High-power high-capacity lithium ion battery and preparation method thereof

A lithium-ion battery, high-capacity technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, non-aqueous electrolyte batteries, etc. Lowering, improving safety, avoiding direct contact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

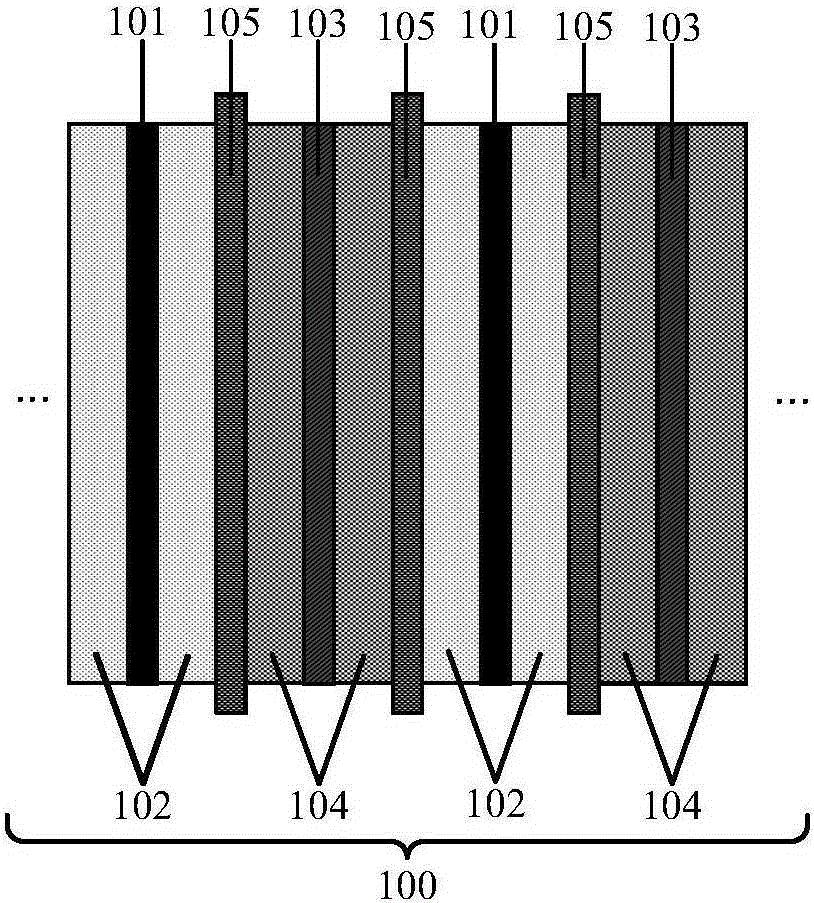

[0044] This embodiment provides a method for preparing a high-power and large-capacity lithium-ion battery with a stacked structure:

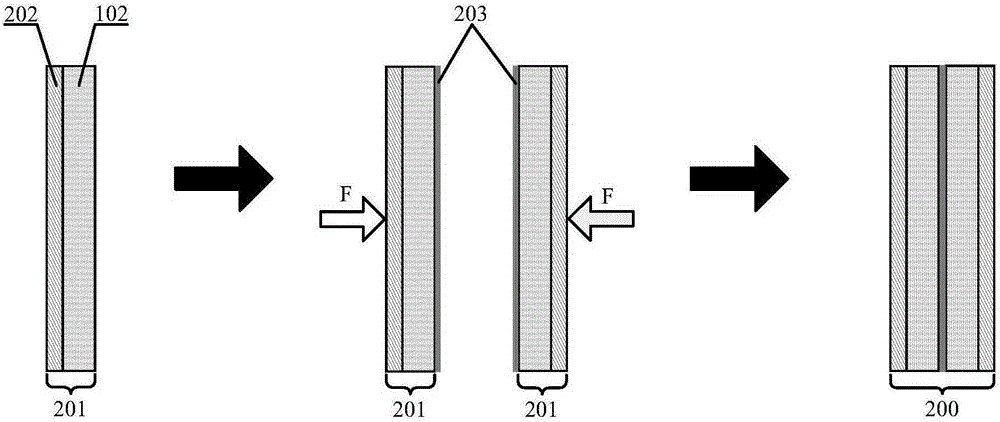

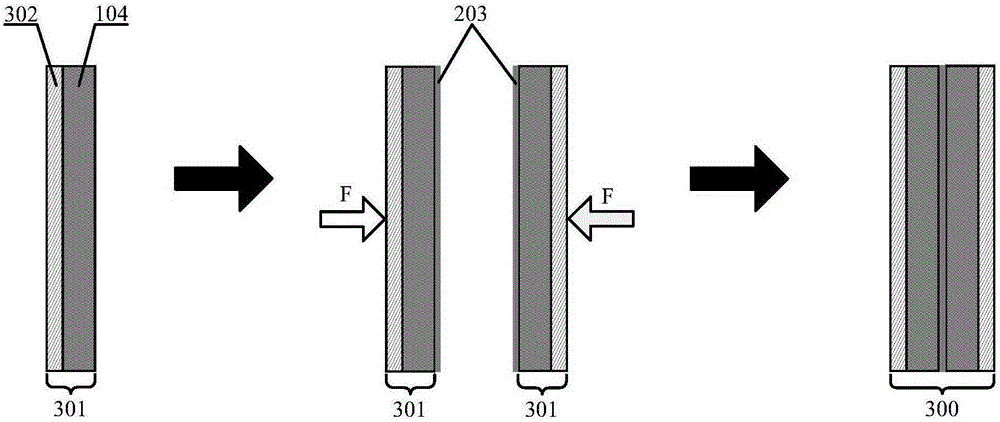

[0045] (1) Preparation of positive electrode sheet: In this embodiment, the porous positive electrode current collector 202 is a mixture of conductive filler and binder, the conductive filler is lithium-containing alloy powder, the binder is polyethylene oxide, and the positive electrode active material is lithium iron phosphate. , the conductive agent is selected from conductive graphite, and the binder is selected from polytetrafluoroethylene, wherein the mass ratio of lithium iron phosphate: conductive graphite: polytetrafluoroethylene is 78:20:2, and the positive electrode solvent is added to form a slurry after being stirred evenly. The plate is coated on one side of the mixture layer of conductive filler and binder, and after drying and pressing, a porous current-collecting positive electrode layer 201 is obtained, wherein the thickness of...

Embodiment 2

[0050] This embodiment provides a method for preparing a winding structure square high-power and large-capacity lithium-ion battery:

[0051] (1) Preparation of positive electrode sheet: In this embodiment, the porous positive electrode current collector 202 is made of porous aluminum foam layer, the positive electrode active material is made of lithium manganese phosphate, the conductive agent is made of carbon black, and the binder is made of polyethylene oxide, wherein lithium manganese phosphate : Carbon black: The mass ratio of polyethylene oxide is 90:9:1, and the positive electrode solvent is added to form a slurry after stirring evenly, and is coated on one side of the porous aluminum foam layer by thermal spraying, and the porous aggregate is obtained after drying and pressing. Flow the positive electrode layer 201, wherein the thickness of the coating, that is, the positive electrode material layer 102 is 800 μm, and then uniformly prepare a layer of nano-conductive l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com