Miniature flat piezoelectric motor and design method

A piezoelectric motor and design method technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problems of difficult miniaturization, limited application, etc. The effect of small, small excitation voltage amplitude and large output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

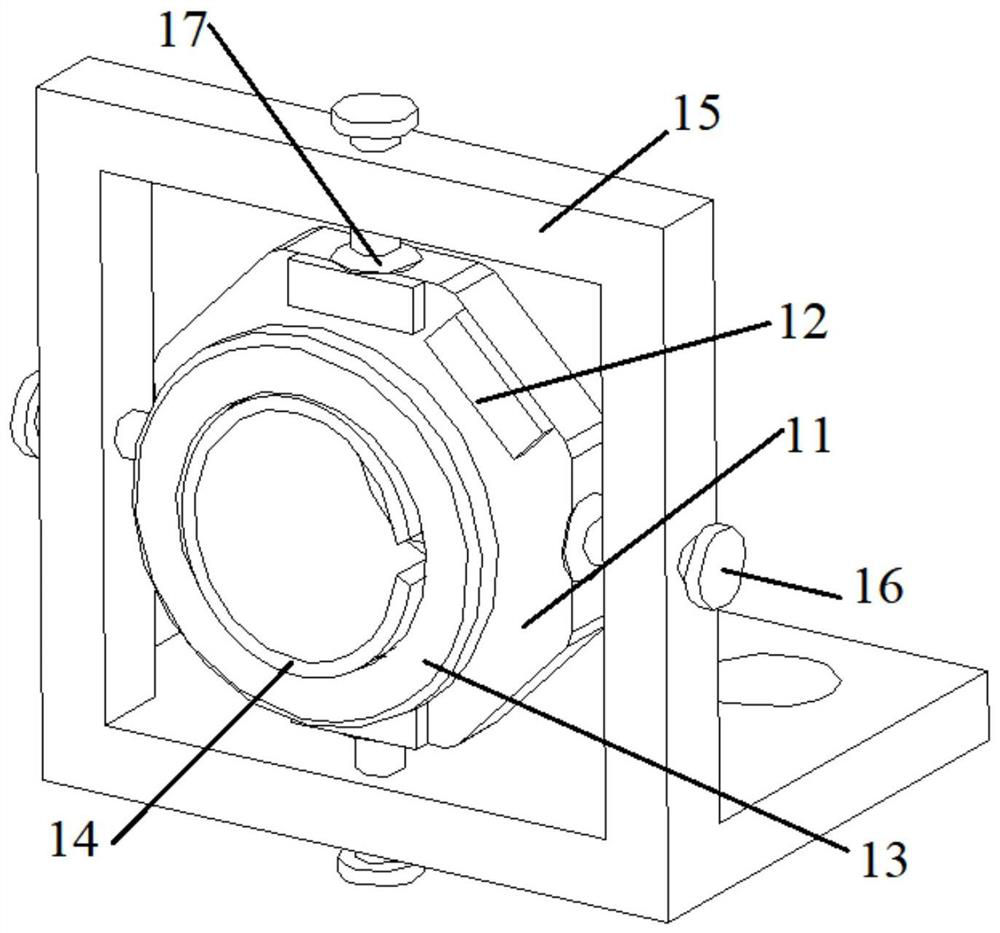

[0041] The piezoelectric ceramic sheet 12 is pasted on the outer surface of the metal base 11 to form a stator; the rotor 14 is an annular structure with a certain opening, and the rotor 14 is embedded in the hollow metal base 11 through threads, and is driven by the threads. The piece 13 moves helically along the axis of the metal base 11 . The support frame 15 is an L-shaped structure, wherein the vertical part of the support frame 15 is a hollow structure for fixing the metal base 11 , and a first through hole is opened in the vertical part of the support frame 15 to apply pressure to the metal base 11 . pre-pressure. In this embodiment, four first through holes are symmetrically formed in the vertical part of the support frame 15 , the fastening nuts 16 are inserted into the first through holes of the vertical part of the support frame 15 , and the pressure is evenly applied to the metal base 11 through the disc spring 17 . In this way, the applied pre-pressure can only act...

