Recycling process and separation device of cathode material of waste lithium iron phosphate battery

A lithium iron phosphate battery, lithium iron phosphate technology, applied in the direction of battery recycling, waste collector recycling, recycling technology, etc., can solve the problems of difficult control of toxic by-products, technical difficulties, environmental pollution, etc., to reduce two Secondary pollution, improved economy, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0047] Disassemble the shell of the waste power supply to obtain the packaged lithium iron phosphate battery, discharge treatment, cut the aluminum shell, separate the battery core from the aluminum shell, peel off the plastic film covering the battery core, remove the electrolyte, and obtain the battery core.

[0048] Take out the positive electrode sheet and the negative electrode sheet of the lithium iron phosphate battery from the battery cell, and unfold the positive electrode sheet and the negative electrode sheet separately.

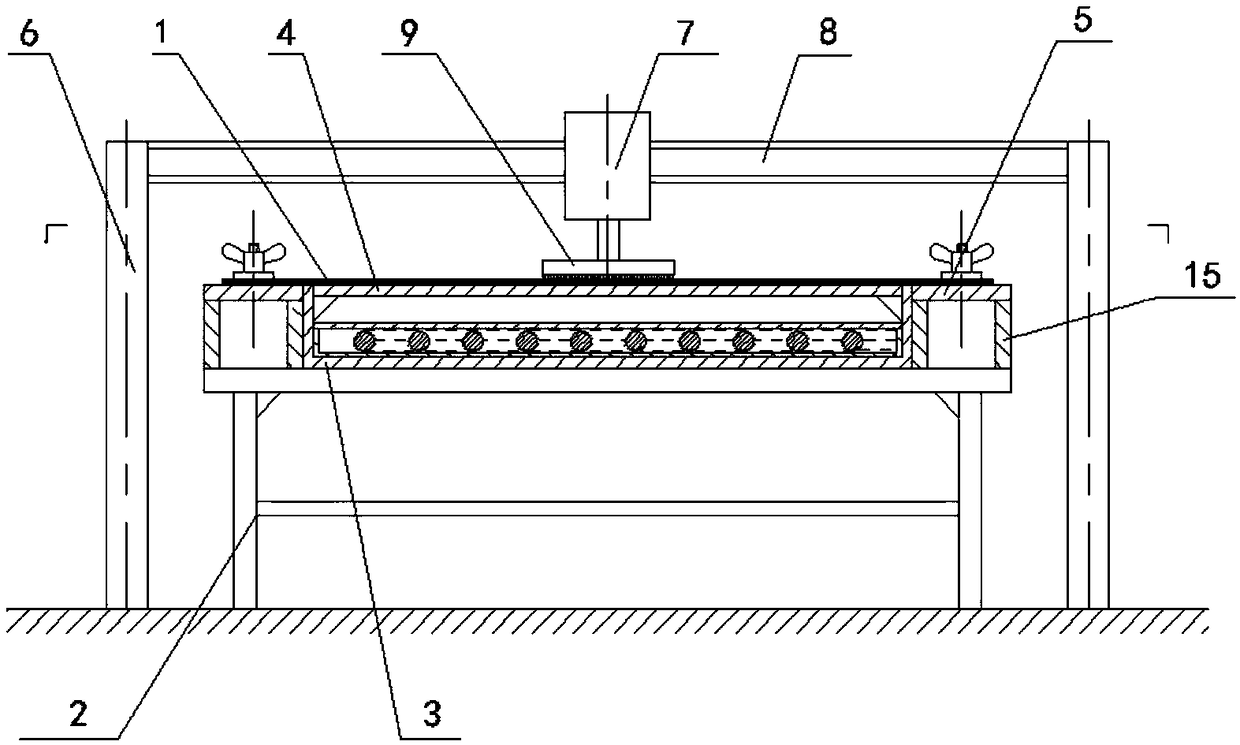

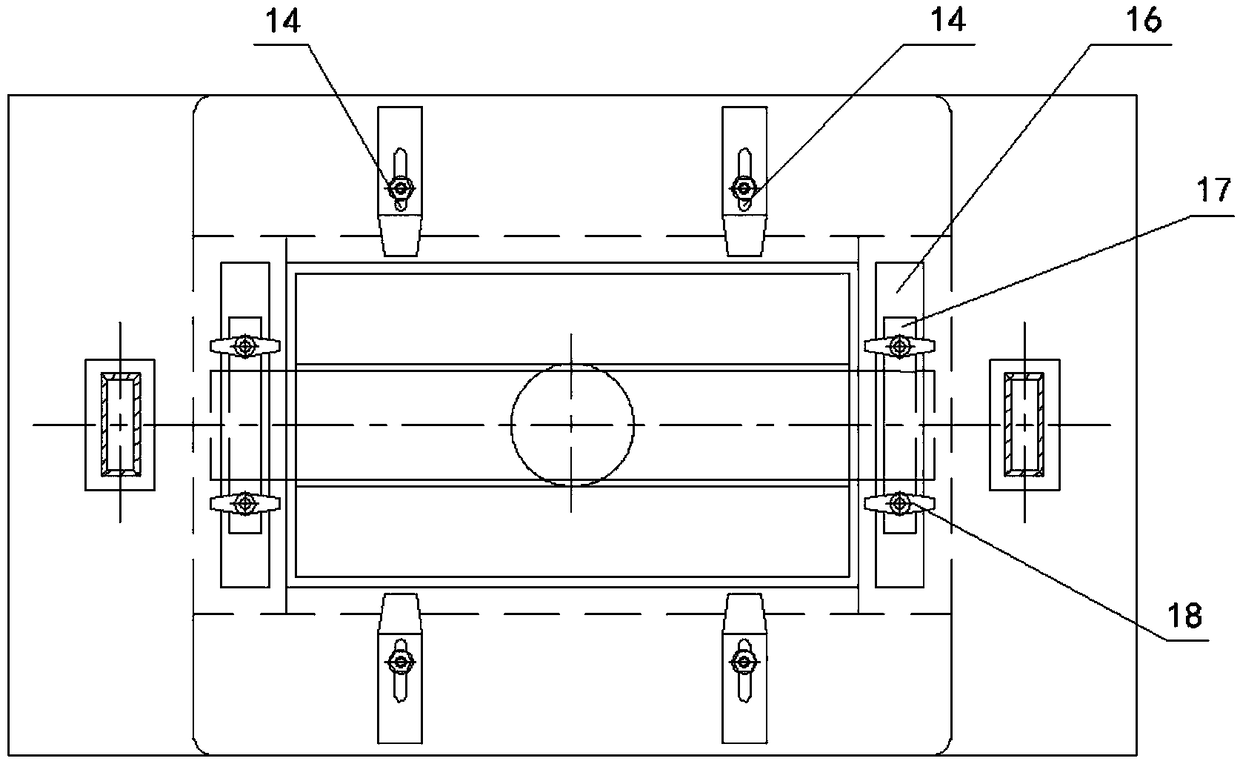

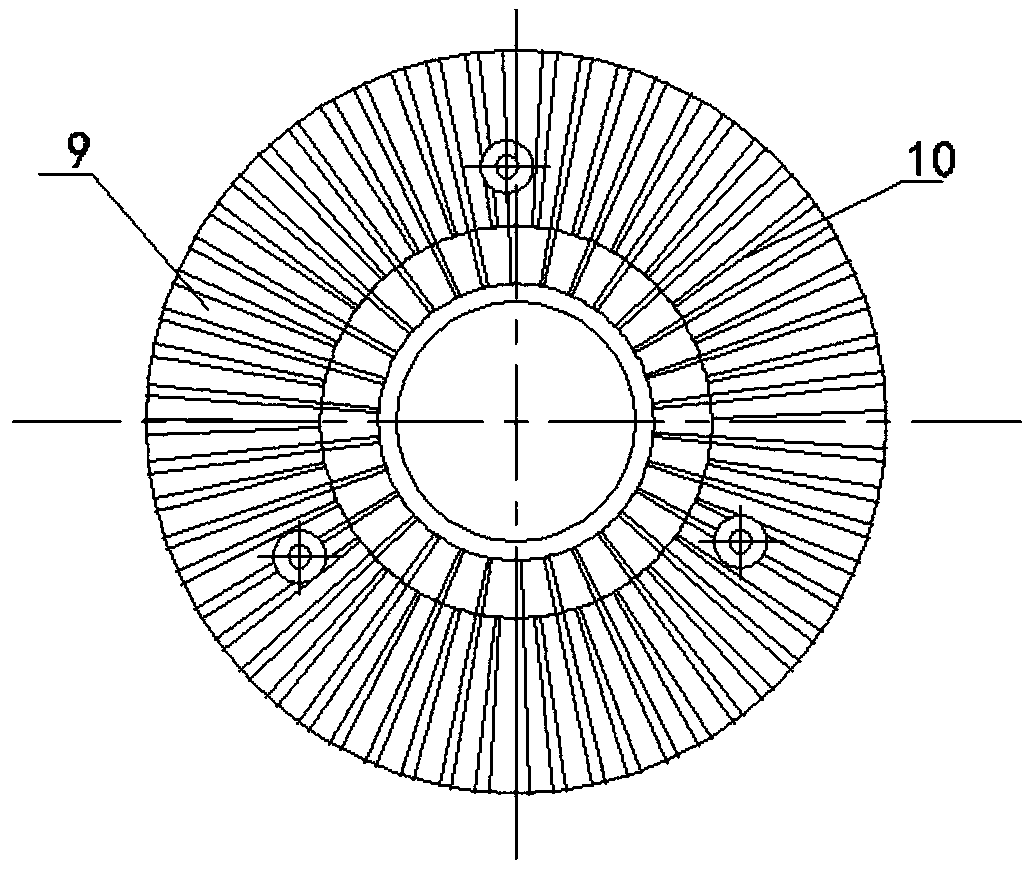

[0049] For the positive plate of lithium iron phosphate battery, the temperature is raised to 100°C by preheating, so that the residual electrolyte is completely volatilized; after the preheating is completed, mechanical separation is performed. Mechanical separation is to use a clamp to fix and tension the positive plate of lithium iron phosphate battery. For The tensioned lithium iron phosphate battery positive plate is ground on its surface with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com