Patents

Literature

33results about How to "Improve assembly processing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

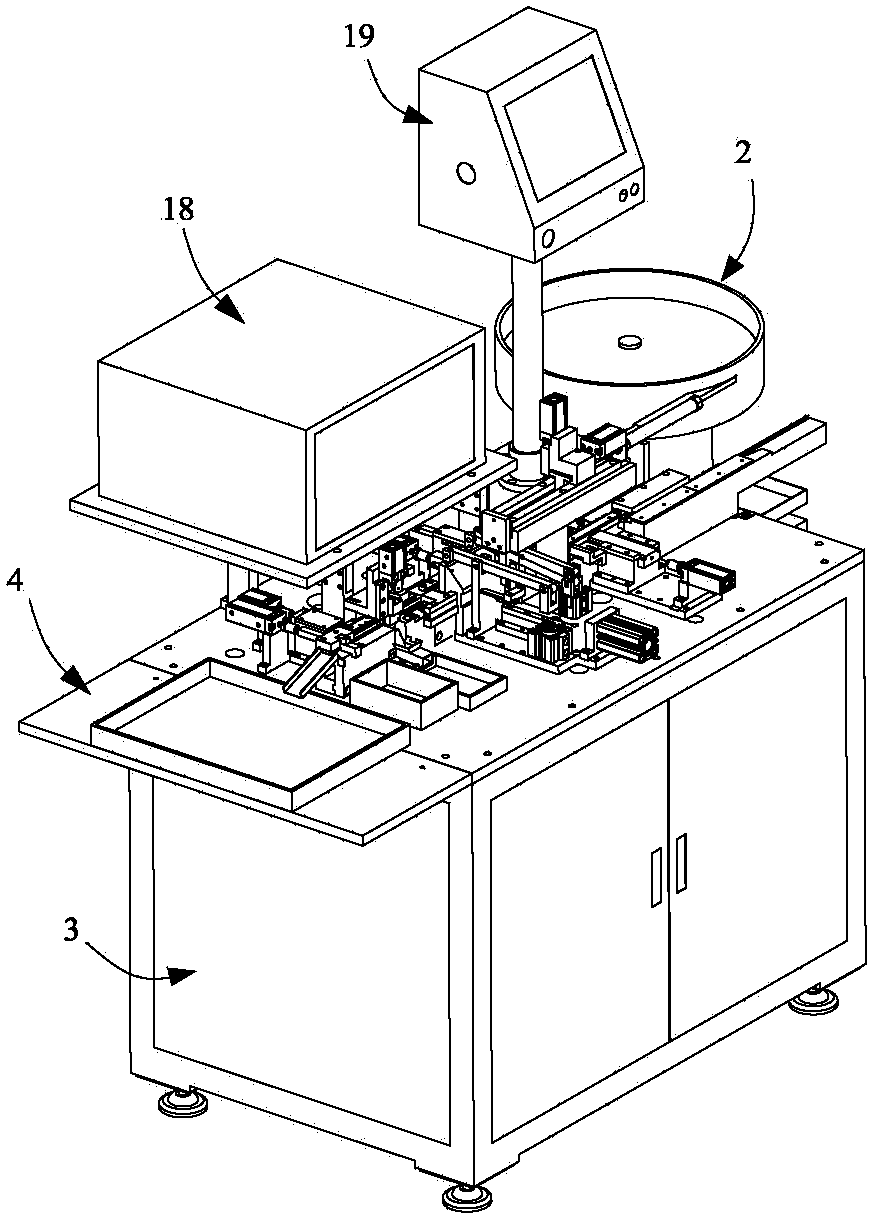

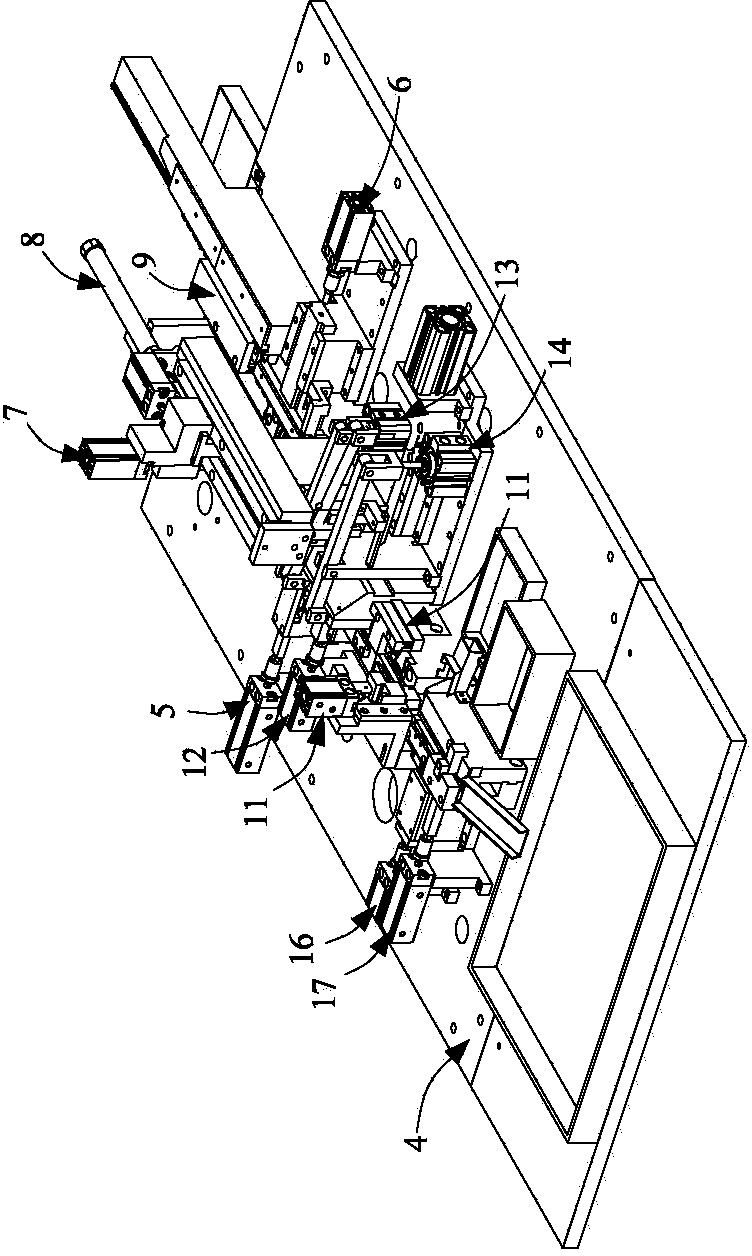

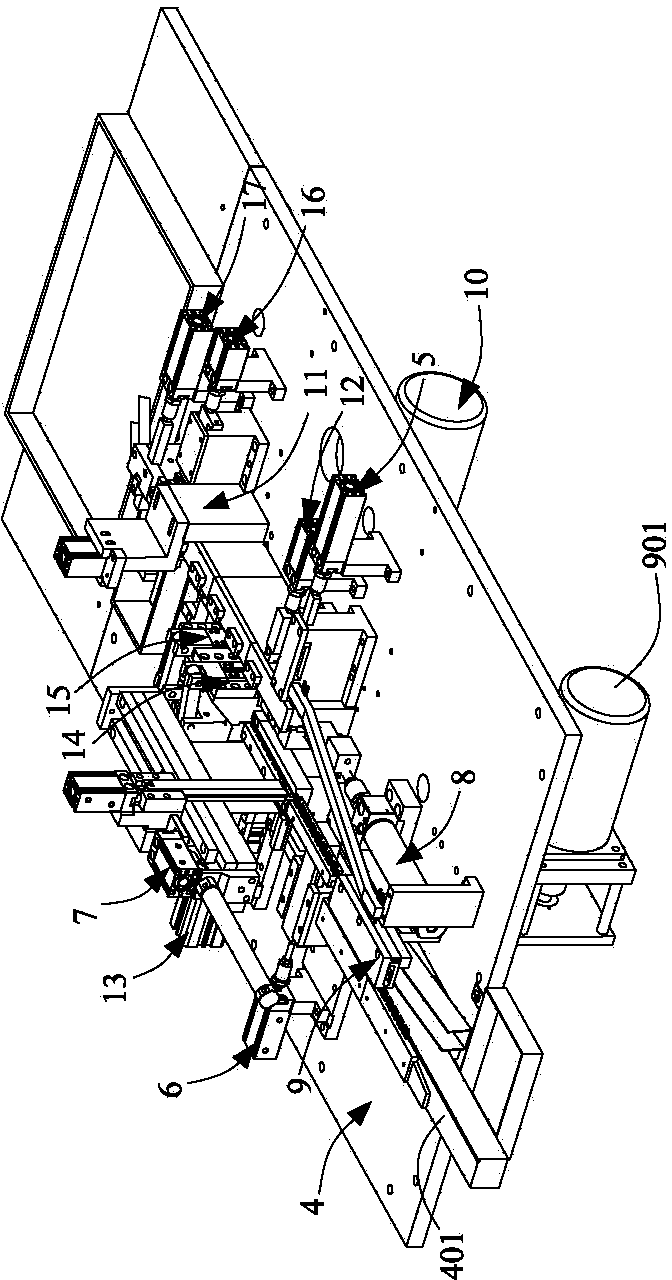

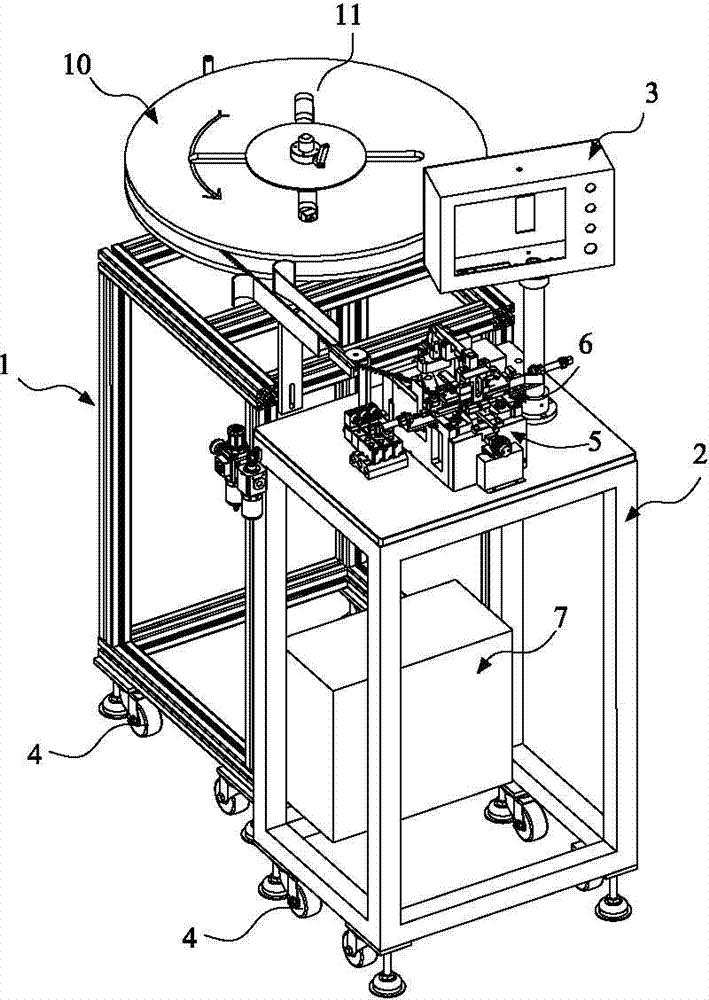

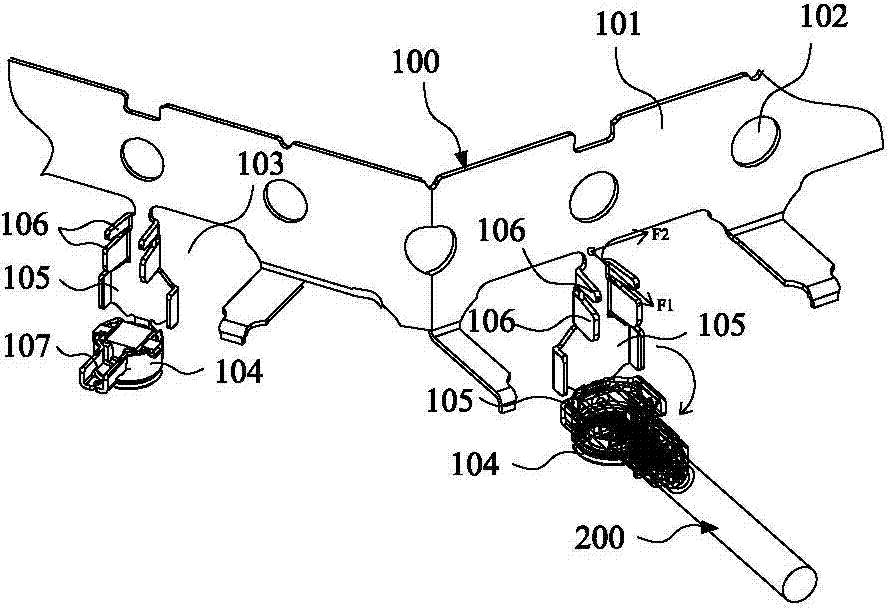

