Punch rivet

A punching riveting and riveting rod technology, which is applied in the direction of rivets, threaded fasteners, connecting components, etc., can solve the problem that the vibration-assisted punching riveting method is not the best structure, etc., so as to improve the cutting process, stabilize the pressing process, and avoid swing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

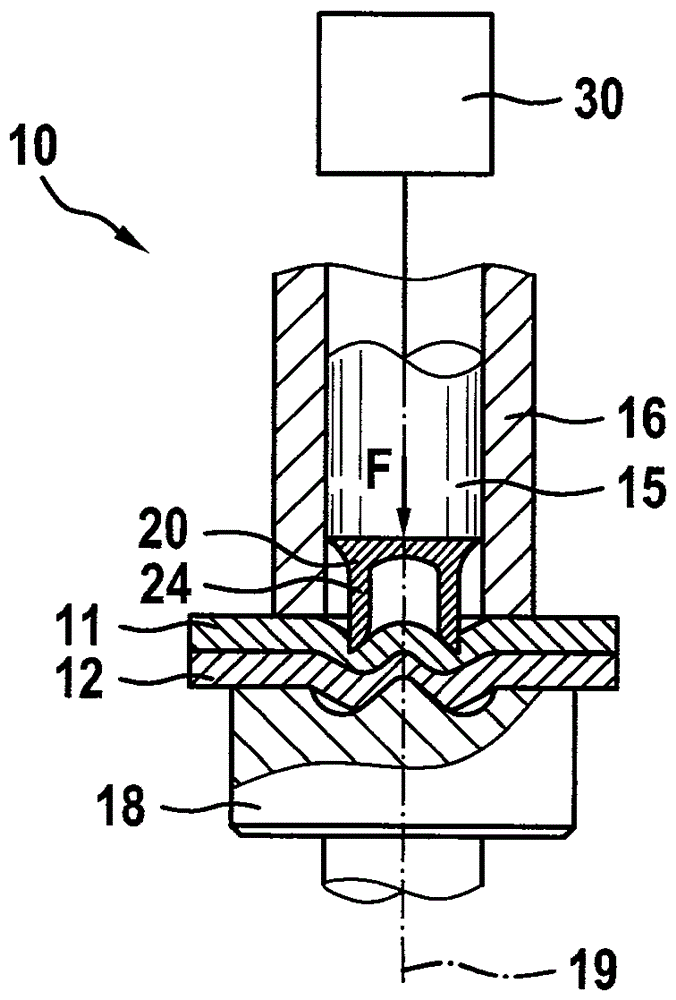

[0022] exist Figure 1a Riveting device 10 is shown in various stages of execution of the riveting method in to 1d. The riveting device 10 has an embossment 15 which, for example, has a circular cross section.

[0023] The embossing 15 is surrounded radially by a sleeve-shaped hold-down device 16 and is arranged displaceably in the longitudinal direction relative to this hold-down device. In particular, the embossing 15 is coupled to a drive (not shown here), for example a hydraulic or pneumatic drive, which is used to apply the force F required for pressing the rivet 20 into the two components 11 , 12 . .

[0024] Likewise, the pressing device 16 is provided for pressing with a pressing force against the surface of the component 11 facing the embossing 15 . For this purpose, for example, a separate drive can be provided. However, the hold-down device can also be coupled to the drive of the emboss 15 , for example by means of a spring.

[0025] On the side of the two compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com