Mechanism for compensating gravitational torque generated by vertical rotary component

A technology of vertical rotation and gravity moment, which is applied in the field of video terminal equipment, can solve the problems of limited adjustable range, waste of energy and materials, etc., and achieve the effect of increasing service life and simplifying the drive control circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

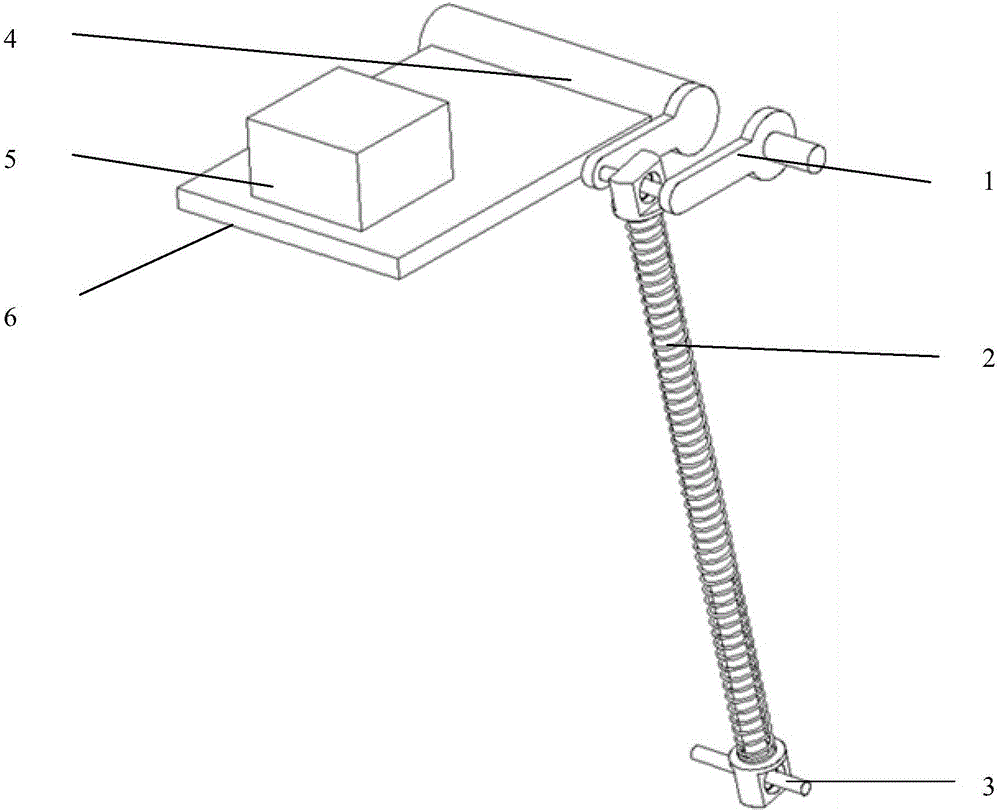

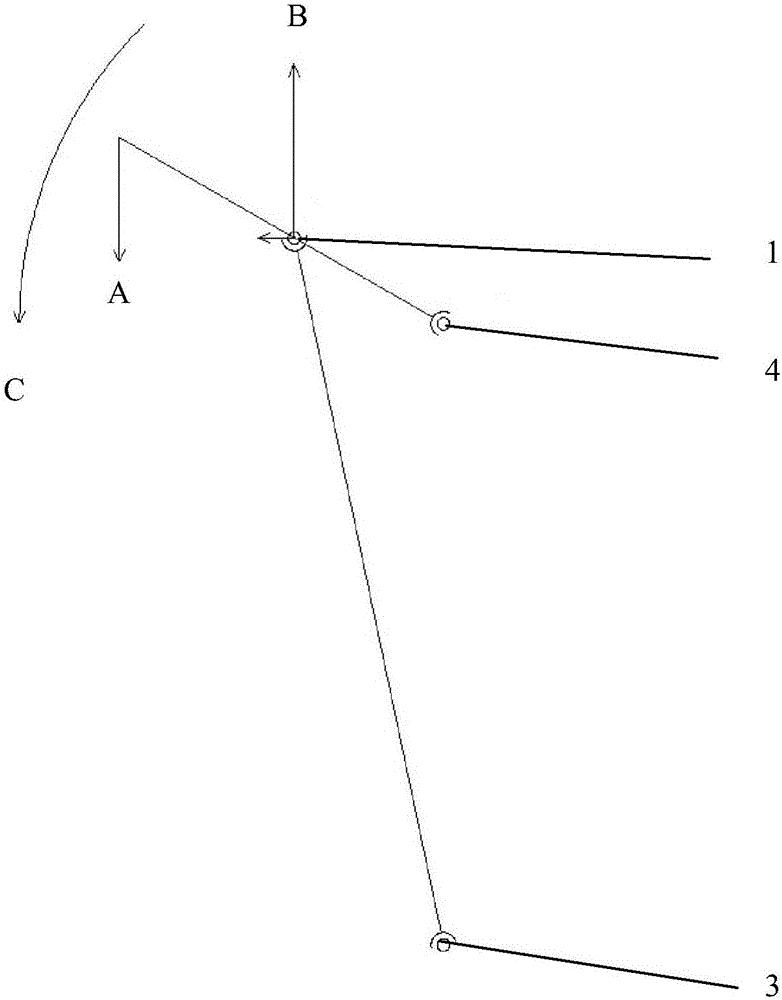

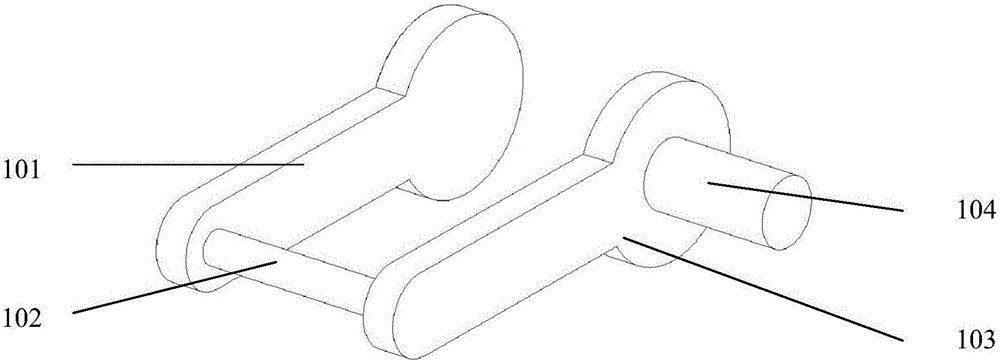

[0029] Such as figure 1 The shown mechanism for compensating the gravitational moment generated by the vertically rotating parts includes: a crankshaft 1 , a booster part 2 , a static support shaft 3 and a main shaft 4 . The crankshaft 1 includes a first crank arm 101 and a connecting rod journal 102 , the end of the first crank arm 101 away from the connecting rod journal 102 is vertically connected to one end of the main shaft 4 in an L shape. Such as figure 1 with image 3 As shown, the first crank arm 101 and the connecting rod journal 102 are vertically connected in an L shape. One end of the booster component 2 is hinged to the connecting rod journal 102, and the other end is hinged to the static support shaft.

[0030] Such as image 3 As shown, the crankshaft 1 further includes a second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com