Rolling bearing and machining method

A rolling bearing and bearing technology, applied in the direction of roller bearings, bearing components, shafts and bearings, can solve the problems that the rollers cannot be replaced, the use of rolling bearings is unfavorable, and the installation is inconvenient. Cost, good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

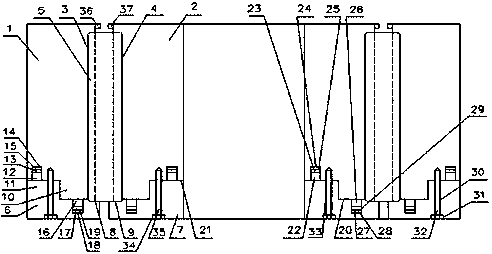

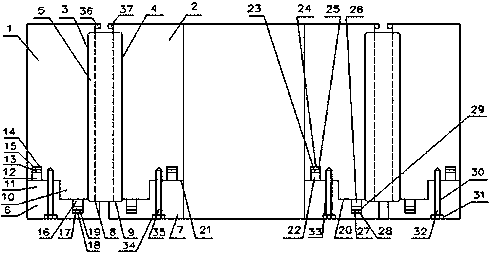

Embodiment 1

[0021] A rolling bearing, which consists of: a bearing outer sleeve 1, a bearing inner sleeve 2. A set of outer vertical slots 3 are opened around the inner circle of the bearing outer sleeve, and the outer vertical slots are closed at the top and open at the bottom. The outer circle of the bearing inner sleeve is provided with a set of inner vertical slots 4 around the circumference. The top of the inner vertical slot is closed and the bottom is open. The outer vertical slot and the inner vertical slot are different from each other. There are rollers 5 in between. The bottom of the bearing housing is connected to the bearing outer sealing sleeve 6. The bearing outer sealing sleeve can seal the outer vertical slot and is convenient for assembly. The bottom of the bearing inner sleeve is connected to the bearing inner sealing Sleeve 7. The inner circle of the outer sealing sleeve of the bearing is provided with a set of outer sealing grooves 8 around the circumference. The outer ...

Embodiment 2

[0023] In the rolling bearing described in embodiment 1, the bottom inner side of the bearing housing has an outer insert sleeve 10, and the top outer side of the bearing outer sealing sleeve has an outer fixing sleeve 11, and the top of the outer fixing sleeve is around the circumference A set of outer top inserting rods 12 are fixedly connected. The outer top inserting rod has a connection function and a positioning function. The top of the outer top inserting rod is bonded with the outer top magnetic sheet 13, and the bottom outer side of the bearing housing A set of outer top insertion holes 14 are opened around the circumference. The bottom of the outer roof insertion holes is bonded to the outer roof magnetic plate 15, and the outer roof insertion rod is inserted into the outer roof insertion hole through the outer roof magnet The sheet attracts and fixes the outer top magnetic plate, which can further fix the connection between the outer top insert rod and the outer top s...

Embodiment 3

[0025] In the rolling bearing described in embodiment 2, the bottom of the outer sleeve is fixedly connected to a set of outsole rods 16 around the circumference. The outsole rods have both a connection function and a positioning function. The bottom of the insert rod is bonded with an outer bottom magnetic sheet 17, a set of outsole insertion holes 18 are opened around the circumference of the top inner side of the outer sealing sleeve of the bearing, and the bottom of the outer bottom insertion hole is bonded with an outer bottom magnetic plate 19, The outsole insert rod is inserted into the outsole insertion hole and fixed by the outsole magnetic sheet attracting the outsole magnetic plate, which can further fix the connection between the outsole insert rod and the outsole insertion hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com