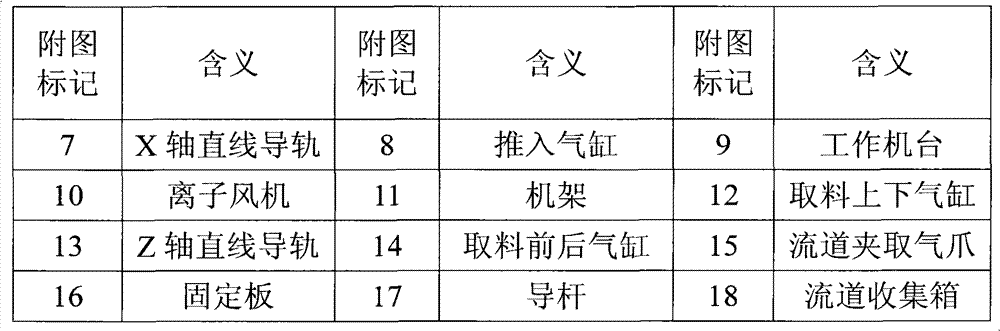

Patents

Literature

53results about How to "High quality consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

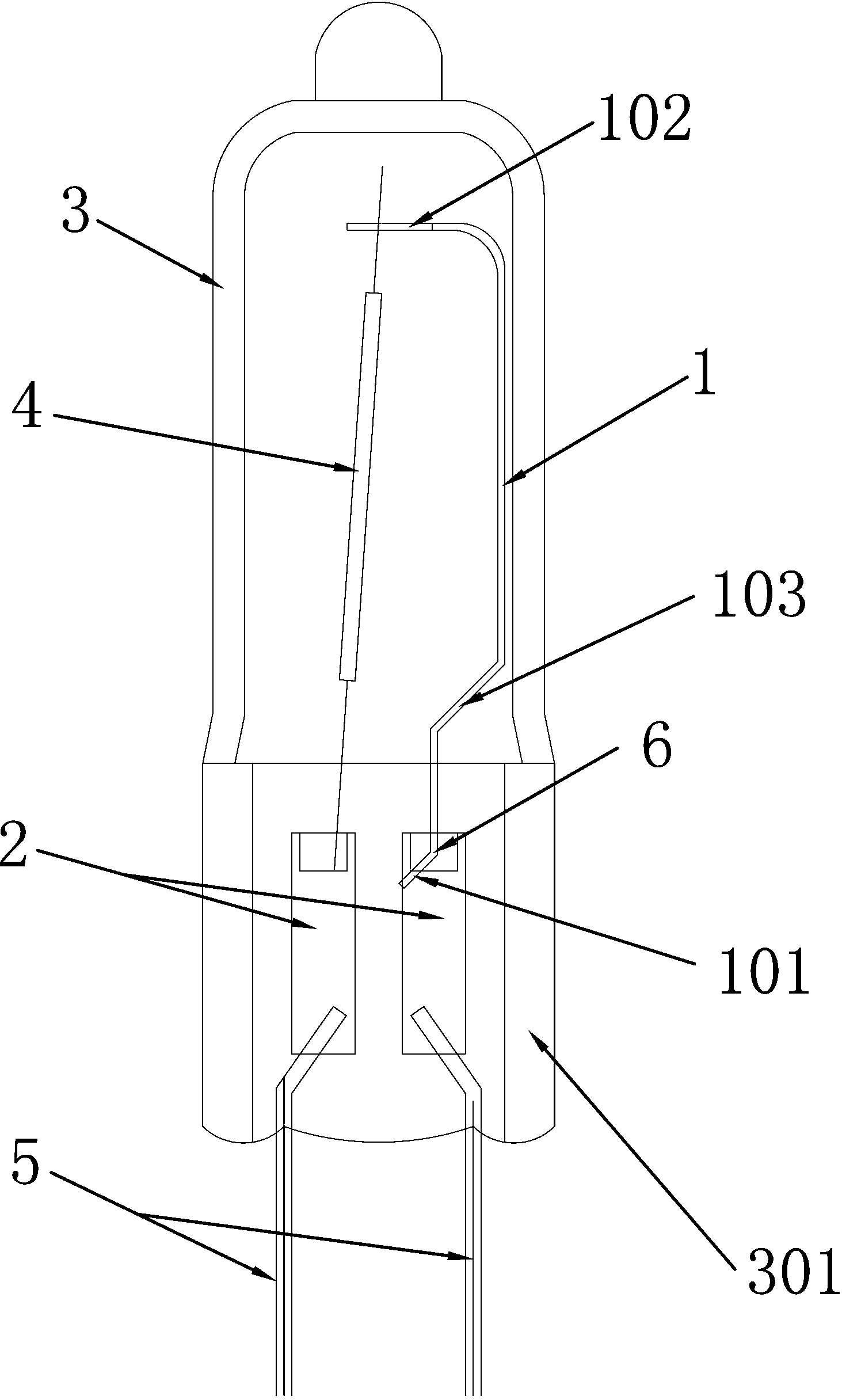

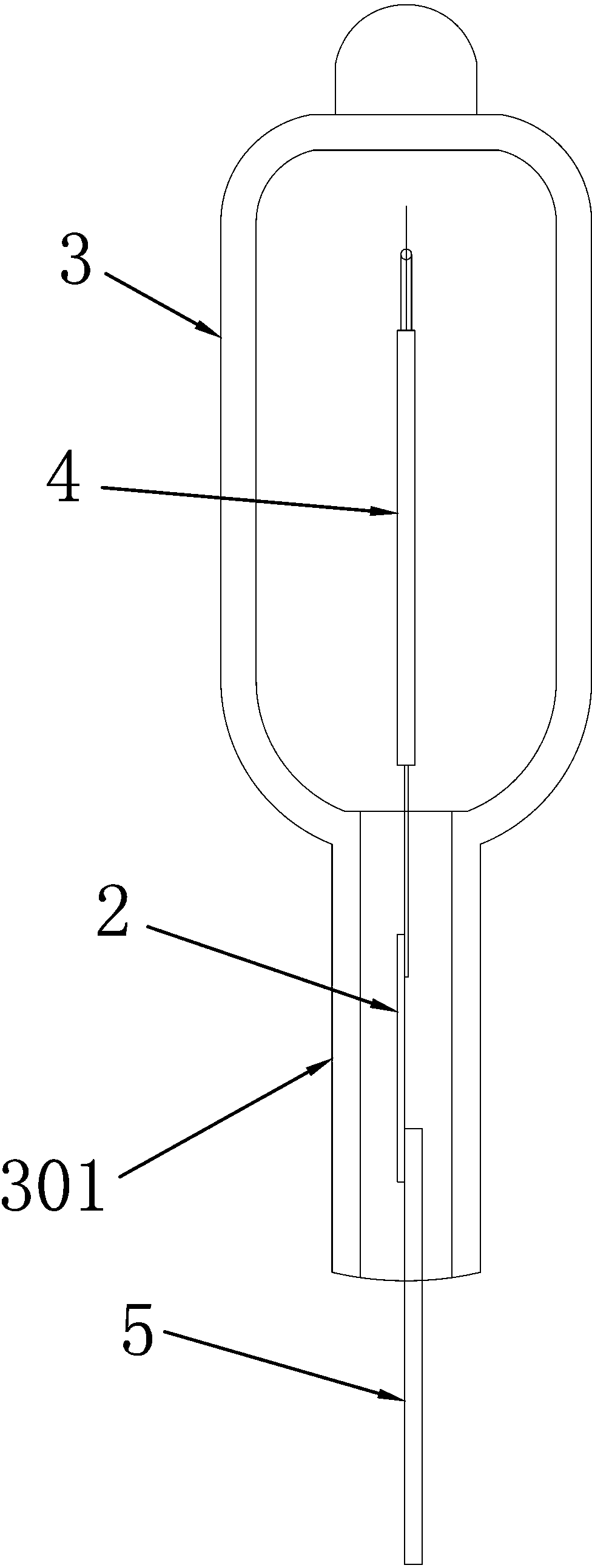

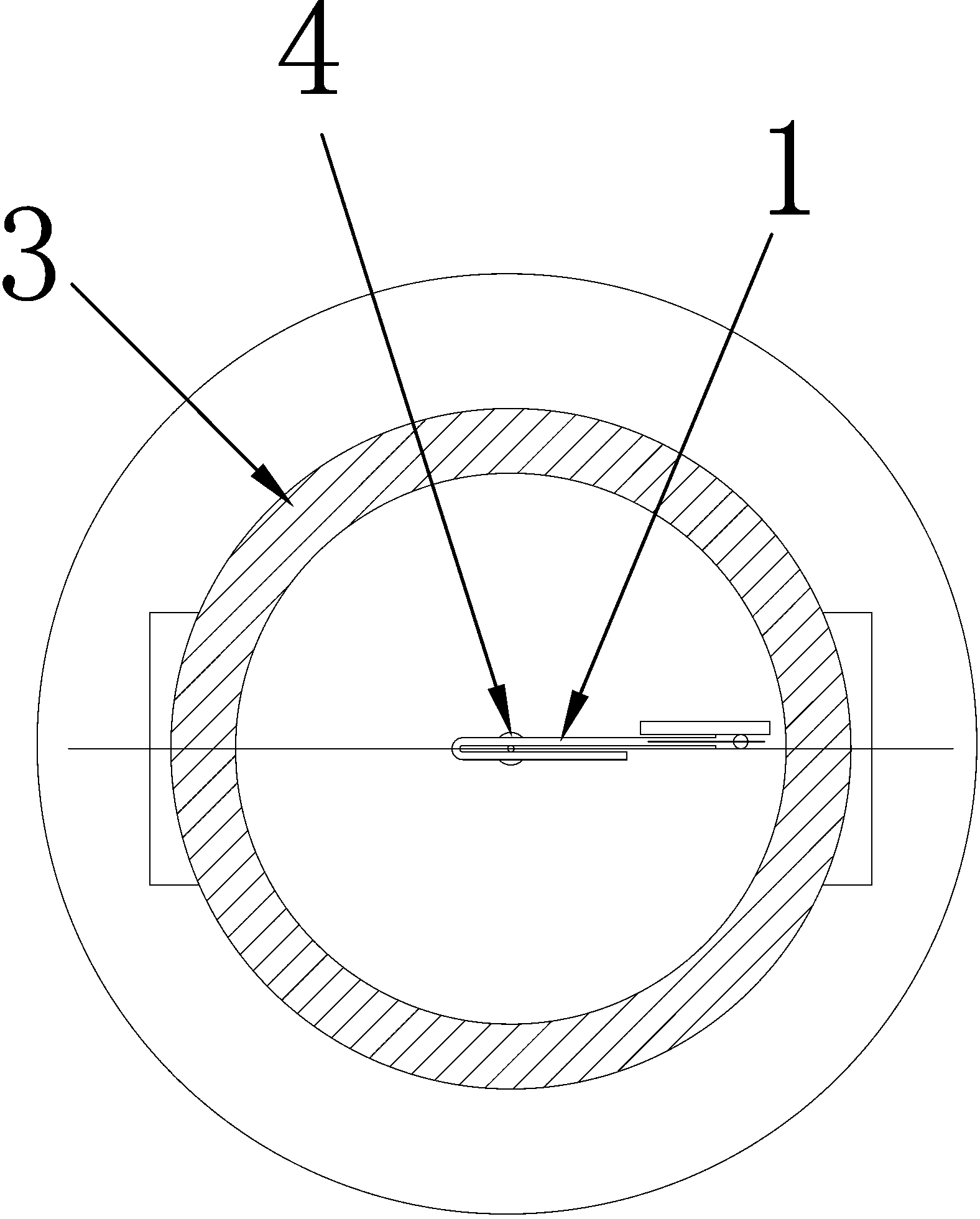

Single-ended halogen lamp with supporting frame locating hook

InactiveCN103413753AThe manufacturing process is stableHigh quality consistencyIncadescent body mountings/supportEngineeringHalogen lamp

The invention provides a single-ended halogen lamp with a supporting frame locating hook. The single-ended halogen lamp with the supporting frame locating hook comprises a lamp filament supporting frame, molybdenum sheets, a bulb shell and a lamp filament, wherein a molybdenum pin is welded to each molybdenum sheet, the lamp filament supporting frame, the molybdenum sheets and the lamp filament are respectively placed in the bulb shell. The number of the molybdenum sheets is two and the two molybdenum sheets are located in the clamping flat positions of the bulb shell. The molybdenum pin of each molybdenum sheet extends out of the bulb shell. One end of the lamp filament supporting frame is bended in the width direction of the bulb shell, so that a lamp filament hook used for supporting the lam filament is formed. One end of the lamp filament is hung on the lamp filament hook, and the other end of the lamp filament is downwards welded to one molybdenum sheet. The other end of the lamp filament supporting frame is welded to the other molybdenum sheet. The end, welded to the other molybdenum sheet, of the lamp filament supporting frame is bended in the welding portion between the end and the molybdenum sheet in the width direction of the bulb shell, so that the locating hook is formed. The locating hook and the lamp filament are on the same plane. By the adoption of the locating hook, after the lamp filament supporting frame is welded to one molybdenum sheet and clamped to the bulb shell in a sealed mode, the lamp filament hook and the lamp filament are both located in the middle of the thickness of the bulb shell. The single-ended halogen lamp with the supporting frame locating hook has the advantages of being stable in production process, high in quality uniformity, even in light distribution, long in service life and the like.

