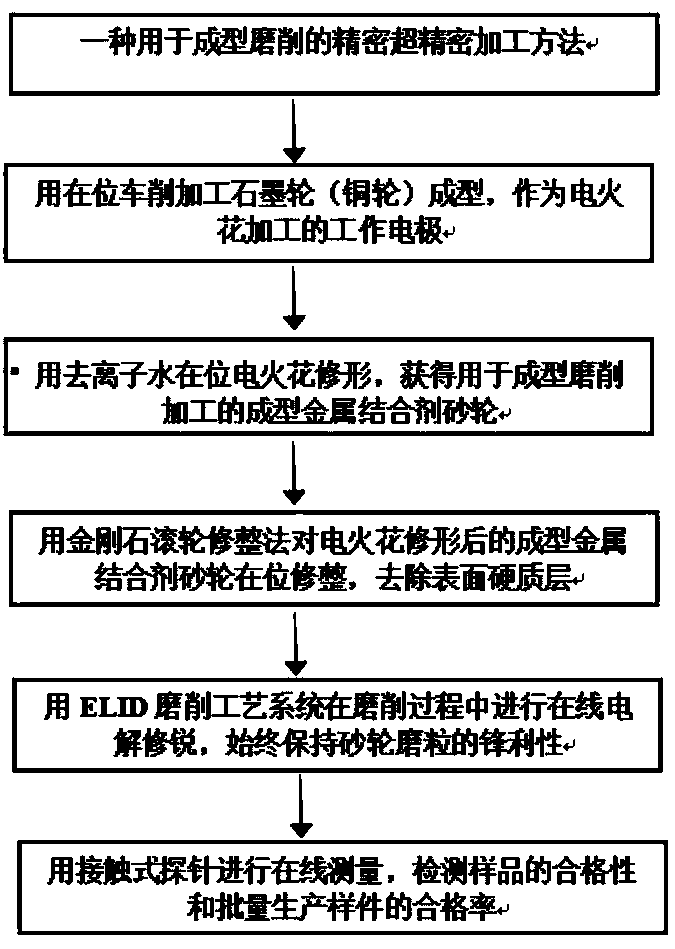

Precision ultra-precision machining method for forming grinding

A technology of ultra-precision machining and forming grinding, applied in ultra-finishing machines, metal processing equipment, manufacturing tools, etc., it can solve the problems of difficulty in ensuring the consistency of machining quality, poor inspection and surface quality, and achieve high-quality Consistency, high quality and consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

