A doubly salient magnetic flux controllable motor with few rare earth yoke complementary

A doubly salient pole and rare earth technology, applied in magnetic circuits, synchronous machines, electrical components, etc., can solve the problems of less rare earth permanent magnet consumption, low torque ripple, and high efficiency, and achieve less harmonic content and torque ripple Small, the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

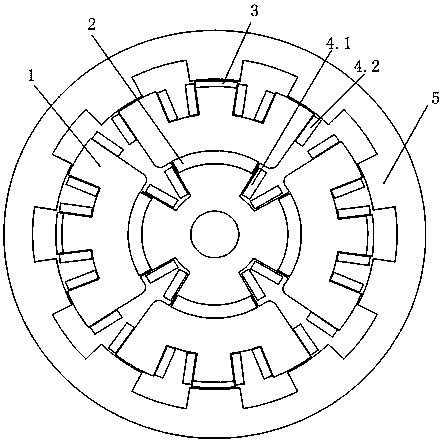

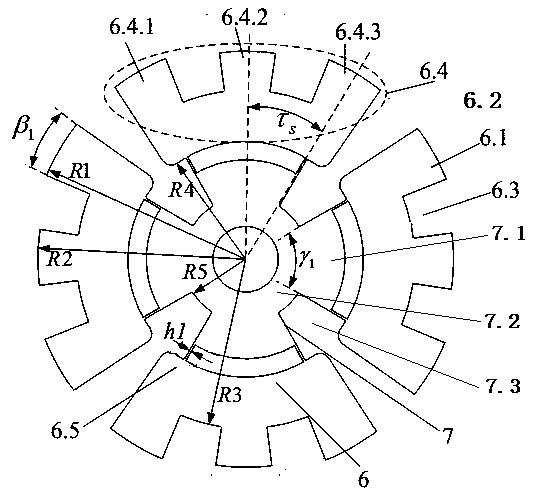

[0025] see figure 1 , the motor of the present invention is an outer rotor and an inner stator structure, the outside is a rotor core 5, the rotor core 5 is connected with the motor torque output shaft, the outer side of the rotor core 5 is a non-magnetic casing, and the casing and the motor end The cover is connected, and the end cover is connected with the torque output shaft through a bearing. The inner center of the rotor iron core 5 is coaxially installed with the stator. The stator is composed of a stator core 1, an AlNiCo permanent magnet 2, a NdFeB permanent magnet 3, a magnetic modulation pulse winding 4.1 and an armature winding 4.2, and the center of the stator core 1 is connected to the fixed shaft of the motor.

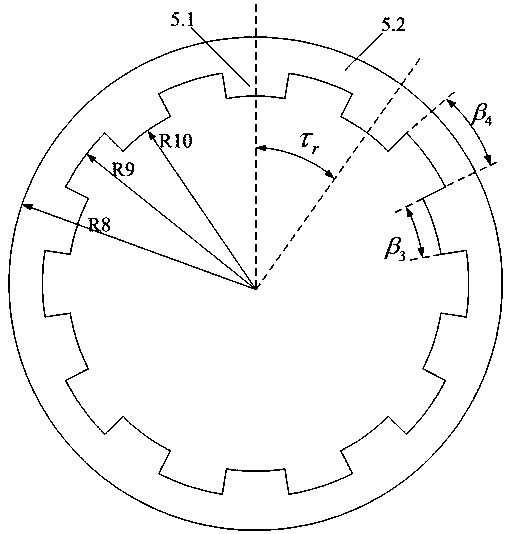

[0026] see figure 2 , the rotor core 5 is a salient pole structure in structure, and the rotor core 5 has neither permanent magnets nor windings. The rotor core 5 contains a total of N r There are two rotor salient poles 5.1, and rotor slots 5.2 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com