Clamping slot lead screw tension test fixture

A technology of tension test and lead screw, which is applied in the field of electric power, can solve the problem that the lead screw of the slot cannot be connected and exert force, and achieve good benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

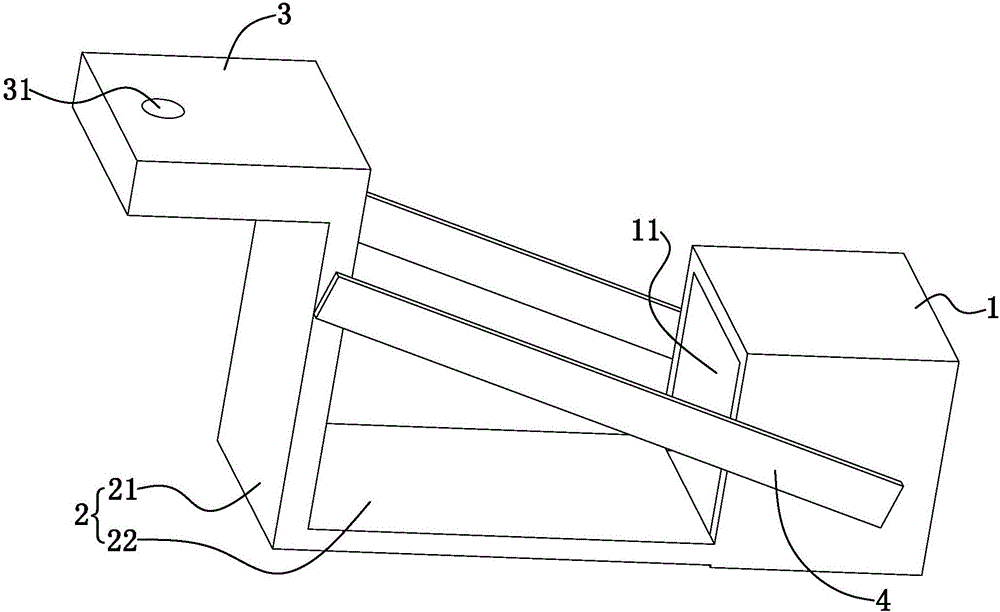

[0022] The invention provides a tension test fixture for a slotted lead screw.

[0023] In this embodiment, the slotted lead screw tensile test fixture, the slotted screw tensile test fixture is installed on the static load testing machine, including: a clamp body 1 provided with an accommodation chamber 11; used to connect the slotted screw tensile test fixture to the static load tester The first connector 3 of the load testing machine; and the second connector 2 connecting the clamp body 1 and the first connector 3; the accommodation chamber 11 is provided with an opening, the clamp body 1 is a hexahedron, the accommodation chamber 11 is a hexahedron, and the accommodation chamber 11 Put the side wall of the slot into the slot of the screw to be tested, and at the same time, the opening is facing the static load testing machine, which determines the direction in which the static load testing machine applies force to the screw to be tested through the slot screw tension test f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com