Assembly processing method of SC battery

A processing method and battery technology, applied in secondary batteries, alkaline storage batteries, secondary battery manufacturing, etc., can solve the problems of low assembly efficiency, uneven assembly quality, high defective rate, etc., and achieve high assembly processing efficiency , high quality consistency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

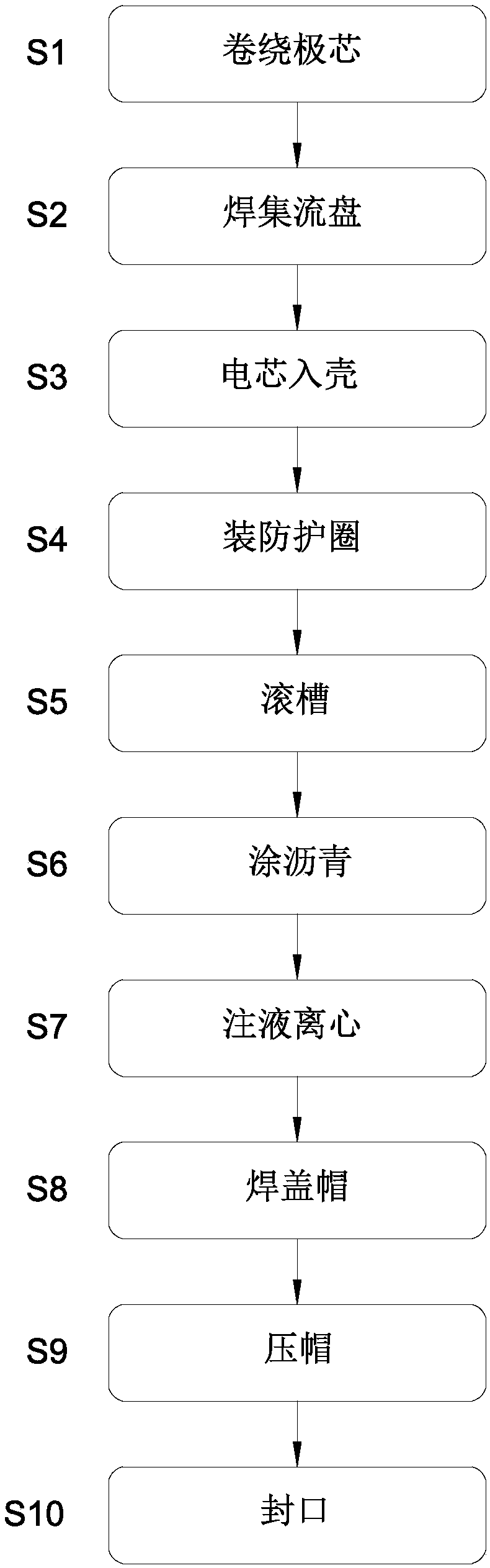

[0027] refer to figure 1 .

[0028] The embodiment of the present invention discloses a method for assembling and processing an SC battery, which includes the following steps in sequence:

[0029] S1. Winding the pole core. The winding device winds the laminated positive electrode, separator and negative electrode to obtain the pole core, and the pole core is transferred to the welding device through the transmission device;

[0030] S2. Weld the current collecting plate. The welding device welds the upper and lower ends of the pole core obtained in S1 to the two current collecting plates respectively to obtain the electric core. The concentricity between the pole core and the current collecting plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com