Clamping arm lead screw tension grip

A tension test and lead screw technology, applied in the field of electric power, can solve the problem that the lead screw of the clamping arm cannot be connected to the force, and achieve good benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

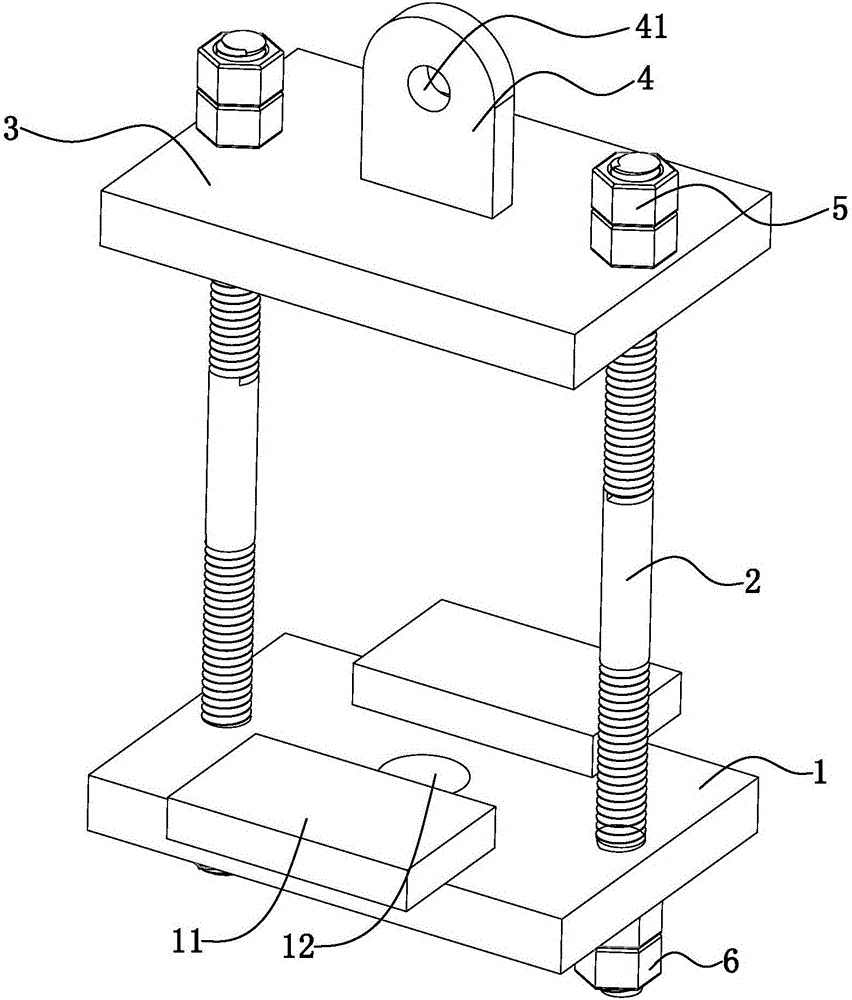

[0022] The invention provides a jig for tensile test of a locking arm lead screw.

[0023] In this embodiment, the jig for pulling force test of the arm screw is installed on the static load testing machine, and includes a traction plate 1 for pulling the arm screw to be tested, a pull bar 2 for pulling the traction plate 1, and a pull bar 2 for pulling the pull plate 1. The pulling plate 3 of the pulling rod 2 and the connecting piece 4 used to connect the arm screw tensile test fixture to the static load testing machine; the connecting piece 4 is welded to the pulling plate 3, and the pulling plate 3 is a rectangular plate with two first connections The two first connecting holes are respectively located near the midpoint of the short side of the rectangular plate. The traction plate 1 adopts a rectangular plate and is provided with two second connecting holes, and the two second connecting holes are respectively located near the short sides of the rectangular plate. Point p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com