Rolling bearing and processing method thereof

A rolling bearing and bearing technology, applied in the direction of roller bearings, shafts and bearings, bearing components, etc., can solve the problems of inconvenient installation, inability to replace rollers, unfavorable use of rolling bearings, etc. The effect of maintenance and production cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

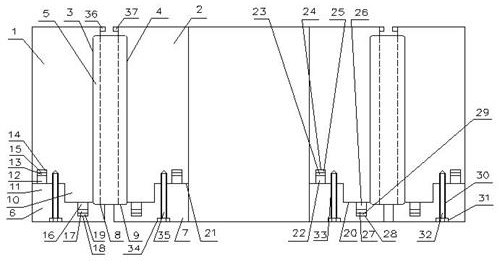

[0021] A rolling bearing, which comprises: a bearing outer sleeve 1, a bearing inner sleeve 2, the inner circle of the bearing outer sleeve is provided with a group of outer vertical slots 3 around the circumference, the top of the outer vertical slots is closed and the bottom is open, The outer circle of the inner sleeve of the bearing is provided with a group of inner vertical slots 4 around the circumference, the top of the inner vertical slots is closed and the bottom is open, and the distance between the outer vertical slots and the inner vertical slots There are rollers 5 in between, the bottom of the bearing outer sleeve is connected to the bearing outer sealing sleeve 6, the bearing outer sealing sleeve can close the outer vertical slot, and it is convenient to assemble, the bottom of the bearing inner sleeve is connected to the bearing inner sealing sleeve Sleeve 7, the inner circle of the outer sealing sleeve of the bearing has a group of outer sealing grooves 8 aroun...

Embodiment 2

[0023] In the rolling bearing described in Embodiment 1, an outer sleeve 10 is provided on the inner side of the bottom of the bearing housing, and an outer fixing sleeve 11 is provided on the outer top of the outer sealing sleeve of the bearing, and the top of the outer fixing sleeve is around the circumference A group of outer top inserting rods 12 are fixedly connected. The outer top inserting rods not only have the function of connecting, but also have the function of positioning. There is a group of outer top jack holes 14 around the circumference, the bottom of the outer top jack hole is bonded with the outer top magnetic plate 15, and the outer top insert rod is inserted into the outer top jack hole through the outer top magnetic plate. The sheet is attracted to the outer top magnetic plate to fix it, which can further fix the connection between the outer top insertion rod and the outer top jack.

Embodiment 3

[0025] In the rolling bearing described in Embodiment 2, the bottom of the outer sleeve is fixedly connected to a group of outsole inserting rods 16 around the circumference. The outsole inserting rods have both connection and positioning functions. The outer bottom The bottom of the plunger is bonded with an outer bottom magnetic sheet 17, and the top inner side of the outer sealing sleeve of the bearing is provided with a group of outer bottom jacks 18 around the circumference, and the bottom of the outer bottom jack is glued with an outer bottom magnetic plate 19, The outer bottom insertion rod is inserted into the outer bottom insertion hole and fixed by the outer bottom magnetic sheet attracting the outer bottom magnetic plate, which can further fix the connection between the outer bottom insertion rod and the outer bottom insertion hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com