A manufacturing method of golf club heads and beating surface plates

A technology for golf club heads and manufacturing methods, which is applied to golf balls, golf clubs, rackets, etc., and can solve problems such as inability to uniformly disperse, affect ball hitting performance, and low manufacturing yield of hitting panels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical features, and advantages of the present invention clearer, preferred embodiments will be specifically cited below, and detailed descriptions will be given below in conjunction with the accompanying drawings.

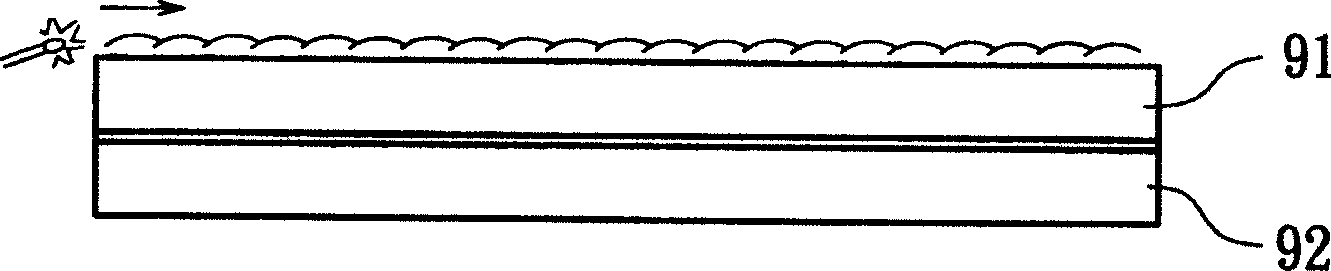

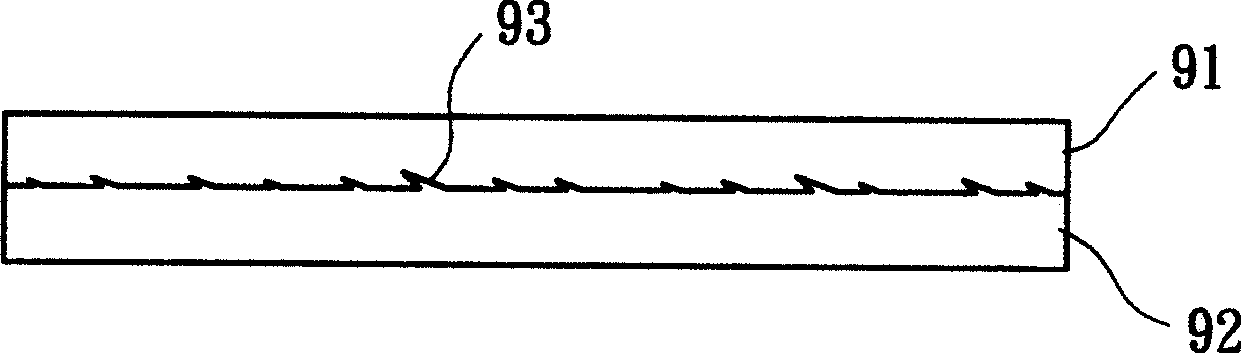

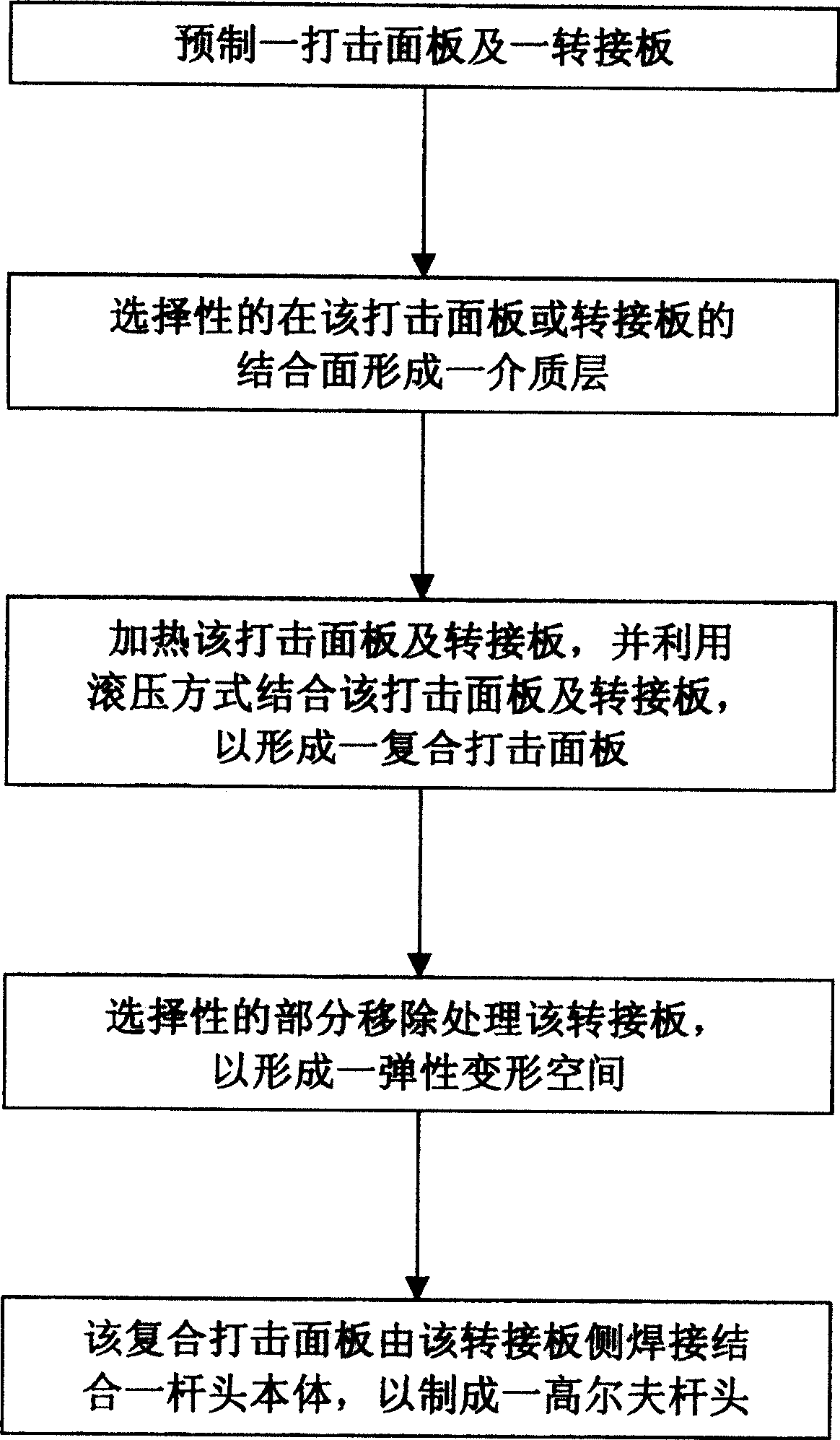

[0030] Please refer to Figure 3-9 As shown, the manufacturing method of the golf club head and the strike panel in the first embodiment of the present invention includes the steps of: prefabricating a strike panel 10 and an adapter plate 20; A dielectric layer 30 is formed on the joint surface; the striking panel 10 and the adapter plate 20 are heated, and the striking panel 10 and the adapter plate 20 are combined by rolling to form a composite striking panel 40; selective partial removal process The adapter plate 20 is used to form an elastic deformation space 21 ; and the composite striking panel 40 is welded from the adapter plate 20 to a club head body 50 to form a golf club head.

[0031] please refer again image 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com