Owner:赵伟明

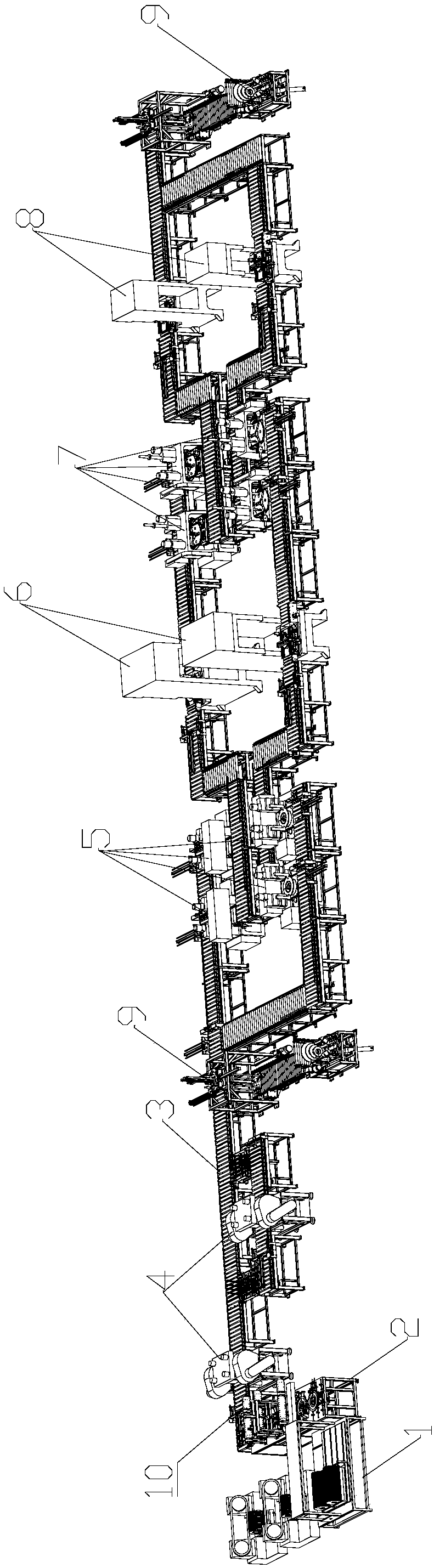

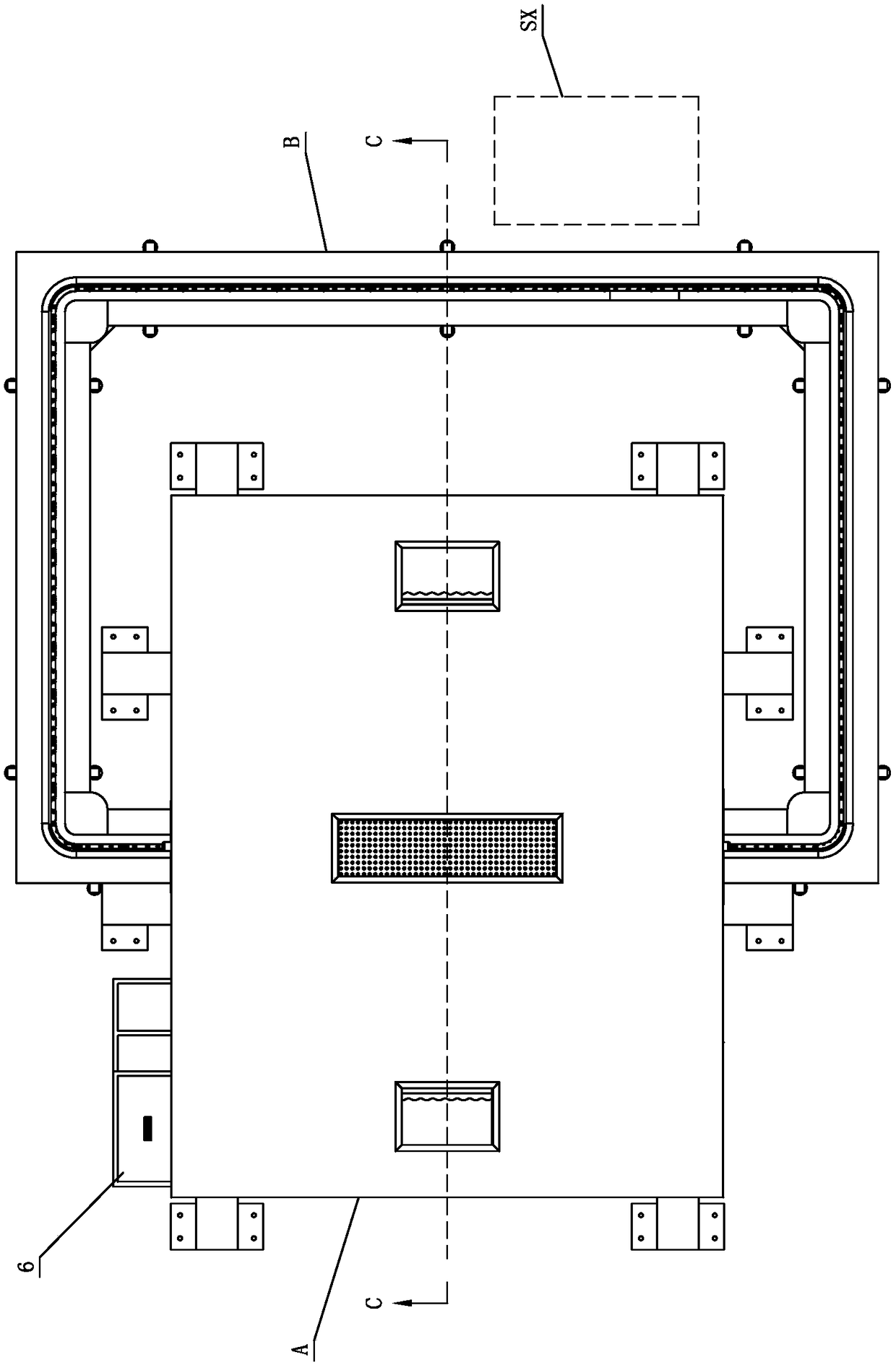

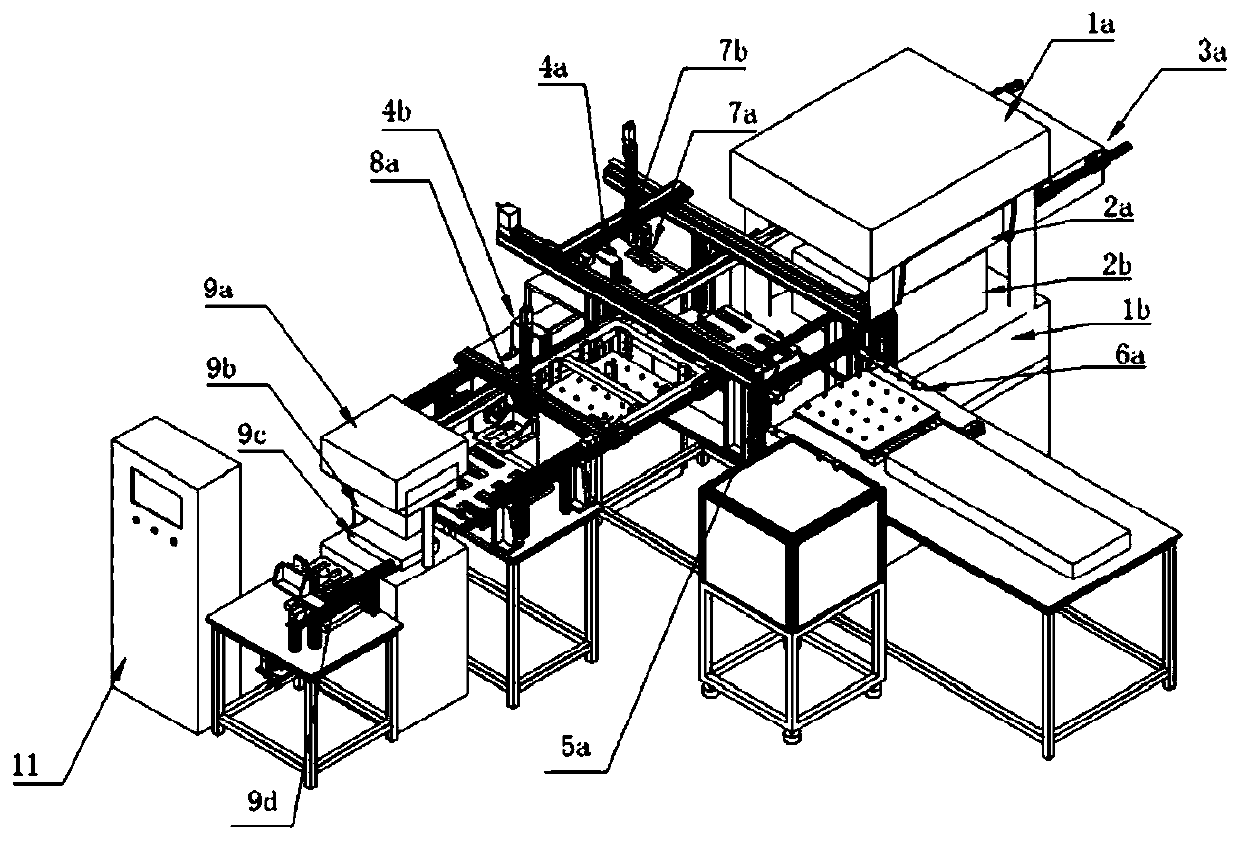

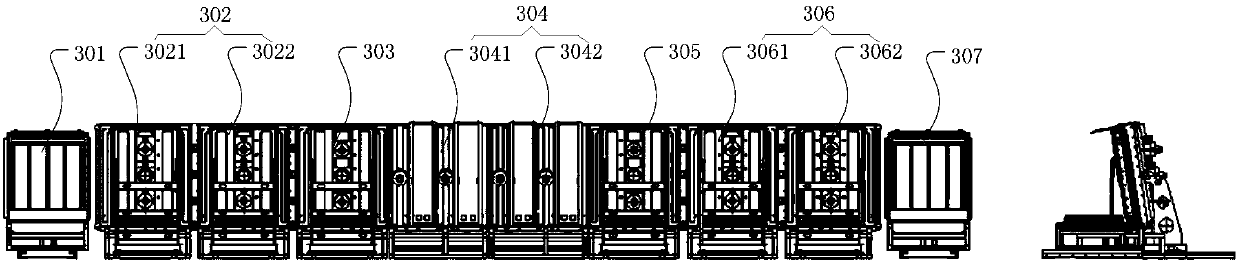

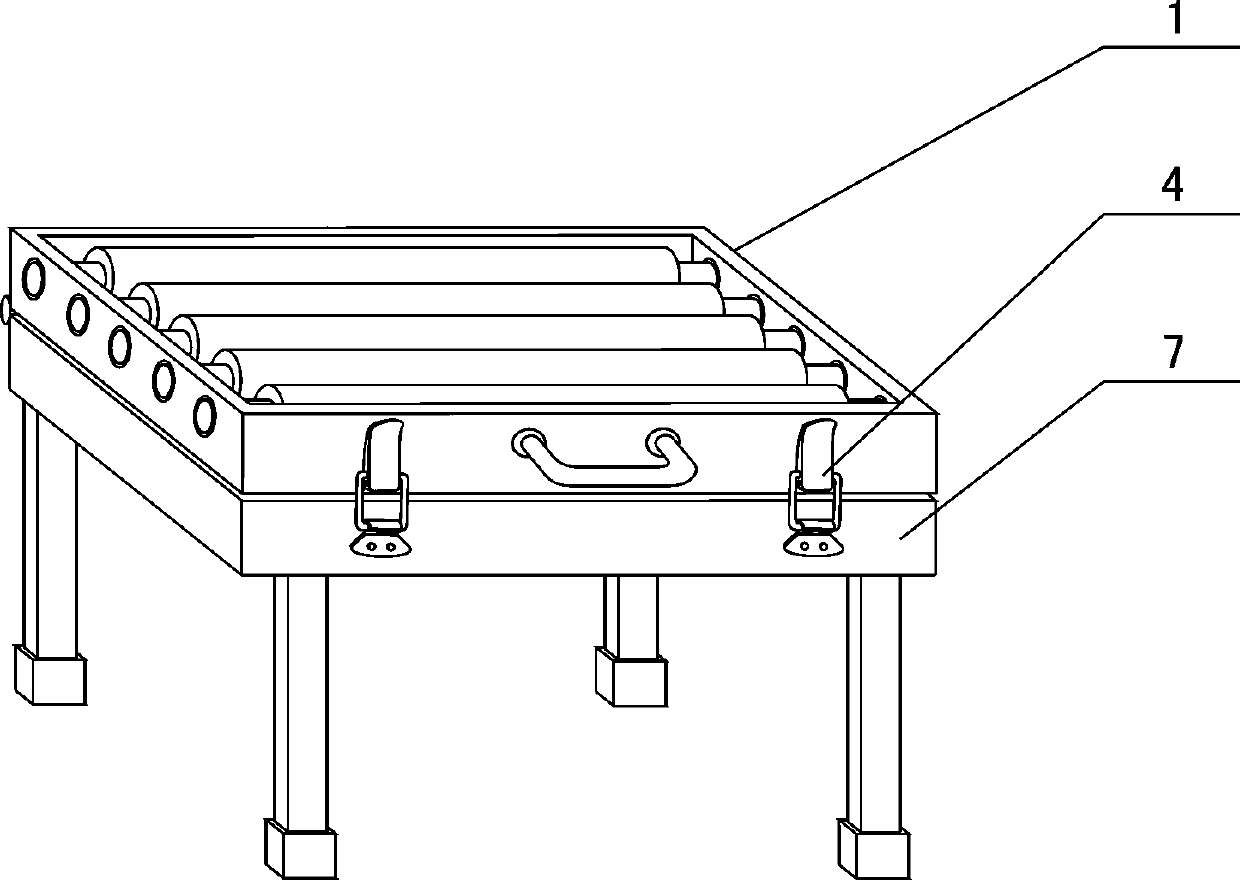

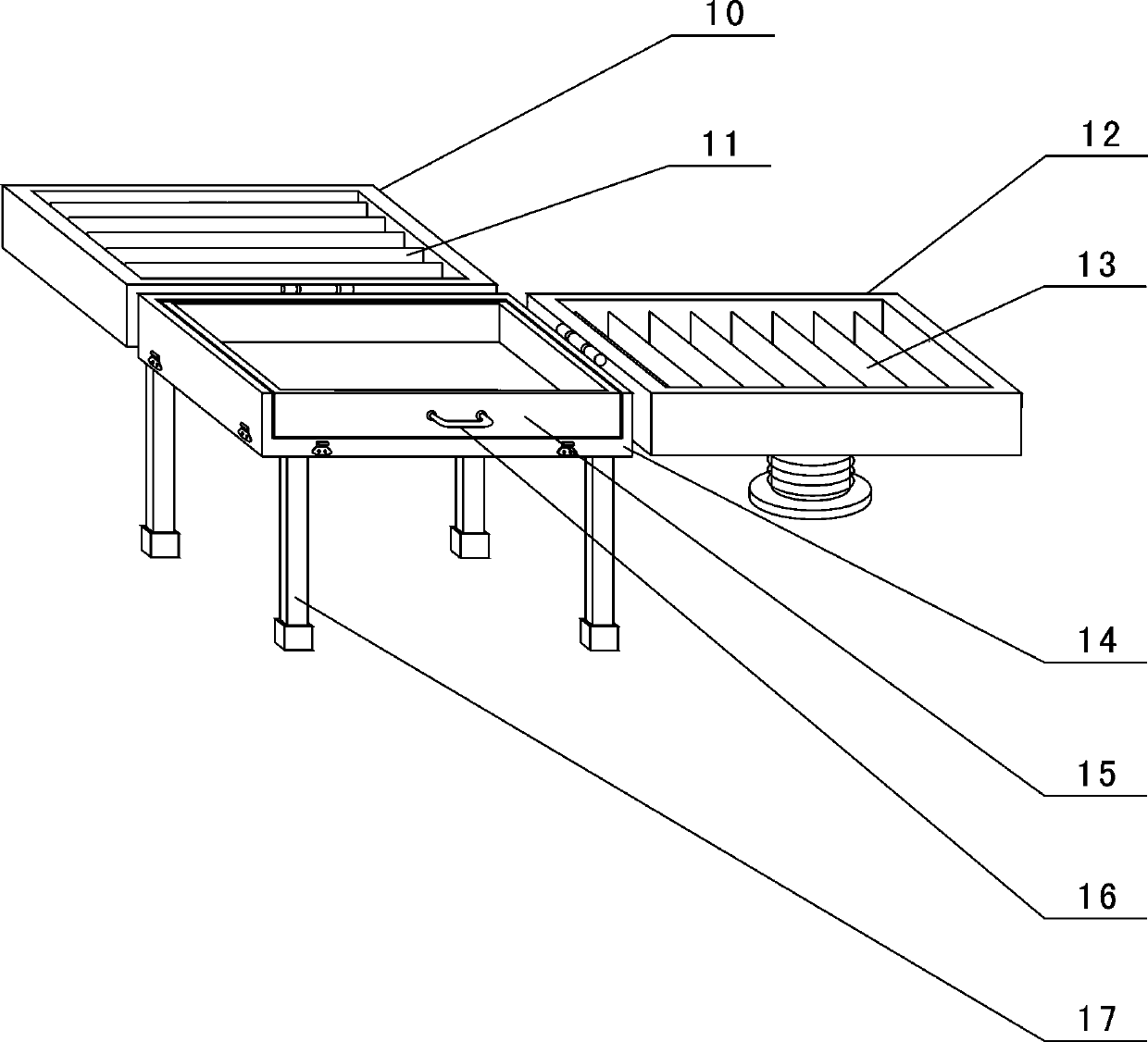

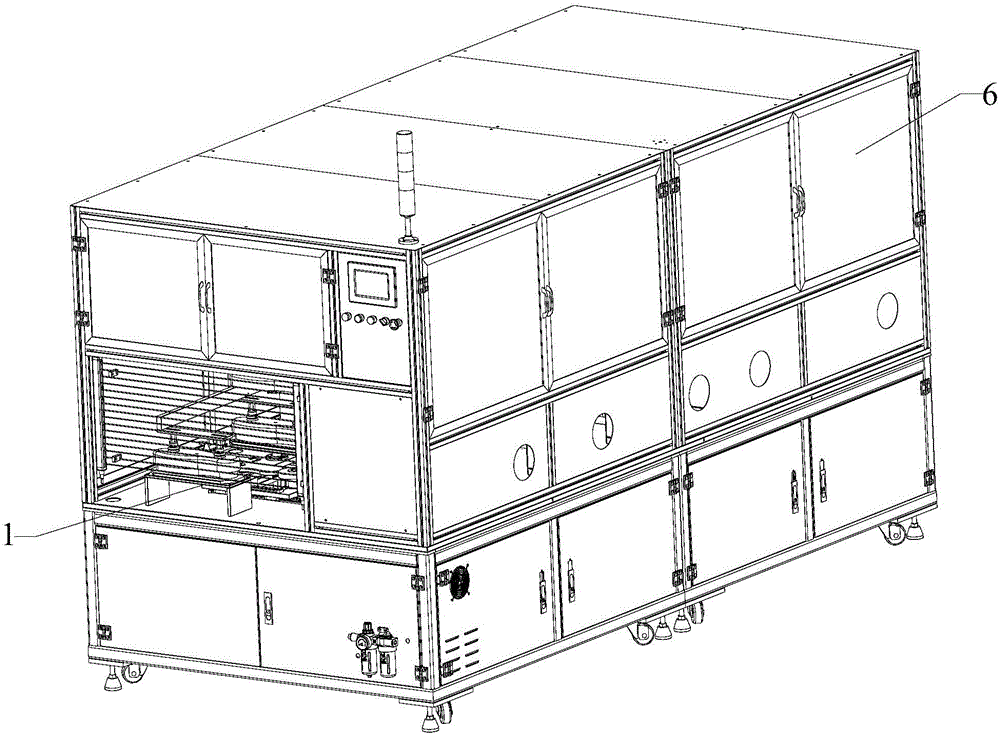

Automatic flange machining production line

PendingCN108381196AReduce labor costsIncrease productivityOther manufacturing equipments/toolsMetal working apparatusProduction linePunch press

The invention provides an automatic flange machining production line. The automatic flange machining production line comprises an automatic feeding mechanism, an automatic welding assembly line, a roller device, roller presses, lathes, punching machines, drilling and tapping machines and an automatic discharging and stacking mechanism; the automatic feeding mechanism comprises a material clampingmechanical arm capable of rotating in multiple dimensions; the automatic welding assembly line comprises a first welding station, a material overturning station, a second welding station and a third welding station, wherein the first welding station is used for welding the front surfaces of flange plates, the material overturning station is used for overturning the flange plates, the second welding station is used for welding the back surfaces of the flange plates, and the third welding station is used for welding the side walls of the flange plates; the roller presses are used for flatteningthe flange plates; the lathes are used for polishing the flange plates; the punching machines are used for punching flange plate holes; the drilling and tapping machines are used for drilling counterbores of the flange plates and performing tapping; and the automatic discharging and stacking mechanism is used for stacking and discharging flange plate finished products. The production line integrates equipment for feeding, welding, rolling, punching and the like to form an integrated machining production line, the labor cost of manual operation can be lowered, the production efficiency can beimproved, and the product quality can be improved.

Owner:FOSHAN FODA HUAKANG TECH CO LTD

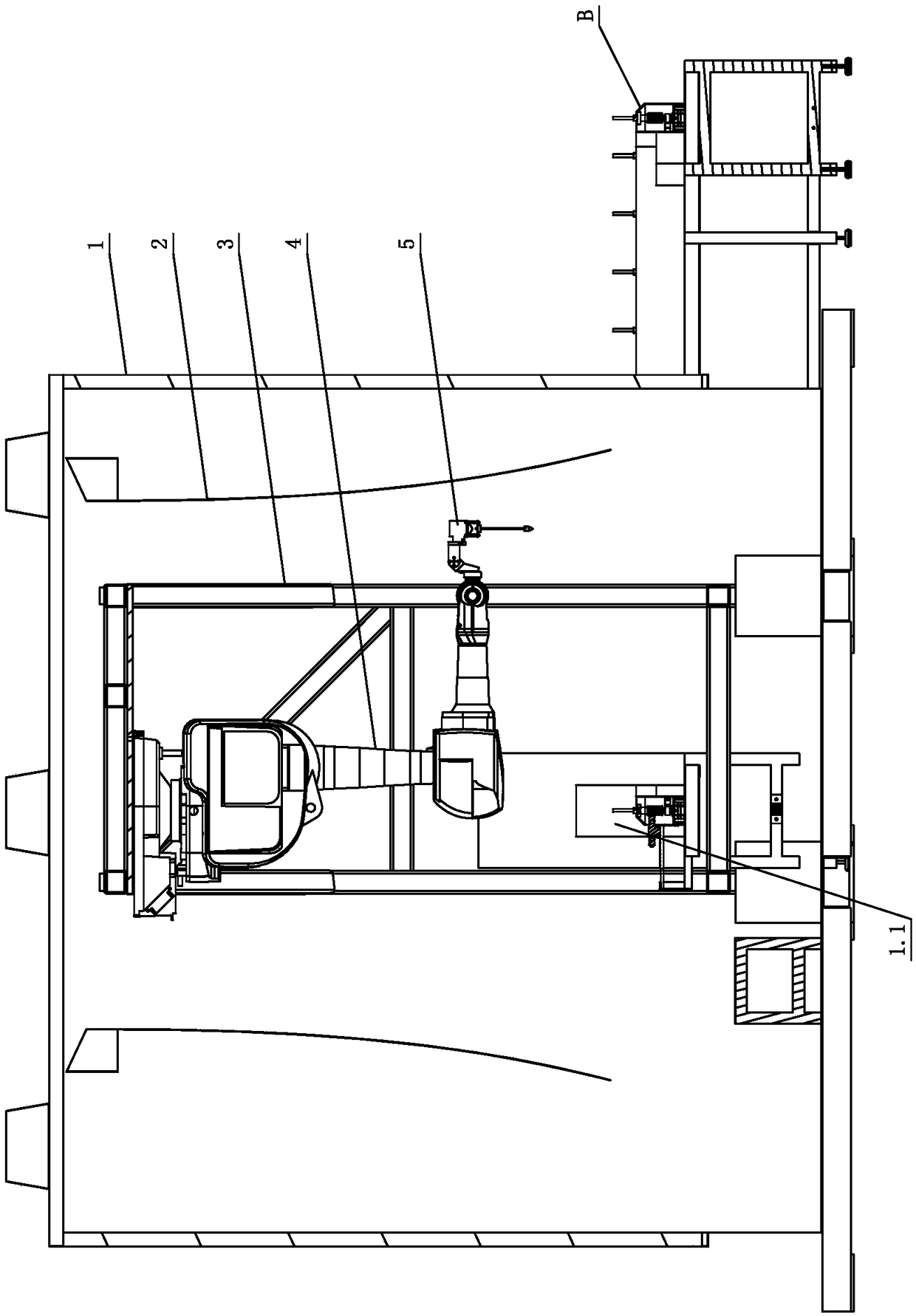

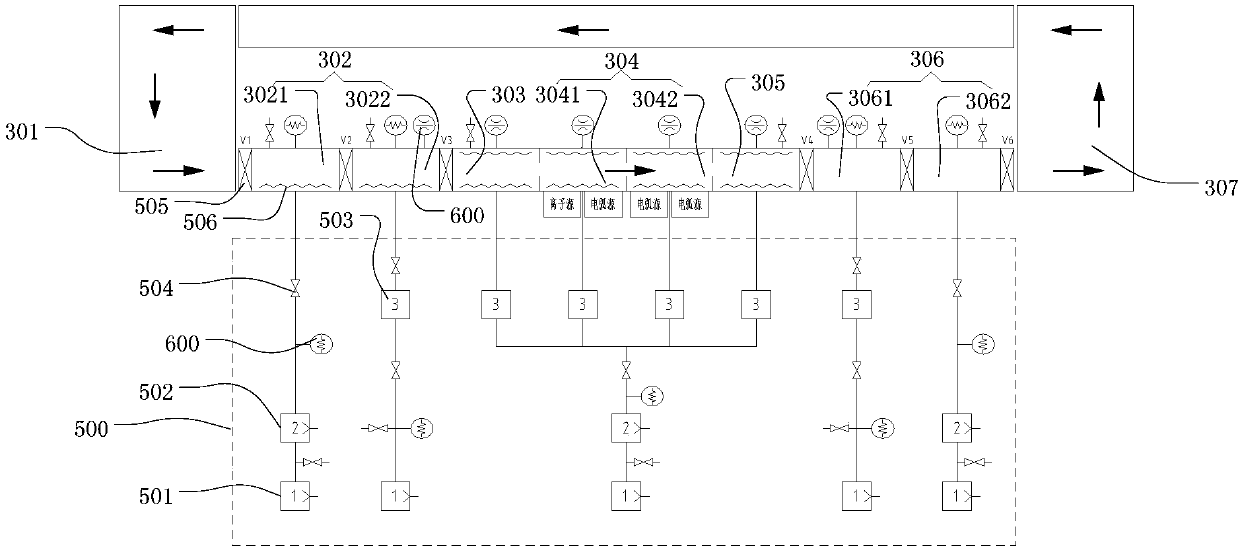

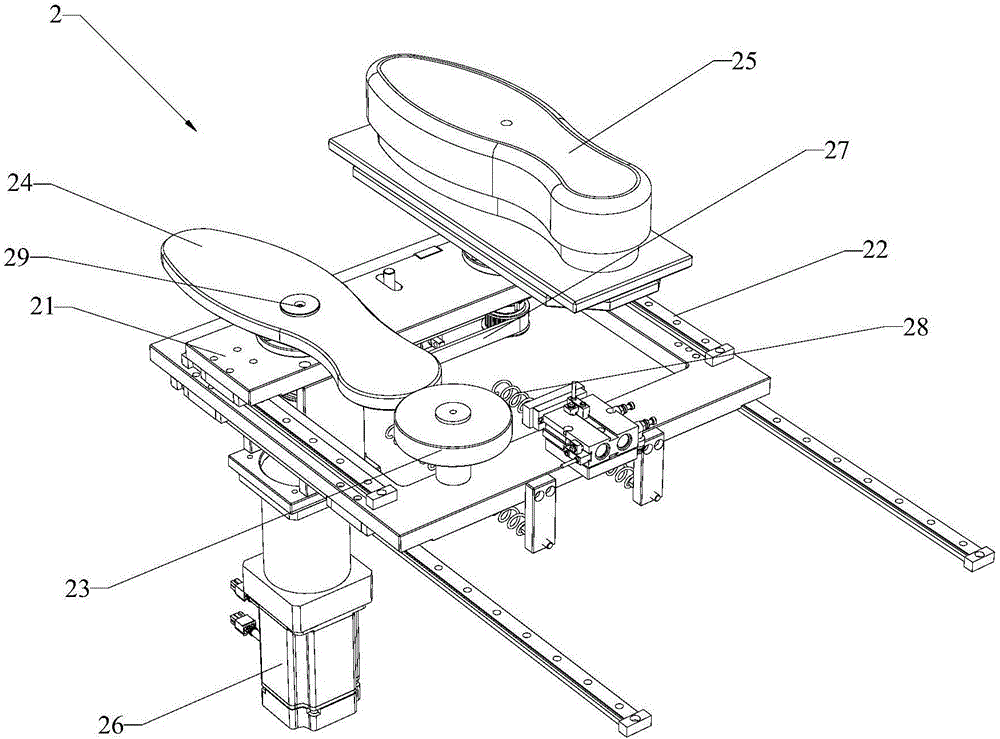

Automatic spraying line for golf club head

The invention relates to an automatic spraying line for a golf club head. The automatic spraying line comprises spraying equipment and conveying equipment, wherein at least one spraying equipment is arranged along the conveying equipment; the conveying equipment is annually arranged and penetrates through at least one spraying equipment; the spraying equipment comprises a water curtain cabinet, asupporting portal frame and a multi-shaft robot, the supporting portal frame and the multi-shaft robot are covered with the water curtain cabinet, the multi-shaft robot is arranged on the supporting portal frame in an upside down manner, and a spraying gun is arranged on the multi-shaft robot; and the conveying equipment comprises a conveying mechanism and a plurality of club head tool assemblies,the conveying mechanism comprises a conveying strip and a conveying driving assembly, the conveying belt is annularly arranged, the conveying driving assembly is used for driving the conveying stripto work, the conveying strip penetrates through the water curtain cabinet through a conveying opening in the water curtain cabinet, the multi-shaft robot is located above the conveying strip which penetrates through the inner side of the water curtain cabinet, and the club head tool assemblies are distributed on the conveying strip. The automatic spraying line is simple and reasonable in structure, high in degree of automation and spraying efficiency, good in spraying quality, high in finished rate and applicable to multiple spraying procedures, and the clean working environment is guaranteed.

Owner:GUANGDONG LXD ROBOTICS CO LTD

Pneumatic gasbag-type semi-automatic polyurethane foaming and molding device

The invention discloses a pneumatic gasbag-type semi-automatic polyurethane foaming and molding device, which consists of a mold part, a pneumatic mold-closing and mold-locking part, a pneumatic sealing part, a rotary supporting part and an electrical control part. By adopting the technical scheme that a pneumatic air cylinder is controlled to automatically lock a mold and open or seal the air vent of the mold through a time sequence and the mold is opened and closed by using an upper gasbag and a lower gasbag, the problems of the conventional manual devices such as low rate of finished products, serious waste, low production efficiency, high labor cost and material cost, and poor consistency of the quality of products are solved. The provided pneumatic gasbag-type semi-automatic polyurethane foaming and molding device makes pneumatic foaming and molding production fulfill the aims of reducing labor intensity, improving the rate of finished products, reducing waste, improving production efficiency, decreasing labor cost and material cost and improving the consistency of the quality of the products through a time-controlled pneumatic semi-automatic operation mode.

Owner:NINGBO FANGZHENG TOOL

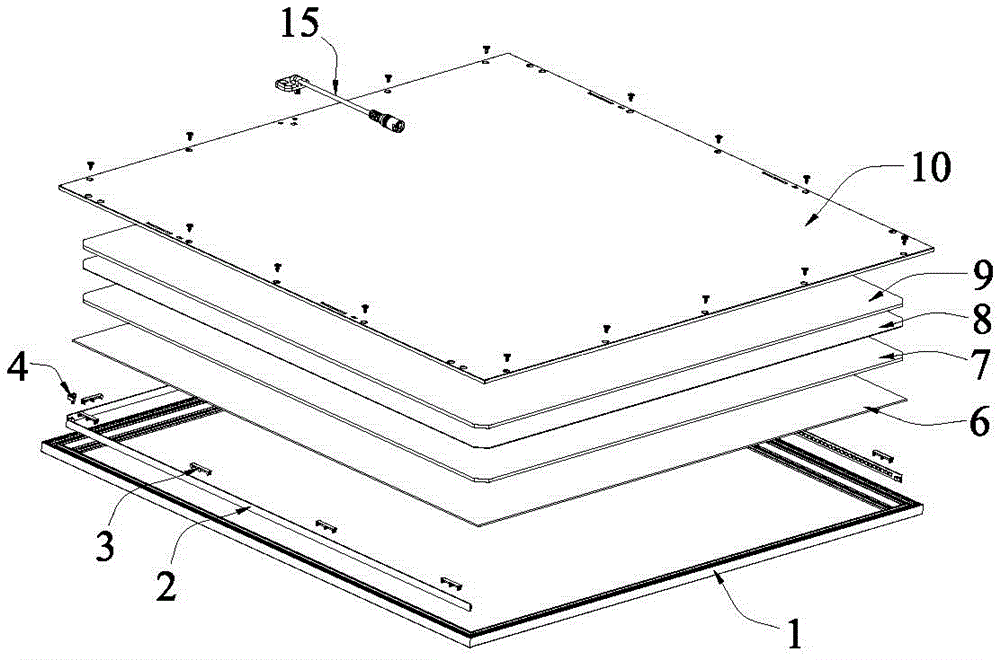

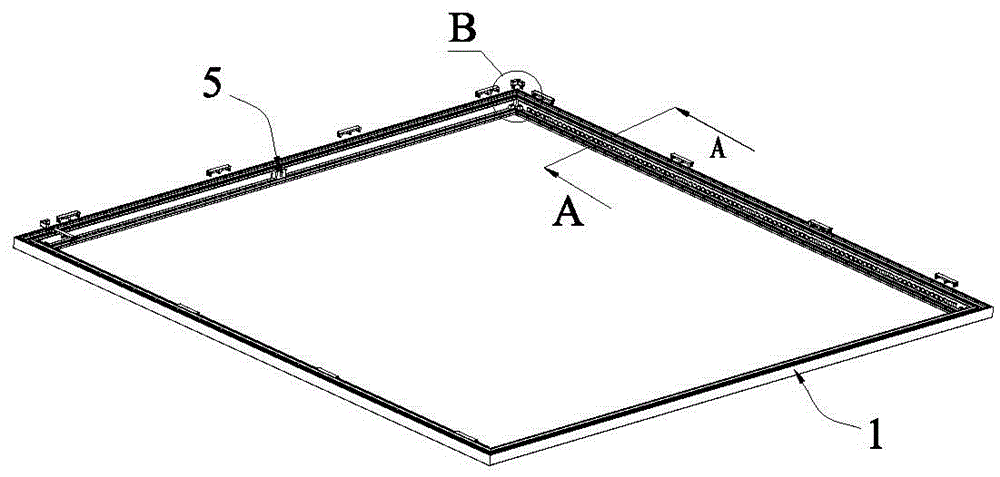

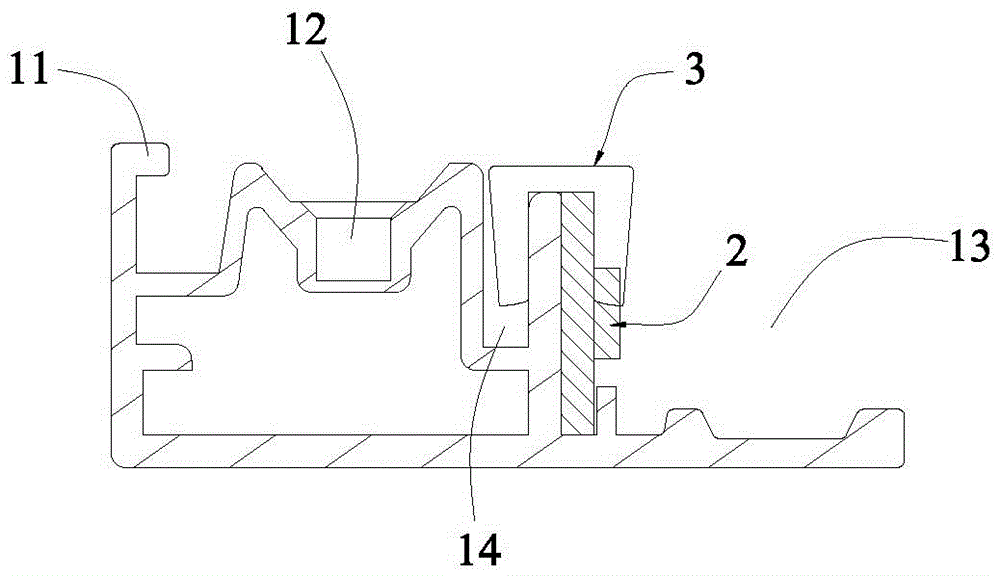

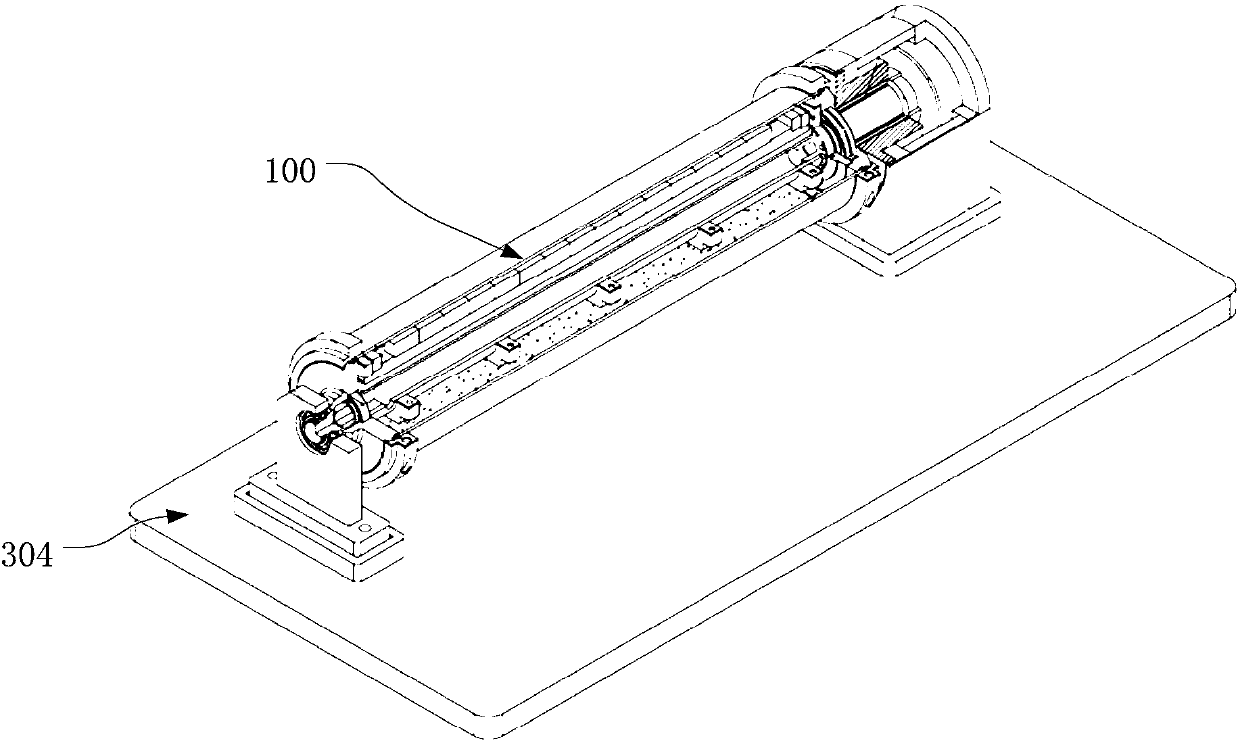

Automatic assembly LED side light-emitting panel lamp and assembly method thereof

InactiveCN106016017AQuick fixQuick connectionMechanical apparatusLighting support devicesLight guideEngineering

The invention discloses an automatically assembled LED side-emitting panel light and an assembly method thereof, which comprises a frame body with an inner cavity, a light bar, a light bar fastener, a light bar plug terminal, a power supply connection terminal, a diffusion plate, and a light guide plate , reflective paper, elastic body pressing plate and back plate; the structure design of the present invention is ingenious and reasonable, the light bar can be quickly fixed on the frame through the light bar fastener, and each The light bar realizes fast connection and conduction. By locking the screws, the diffuser plate, light guide plate, reflective paper and elastic compression plate can be quickly fixed on the frame through the back panel, effectively saving the traditional complicated glue and welding wires Wiring and other processes not only effectively simplify the traditional assembly process and improve production efficiency, but also help reduce production costs and enhance the overall competitiveness of enterprises. The process of the method provided by the invention is simple, and robots can be used to replace human hands to realize automatic assembly, which greatly improves product assembly efficiency and quality consistency.

