An automatic sealing system for electric energy meters

An electric energy meter sealing and automatic technology, applied in the direction of measuring electric variables, instruments, measuring devices, etc., can solve the problems of low production efficiency and quality of lead seals, increase the cost of electric meter products, occupy a large space, etc., and achieve simple structure and repeated positioning The effect of high precision and low impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

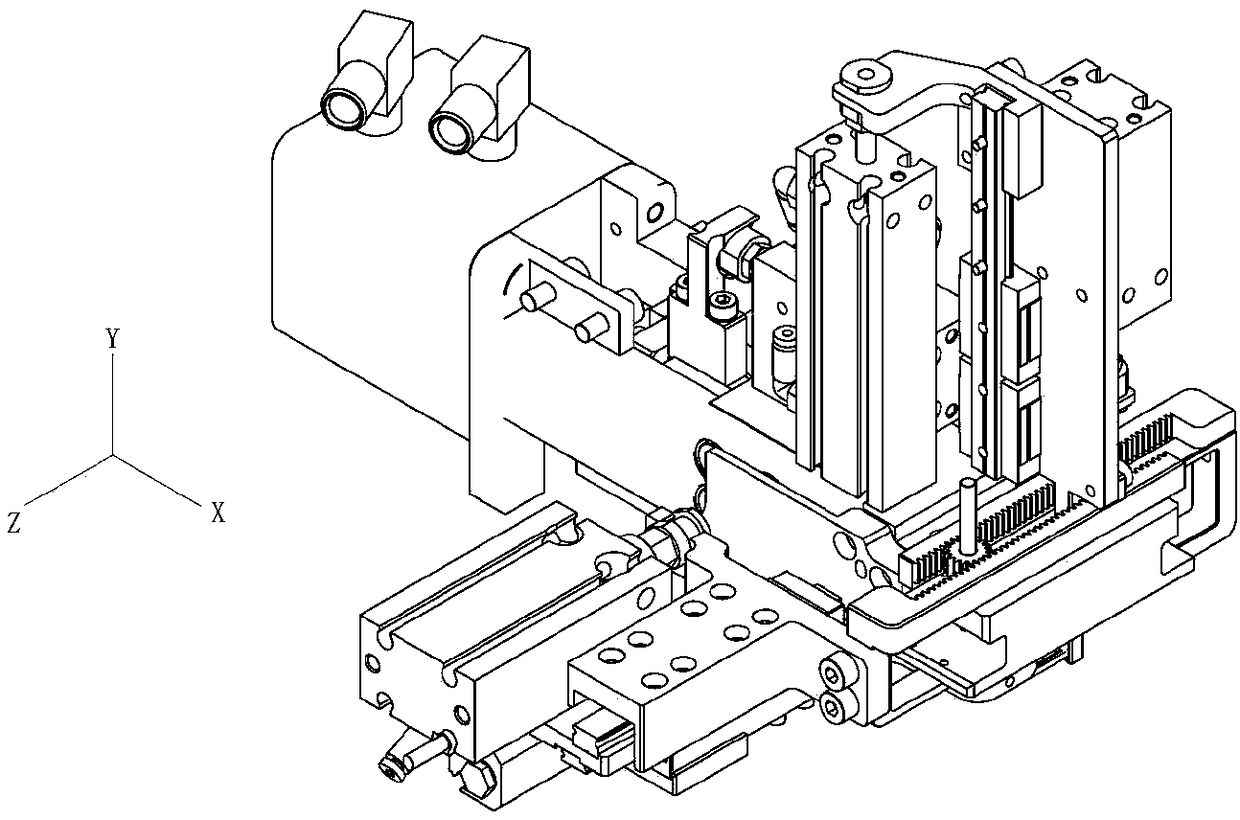

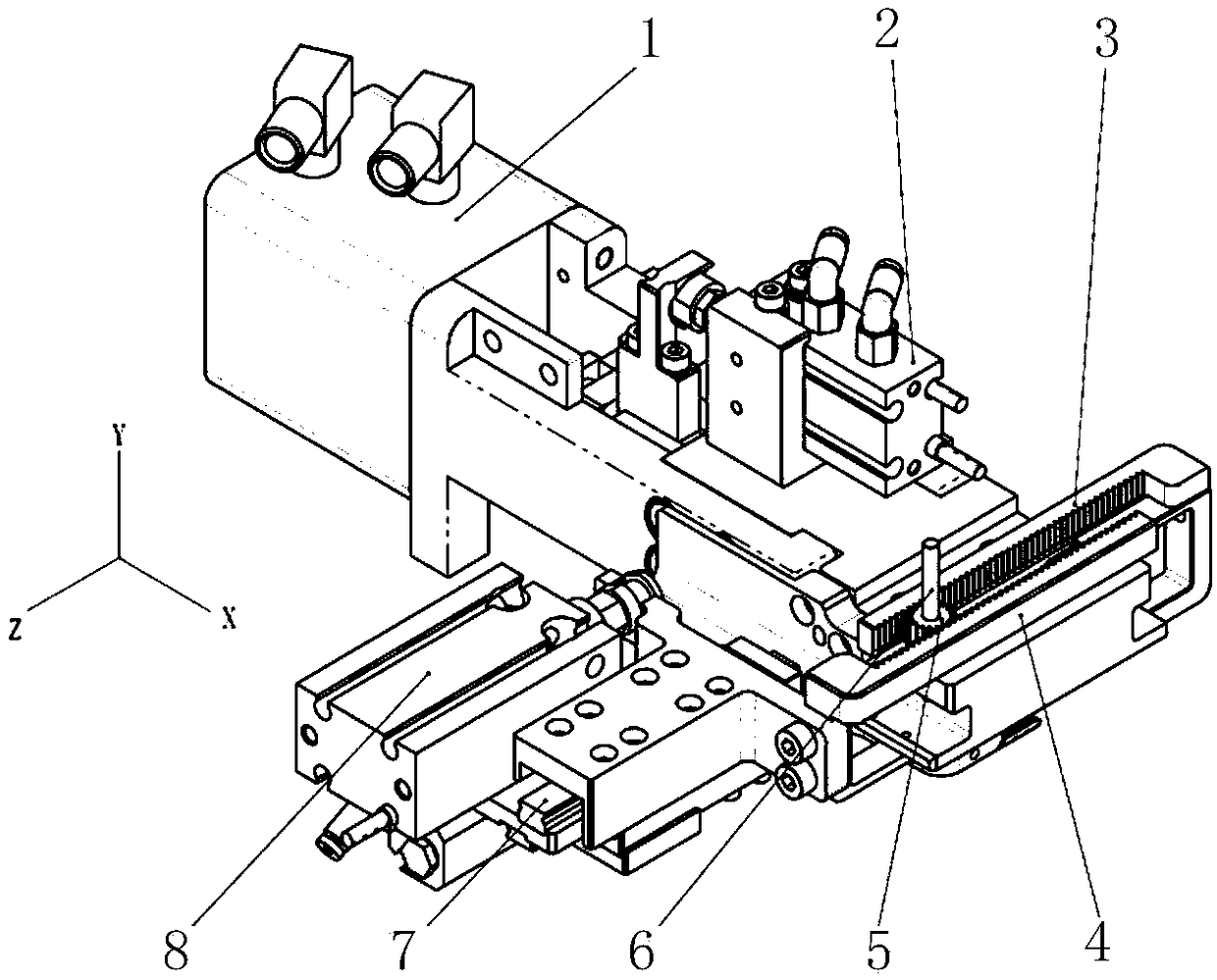

[0026] As shown in the figure, the electric energy meter seal automatic sealing system provided by this embodiment includes a wire feeding device, a seal feeding device, a lead seal blocking component, a wire-feeding module and a riveting component;

[0027] The wire feeding device sends the wire required for sealing to the riveting assembly;

[0028] The seal feeding device transports the seal to the sealing station;

[0029] The lead seal blocking component is used to block the position of the positioning seal;

[0030] The wire fetching module is used to obtain the wire conveyed by the wire feeding device;

[0031] The riveting component is used to feed the silk thread into the lead seal notch of the seal and connect the thread and the seal by riveting.

