Trimming rolling cutter for machine use for automotive trim injection-molded products

A technology for injection molding products and automotive interiors, which is applied in the direction of cutting tools, milling cutters, and manufacturing tools for milling machines. The effect of good and rejected products, improved consistency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

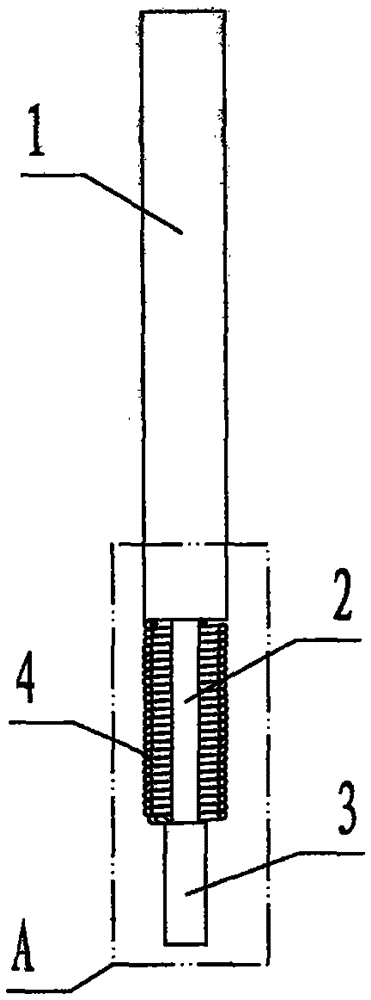

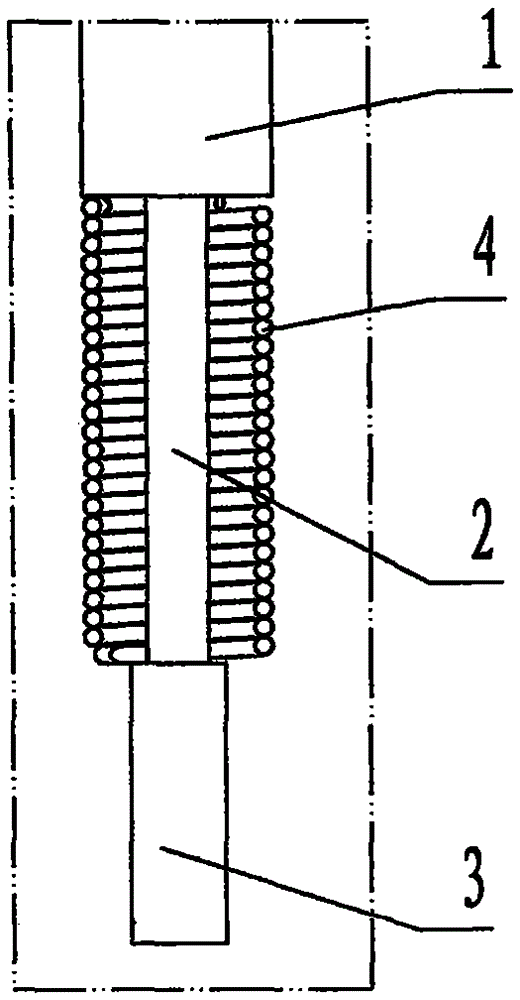

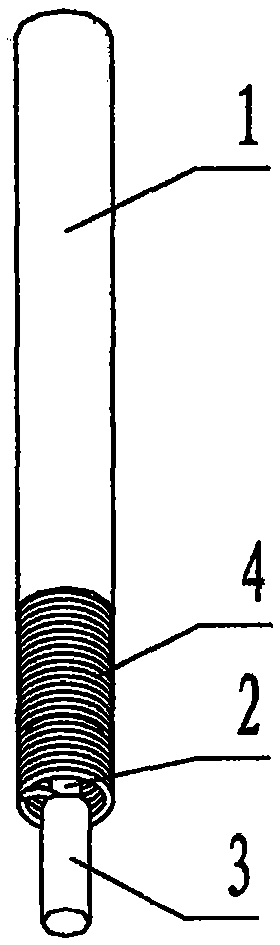

[0016] refer to Figure 1 ~ Figure 3 , a machine trimming roller knife for automotive interior injection molding products of the present invention, referred to as the roller knife, the roller knife is composed of a handle 1, a knife bar 2, a knife head 3 and a spring 4, wherein: the knife The handle 1, the cutter bar 2 and the cutter head 3 are integral members of cylindrical stepped spring steel, the handle 1 is positioned above the cutter rod 2, the cutter head 3 is positioned below the cutter rod 2, and the The diameter is larger than the diameter of the cutter bar 2, and the diameter of the handle 1 is larger than the diameter of the cutter head 3; the cylindrical surface of the cutter head 3 is a smooth mirror surface;

[0017] The spring 4 is a cylindrical helical tension spring with dense turns. The spring 4 is set on the knife bar 2. The end faces are fixed and welded.

[0018] Working Principle and Beneficial Effect

[0019] In application, the roller cutter carrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com