Owner:DOANGUAN LEWEI ENERGY SAVING TECH CO LTD

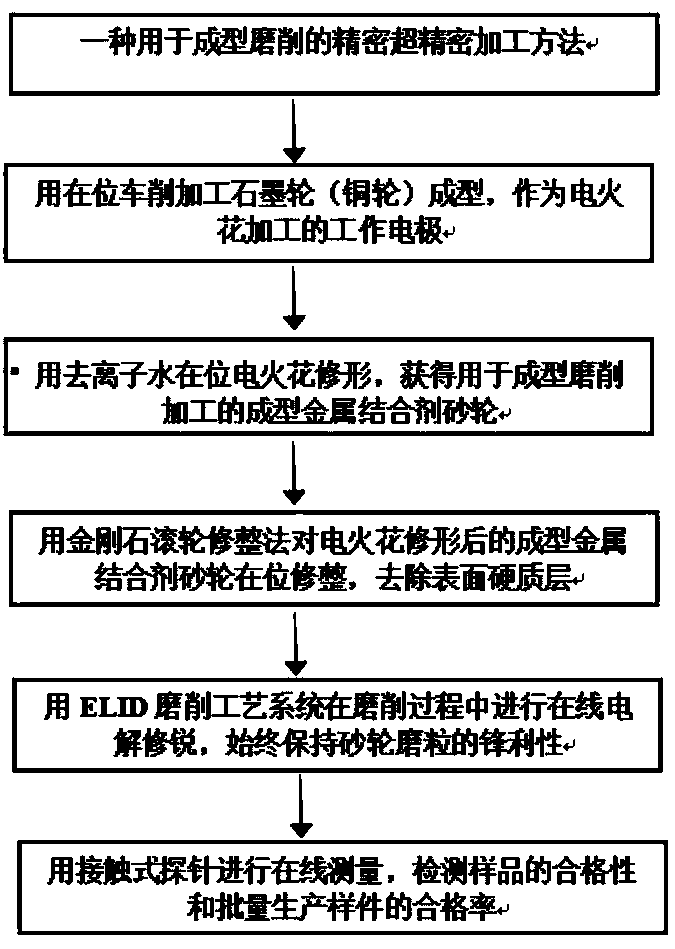

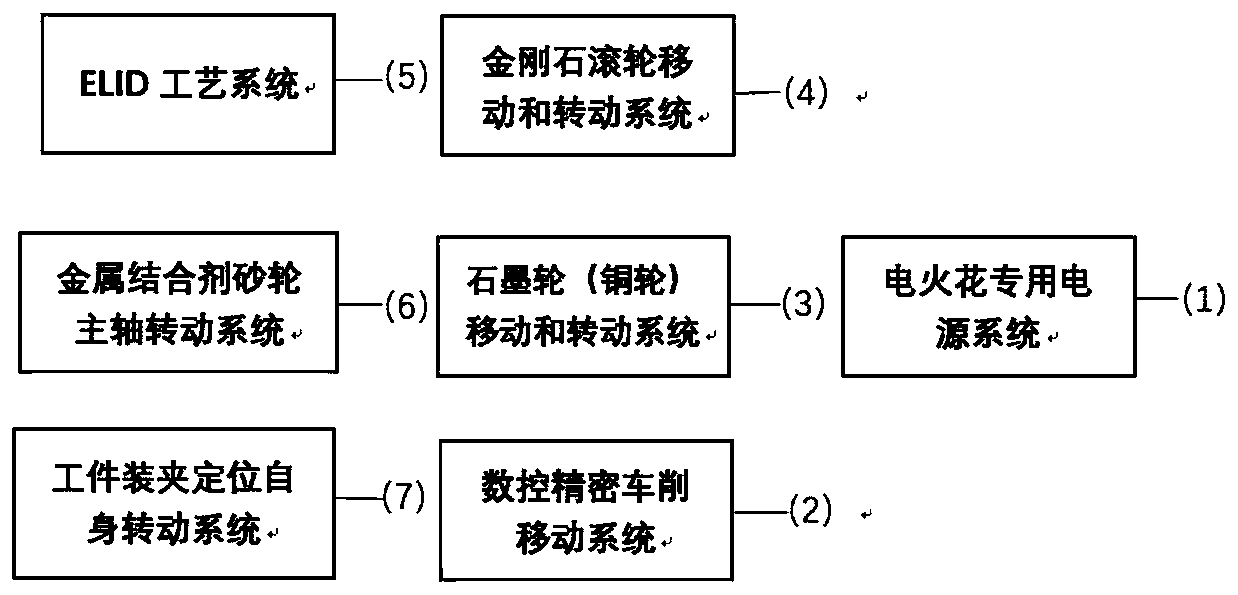

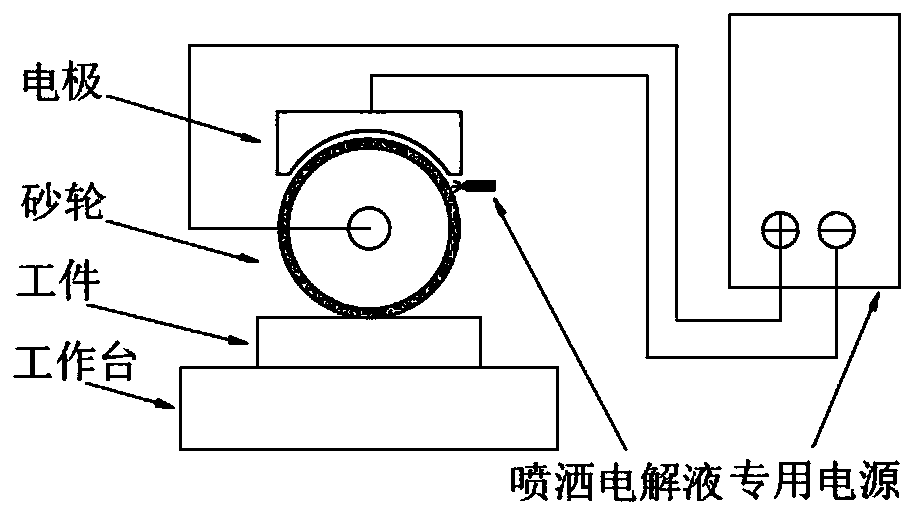

Precision ultra-precision machining method for forming grinding

InactiveCN110253418AHigh Quality ConsistencyHigh precisionSuperfinishing machinesBatch productionDimensional precision

The invention discloses a precision ultra-precision machining method for forming grinding. Through the method, the precision progressive type grinding machining technology mode, including in-place shape correcting, in-place trimming, online electrolytic sharpening and online detection, of a metal-bonded grinding wheel is achieved. The method is characterized in that graphite wheel precision turning forming is achieved in place; deionized water serves as a medium, and grinding wheel electric spark precision forming and shape correcting are achieved; through a diamond roller opposite-grinding trimming method, in-place trimming of the grinding wheel is achieved, and a hard layer is removed; online electrolytic sharpening is conducted, and it is achieved that the good sharpness of the grinding wheel is kept all the time in the grinding and removing processes; online detection is conducted, and dimensional precision detection of a machined part is achieved; and according to the grinding wheel particle size, the concentration and progressive magnitude between different procedures, precision progressive type precision forming grinding machining is achieved. Through the precision ultra-precision machining method, the problems that a traditional machining mode is poor in offline shape correcting, trimming, sharpening, detection and machined surface quality, and the machining quality consistency is difficult to ensure are solved, and precision ultra-precision forming grinding machining can be achieved under the batch production conduction.

Owner:BEIJING UNIV OF TECH

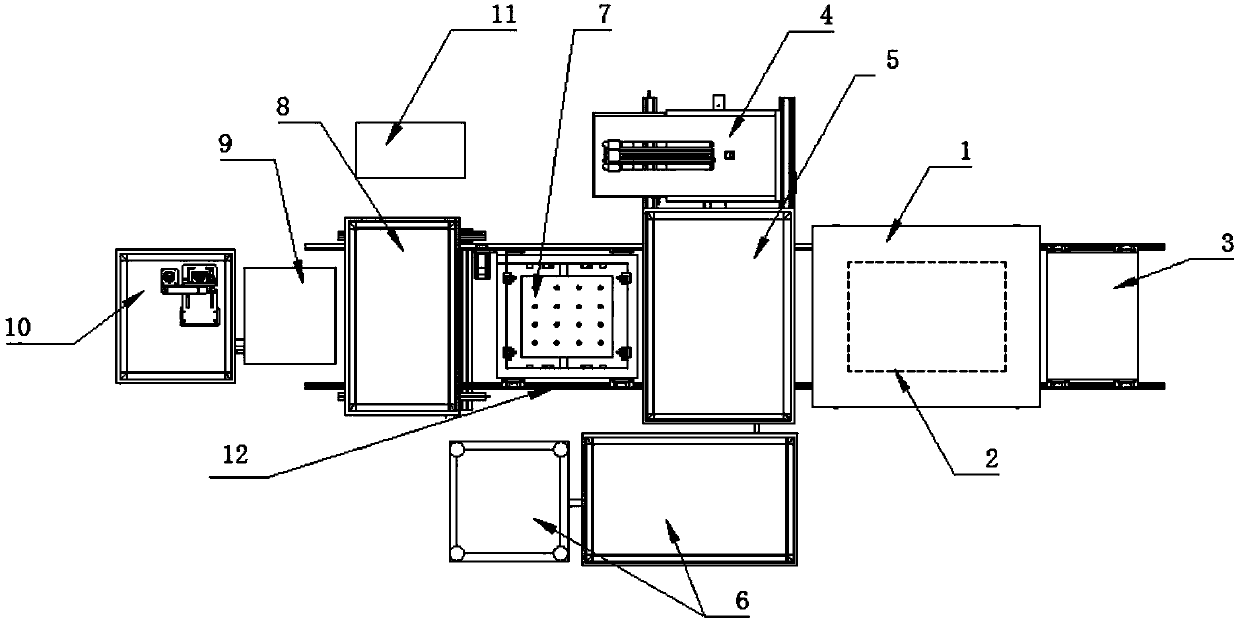

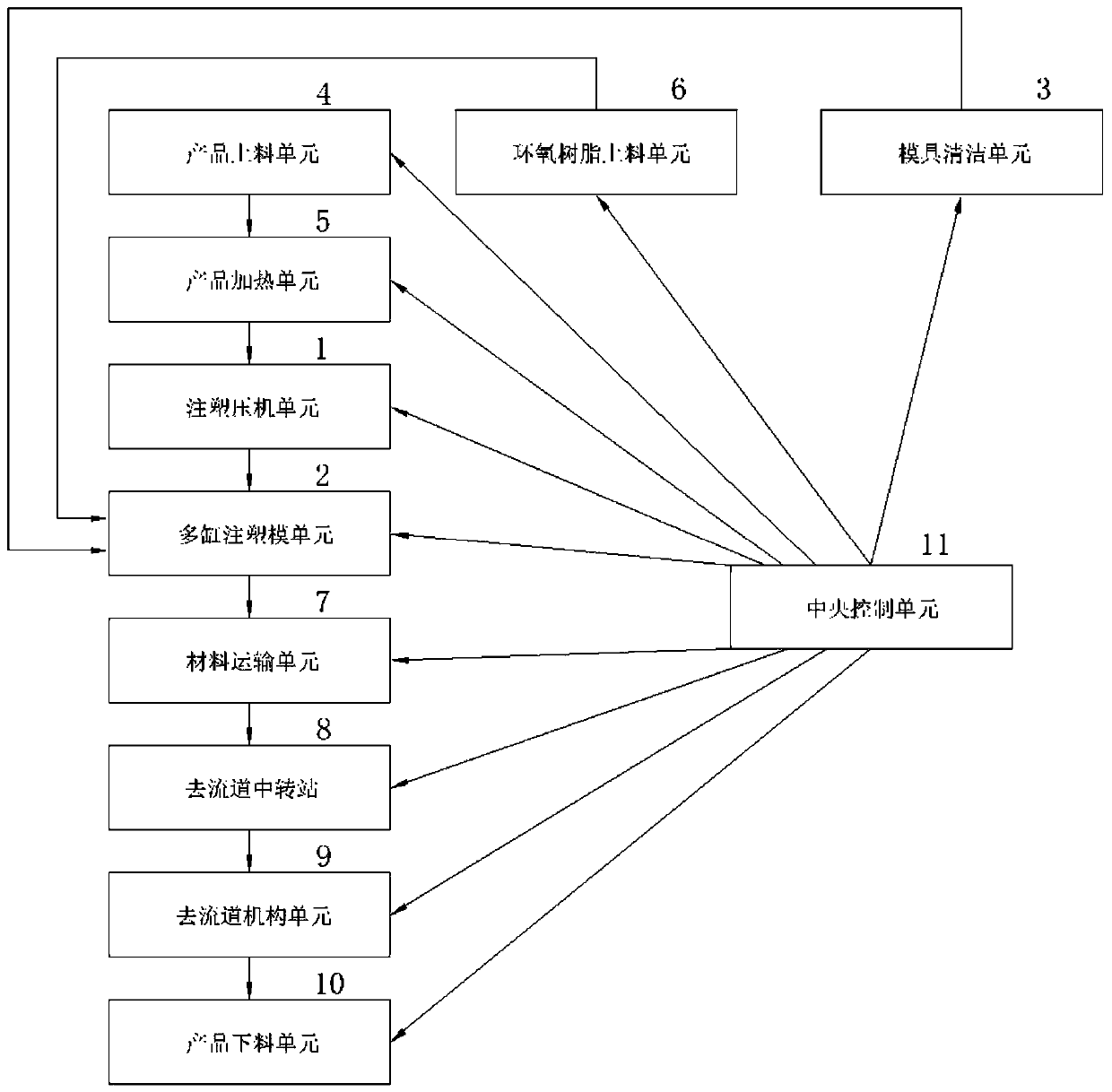

Automatic injection molding system for semiconductor component packaging and working method of automatic injection molding system

The invention discloses an automatic injection molding system for semiconductor component packaging and a working method of the automatic injection molding system. The automatic injection molding system comprises an injection molding press unit (1), a multi-cylinder injection mold unit (2), a mold cleaning unit (3), a product feeding unit (4), a product heating unit (5), an epoxy resin feeding unit (6), a material conveying unit (7), a flow passage transfer station (8), a flow passage mechanism unit (9), a product discharging unit (10) and a central control unit (11), and the central control unit controls the operation of each unit. By adopting the mode that the multi-cylinder injection mold is automatically operated, only manual emptying and material taking are needed, so that the production process automation is realized, the consistency of the product quality is improved, the production efficiency is improved, and the labor is saved.

Owner:苏州旭芯翔智能设备有限公司

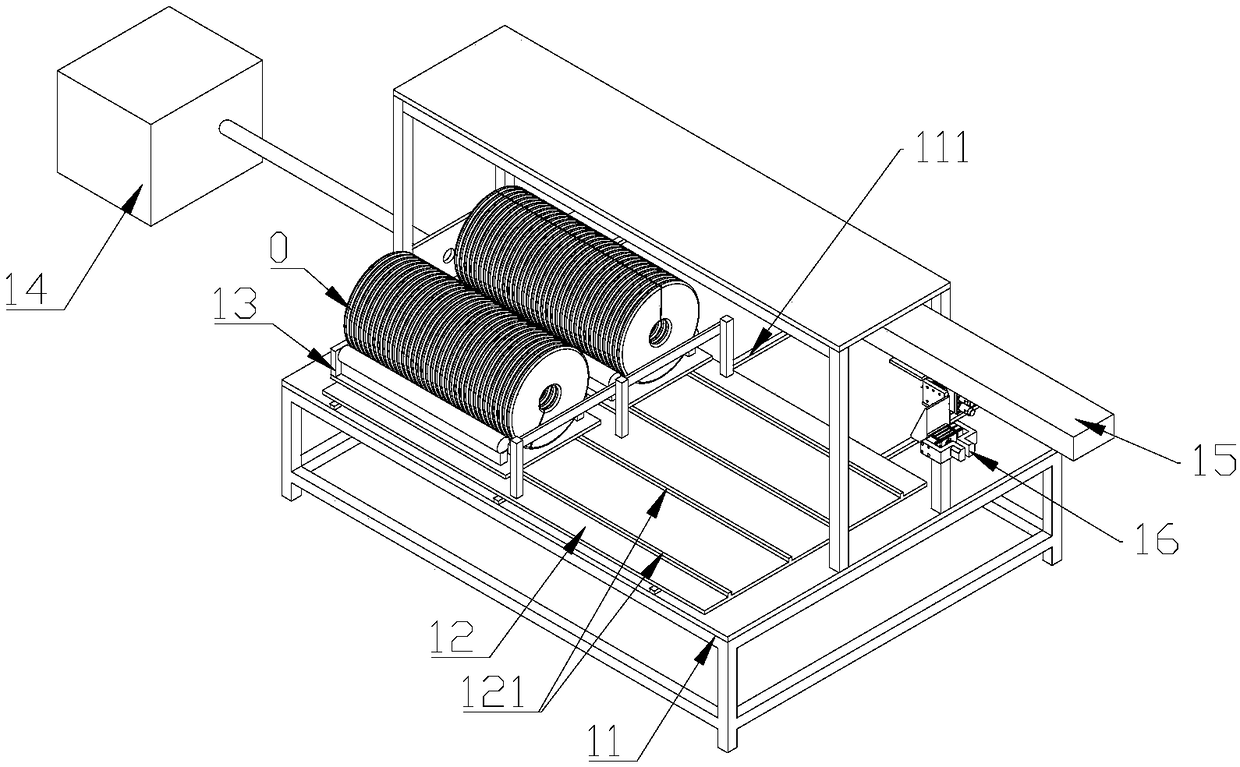

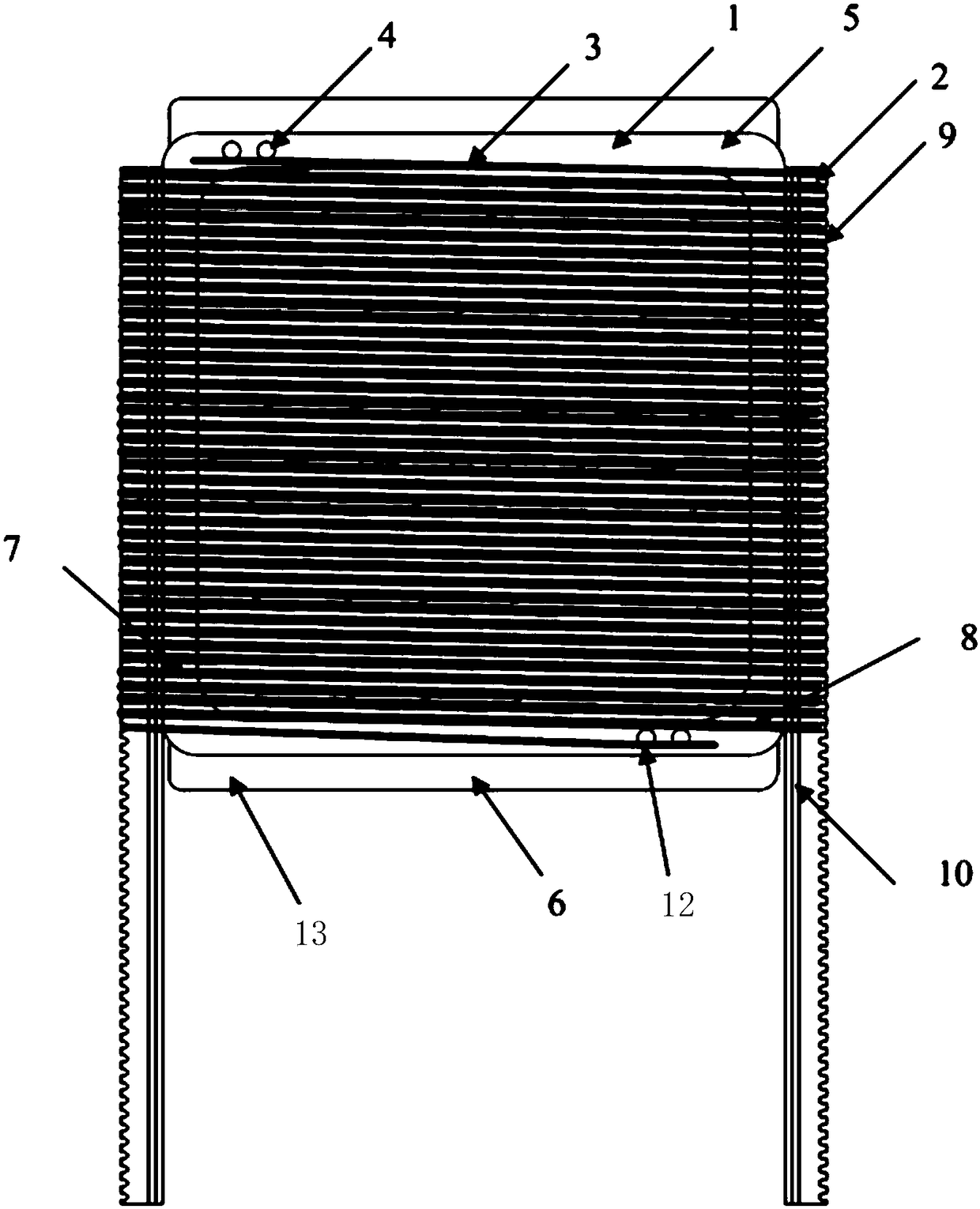

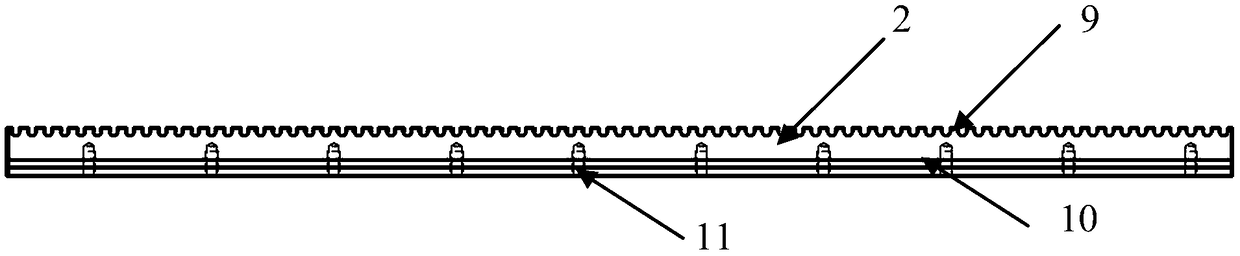

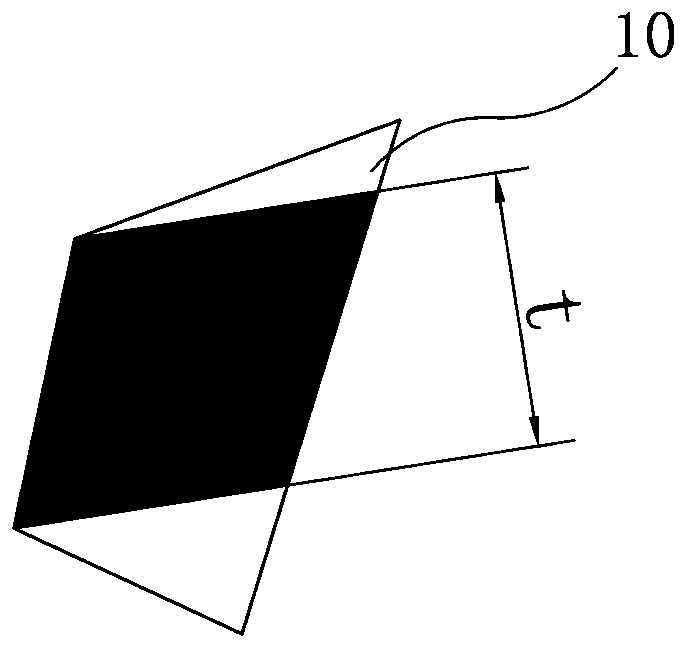

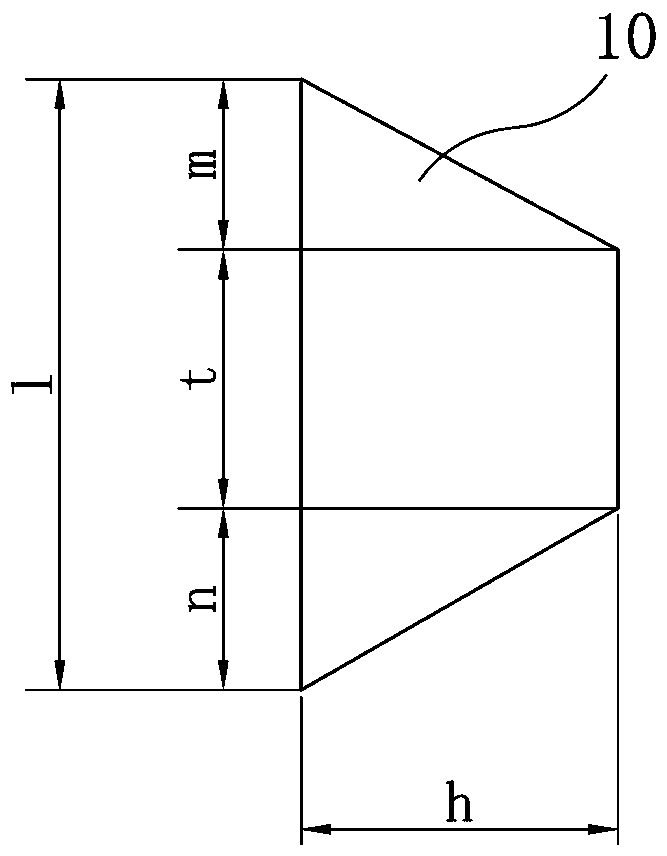

Positioning piece of polarized grid mesh for winding metal wire, winding method and polarized grid mesh

