Pneumatic gasbag-type semi-automatic polyurethane foaming and molding device

A foam molding and semi-automatic technology, which is applied in the field of pneumatic airbag-type semi-automatic polyurethane foam molding devices, can solve the problems of low yield, large waste and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: basic structural form

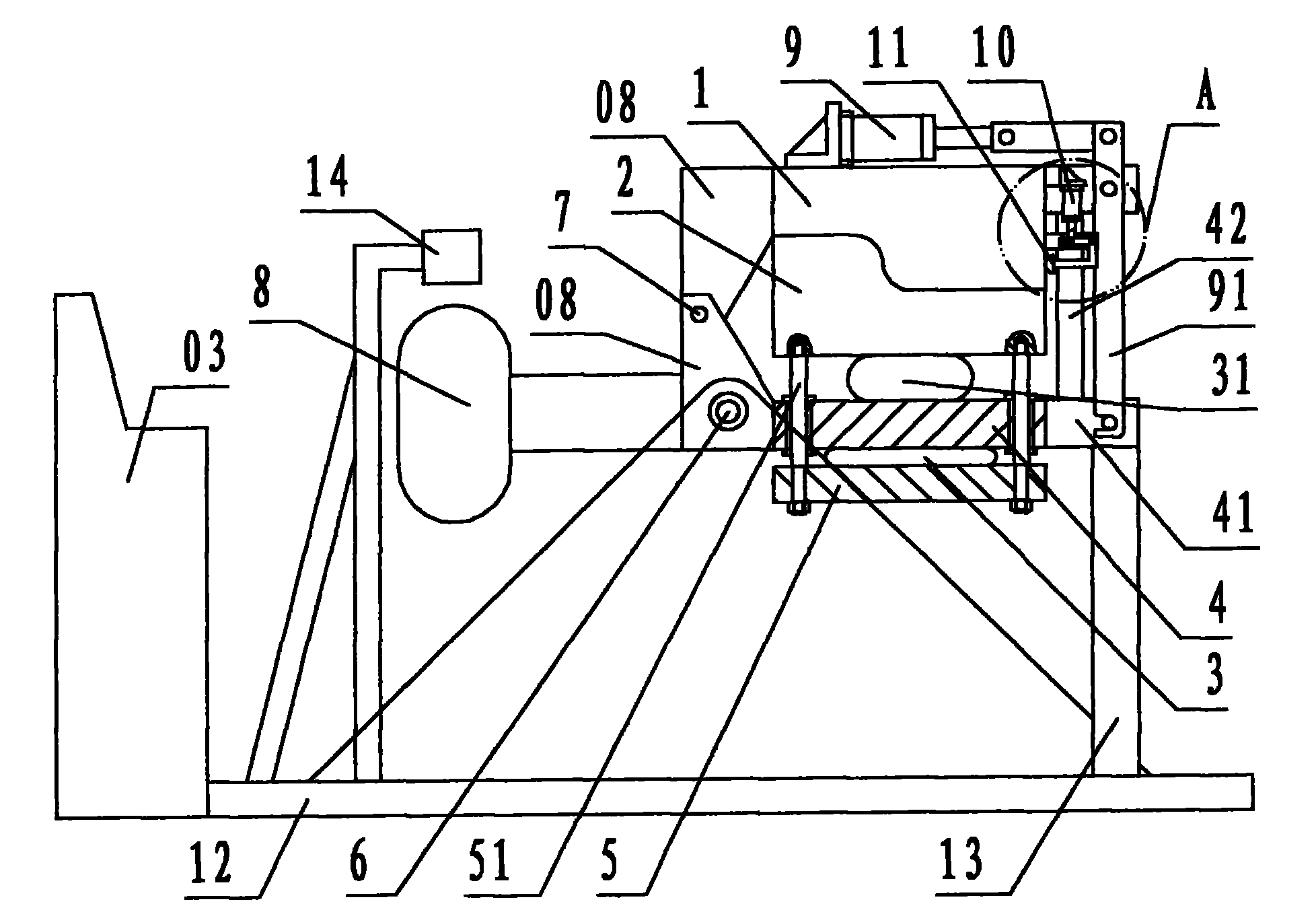

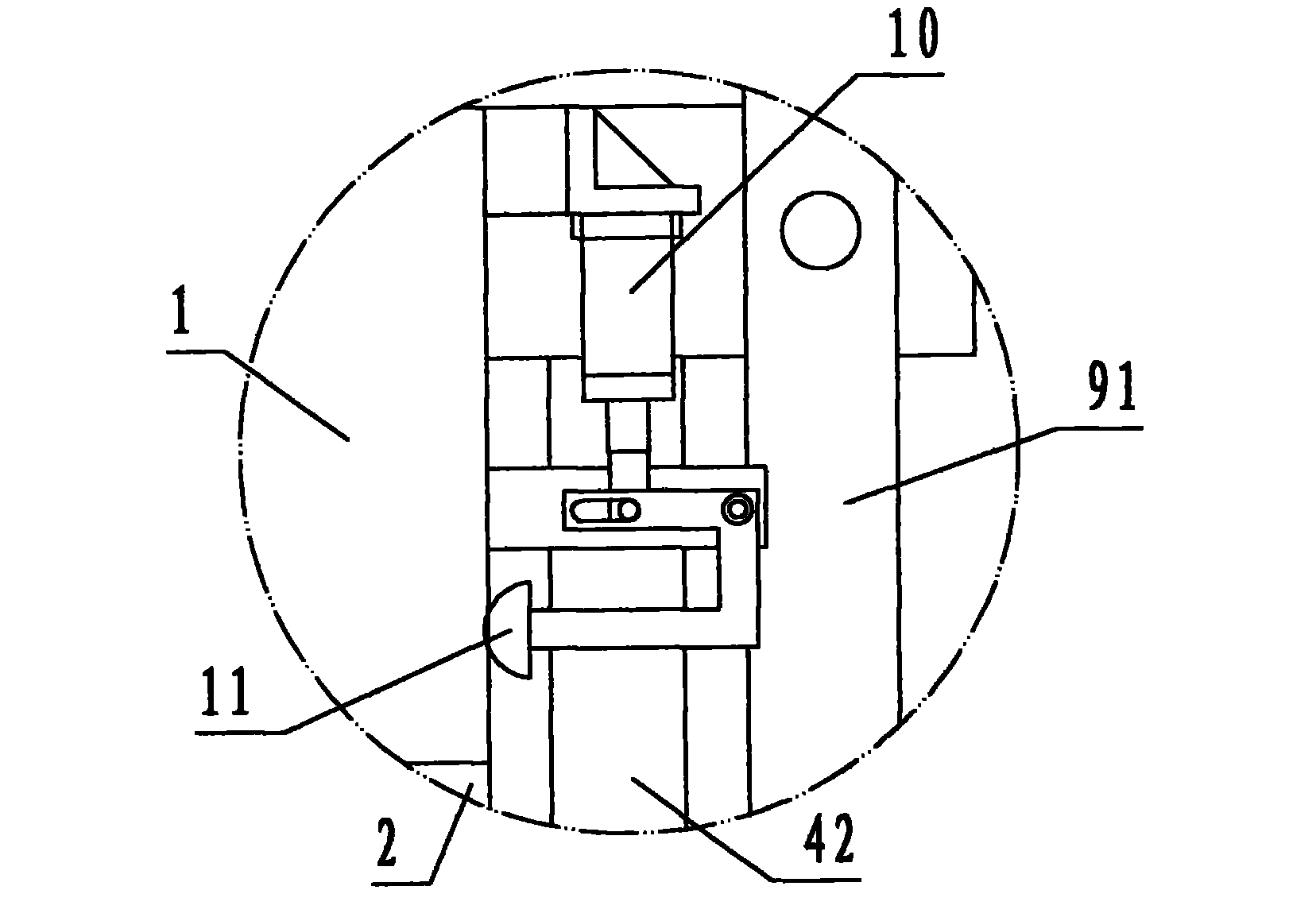

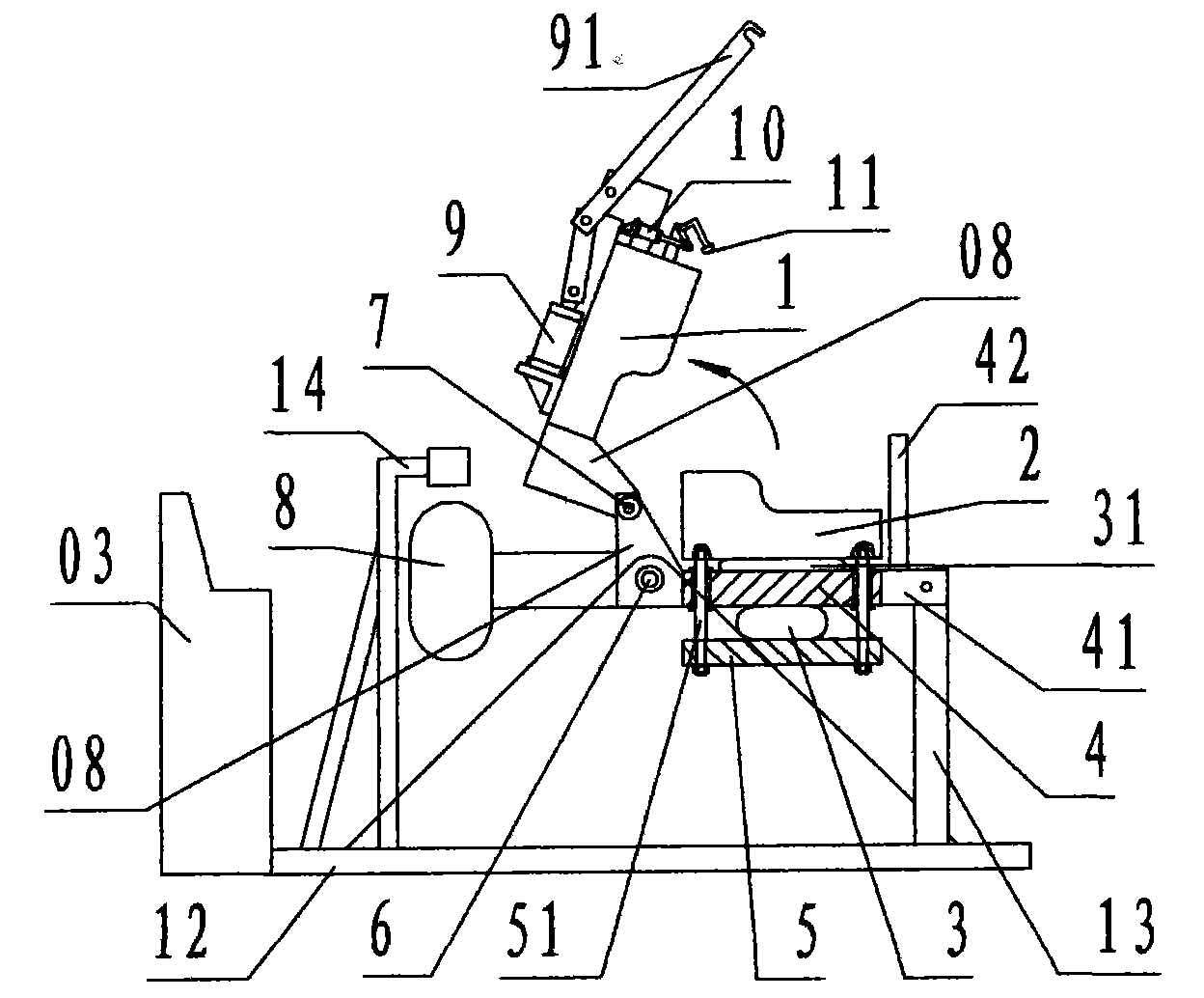

[0030] refer to Figure 1 to Figure 10, a pneumatic airbag type semi-automatic polyurethane foam molding device of the present invention, comprising a mold part, a pneumatic mold clamping part, a pneumatic sealing part, a rotating support part, and an electrical control part, wherein: the mold part is composed of the above