End effector, industrial robot, and method for operating same

一种工业用机器人、末端执行器的技术,应用在机械手、制造工具、夹头等方向,能够解决机器人制造成本增加、空间增大等问题,达到抑制制造成本增加、扩大范围的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

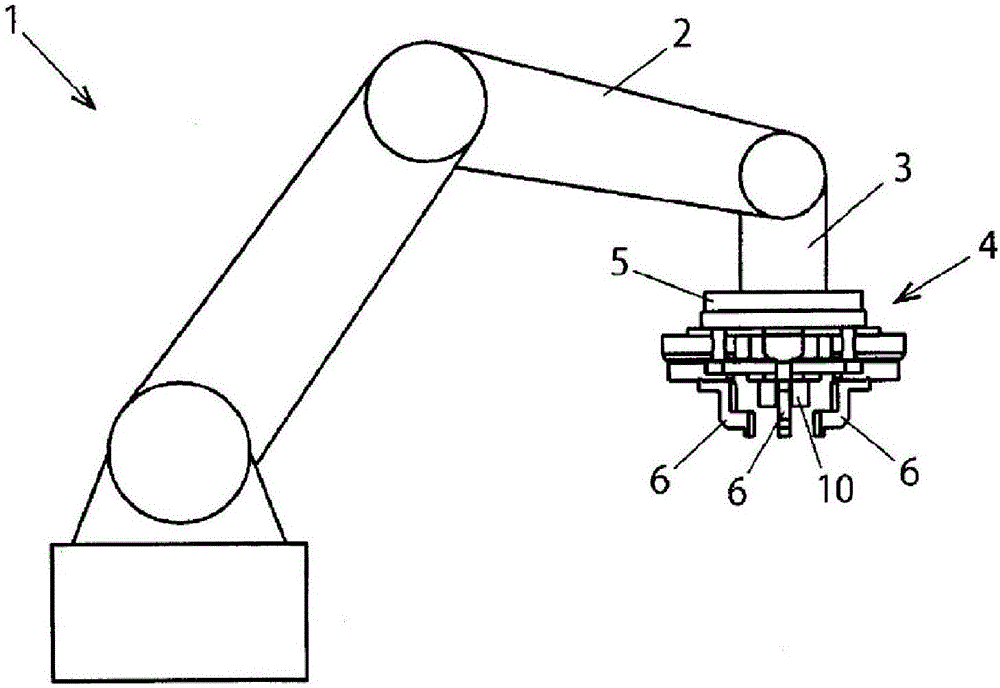

[0031] Hereinafter, the end effector 4 of the industrial robot 1 according to an embodiment of the present invention will be described with reference to the drawings.

[0032] Such as figure 1 As shown, the industrial robot 1 of the present embodiment includes: an articulated robot arm 2; and an end effector (hand) 4, and a wrist shaft 3 attached to the tip of the robot arm.

[0033] In addition, the type of industrial robot to which the present invention is applied is not particularly limited, and can be applied to various industrial robots such as a vertical articulated robot or a horizontal articulated robot.