ActiveCN108832234AEvenly arrangedHigh product quality consistencyWaveguide type devicesWire frameConductor Coil

The invention discloses a positioning piece of a polarized grid mesh for winding a metal wire, a winding method and the polarized grid mesh, which solve the problems in the prior art that the windingdifficulty of the polarized grid mesh increases with the increase of the density of the metal wire and the arrangement of the metal wire is not uniform. The polarized grid mesh comprises a wire frameand a wire, and the wire frame comprises a first side and a second side opposite to each other; the positioning member of the polarized grid mesh for winding a wire comprises a threaded hole for fixedly connecting the positioning member to the outside of the second side; a side surface of the positioning member remote from the second side is provided with grooves arranged in parallel for accommodating the wires when the wires are wound, the grooves having a pitch equal to the pitch of the wires. The polarization grid mesh wire produced by the polarization grid mesh winding method provided by the invention is uniformly arranged, the positioning member can be reused, and the product quality is high.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

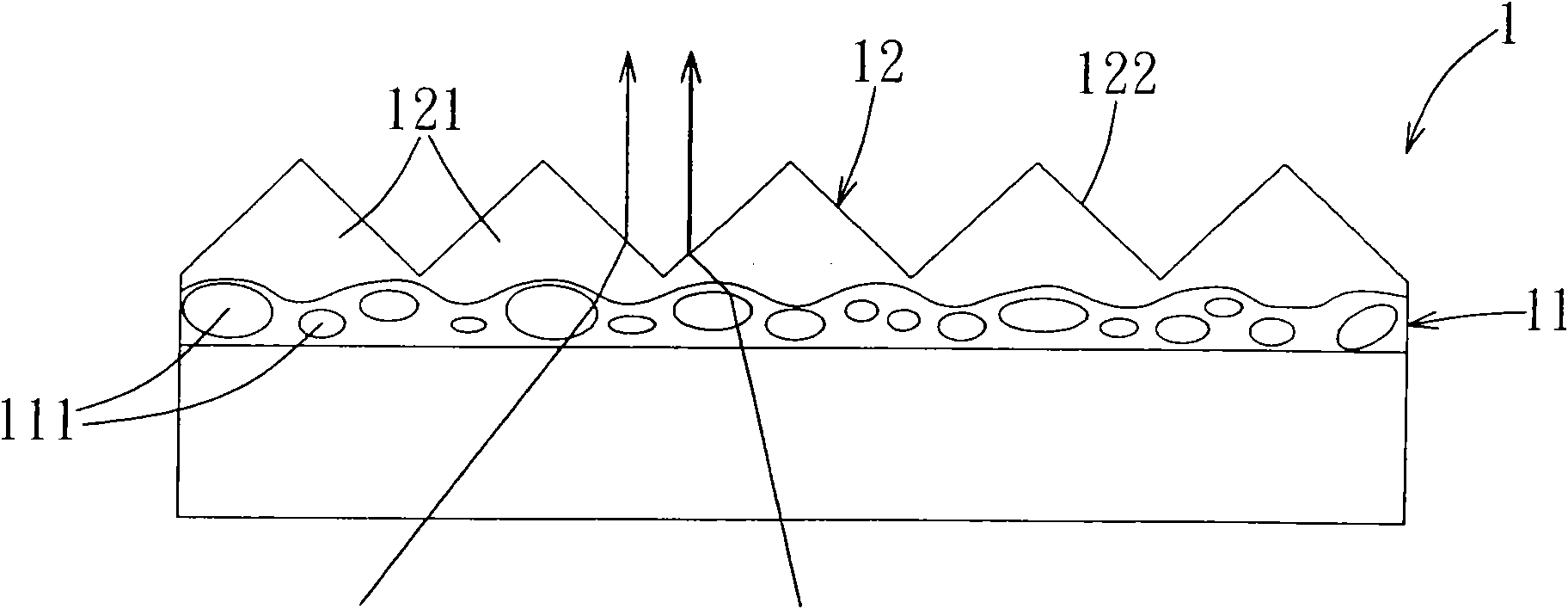

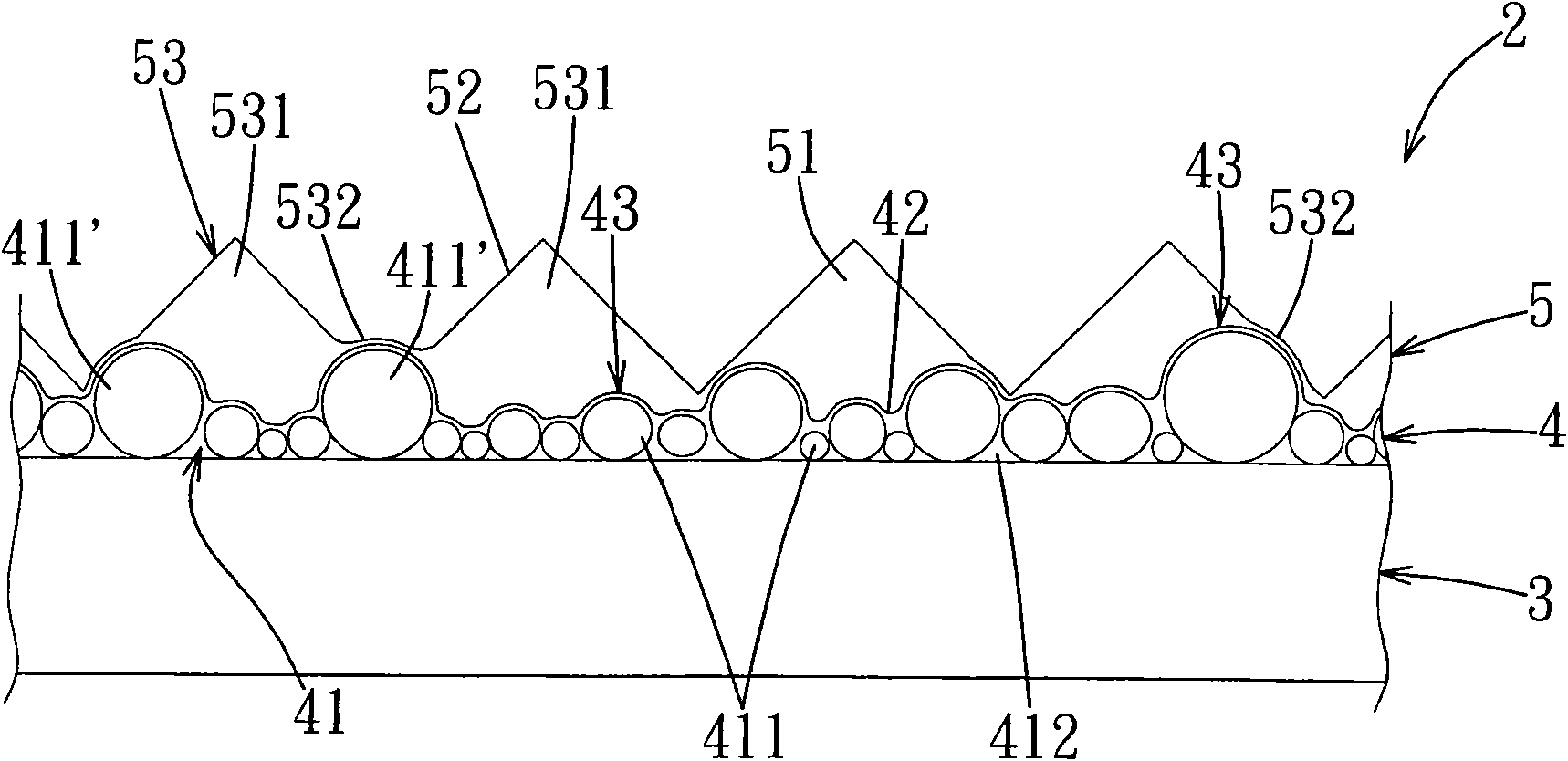

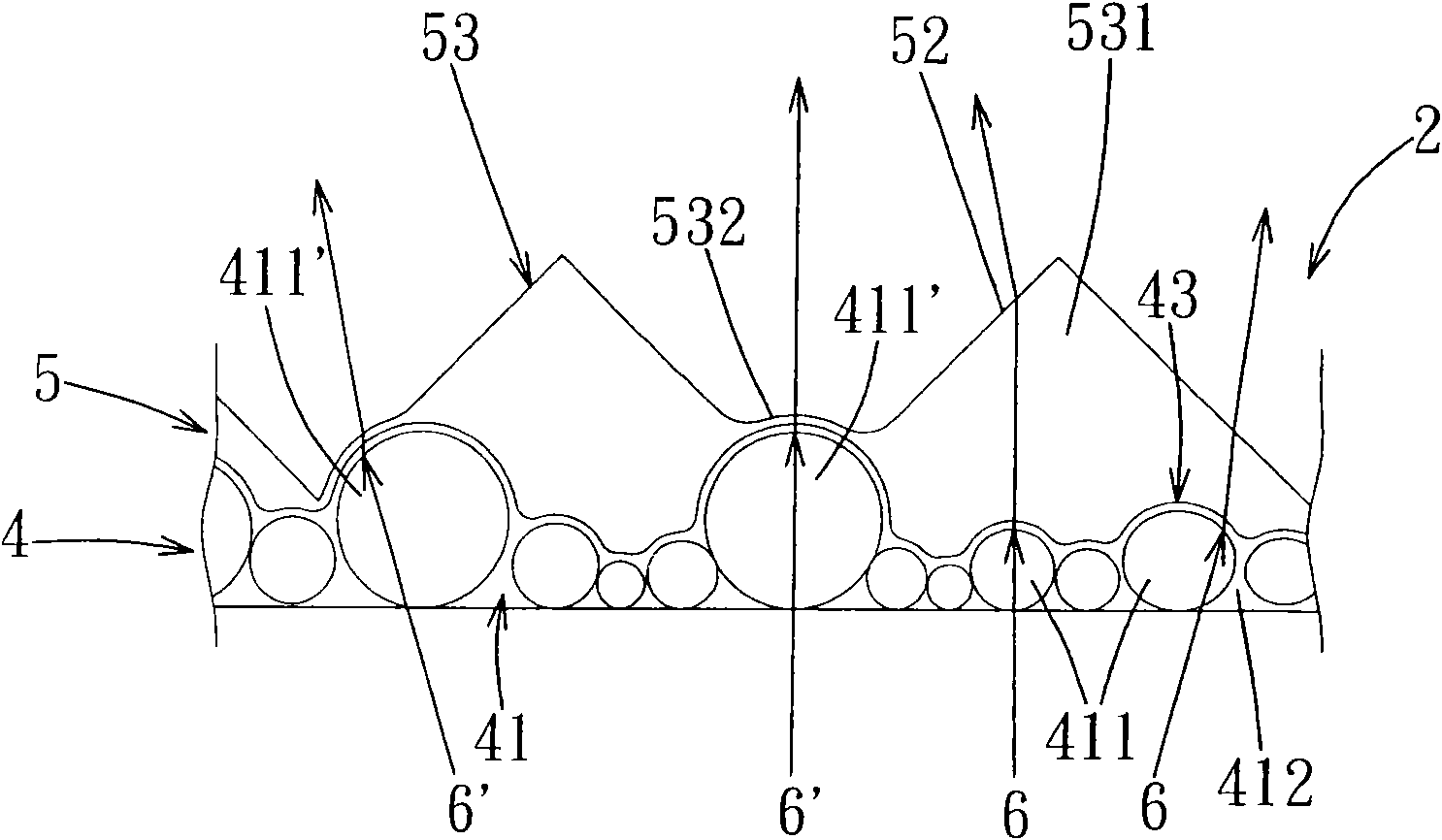

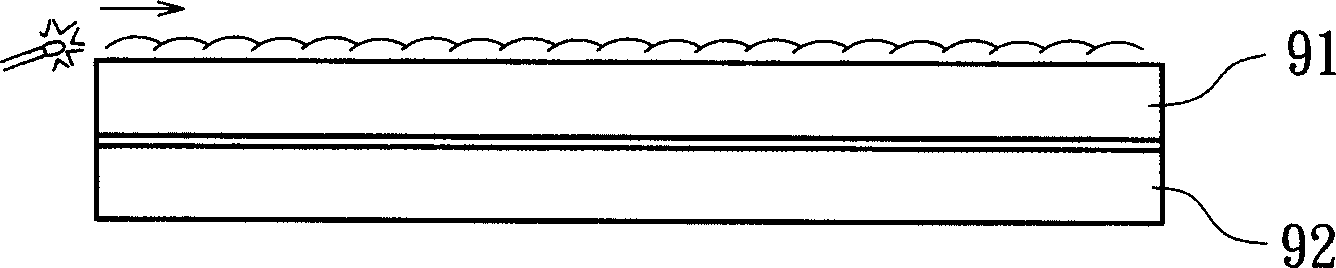

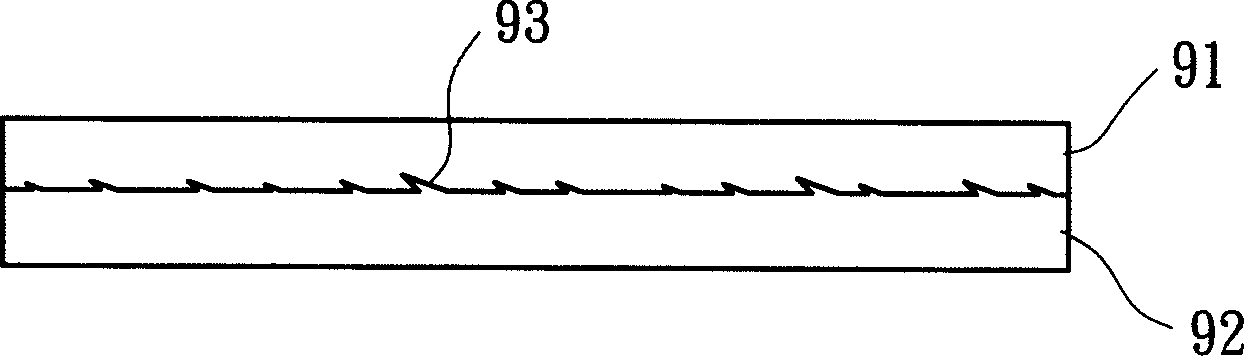

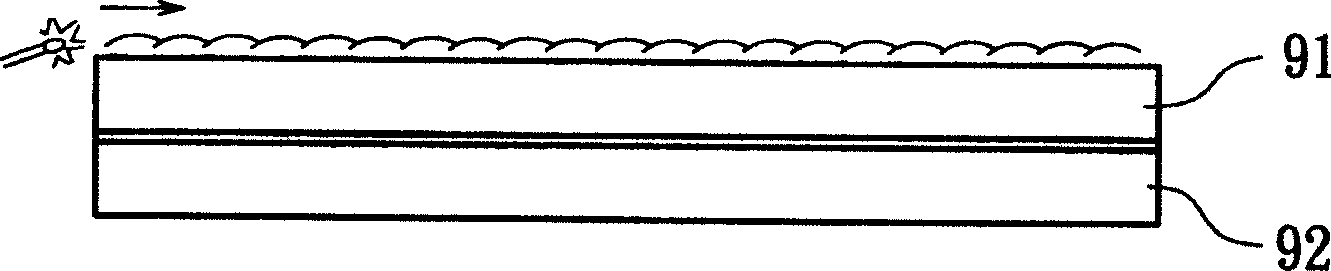

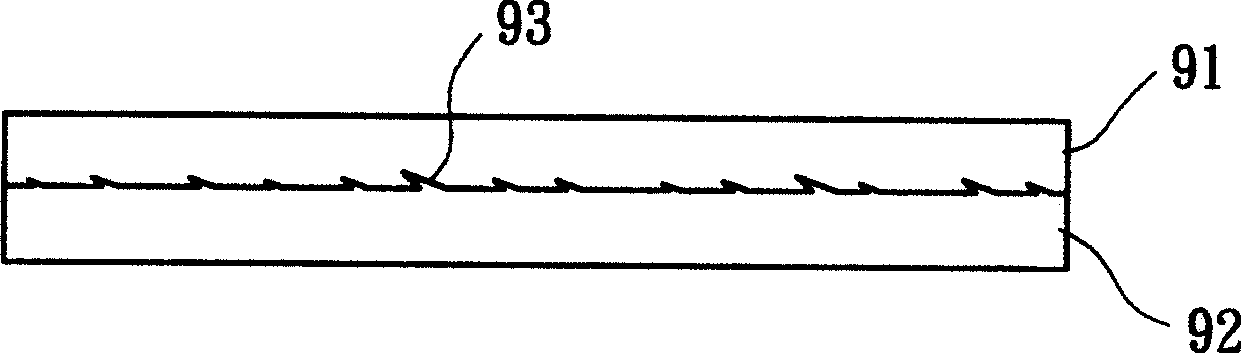

Composite optical film and manufacturing method thereof

InactiveCN101625475AExcellent brightness performanceSame effectNon-linear opticsProduction lineHigh luminance

The invention discloses a composite optical film with high luminance, high diffusance and no interference of Newton rings, which comprises a base material layer, a diffusion layer and a light condensing layer stacked in sequence, wherein the diffusion layer comprises a diffusion layer resin which comprises a plurality of particles, is adjacent to a particle swarm of the base material layer and fixes the particle swarm; the light condensing layer comprises a light condensing layer resin, forms a light outlet surface and a microstructure unit capable of collectively emitting light rays; and the microstructure unit comprises a plurality of main microstructures regularly arranged. The composite optical film is characterized in that: a joint surface for joining the diffusion layer with the light condensing layer is formed to trend to the particle swarm periphery; the diffusion layer is provided with a plurality of bulges covering at least one particle respectively; and the microstructure unit also comprises a plurality of secondary microstructures which cover at least one bulge respectively, trend to extend between two adjacent main microstructures, and / or extend the covered main microstructures. The composite optical films have consistent efficacy performance between different optics under the circumstance of mass manufacture of production lines.

Owner:GLORY SUN OPTO ELECTRONICS CORP

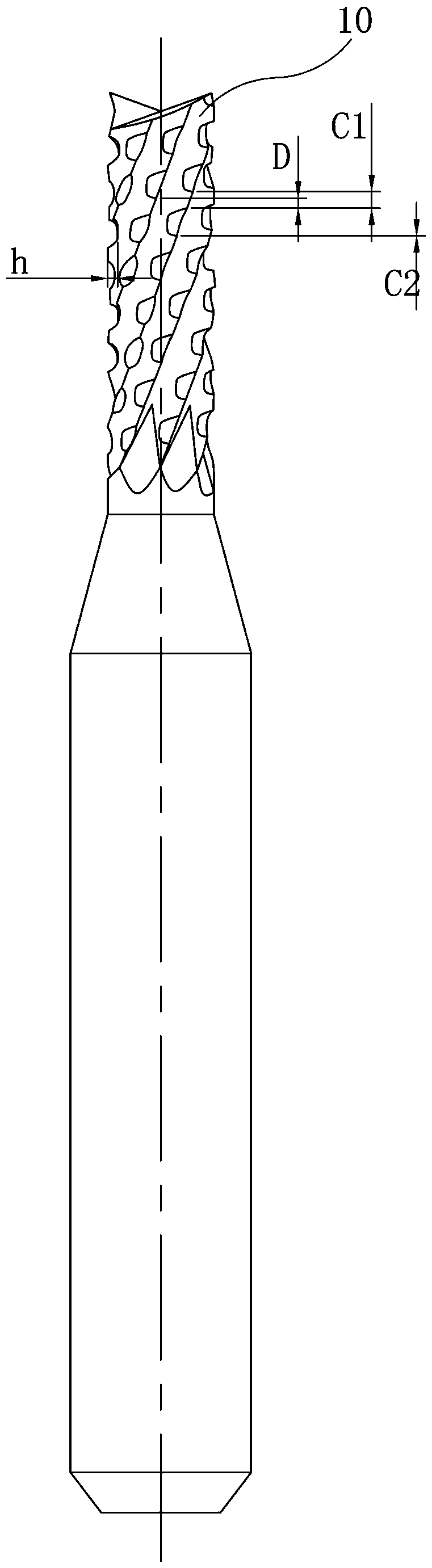

Design method of chip breaking type milling cutter

ActiveCN110052654AImprove processing efficiencyHigh quality consistencyMilling cuttersMilling cutterEngineering

The invention discloses a design method of a chip breaking type milling cutter. The design method includes the following steps that target parameter requirements are determined, the cutting marks of right-handed rotation 2 grinding wheels on a groove type are compared, the widths of the grinding wheels participating in grinding are calculated, the longitudinal cutting values of the grinding wheelson rods are calculated, the cutting actual widths of the grinding wheels are calculated, right-handed rotation 2 groove lengths are calculated, groove distances are calculated, actual values of the groove distances are calculated, and integrated calculation is carried out according to the parameters acquired in the steps. As geometric correlation exists between RRC milling cutter right-handed rotation 2 parameters, the forming result of a cutter type is simulated with the help of the geometric correlation and the machining principle of the cutter type, a complete set of formulas are formulated, when the parameters are designed, corresponding cutter type parameters are simulated according to input of different influence factors, finally the cutter type parameters are matched with needed equipment set parameters, and the design method has the beneficial effects of being short in machining time and high in machining efficiency.

Owner:厦门鸿鹭联创工具有限公司

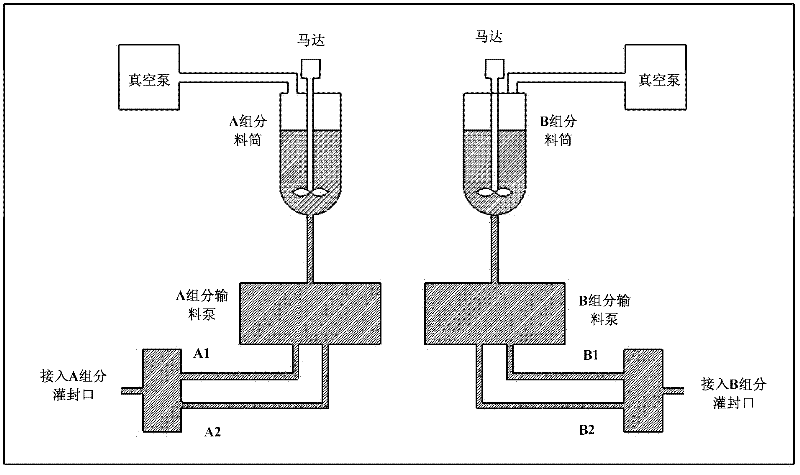

Silica gel preparation method

InactiveCN102641698AHigh quality consistencyGood defoaming effectColloidal chemistry detailsSilica gelMechanical engineering

The invention provides a silica gel preparation method which comprises the following steps of: respectively placing more than two aged raw material components for preparing silica gel in barrels of a stirring mechanism, maintaining in the vacuum state and respectively intermittently stirring the raw material components of the silica gel for foam discharging; arranging discharging holes in the barrels, communicating with transporting pipelines through transporting pumps, connecting the transporting pipelines with filling and sealing openings of the raw material components, arranging reflow pipelines capable of being closed between the filling and sealing openings and the transporting pumps, and sending the raw material components subjected to the foam discharging into respective transporting pipelines; and closing the filling and sealing openings of the transporting pipelines, and enabling the raw material components to return to the barrels through reflow pipelines to form reflow, and controlling the reflow states of the materials until the whole transporting pipelines of all components are in the vacuum state. The preparation method meets the requirements of an IGBT (Insulated Gate Bipolar Transistor) module for consistency and reliability of products produced massively and in batches.