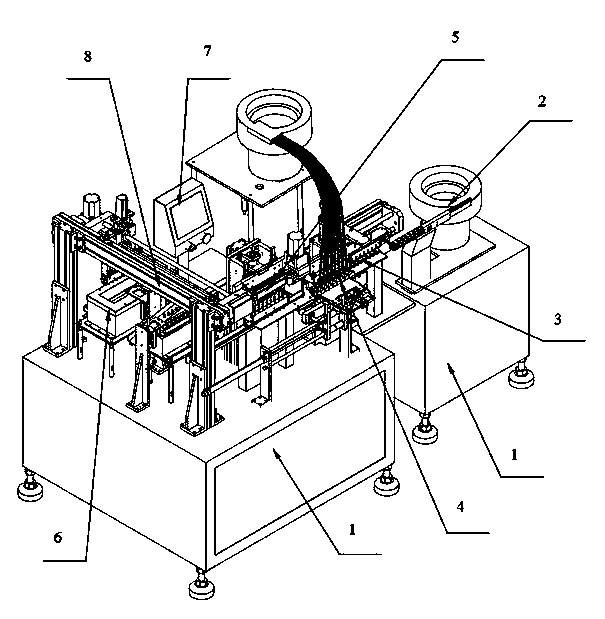

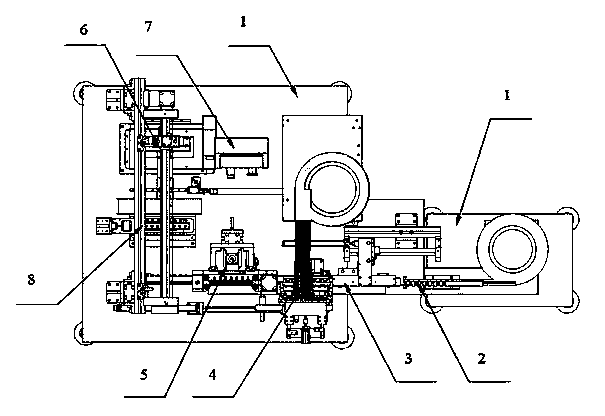

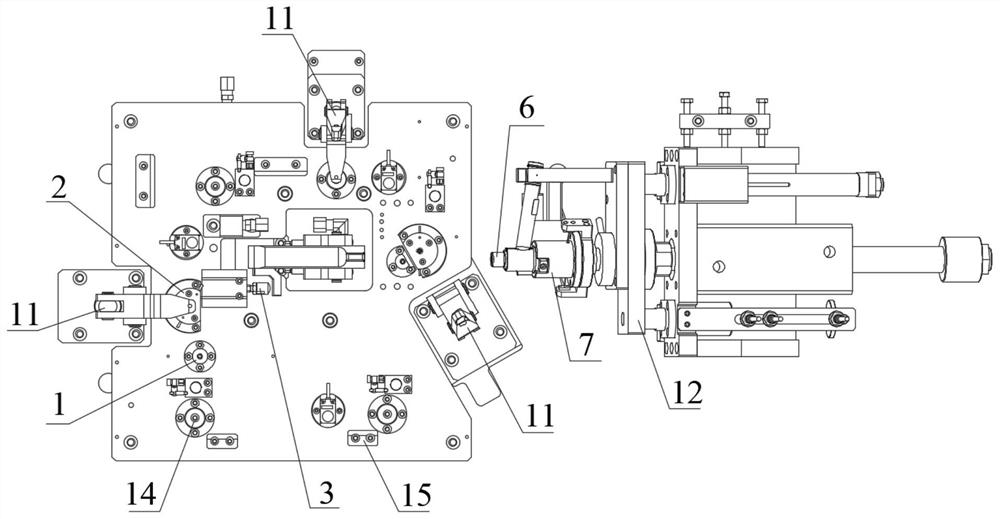

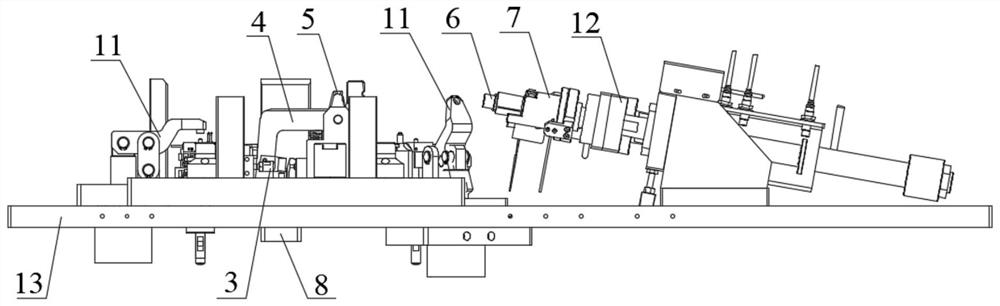

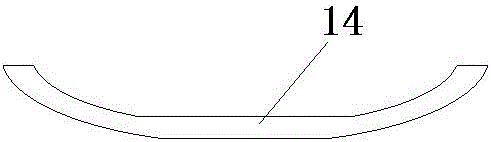

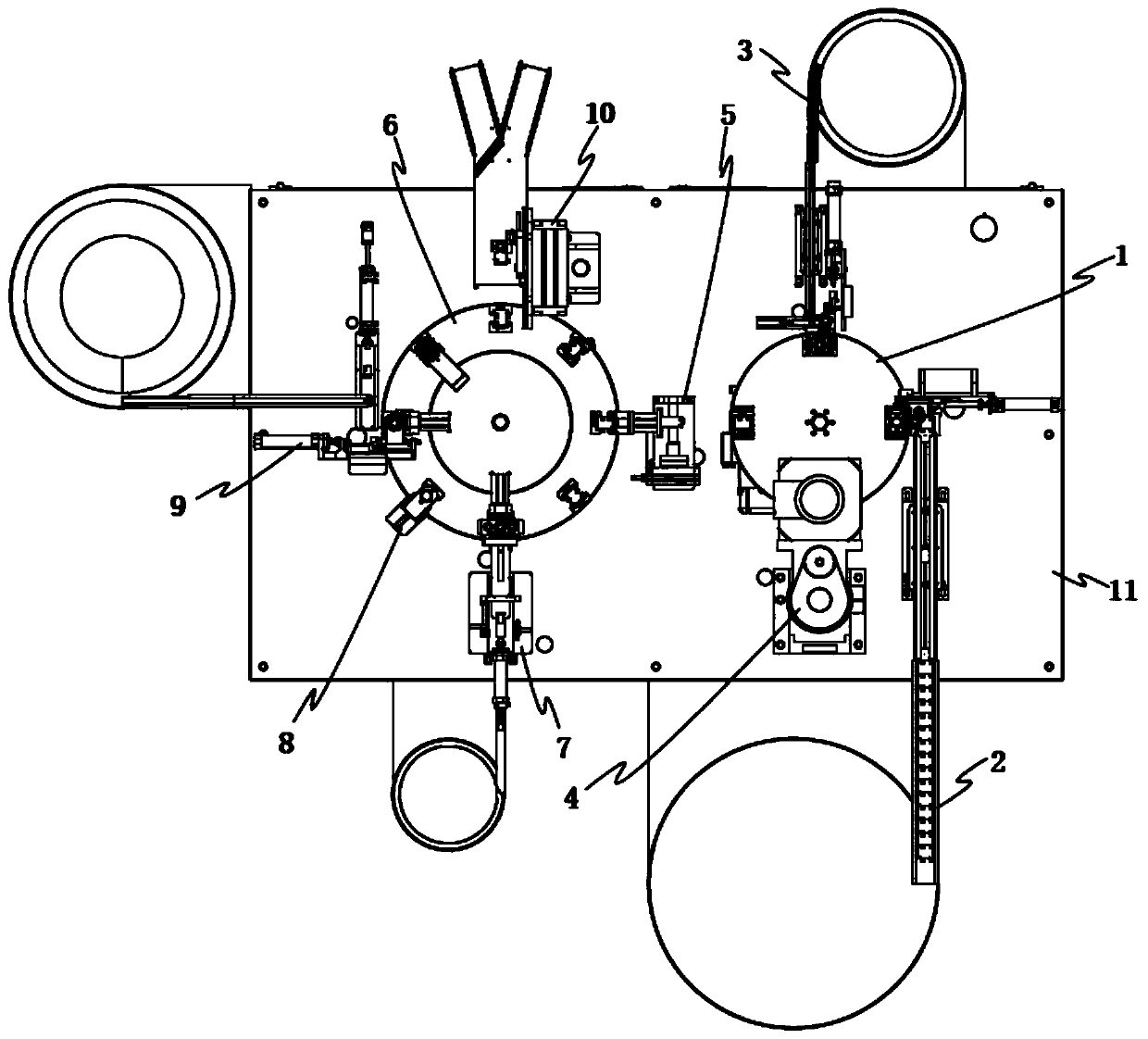

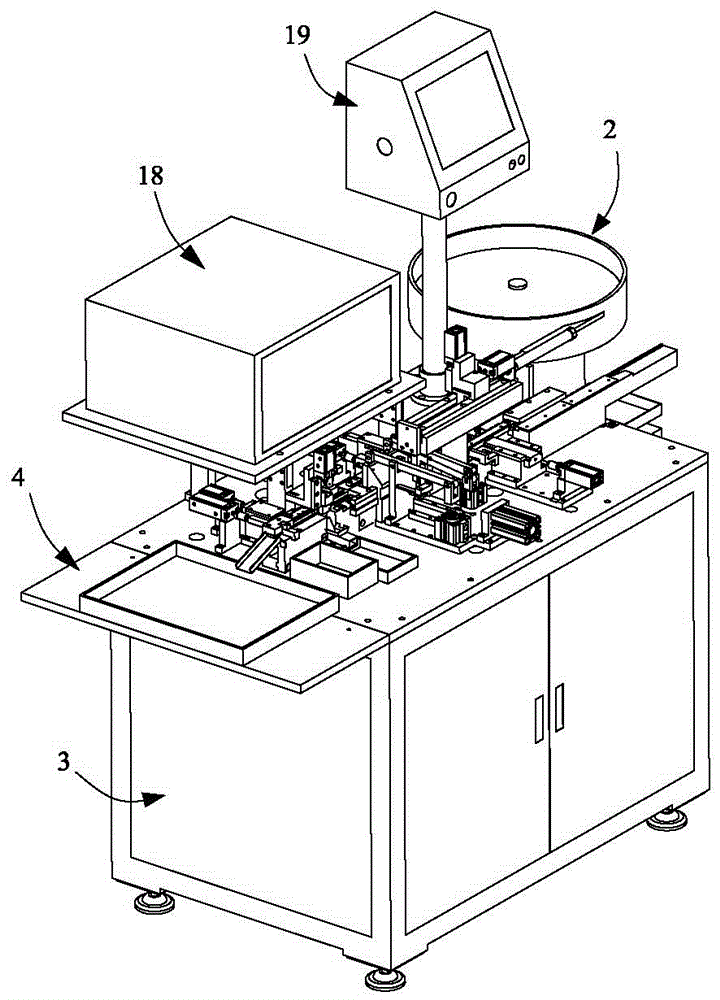

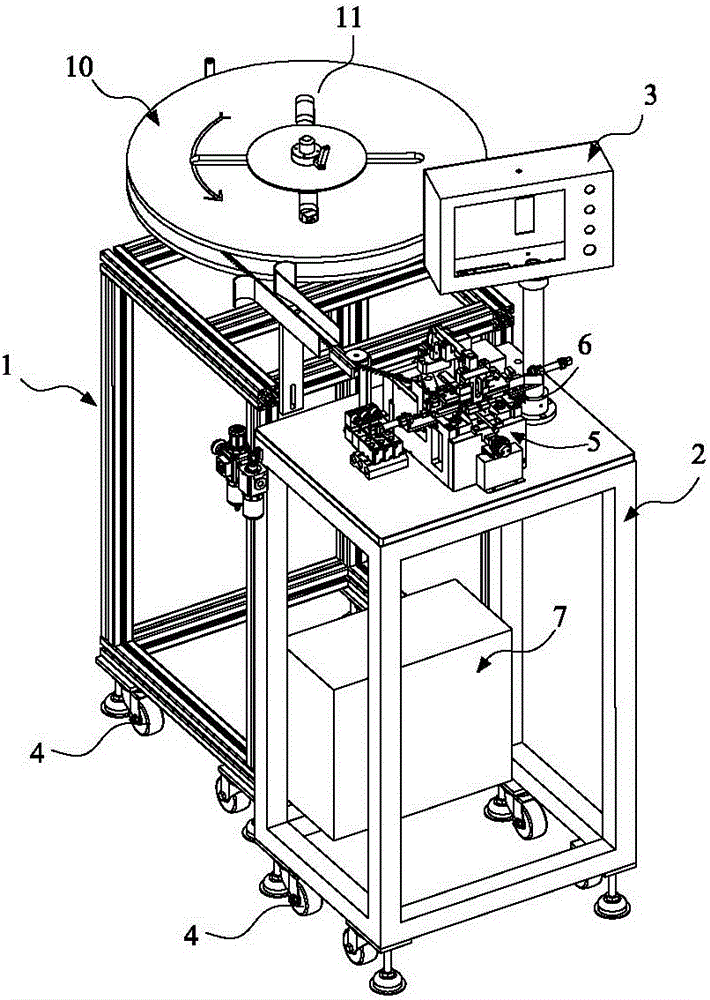