Mold 1 and movable mold 2 are composed of upper mold 1 at the top and movable mold 2 at the bottom. Upper mold 1 and movable mold 2 are respectively equipped with half-valve cavities for the product, and cooperate with each other up and down through the corresponding parting surface; The inner cavity wall of the mold 1 is provided with a vent hole leading directly to the outer wall of the upper mold, and the front and rear sides of the left side of the upper mold 1 are provided with an extended pivot plate 08 with a shaft hole, and the pivot plate 08 of the upper mold 1 The opening and closing pivot 7 of the pneu...

Embodiment 2

[0039] Embodiment 2: Pneumatic airbag type semi-automatic polyurethane foam molding device for automobile seat backrest

[0040] refer to Figure 11 , Figure 12 , as shown in the figure, on the basis of the basic structure of Example 1, according to the specific car seat pillow products and operating requirements, additional mold feet 01, self-locking handle 02, button switch 04, rotating core 05, core Rocker 06, core lock pin 07 and other mechanism devices;

[0041] Before clamping the mold, manually rotate the core handle 06 to rotate the rotating core 05 and insert it into the cavity of the upper mold 1, and the core locking pin 07 automatically locks the rotating core 05 by spring and pawl;

[0042] When taking out product 09, mention core lock pin 07, manual core rocker 06, rotate core 05 together with product 09 and turn out the cavity of upper mold 1, product 09 is extracted from rotating core 05 manually.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com