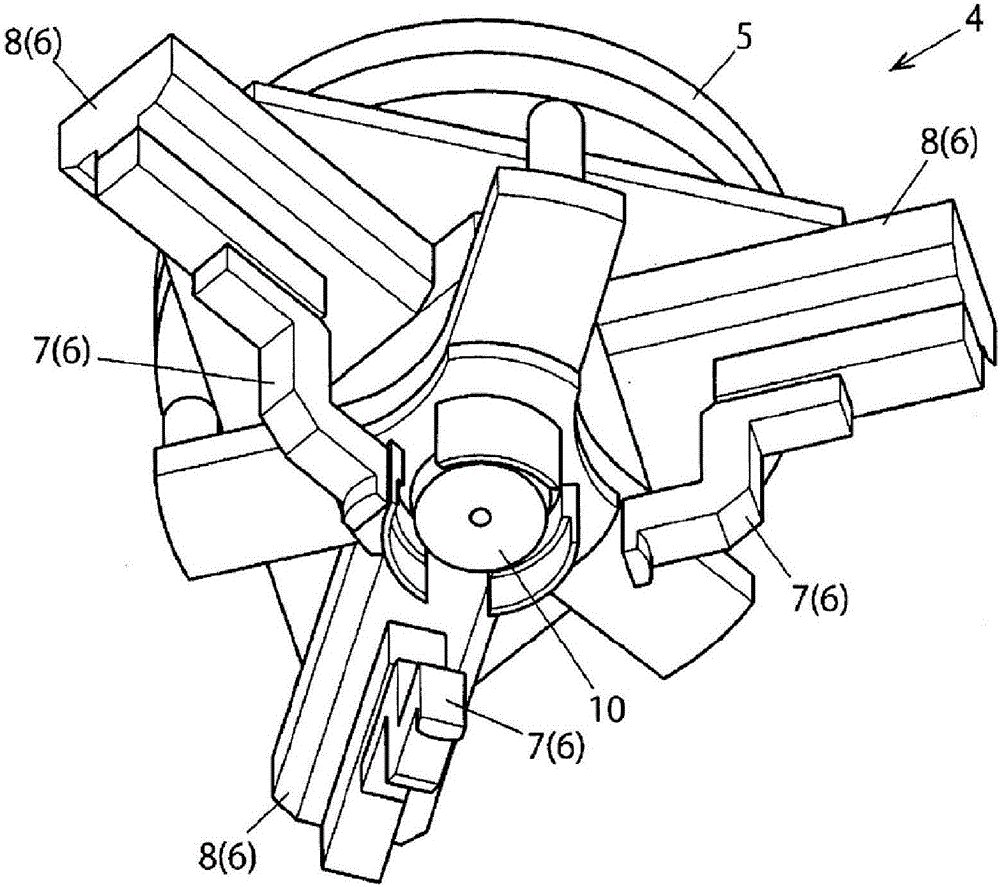

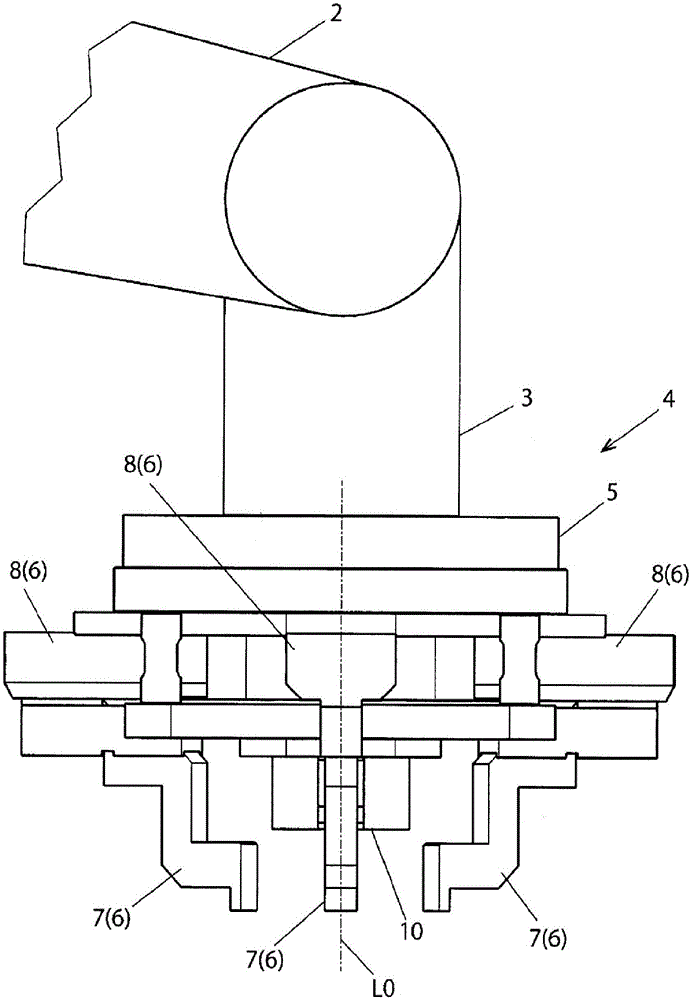

[0034] Such as Figure 2 to Figure 4 As shown, the end effector 4 in this embodiment is provided with an end effector base 5 connected to the robot arm 2 ( figure 1 ). The end effector base 5 is provided with a first object holding mechanism 6 for holding a first type of processing object.

[0035] The first object holding mechanism 6 has a plurality of first grasping membe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com