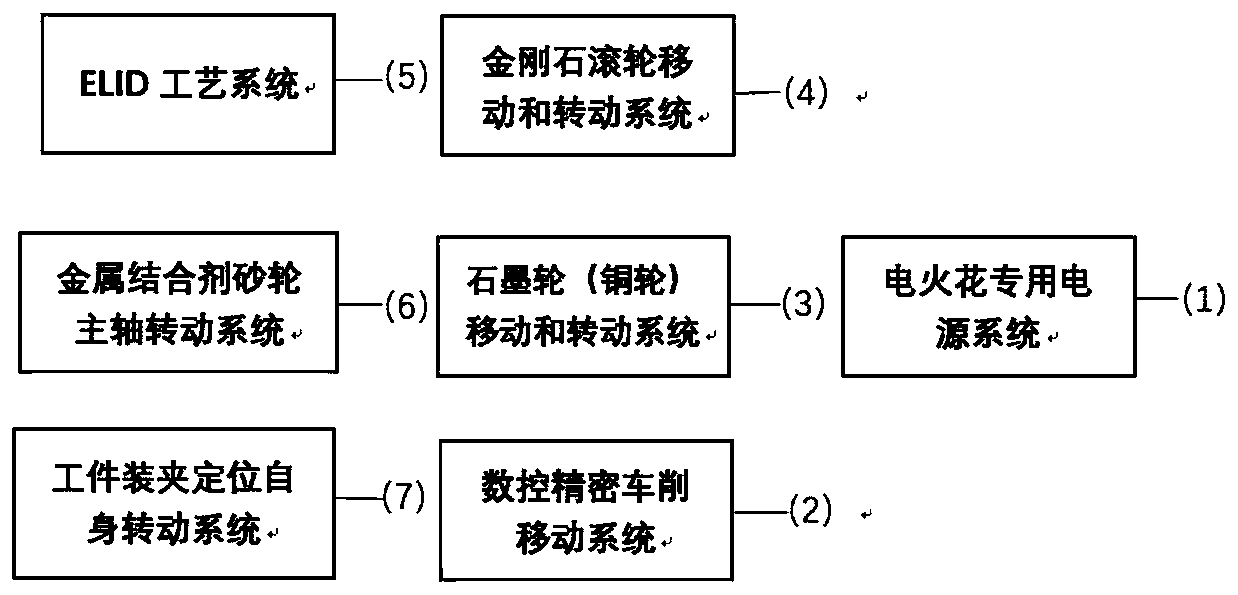

Method used

Image

Examples

example 1

[0032] Example 1: Example of forming and grinding the inner raceway of the outer ring of the bearing

[0033] ⑴Technical background

[0034] The processing technology used for the inner raceway of the traditional bearing outer ring is ultra-precision grinding with fine-grained whetstone after grinding with a shaped grinding wheel. Although the whetstone precision grinding process can significantly improve the surface quality and accuracy of the workpiece, it still has low processing efficiency and surface quality. Problems such as burns, cracks, and poor consistency of raceway dimensions. In the finishing processing of large and medium-sized bearing raceways, due to the large processing area, high roughness of the original surface, and large processing allowance, the mold blockage is more serious. It is urgent to improve the processing accuracy and processing quality of the surface of the bearing raceway, and to innovate and develop a new processing method for the inner racew...

example 2

[0041] Example 2: "Precise progressive" grinding removal method to process bearing manganese steel to ensure the consistency of processing quality optimization control experiment

[0042] (1) Experimental conditions:

[0043]

[0044] According to the ELID grinding principle and removal mechanism and the "precise progressive" processing method, 10 bearing manganese steel samples were used to conduct the "precise progressive" surface processing quality consistency control optimization experiment.

[0045] (2) Experimental method

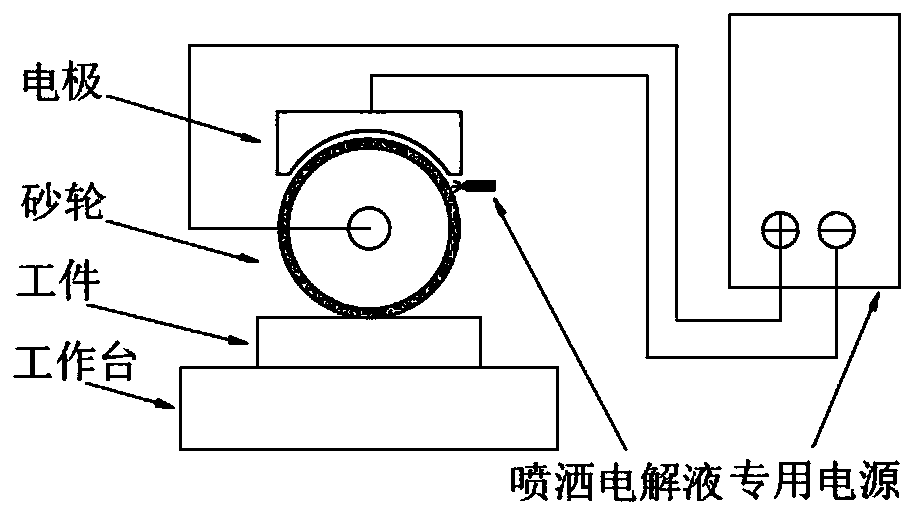

[0046] Such as image 3 As shown in the principle of ELID grinding and removal, the ELID grinding experiment of 10 bearing manganese steel samples is carried out on the basis of the existing conditions, and the manganese steel samples are placed on the horizontal test bench. 2500r / min, feed rate 5m / min, magnification 50%, electrolysis voltage 60V, electrolysis gap 0.4-1mm, choose w10 particle size iron-based bond grinding wheel for grinding remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com