Rotor angle subdivision method for switched reluctance motor speed regulation system

A technology of switched reluctance motor and speed regulation system, applied in control system, electronic commutator, AC motor control and other directions, can solve the problems of frequency division multiple limitation, low rotor angle subdivision accuracy, low reliability, etc. Achieve high precision, low cost and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

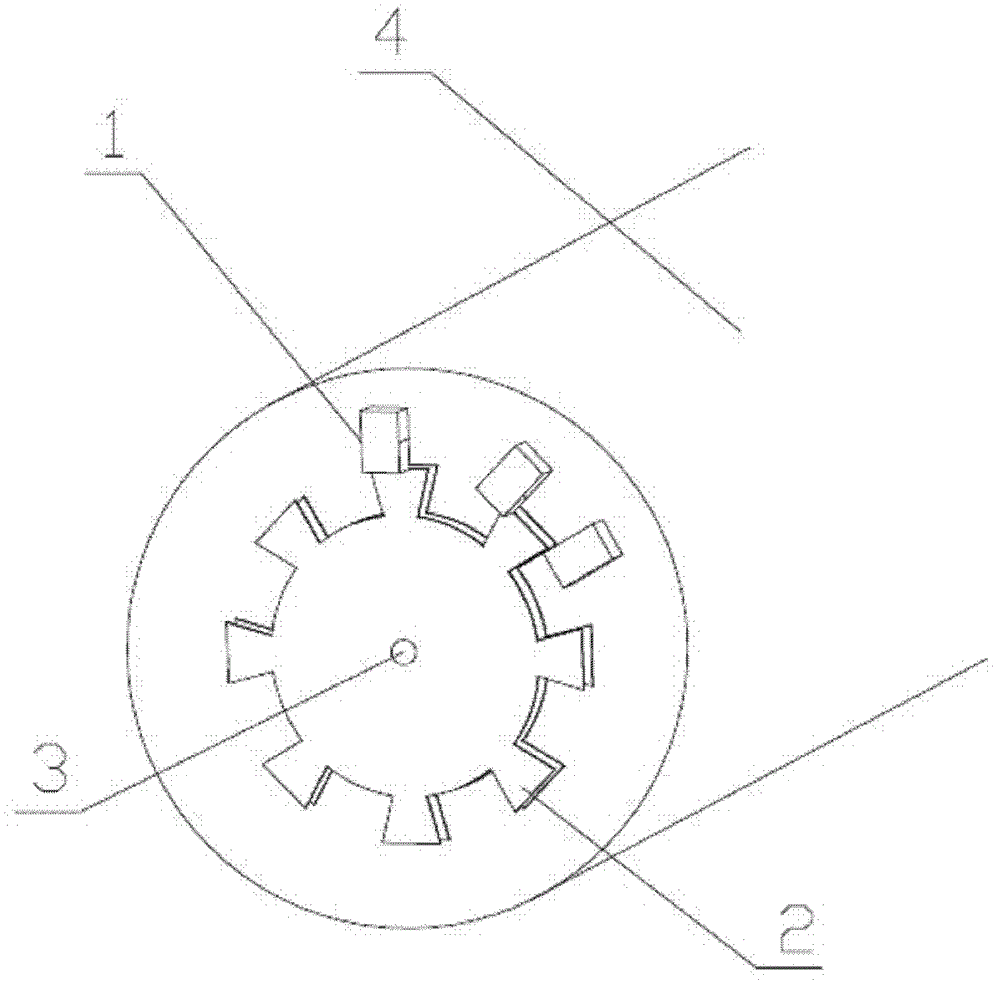

[0013] Taking the three-phase stator twelve-slot and rotor eight-pole switched reluctance motor speed control system based on the TMS320F2812 produced by TI as the control chip as an example, the position detection part of the system is as follows: figure 2 Shown are: three photoelectric tubes 1 at a distance of 15° from each other on the concentric circle of the rotor; a tachymeter disk 2 with eight tooth slots and equal width, which is concentric with the rotor and fixed on the rotating shaft. When the teeth of the tachometer disc 2 block the optical path of a certain photoelectric pair tube 1, the photoelectric pair tube 1 outputs a high level, otherwise it outputs a low level. Because when the output signal of photoelectric pair tube 1 jumps, the rotor position is uniquely determined, so it is defined within one electrical cycle (360° / 8=45°) that the output signal of any one photoelectric pair tube 1 jumps. position is the standard position.

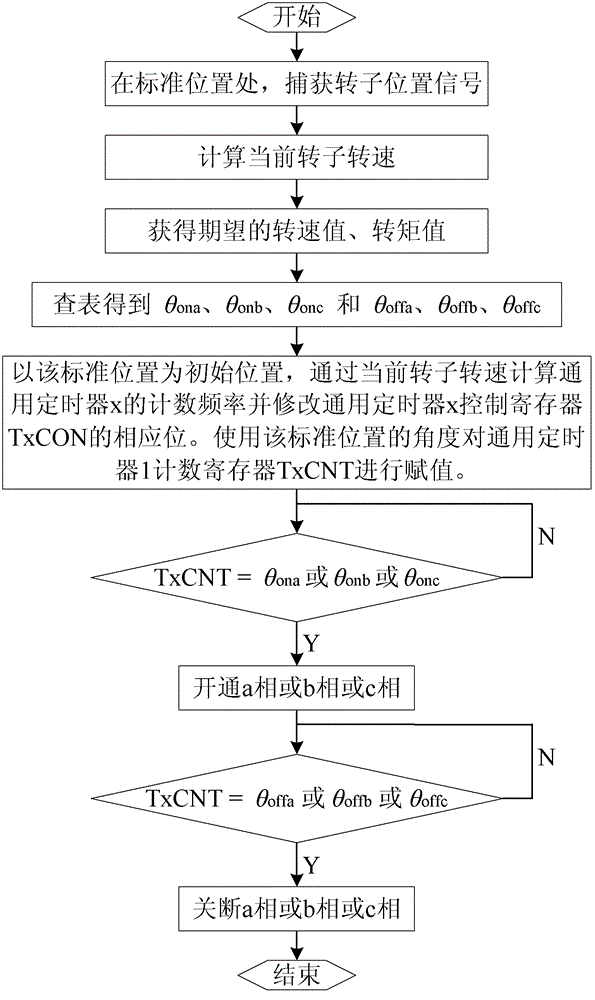

[0014] Such as figure 1 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com