Owner:XIAN YONGDIAN ELECTRIC

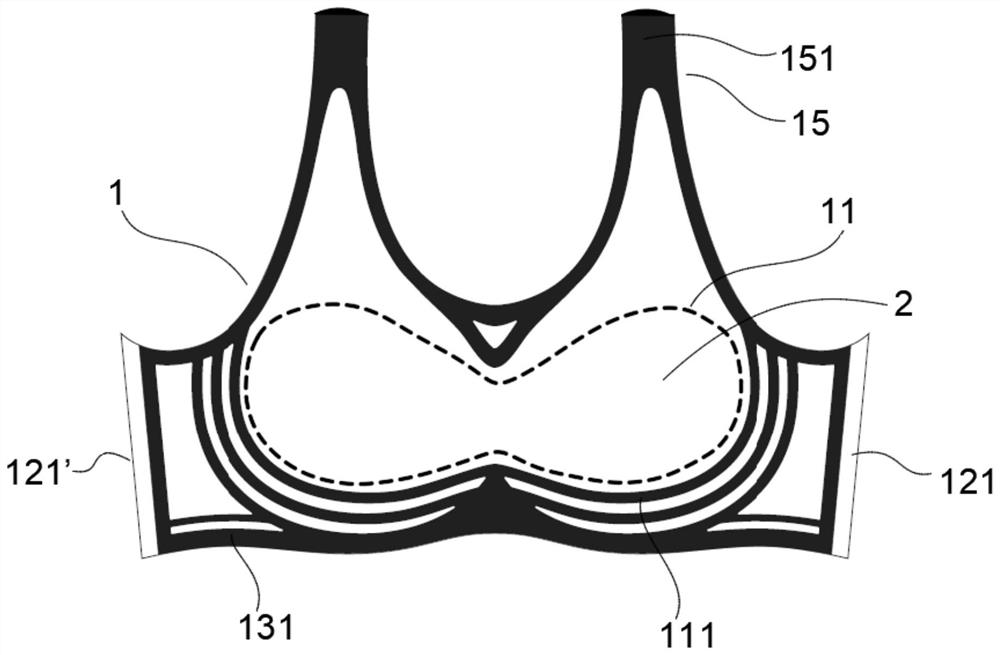

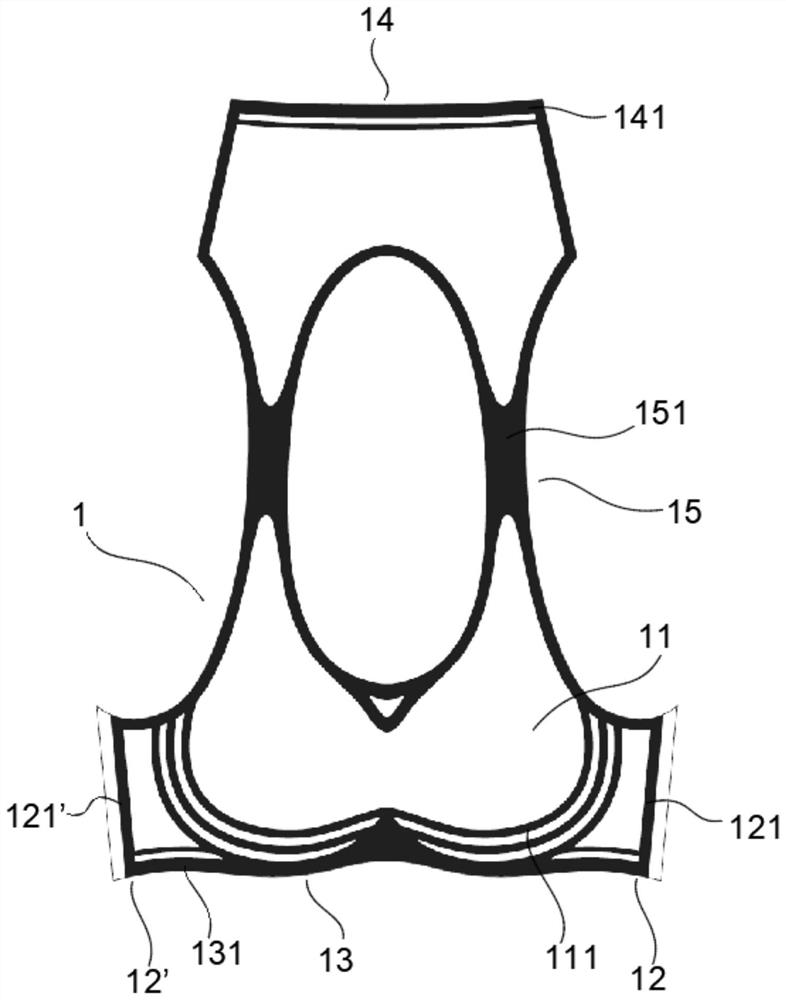

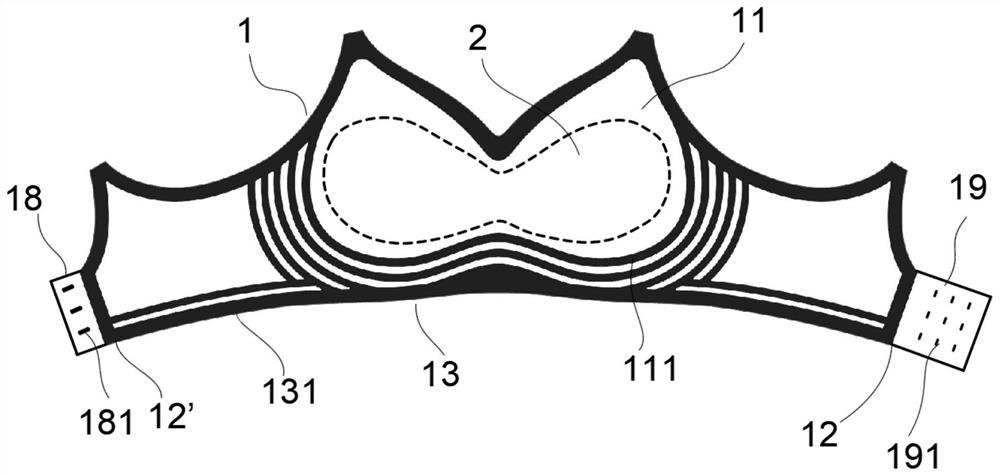

Close-fitting underwear and production method thereof

PendingCN111631443AComfortable to wearDress fitBrassieresCorsetsMechanical engineeringIndustrial engineering

The invention belongs to the technical field of underwear, and particularly relates to close-fitting underwear and a production method thereof. The close-fitting underwear comprises a breast pad and an elastic underwear main body. Wherein the elastic underwear main body is provided with a breast pad mounting part, two side breast position parts, a front lower surrounding part and a rear lower surrounding part; the breast pad is arranged in the breast pad mounting part; a plurality of first elastic rubber strips are arranged on the elastic underwear main body and located on the periphery of thebreast pad mounting part. The close-fitting underwear has the advantage of being comfortable to wear, is more close-fitting, and is particularly suitable for being worn during sports. And after dailycleaning, the close-fitting underwear is not easy to deform and has no wrinkles. The production method of the close-fitting underwear comprises the following steps of (1) sizing material spraying, (2) hot pressing and (3) punching and seaming, and has the advantages of being high in production efficiency, suitable for industrial large-scale production and high in product quality consistency.

Owner:魏少强

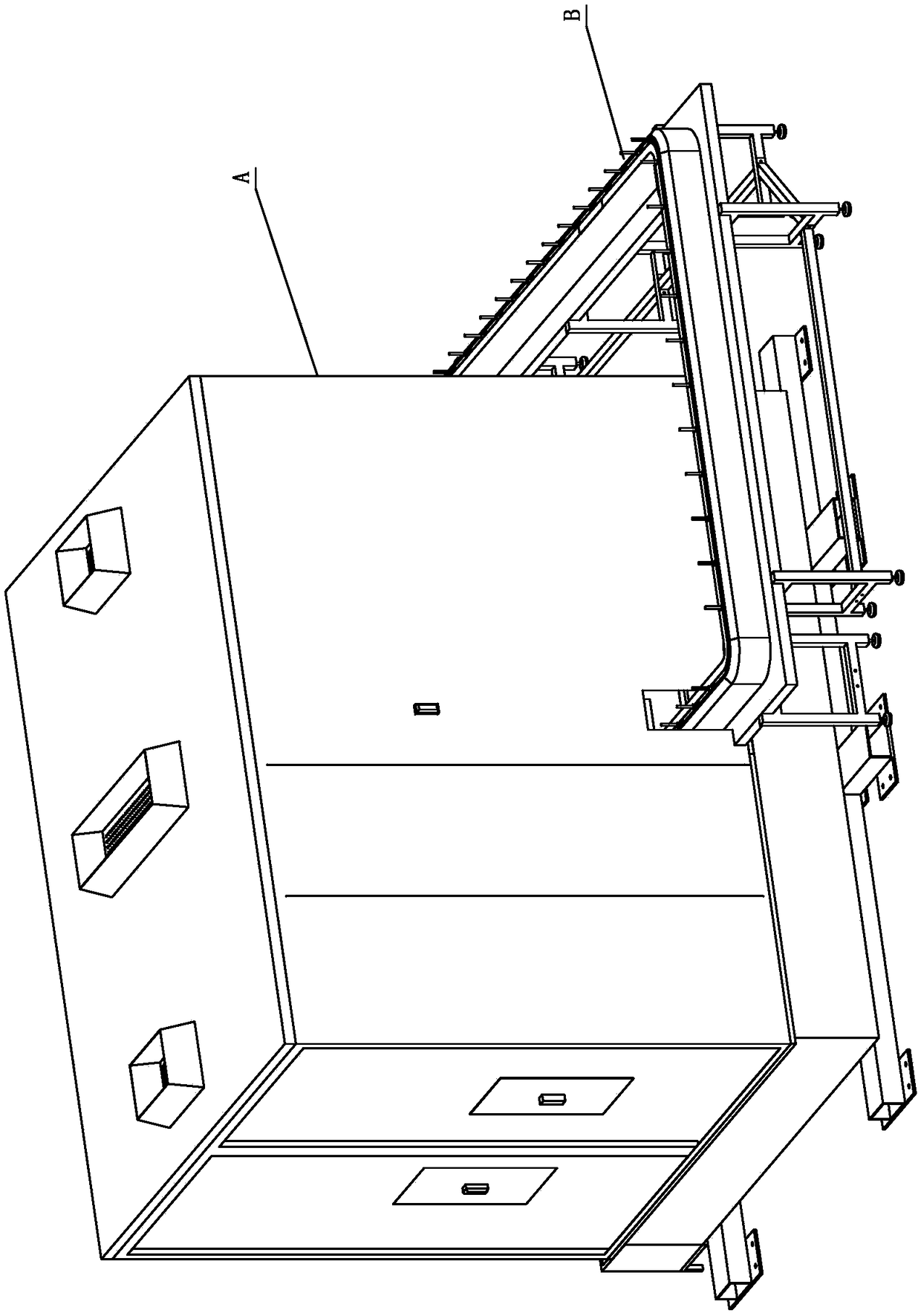

Arc ion plating device

ActiveCN107779826AHigh product quality consistencyLess impurity gasVacuum evaporation coatingSputtering coatingIonEngineering

The invention discloses an arc ion plating device, which is used for plating a work piece placed in a work piece frame; the arc ion plating device comprises a loading section, an unloading section, avacuum chamber body, an ion bombardment system, an arc ion plating system, and a driving system; the vacuum chamber body is arranged between the loading section and the unloading section, and comprises a first vacuum transition section, a processing section, and a second vacuum transition section which are linked in series orderly; the processing section comprises a front section and a back section which are connected to each other; the ion bombardment system is arranged at the front section, and the arc ion plating system is arranged at the back section; the driving system conveys the work piece frame so that the work piece is conveyed from the loading section to the first vacuum transition section, the front section, the back section, and the second vacuum transition section of the vacuum chamber body orderly to process and then conveyed to the unloading section. The arc ion plating device has the advantages of improving the product applicability, film quality and production efficiency of the arc ion plating device.

Owner:广东生波尔光电技术有限公司

Suaeda salsa Pu'er green orange tea and preparation method thereof

The invention relates to suaeda salsa Pu'er green orange tea and a preparation method thereof. The suaeda salsa Pu'er green orange tea relates to tea. The suaeda salsa Pu'er green orange tea is prepared from the following components in parts by weight: 10-15 parts of suaeda salsa, 1-2 parts of germinated brown rice and 3-5 parts of green oranges. The invention discloses the suaeda salsa Pu'er green orange tea and the preparation method thereof. Made from suaeda salsa, Pu' er, small green oranges and germinated brown rice as raw materials, the tea has the function of reducing the serum uric acid concentration of human body, maintaining the serum uric acid of the human body in a normal range and reducing blood fat. In a preparation process, a tea leave press fit and tea cake cutting processis adopted, so that loose tea is prevented from filling directly, and the tea is convenient to transport and carry, and meanwhile, the taste and flavor of the tea leaves can be retained and enhanced.

Owner:盐地碱蓬基因生物科技(辽宁)集团有限公司

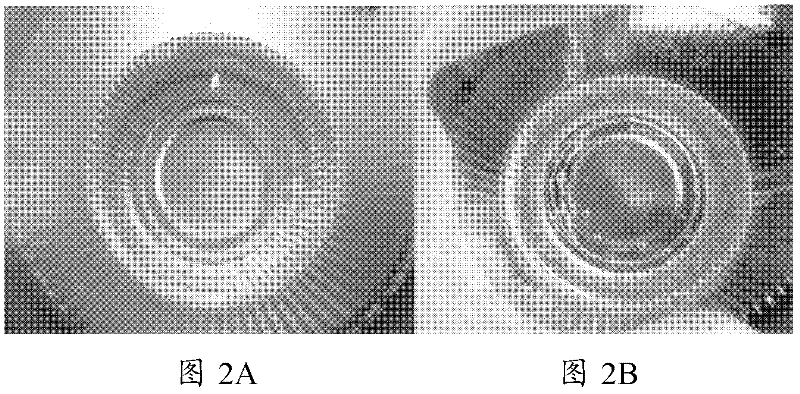

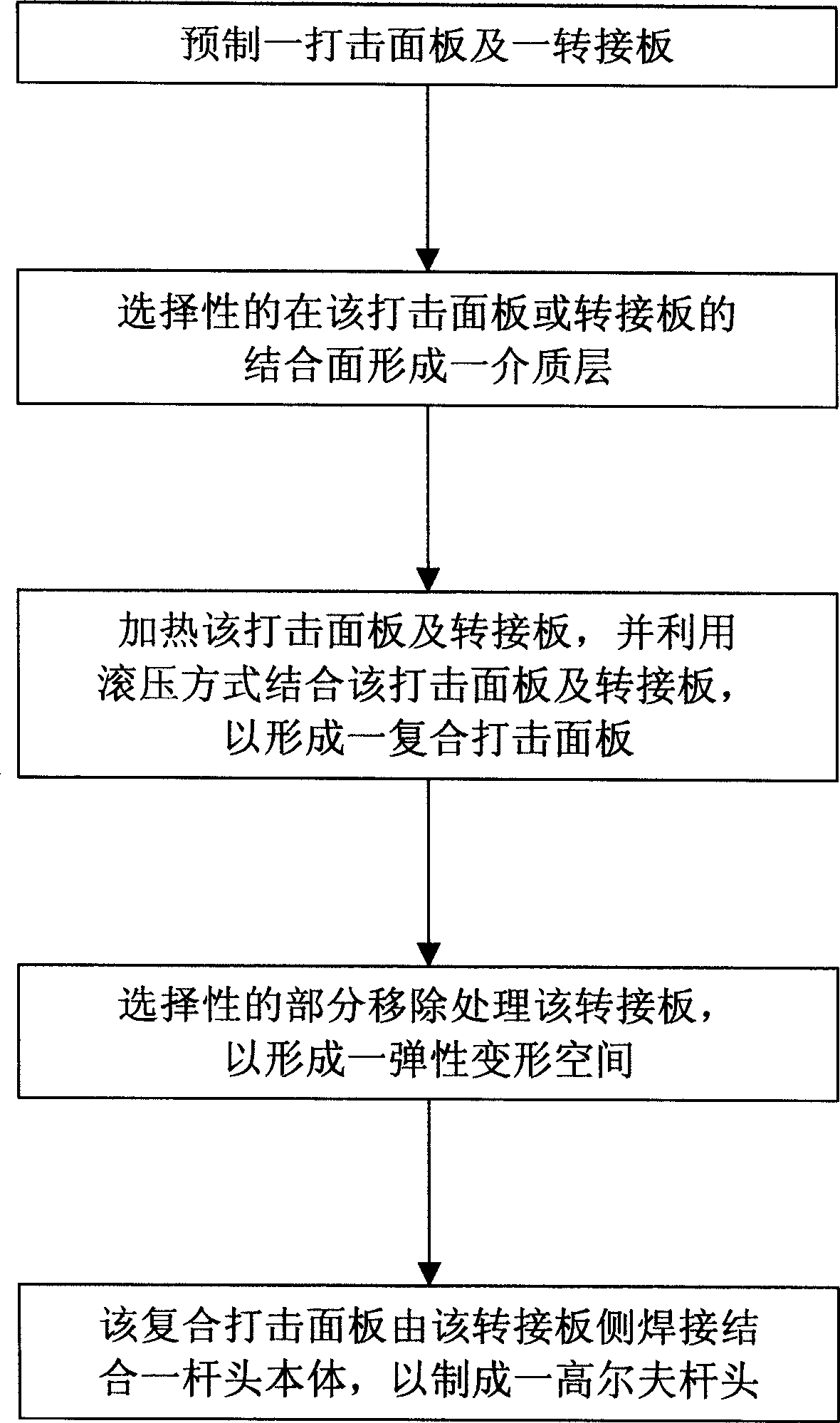

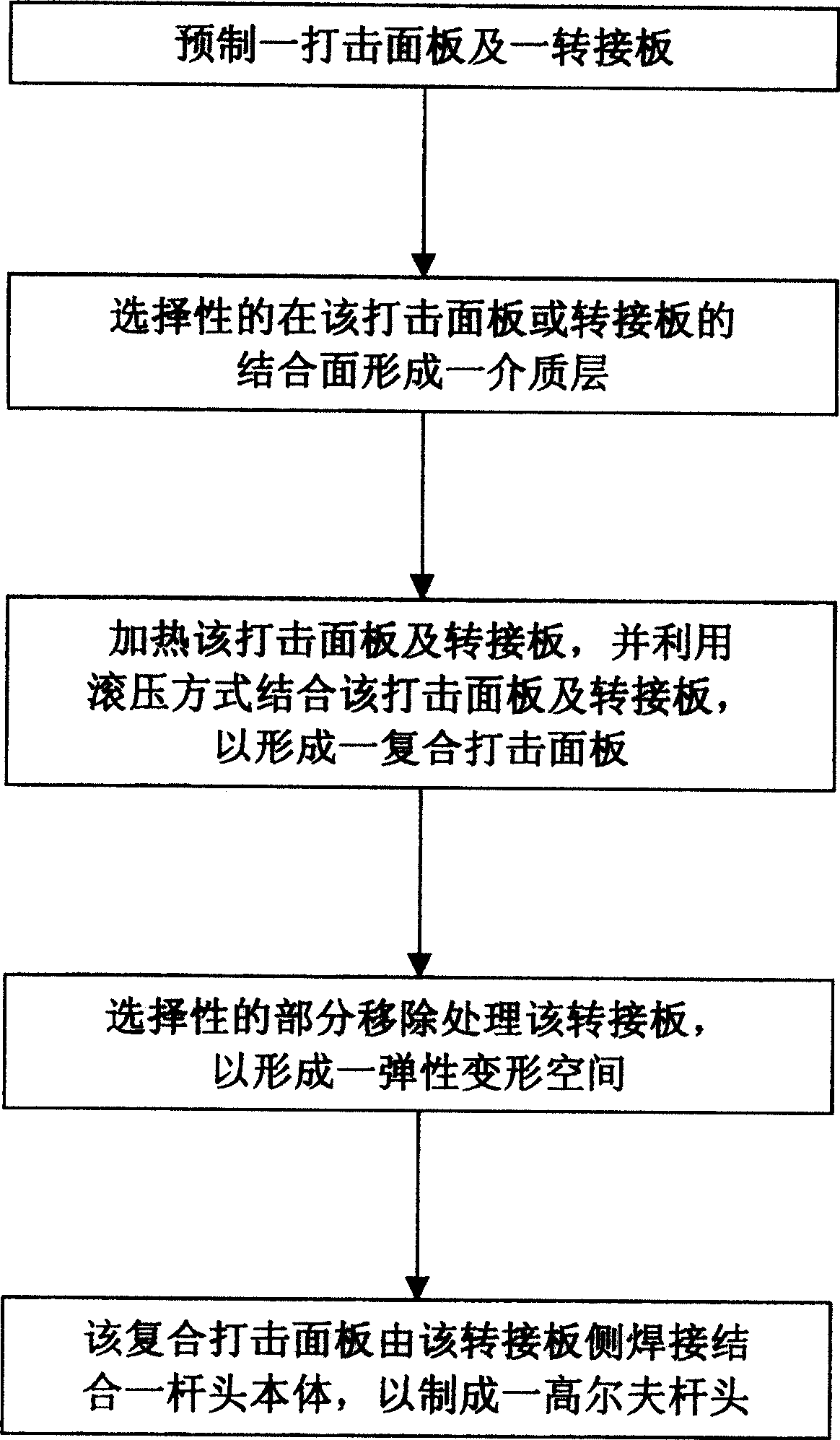

Method for making head of golf club and beating surface plate

InactiveCN1903395AHigh bonding strengthImprove manufacturing yieldGolf clubsRacket sportsEngineeringGolf club

Owner:NELSON PRECISION CASTING

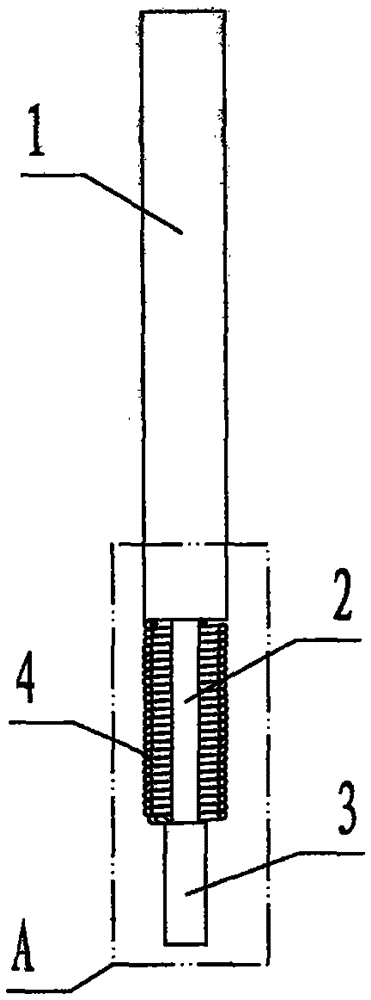

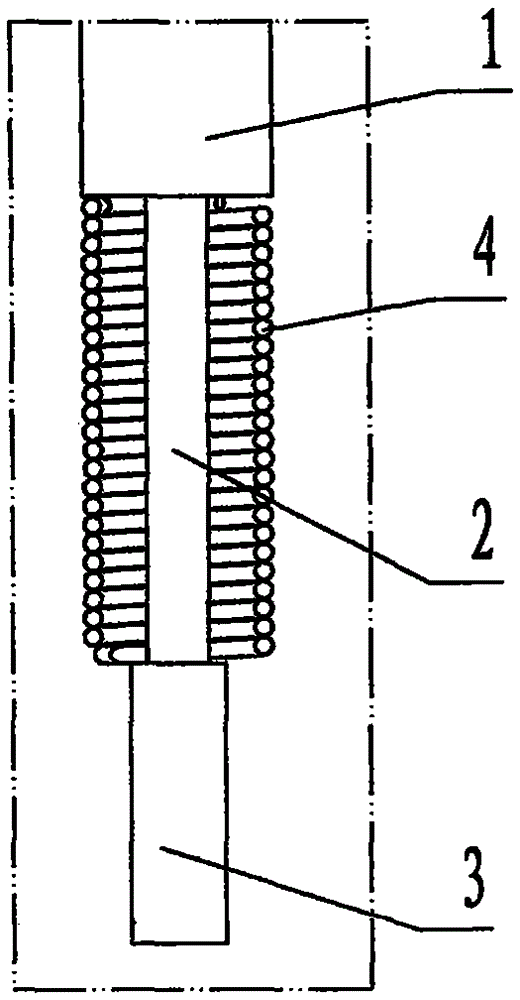

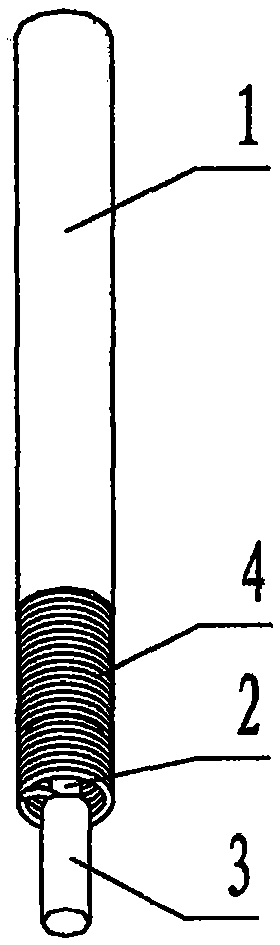

Trimming rolling cutter for machine use for automotive trim injection-molded products

InactiveCN105459310ASimple structureWork reliablyMilling cuttersWorkpiecesNumerical controlEngineering

The invention discloses a trimming rolling cutter for machine use for automotive trim injection-molded products. The trimming rolling cutter is composed of a shank (1), a cutter bar (2), a cutter head (3) and a spring (4). The shank, the cutter bar and the cutter head of the rolling cutter of the present invention from top to bottom are formed into a spring steel integral component in a cylindrical stepped shape; the spring sleeves the cutter bar; an upper end of the spring is fixedly welded with a lower end face of the shank, while a lower end of the spring is fixedly welded with an upper end face of the cutter head; in use, the following technical solution is adopted: numerical control locating trimming is performed on an automotive trim injection-molded product by using a numerical control engraving and milling machine tool; during working, the automotive trim injection-molded product is clamped on a template on a worktable of the numerical control engraving and milling machine tool, and the shank is clamped by an electric spindle of the numerical control engraving and milling machine tool and rotates at a high speed, and then rolling trimming is realized to flashings by using a cylindrical surface of the cutter head rotating at the high speed along the edges of the automotive trim injection-molded product; as a result, in the trimming to the automotive trim injection-molded products, the purposes of improving the consistency of quality, eliminating defective products and scraped products, improving efficiency and reducing costs are achieved.