Embodiment 2

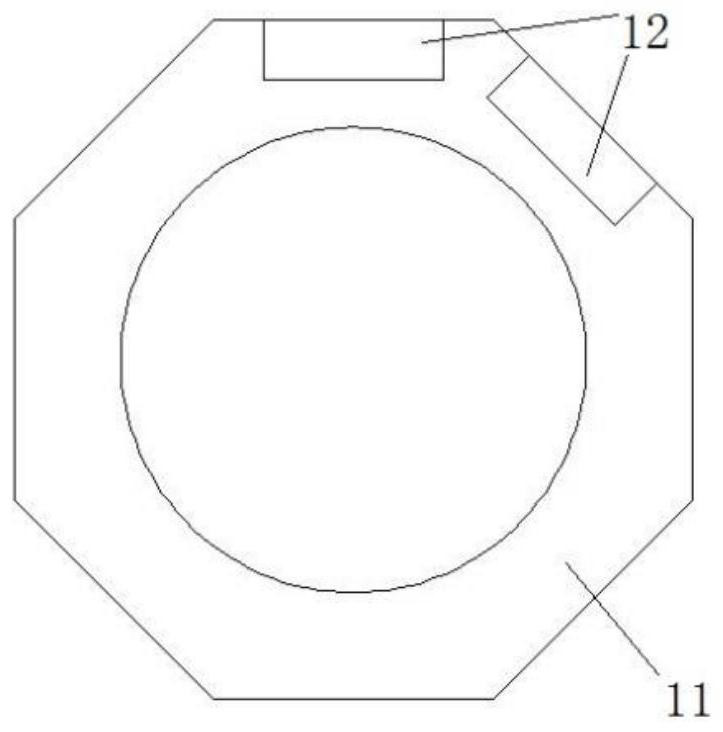

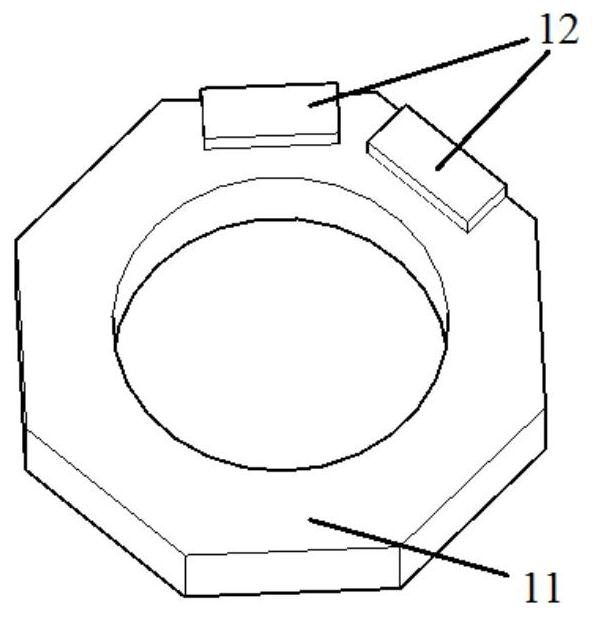

[0045] In order to further increase the output displacement of the motor, the present invention proposes an improved stator structure, whose top view is as follows: Figure 4 shown. It includes a metal base 11 and two sets of piezoelectric ceramic sheets 12 . The metal base 11 is brass, and the two groups of piezoelectric ceramic sheets 12 are symmetrically pasted by epoxy resin glue, and each group contains two pieces, the piezoelectric ceramic sheets in each group are pasted adjacently, and each piezoelectric ceramic sheet is attached thickness direction polarization. When two sets of piezoelectric ceramic sheets 12 in the stator are respectively excited by two-phase sinusoidal AC voltages with a peak value of 50V and a phase difference of 90°, the maximum vibration displacement in the x and y directions at the driving point of the stator 12 is measured to be is to adopt figure 2 The stator structure shown in , and two times of the maximum output displacement generated w...

Embodiment 3

[0048] The present invention also proposes such as Figure 5 shown stator structure, which is the same as figure 2 The difference in the stator construction shown in is the rounded corners on the metal base. It is obtained through simulation analysis, and figure 2 Compared to the performance of the stator shown in, Figure 5 The output displacement of the stator drive surface particles shown in is larger, and the specific displacement magnification is the same as Figure 5 It is related to the radius of the fillet opened in . In addition, it is also possible to Figure 5 Two sets of piezoelectric ceramic sheets are pasted on the stator structure shown in Figure 4 The stator structure diagram. Similarly, after rounding the corners, the output displacement of the stator driving surface particles is also higher than that of using Figure 4 The structure shown is larger, and the specific displacement magnification is determined by the rounded corners.

[0049] Other par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com