[0032] The wire feeding device includes a main body and a wire feeding device, a straightening device, a first wire pulling device, a length fixing device, a second automatic wire pulling device and a processor arranged ...

Embodiment 2

[0056] The electric energy meter seal automatic sealing system provided in this embodiment consists of five parts: a wire feeding device, a seal feeding device, a lead seal blocking component, a wire-feeding module, and a riveting component. The functions and implementation methods of each part will be introduced respectively below.

[0057] The wire feeding device sends the wire required for sealing to the required place through the straightener, encoder, wire pulling mechanism, etc. Provide raw materials for sealing.

[0058] The seal feeding device transports the materials (seals) required for sealing to the sealing station for use by the automatic sealing system. This device also provides raw materials for sealing.

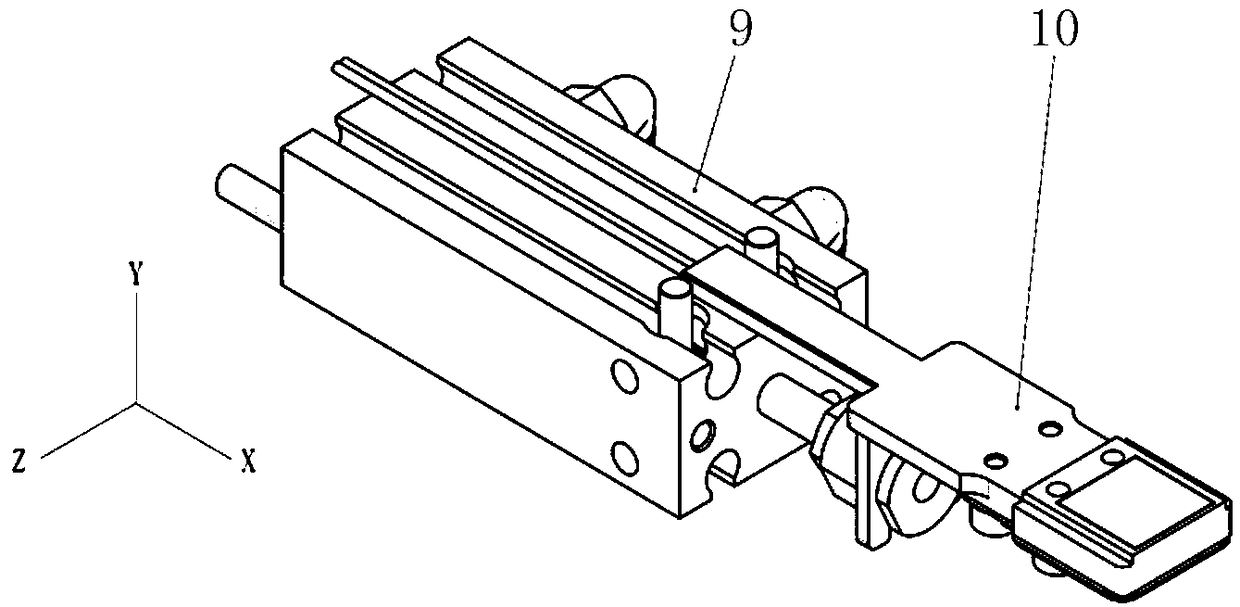

[0059] The lead seal blocking assembly is made up of a cylinder 9 and a lead seal block 10, wherein the lead seal block 10 can move along with the movement of the cylinder 9. When needing to block the lead seal, the cylinder 9 stretches out, and then the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com