Owner:NINGBO TIANYI NUMERICAL CONTROL MACHINERY

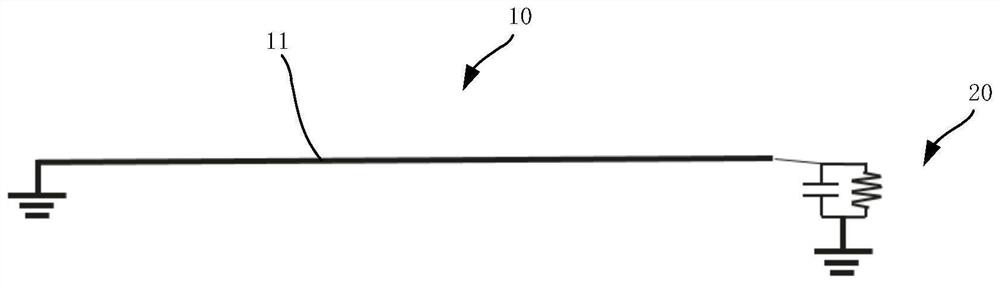

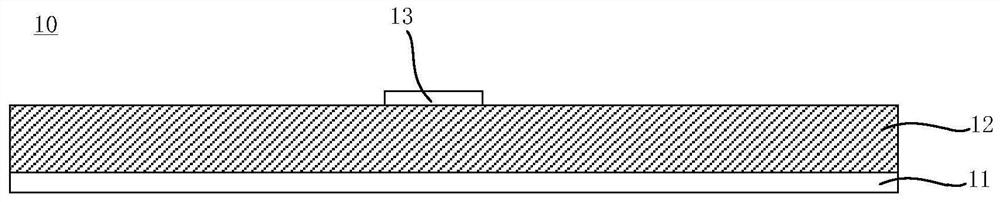

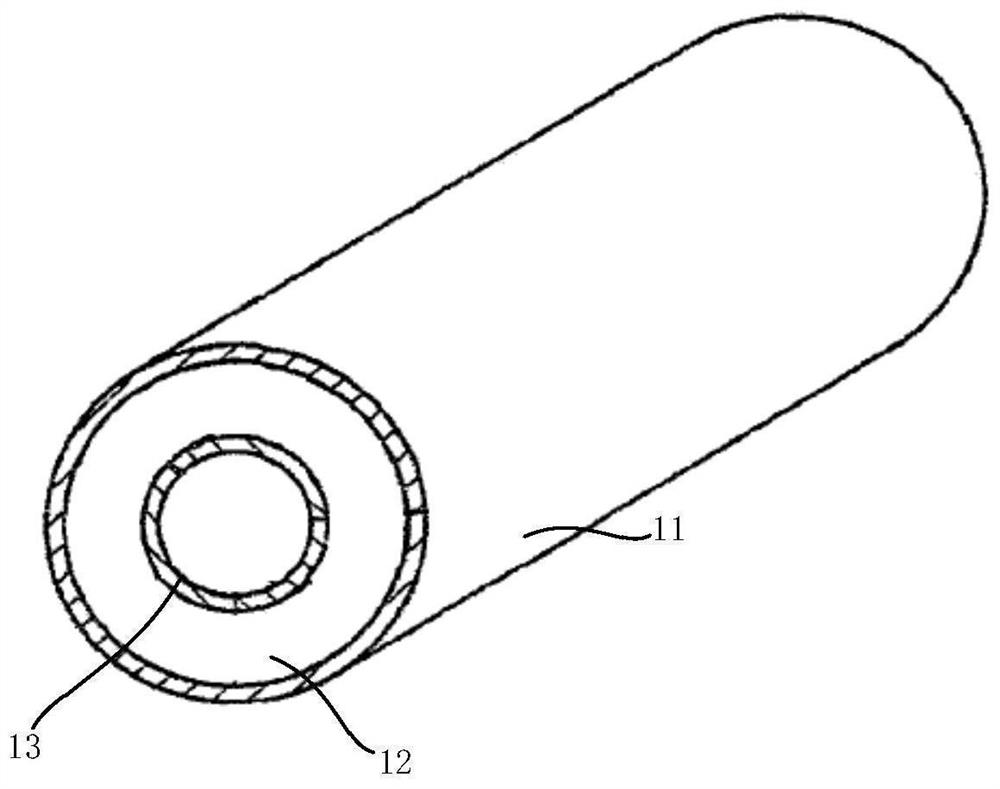

Transmission line assembly, antenna assembly and mobile terminal

ActiveCN114498041AGuaranteed Radiation EfficiencyGuarantee the quality of signal transmissionSimultaneous aerial operationsAntenna supports/mountingsRadio frequency signalOperating frequency

The invention provides a transmission line assembly, an antenna assembly and a mobile terminal, relates to the technical field of communication, and aims to solve the problem of transmission line clutter. A transmission line and a first filter are included. The transmission line is used for transmitting radio frequency signals, and the transmission line is provided with a first end and a second end. Wherein the transmission line comprises an inner conductor and an outer conductor, the first filter is connected with one end of the outer conductor of the transmission line, and the first end of the outer conductor is grounded through the filter. According to the transmission line assembly provided by the invention, the filter is additionally arranged between the outer conductor and the ground, so that the transmission line can be ensured to go down to the ground within a working frequency range, and the clutter position can be moved, and therefore, the clutter can be tuned, and adverse effects generated by the clutter can be reduced.

Owner:HUAWEI TECH CO LTD

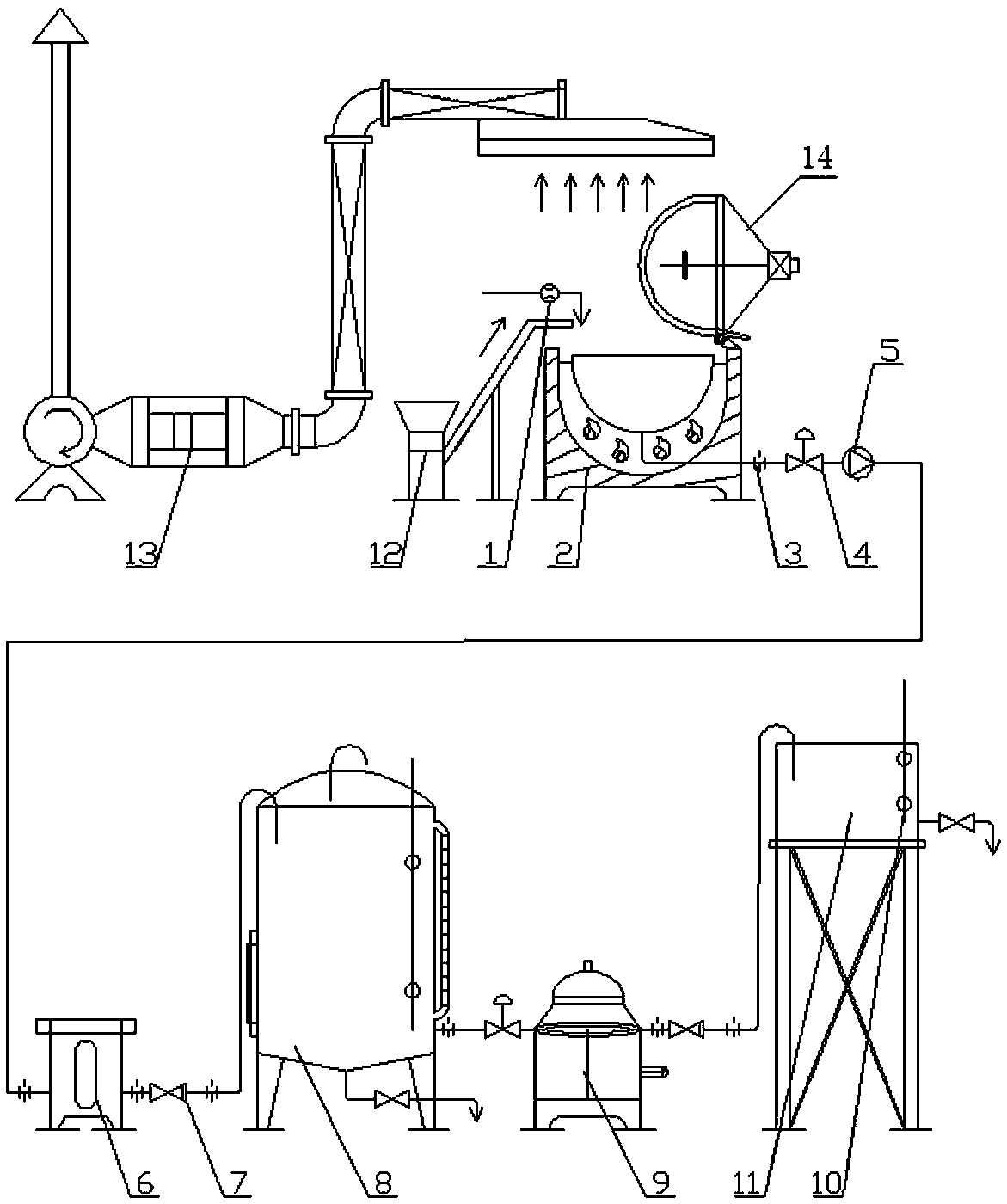

Automatic continuous preparation system for instant noodles seasoning oil

The invention discloses an automatic continuous preparation system for instant noodles seasoning oil. The system comprises an edible oil quantitative flow device, a loading machine, an oil stewing pot, a multi-layer filter, an oil storage tank, a centrifugal separator, an oil product box and a control unit, and the control unit controls the edible oil quantitative flow device to quantificationallyadd oil into the oil stewing pot for oil stewing, the loading machine sends spices into the oil stewing pot, the oil stewing pot outputs oil to the oil storage tank through a control valve, a coarsefilter pump and the multi-layer filter, the oil storage tank outputs oil to the oil product box through a control valve and the centrifugal separator, and the oil product box is connected to packagingequipment. The invention realizes the smooth combination of the processes through the overall design of the preparation system and the effective configuration of the equipment functions, the qualityuniformity of stewed seasoning oil is high, the homogenization time is not required in the oil storage tank, the continuous and automatic production is realized, and the quality uniformity of multi-batch products is stable. The system greatly improves production efficiency, reduces labor intensity of employees, facilitates equipment maintenance and pipeline cleaning, and meets environmental protection requirements for soot emissions.

Owner:HUAIBEI SHUNFA FOOD

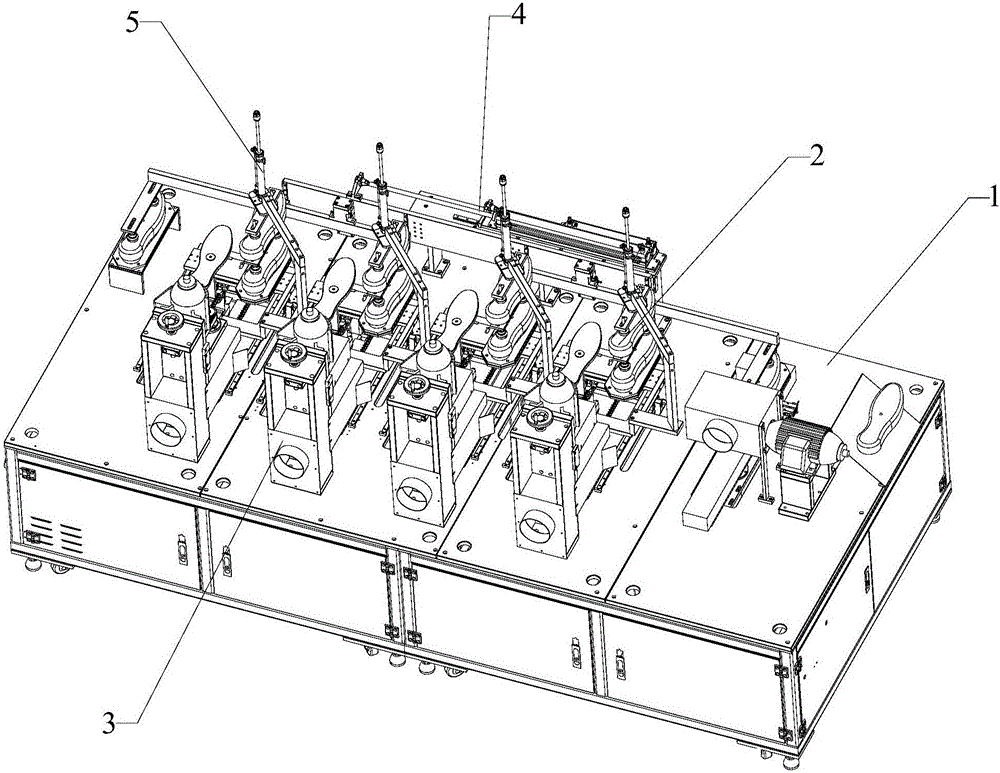

Automatic roughing device for midsoles of sports shoes

The invention relates to the field of shoe-making processes and aims to provide an automatic roughing device for midsoles of sports shoes. The automatic roughing device for the midsoles of the sports shoes comprises a machine frame as well as a movement mechanism and a roughing mechanism which are mounted on the machine frame, wherein the movement mechanism comprises a sliding block, a sliding rail, a roller wheel, a contour wheel, a midsole mounting seat, a servomotor, a synchronous belt and a spring; the sliding rail and the roller wheel are mounted on the machine frame; the sliding block is slidably mounted on the sliding rail; and two rotary shafts are vertically arranged in the sliding block and are connected through the synchronous belt. The automatic roughing device has the benefits that the labor intensity of workers is reduced; and the workers only need to put the midsoles on the midsole mounting seat in the device and then the device can automatically finish roughing work, so that the technical requirements on the workers are low, the working environment of the workers is improved, the production efficiency is improved, the labor costs of enterprises are reduced, and the enterprise benefits are increased.

Owner:深圳市力生机械设备有限公司

Method for making non-odor konjac tofu

The invention discloses a manufacturing method of Konjac tofu without particular smell, using compound coagulant consisting of carbonate, calcium hydroxide and phosphate. The application of the compound coagulant does not change the traditional fabricating method of the Konjac tofu, but the Konjac tofu heat-solidifying method needs to adopt high temperature (greater than 100 DEG C) to process; the Konjac tofu thus obtained has the same gel strength and structure without affecting the presence of edible alkali taste; and the Konjac tofu does not need to be washed repeatedly, thus improving the edible quality of Konjac tofu, simplifying the manufacturing procedure, and reducing water dosage.

Owner:SOUTHWEST UNIV

Preparation of piezoelectric quartz unseeded acoustic surface wafer

InactiveCN101372758AEliminate Angle DeviationImprove the qualified rate of finished productsFrom normal temperature solutionsWire cuttingSurface wave

The invention provides a method for preparing a seed-crystal-free acoustic surface wafer of piezoelectric quartz, which belongs to a method for preparing the material for an acoustic surface wave device, and aims at solving the problems of long production period, low yield, low utilization rate of materials and high cost existing in the prior preparation method at home and abroad. The method comprises the following steps: seed crystal is placed in a high-pressure autoclave to culture crystal by hydrothermal temperature difference method; then, the crystal is cut into crystal wafers, wherein, the seed crystal is a seed crystal wafer in acoustic surface wave propagating angle with the dimension being 2 to 6 inches; sodium hydroxide aqueous alkali and sodium carbonate aqueous alkali are filled in the high-pressure autoclave, the seed crystal is placed on the upper part of the high-pressure autoclave, while raw materials for dissolving is arranged on the lower part of the high-pressure autoclave; the two kinds of solution convectively move upwards, so that the crystal is crystallized along the acoustic surface wave propagating angle to grow a crystal block according to the specification; according to the thicknesses of acoustic surface wafers required by different categories, cutting processing is carried out on the crystal block by wire cutting according to different thicknesses by taking a seed basal lamina as the standard of cutting angle, so as to obtain the seed-crystal-free acoustic surface wafer with the different thicknesses in the acoustic surface wave propagating angle.

Owner:SICHUAN SANTAI CRYSTAL ELECTRONICS

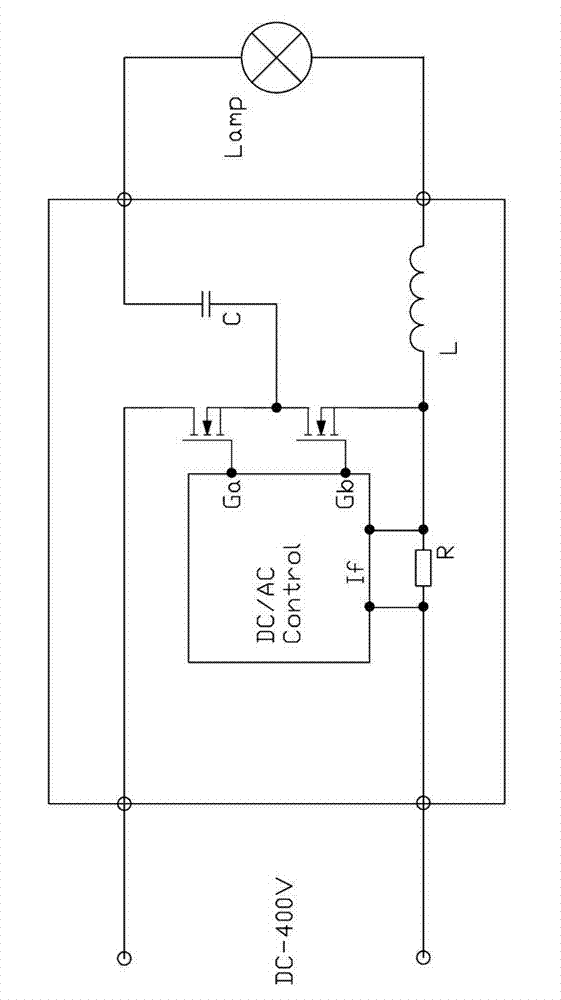

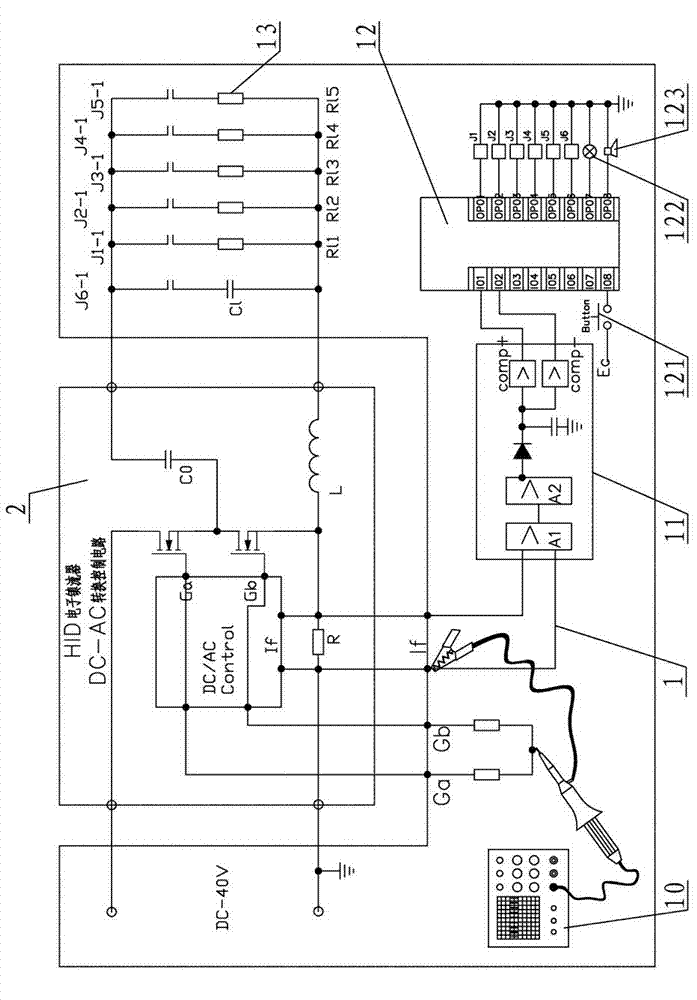

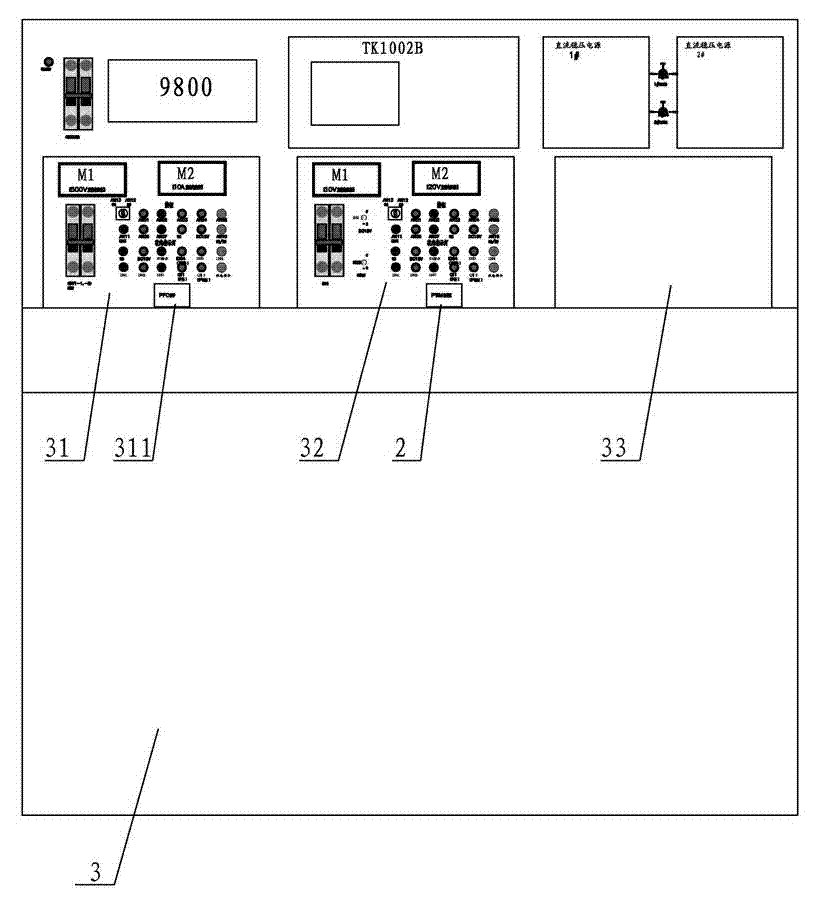

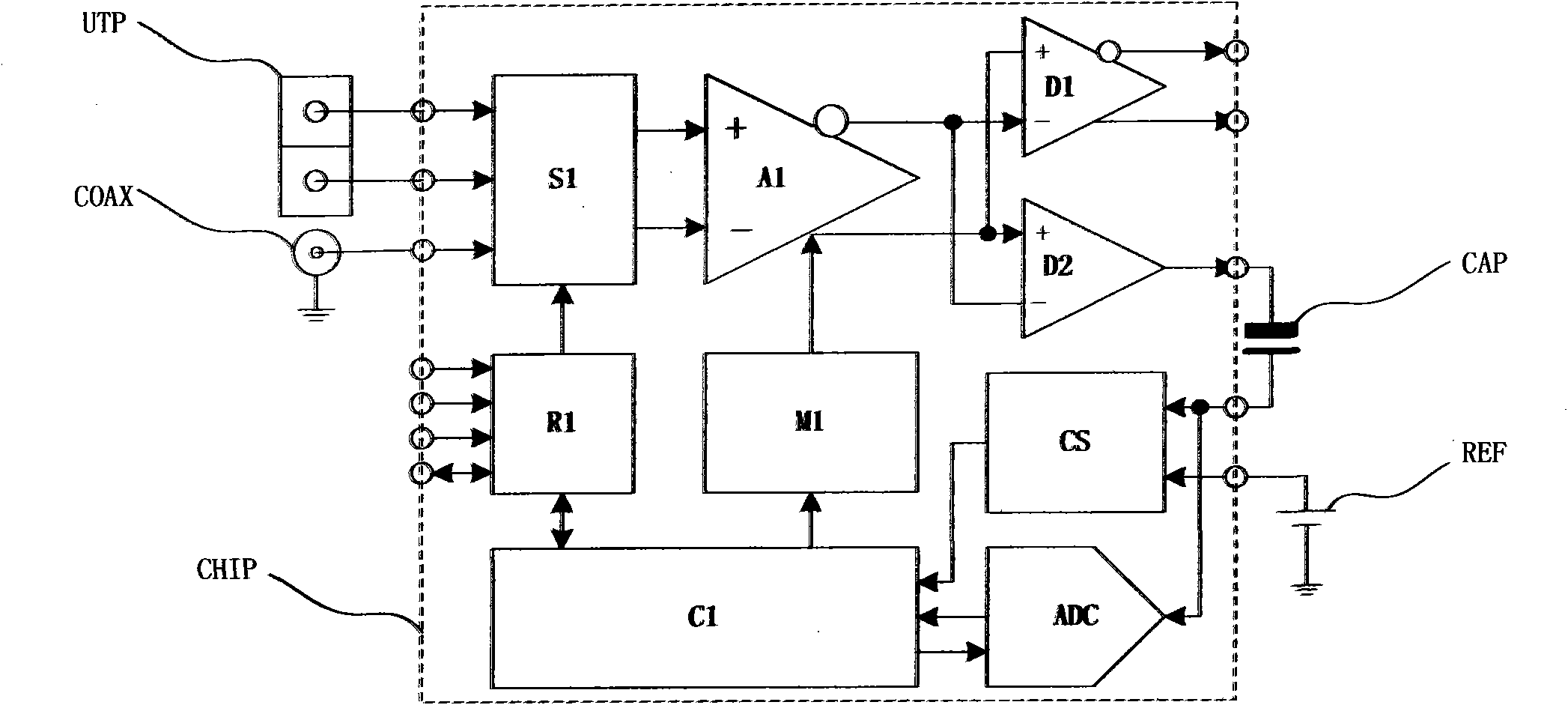

HID (high intensity discharge) electronic ballast on-line tester

InactiveCN103116094AImprove work efficiencyHigh quality consistencyElectrical testingConstant powerAlternating current

The invention relates to electronic ballast production on-line testing equipment, in particular to an HID (high intensity discharge) electronic ballast on-line tester which mainly tests constant power control portion in an electronic ballast DC-AC (direct current-alternating current) conversion circuit. The specific technical scheme includes that the HID electronic ballast on-line tester comprises a tester body and a test circuit arranged on the tester body and is characterized in that the test circuit comprises an oscilloscope, a programmable controller, an amplifying / comparison circuit and a dummy load, the oscilloscope is used for testing waveforms of output Ga and Gb of a circuit on a tested constant power control panel, the programmable controller comprises a program starting button, a positive error out-of-tolerance signal I01, a negative error out-of-tolerance signal I02 and an output executing relay J which are positioned at an input end, the amplifying / comparison circuit comprises a current amplifying portion and a comparator COMP, the dummy load is formed by connecting a capacitor with a resistor and used for substituting for a bulb portion on the tested constant power control panel.

