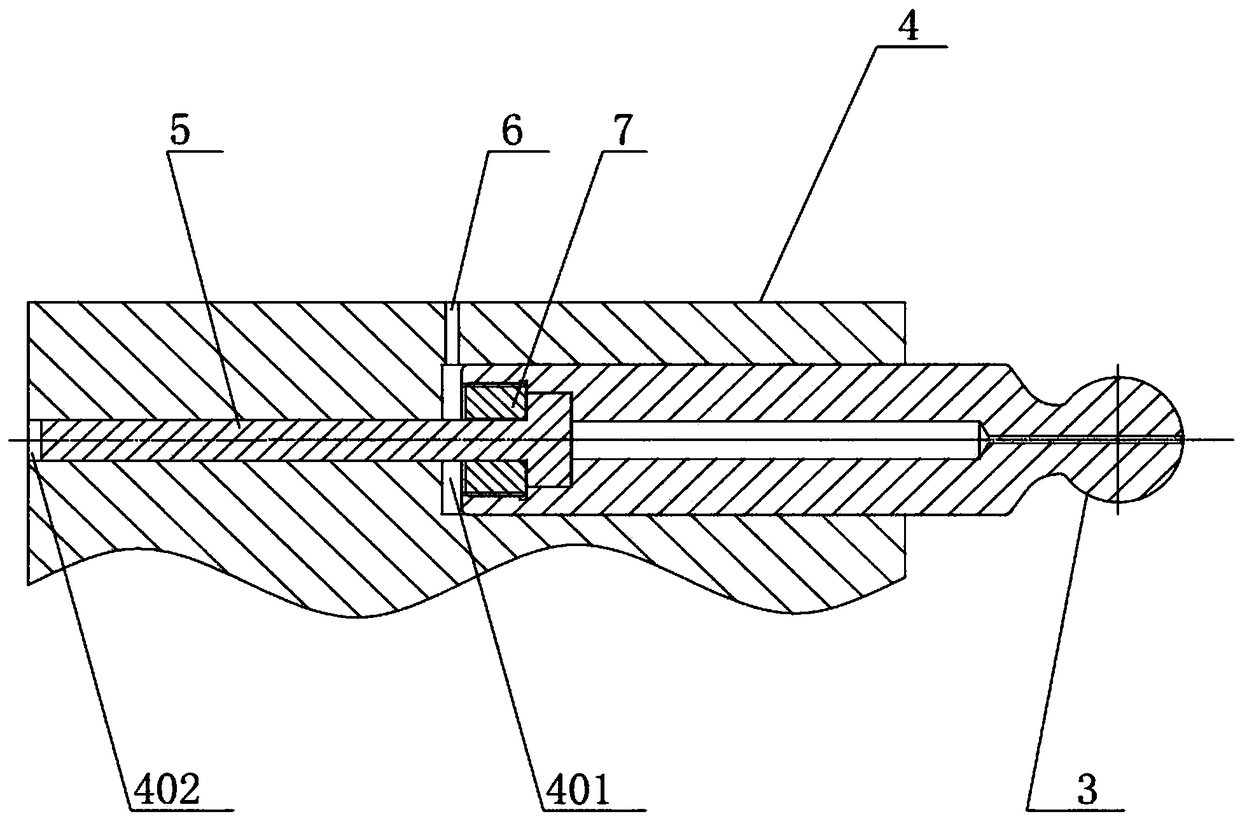

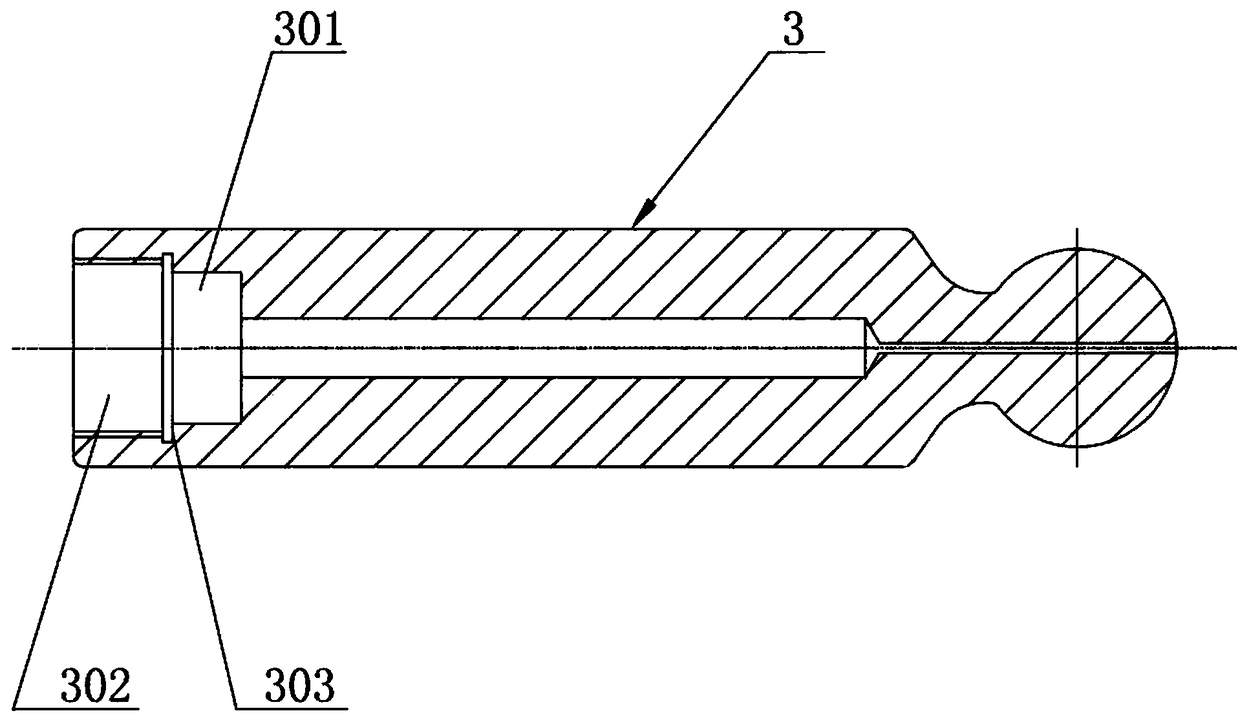

[0021] Such as figure 2 As shown, a plunger pair structure for an ultra-high pressure axial plunger pump includes a cylinder 4, a first plunger hole 401 for installing the first plunger 3 and a first plunger hole 401 for installing the first plunger 3 are opened in the cylinder 4 respectively. The second plunger hole 402 of the second plunger 5, the above-mentioned first plunger hole 401 communicates with the second plunger hole 402 to form a stepped hole, and the first plunger 3 extends into one end of the first plunger hole 401 by pressing The nut 7 cooperates with the end of the second plunger 5 extending into the first plunger hole 401 . On the cylinder body 4, also offer the small hole 6 that communicates with the first plunger hole 401, the central axis of the small hole 6 is perpendicular to the central axis of the first plunger hole 401, and the small hole 6 is not connected with the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com