Method and device for joining sheets of glass to form insulating glass panes

A technology of insulating glass and glass plates, applied in windows/doors, building components, building structures, etc., to achieve the effect of shortening the time period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

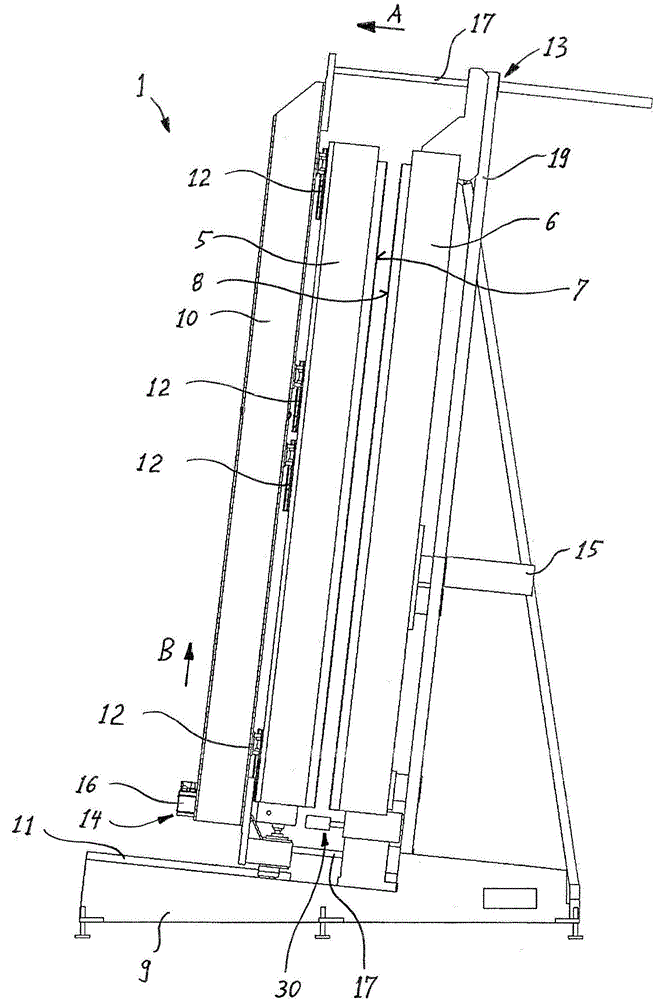

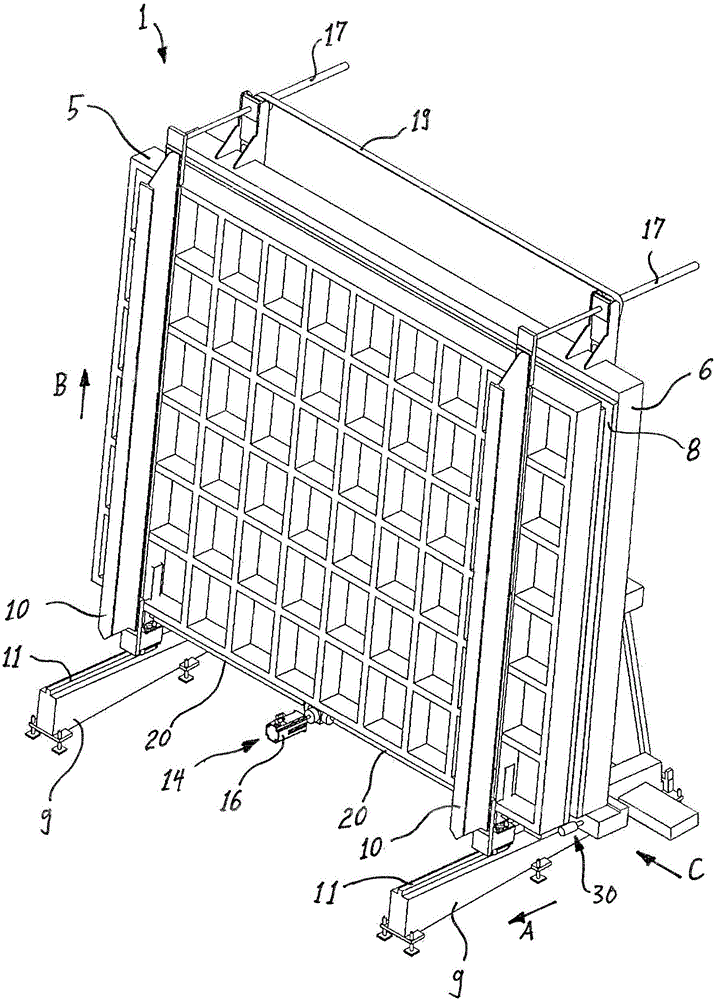

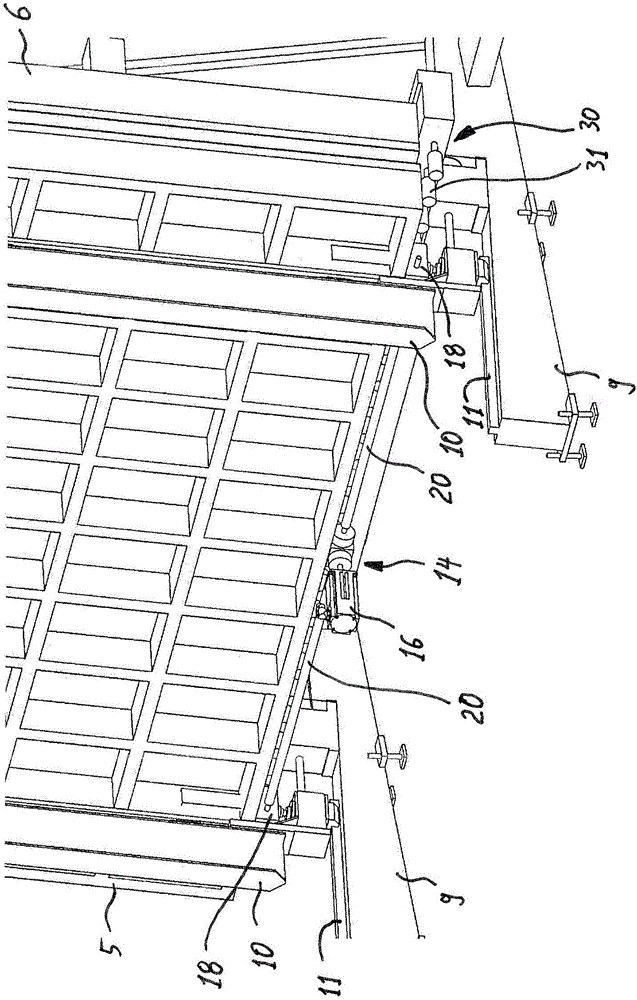

[0043] exist Figures 1 to 6 A first embodiment of a device 1 for assembling spacers 2 and glass panes 3, 4 to form an insulating glass pane is shown in FIG. The insulating glass pane is assembled from a first glass pane 3 , a second glass pane 4 and frame-like spacers 2 extending along the edges of the glass panes 3 , 4 . The spacer 2 separates the two glass panes 3 , 4 from one another in a known manner and is glued to them. Figure 6 and 7 The two glass panes 3 and 4 are shown with the spacer 2 arranged between them. The device 1 comprises a first press plate 5 with its corresponding pressing face 7 and a second press plate 6 with its pressing face 8 . Two pressing plates 5 , 6 are vertically arranged in the device 1 . The device consists of a stationary base frame 9 which needs to remain fixed and screwed to the floor. The first pressing plate 5 is disposed on the base frame 9 approximately horizontally along the first spatial direction A, and is movably disposed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com