Owner:JINHUA SANQI ELECTRIC SCI & TECH CO LTD

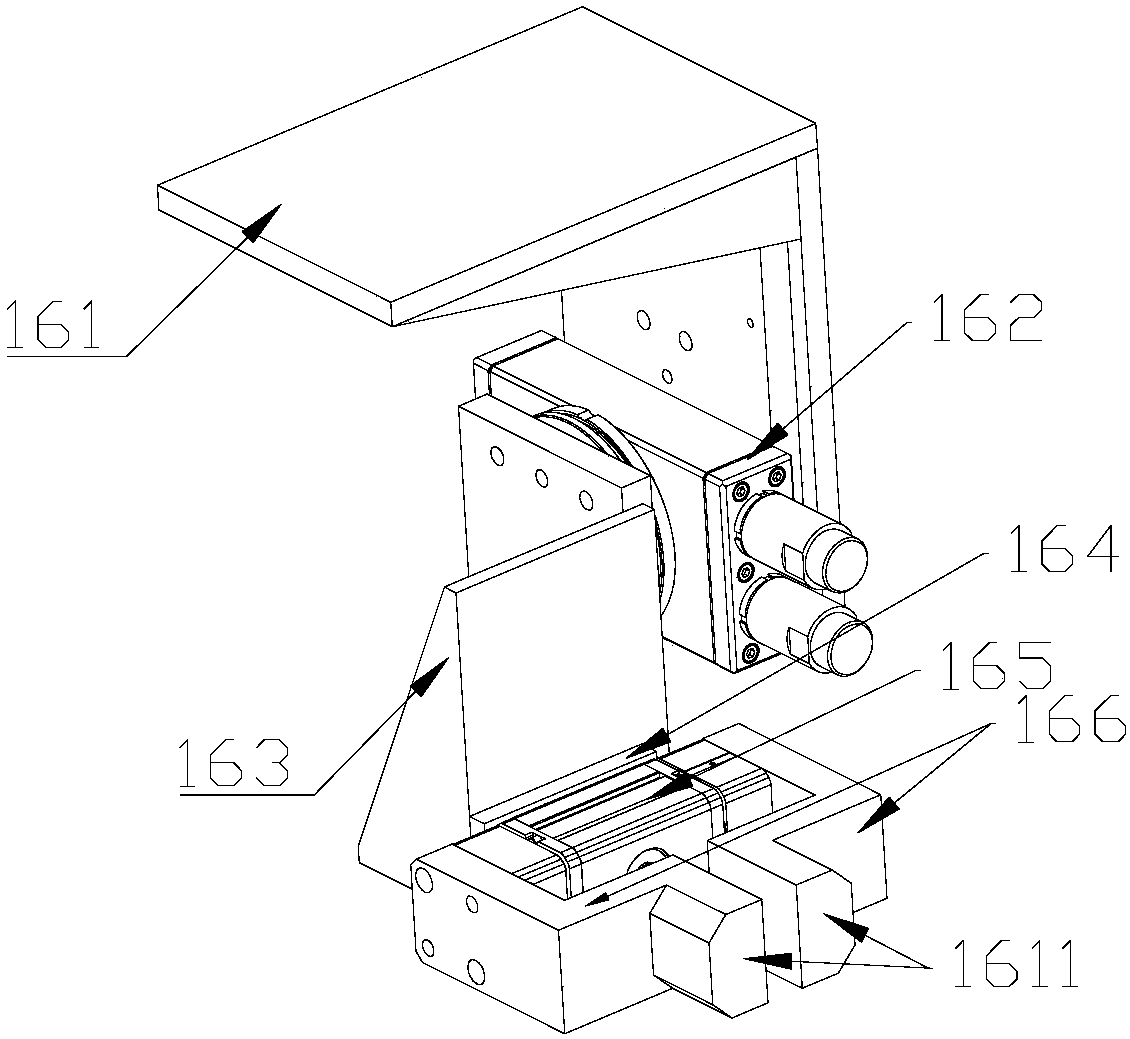

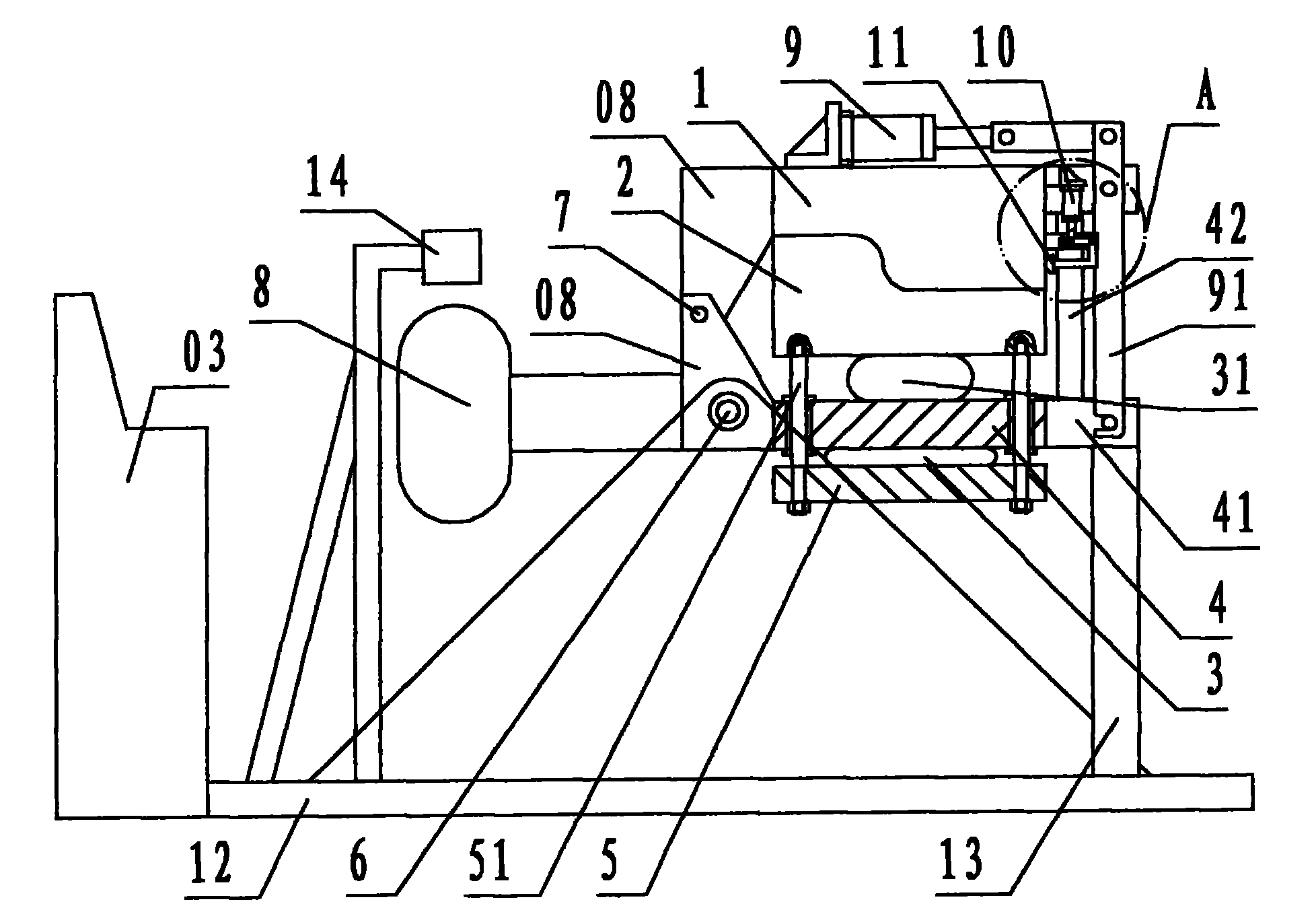

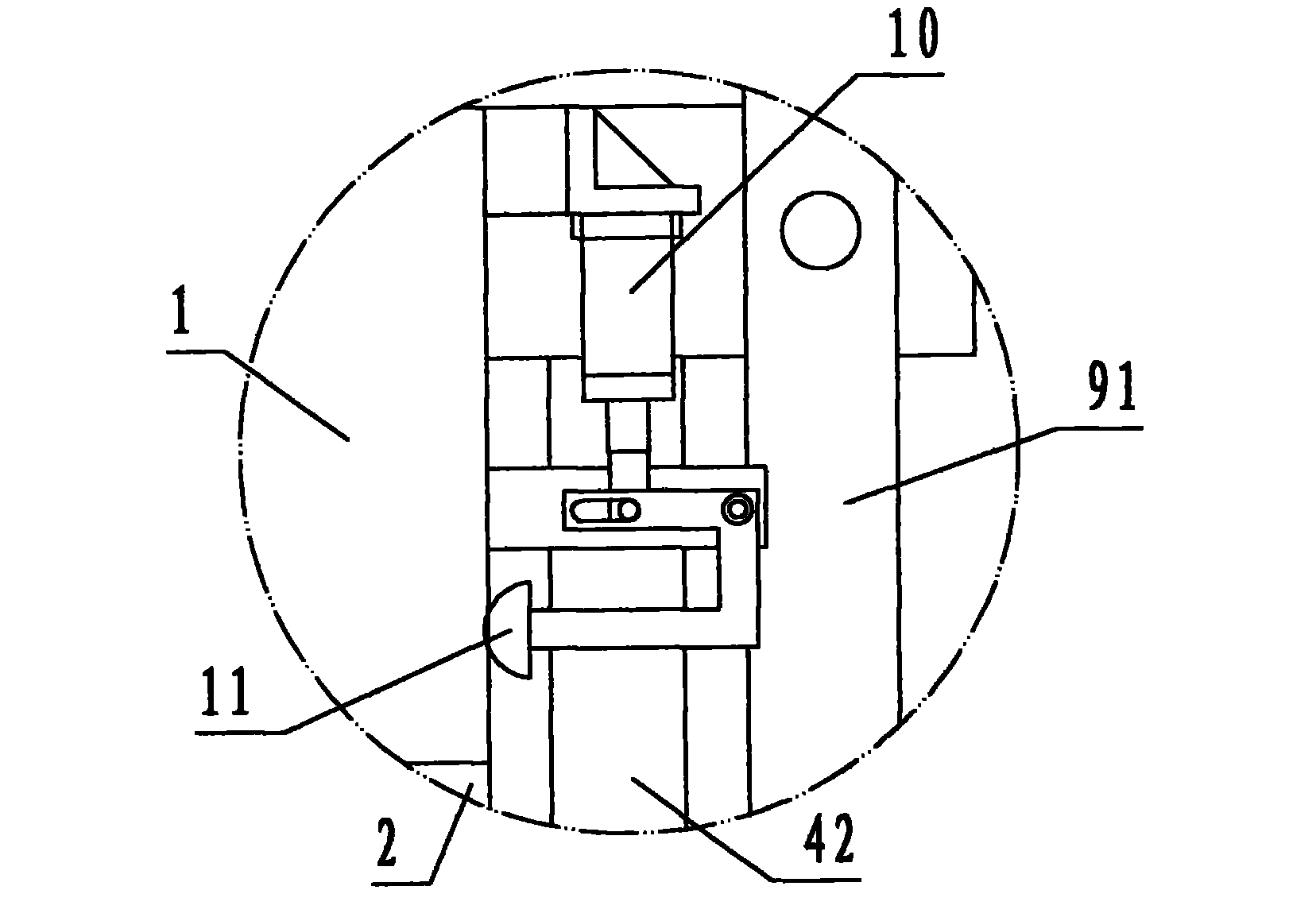

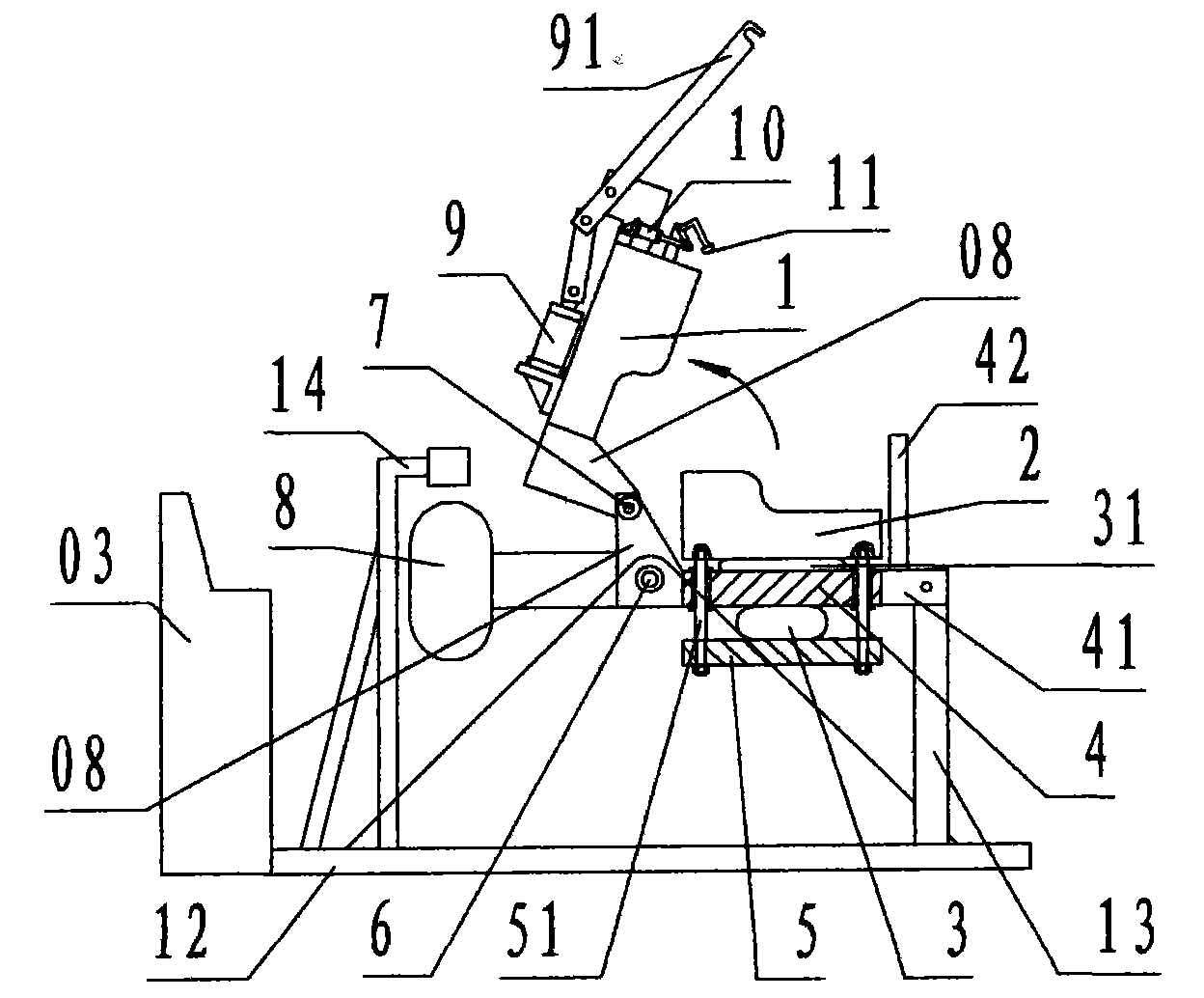

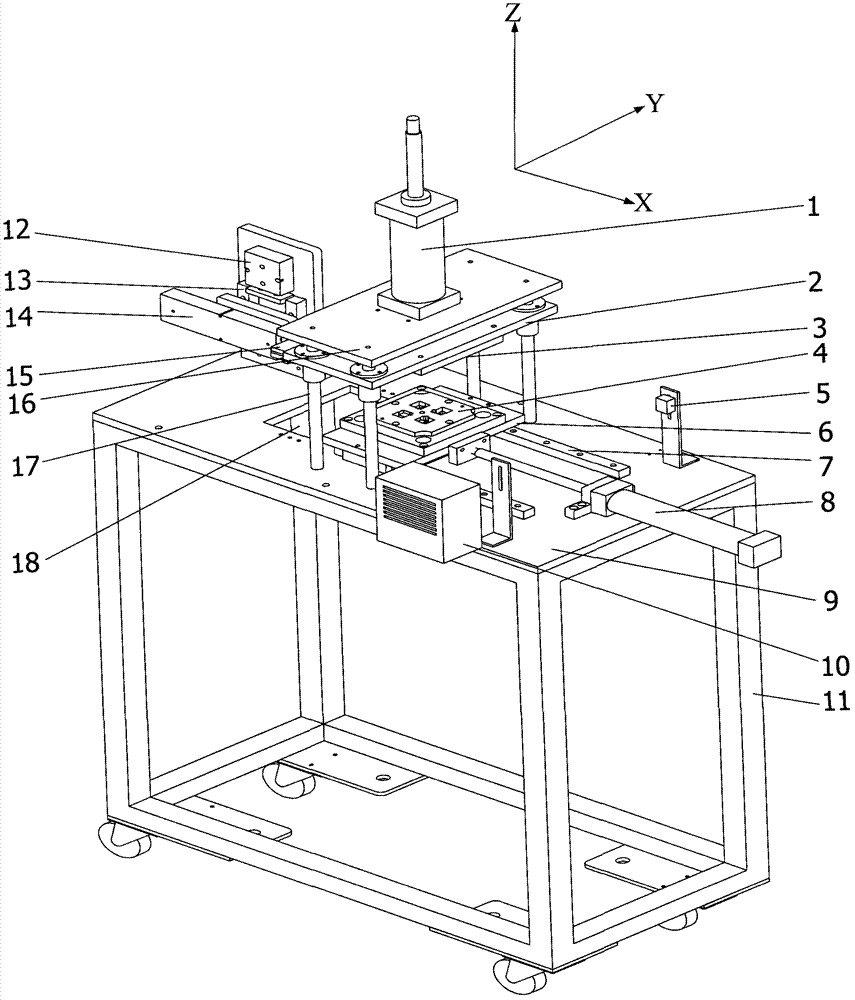

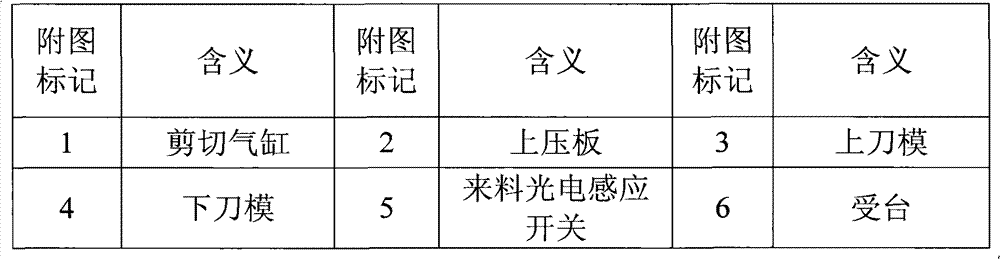

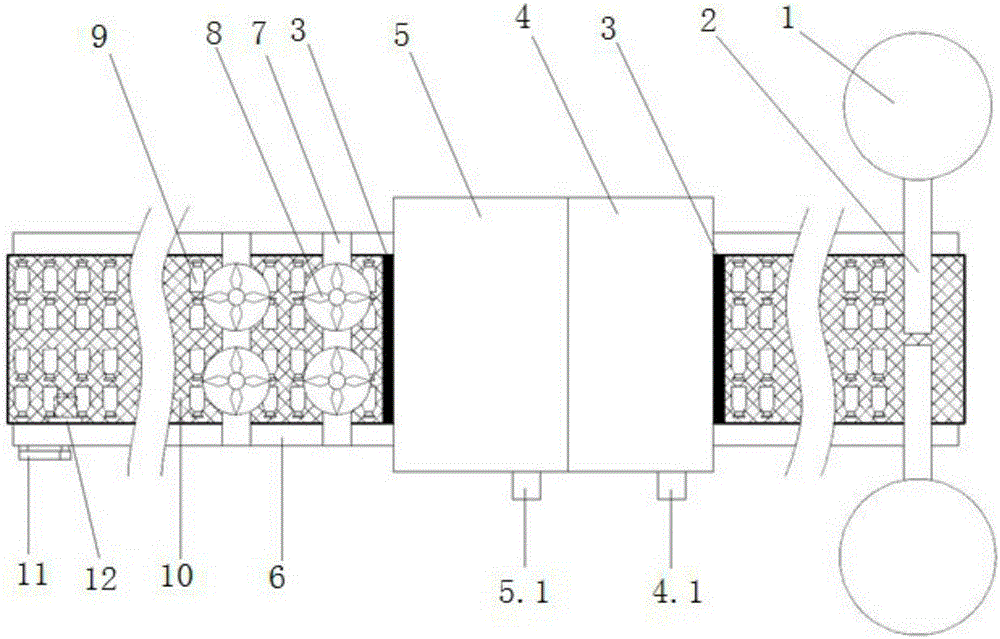

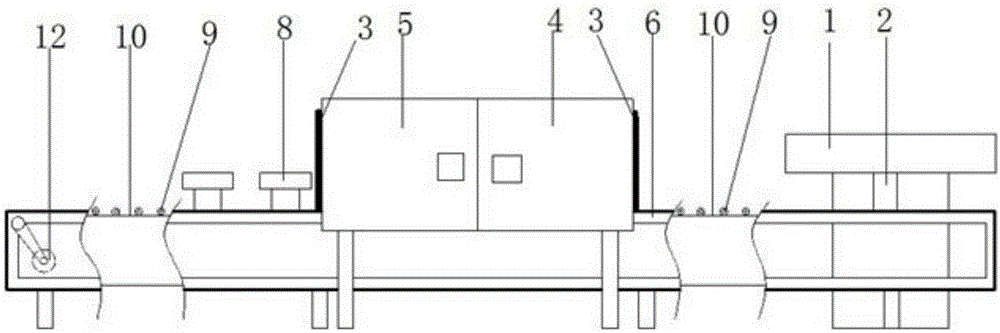

Full-automatic flow passage shearing machine

The invention relates to a full-automatic flow passage shearing machine. An X axial straight guide rail is arranged on an operating platform, wherein a receiving platform is mounted on the X axial straight guide rail; a lower cutting die is fixed on the receiving platform; a piston rod for pushing a cylinder on the operating platform is connected to the receiving platform; four guide rods are distributed on the operating platform; four guide holes are formed on an upper pressing plate; the upper pressing plate is sleeved on the guide rods; a fixed plate is fixed at the tops of the guide rods;a shearing cylinder is mounted on the fixed plate; the piston rod of the shearing cylinder is connected to the top surface of the upper pressing plate in the form of passing through the fixed plate; an upper cutting die is fixed on the bottom surface of the upper pressing plate; a vertical upright plate is fixed on the operating platform; a Z axial straight guide rail is arranged on the vertical upright plate; a front-and-back material-taking cylinder is mounted on the Z axial straight guide rail; an up-and-down material-taking cylinder is fixed on the vertical upright plate; the piston rod of the up-and-down material-taking cylinder is in driving connection with a base of the front-and-back material-taking cylinder; and a pneumatic flow passage clamping claw is mounted on the piston rod of the front-and-back material-taking cylinder. The full-automatic flow passage shearing machine can be used for realizing unmanned operation and increasing the quality consistency of products after being sheared to 100%.

Owner:苏州川鹏塑料有限公司

Annealing method of injection bottles made from glass tubes

The invention discloses an annealing method of injection bottles made from glass tubes. The method includes the following steps: glass bottles are tumbled to a meshy conveyor belt through a dropping groove from the interior of a bottle preparation machine; the glass bottles are conveyed into an annealing furnace through the meshy conveyor belt, then successively pass through a temperature control room for heating, and pass through a heat preservation room for heat preservation annealing; and the glass bottles after heat preservation annealing pass through the underneath of a cooling fan for cooling the glass bottles, and thus the whole annealing process is completed. The annealing process and the production process of the medicinal glass bottles are combined, after the products are molded, the waste heat of the bottle bodies is fully utilized, and automatic and continuous annealing is directly carried out; the energy conversation effect is obvious, the heat preservation performance of the annealing furnace is good and the thermal efficiency is high; the manpower resource for manually carrying glass is saved, the error of manual operation is reduced and the consistency of the quality of the medical glass bottles is improved greatly.

Owner:ANHUI HUAXIN PHARMA GLASS

Preparation method of novel tetanus toxoid medium

InactiveCN104498388ALarge and stable toxin productionHigh purity and stabilityBacteriaMicroorganism based processesInorganic saltsTetanus toxoids

The invention discloses a preparation method of a novel tetanus toxoid medium. The medium is prepared by peptone, yeast powder, vitamins and inorganic salts through the corresponding preparation method. The problems of large hydrolysis degree difference, low quality consistence, difficult purification of toxins, and unstable toxin output in the prior art are solved, and the tetanus toxoid medium prepared in the invention has the advantages of hydrolysis difference reduction, quality consistence improvement, easy purification of the toxins, and stable increase of the output of the toxins.

Owner:ZHEJIANG VACIN BIO PHARMA LTD

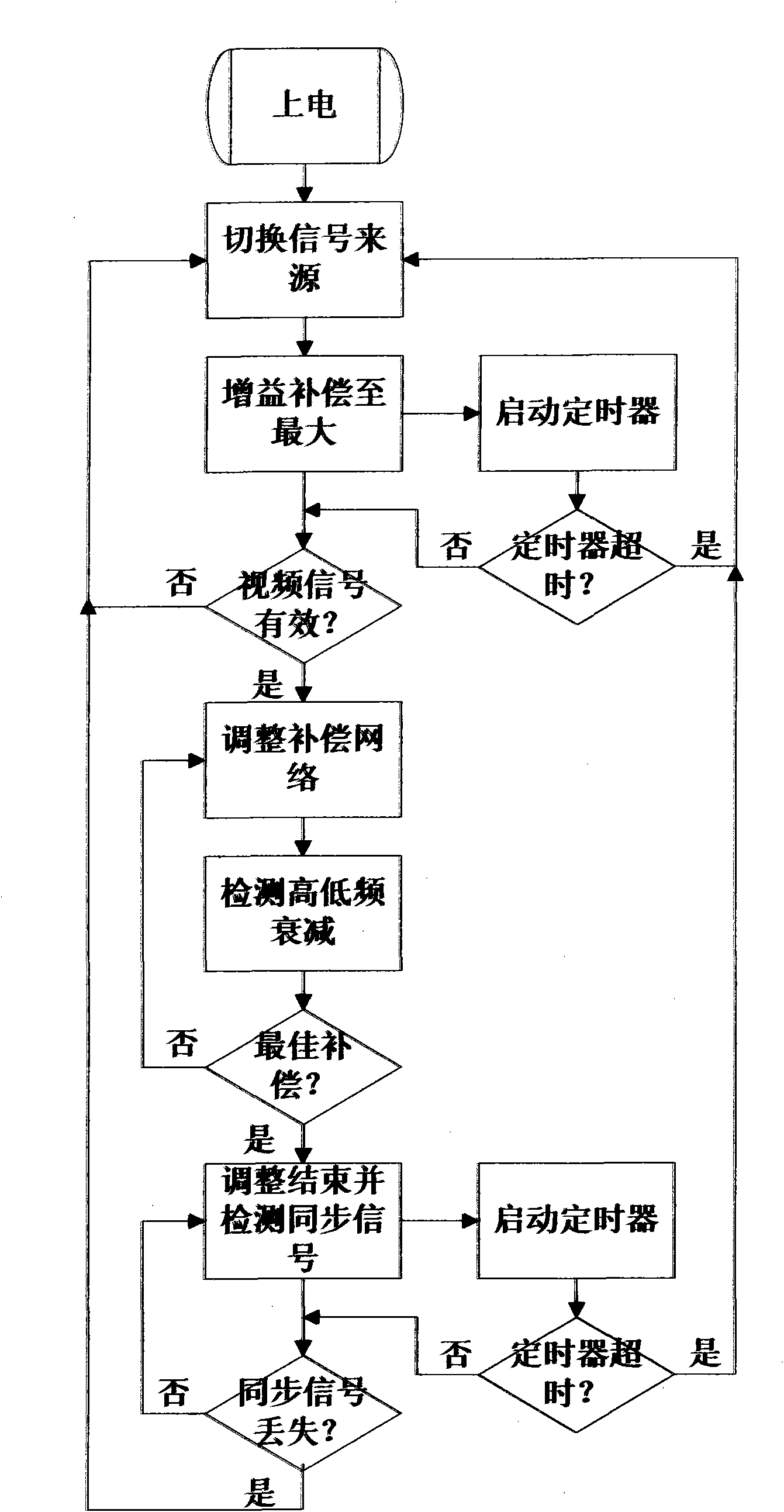

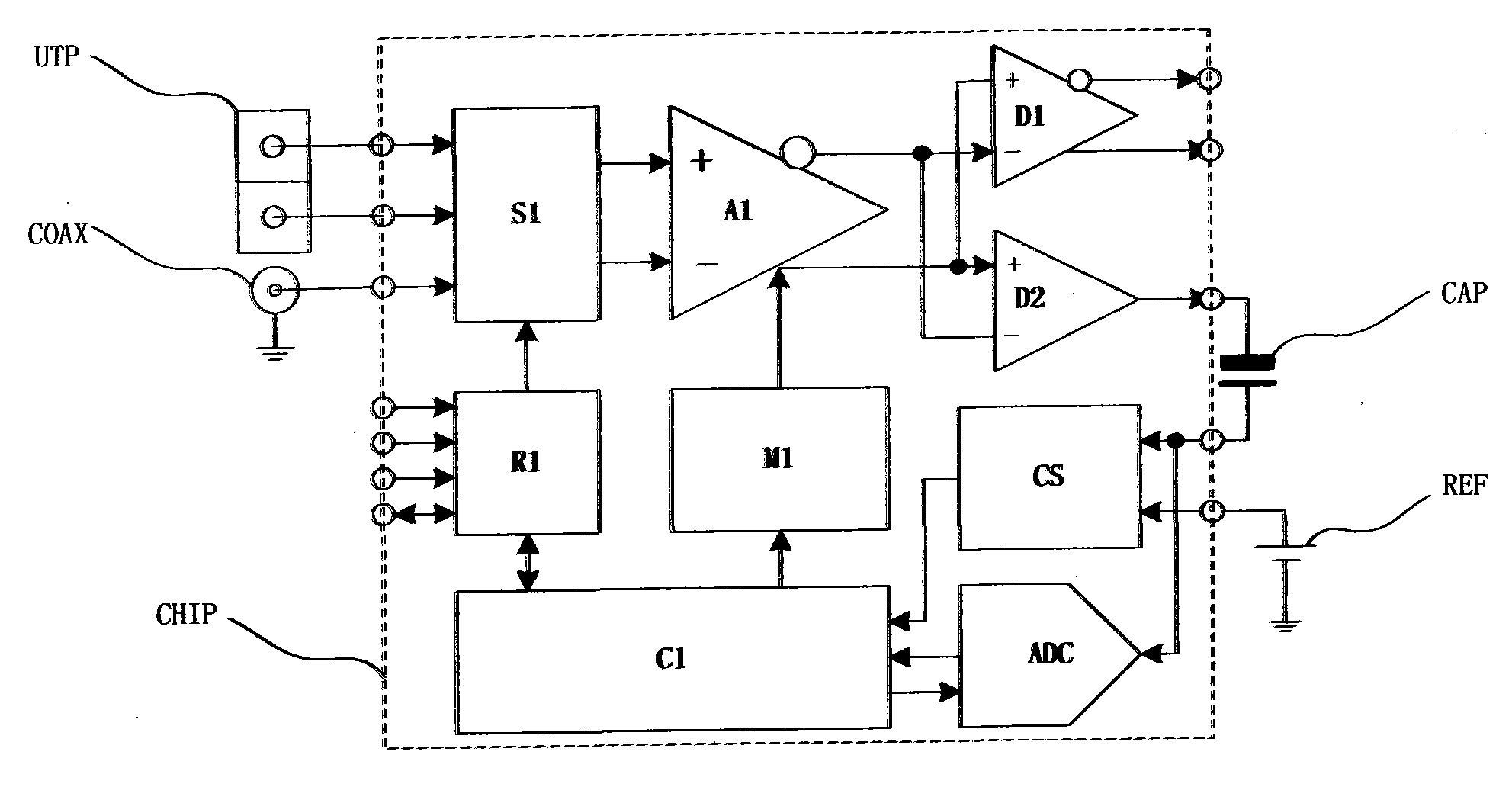

Adaptive balanced and non-balanced dual mode video receiving chip

ActiveCN102075724ARestore signal attenuationReduce qualityClosed circuit television systemsElectrical cable transmission adaptationDual modeAdaptive video

The invention discloses an adaptive balanced and non-balanced dual mode video receiving chip, which comprises a balanced and non-balanced video signal input unit, a balanced video signal amplifying unit, a balanced and non-balanced signal driving unit, a video synchronous separating and clamping unit, a video signal digitalization processing unit, an intelligent phase and gain compensation operating control unit, a high and low frequency phase and gain compensation unit, and a state indicating and function setting unit. The adaptive balanced and non-balanced dual mode video receiving chip hasthe advantages of adaptive balanced signal and non-balanced video signal receiving, adaptive balanced signal polarity and function of outputting a balanced and non-balanced signal. The receiving adaptation is that: the chip automatically identifies the source of a video signal, automatically analyzes and calculates the phase, the gain and the loss of an input signal, and compensates and recovers the video signal to the largest extent; and the polarity adaptation is that: the polarity of the balanced signal can transposed. The adaptive balanced and non-balanced dual mode video receiving chip is used for adaptive video receiving and relaying equipment.

Owner:重庆中舜微电子有限公司

A manufacturing method of golf club heads and beating surface plates

InactiveCN100464807CHigh bonding strengthImprove manufacturing yieldGolf clubsRacket sportsEngineeringGolf club

Owner:NELSON PRECISION CASTING

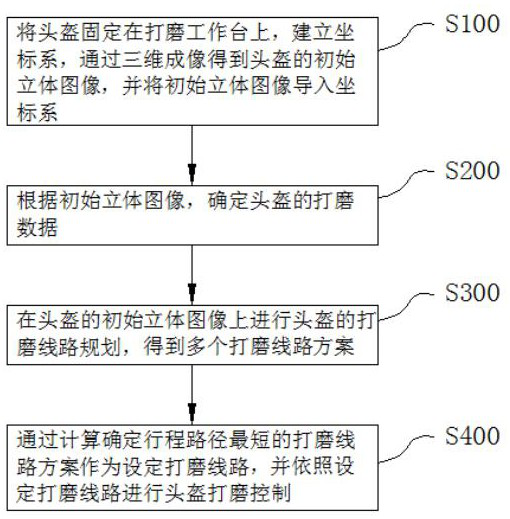

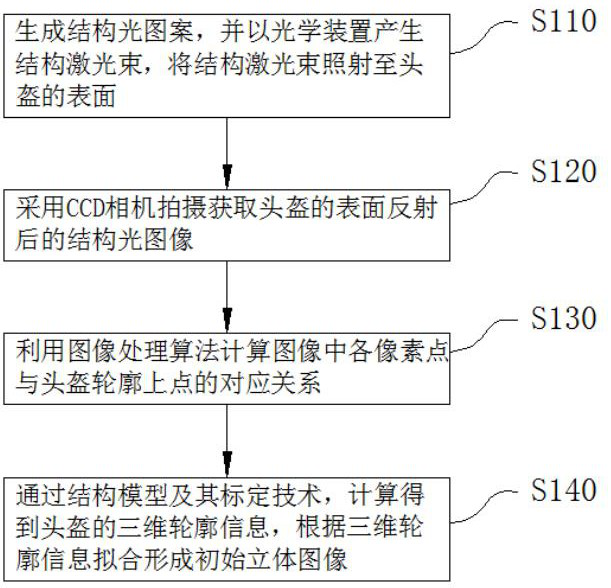

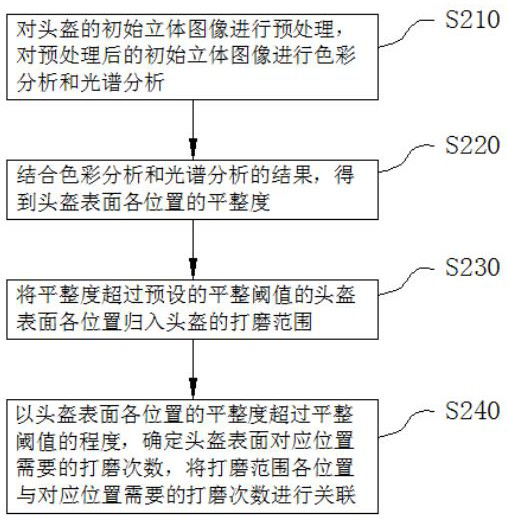

Polishing line setting and control method for helmet manufacturing

ActiveCN114434265AIncrease productivityEasy to controlDetails involving processing stepsImage enhancementStereo imageMechanical engineering

The invention relates to the technical field of helmet polishing control, and particularly provides a polishing line setting and control method for helmet manufacturing, which comprises the following steps: fixing a helmet on a polishing workbench, establishing a coordinate system, obtaining an initial stereo image of the helmet through three-dimensional imaging, and importing the initial stereo image into the coordinate system; determining polishing data of the helmet according to the initial three-dimensional image; carrying out grinding line planning on the helmet on the initial three-dimensional image of the helmet to obtain a plurality of grinding line schemes; and the polishing line scheme with the shortest stroke path is determined through calculation to serve as a set polishing line, and helmet polishing control is conducted according to the set polishing line. According to the invention, accurate helmet polishing line and polishing program control can be realized, the production efficiency is improved, the adverse effects of labor cost and human factors on the product quality are reduced, and the yield and quality consistency of helmets can be improved.

Owner:广东熙瑞智能科技有限公司

Arc ion coating equipment

ActiveCN107779826BHigh quality consistencyMeet the requirements of large capacityVacuum evaporation coatingSputtering coatingIon bombardmentEngineering

The invention discloses an arc ion plating device, which is used for plating a work piece placed in a work piece frame; the arc ion plating device comprises a loading section, an unloading section, avacuum chamber body, an ion bombardment system, an arc ion plating system, and a driving system; the vacuum chamber body is arranged between the loading section and the unloading section, and comprises a first vacuum transition section, a processing section, and a second vacuum transition section which are linked in series orderly; the processing section comprises a front section and a back section which are connected to each other; the ion bombardment system is arranged at the front section, and the arc ion plating system is arranged at the back section; the driving system conveys the work piece frame so that the work piece is conveyed from the loading section to the first vacuum transition section, the front section, the back section, and the second vacuum transition section of the vacuum chamber body orderly to process and then conveyed to the unloading section. The arc ion plating device has the advantages of improving the product applicability, film quality and production efficiency of the arc ion plating device.

Owner:GUANGDONG SHENGBOER PHOTOELECTRIC TECH CO LTD

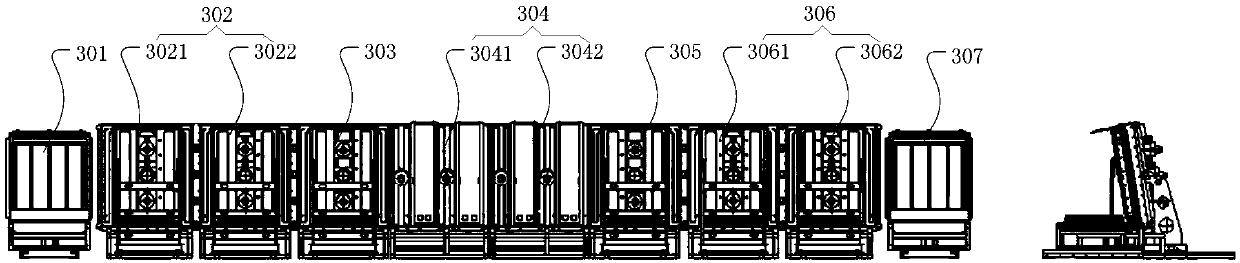

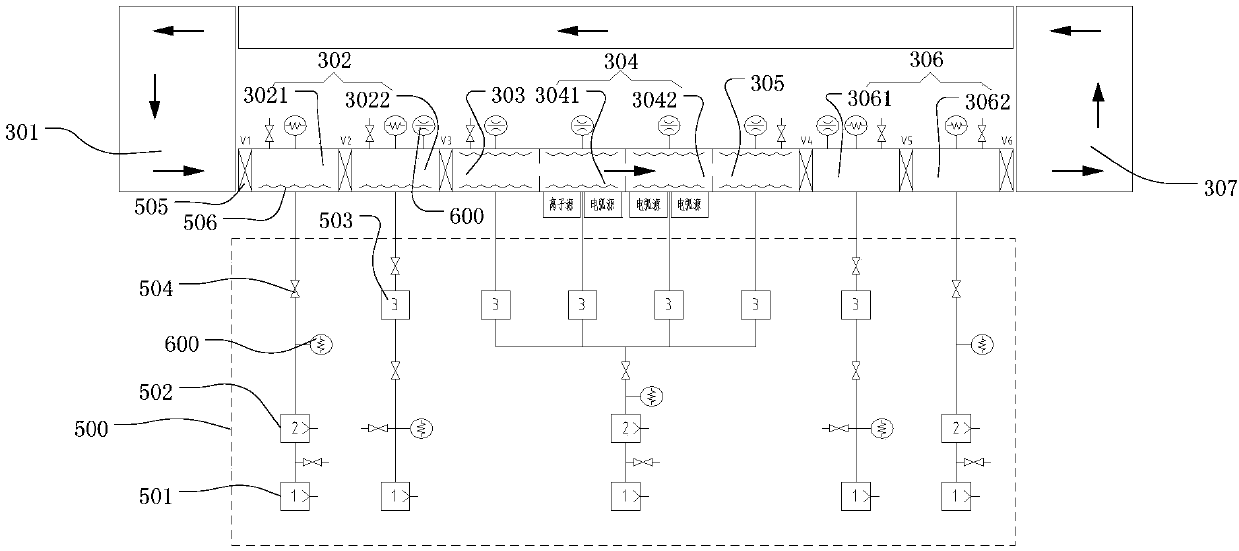

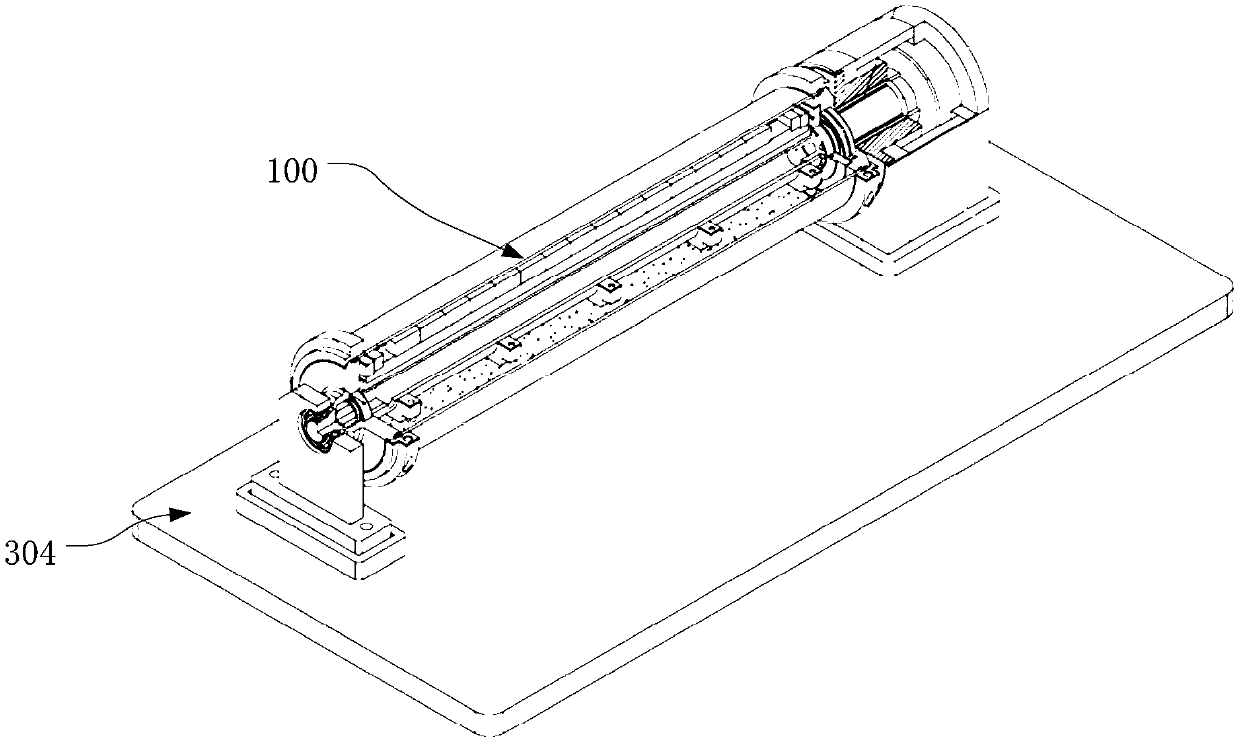

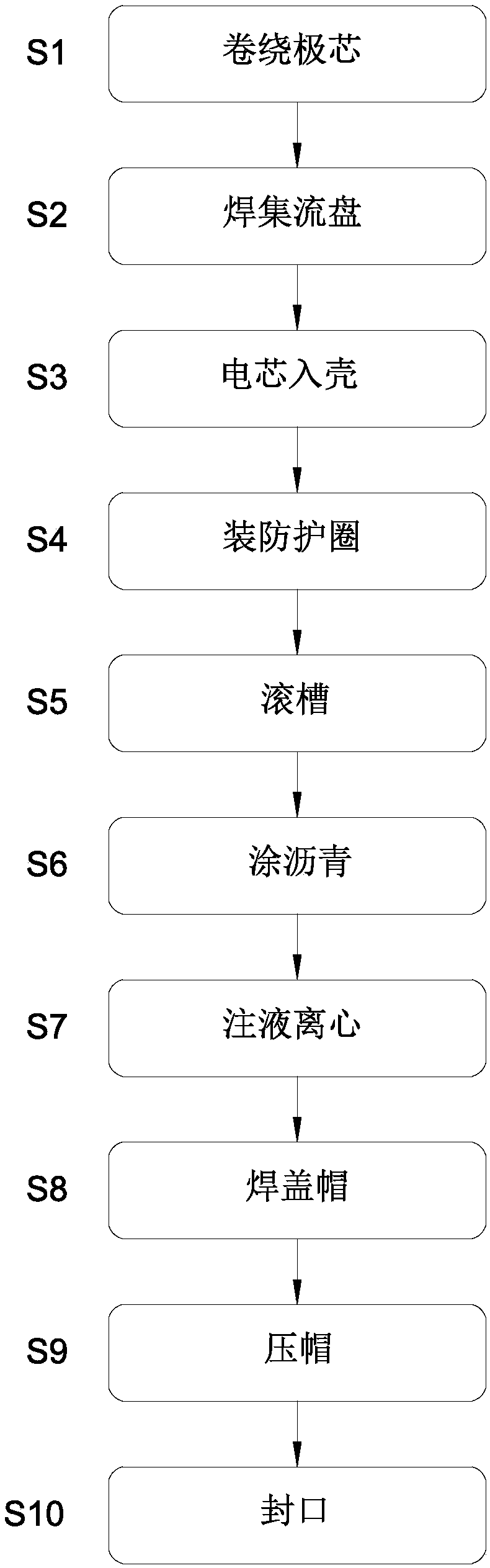

Assembly processing method of SC battery

InactiveCN108232274AGuaranteed performanceStable structureFinal product manufactureCylindrical casing cells/batteryCentrifugationEngineering

The invention provides an assembly processing method of an SC battery. The assembly processing method sequentially comprises the following steps of winding a pole shank; welding a collector plate, wherein the concentricity of the pole shank and the collector plate is within 0.2mm, welding points are 8 to 12, and the welding tension is not less than 20N; loading the pole shank into a shell; mounting a protective ring: embedding, by a manipulator, the protective ring between the battery shell and the collector plate; slot rolling: wherein the width of a groove is 3mm to 5mm, and the depth of thegroove is 1.2mm to 1.6mm; asphalt coating; electrolyte injection and centrifugation: injecting an electrolyte into the battery shell and realizing centrifugal operation by an electrolyte injection and centrifugation device; cap welding, wherein the welding tension is not less than 15N; cap pressing; sealing. The assembly processing method can be used for preventing the collector plate and the battery shell from generating a short circuit; thus, the performance of the SC battery is effectively ensured; the made SC battery is stable in structure and high in sealability, and further, has higherresistance; the service life of the battery is long; the assembly processing efficiency is high, and the quality consistency of SC batteries made in a batch manner is high.

Owner:东莞市朗泰通实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com