HDMI-CF electric coupler automatic assembling machine

InactiveCN103855592AImprove assembly processing efficiencyTo achieve the purpose of automated productionContact member assembly/disassemblyHDMIEngineering

The invention discloses an HDMI-CF electric coupler automatic assembling machine. A vibration disk is arranged and a first feeding mechanism is arranged on an operating platform, so automatic feeding of metal shells can be achieved; a second feeder and a third feeder are arranged on the operating platform, so automatic feeding of rubber core material strips can be achieved; in addition, when the rubber core material strips are fed, a first material cutting mechanism can cut off wastes at head ends of the rubber core material strips; through a metal shell fixing mechanism and a rubber core inserting mechanism, rubber cores can be inserted into the metal shells; a rubber core correcting mechanism is arranged subsequently, so the rubber cores can be corrected; a clamping point riveting mechanism can rivet clamping points of the metal shells and enable the rubber cores not to retreat; a material strip pre-cutting mechanism works in cooperation with a second material cutting mechanism to cut off the material strips at the back ends of the rubber cores to obtain finished products; the finished products are conveyed to a detection mechanism for automatic quality and performance detection, qualified products can be used for feeding directly, unqualified products can be conveyed to an unqualified product collection box through a sorting mechanism, so full-automatic production of the rubber cores and the metal shells can be achieved.

Owner:DONGGUAN KECHENDA ELECTRONICS TECH

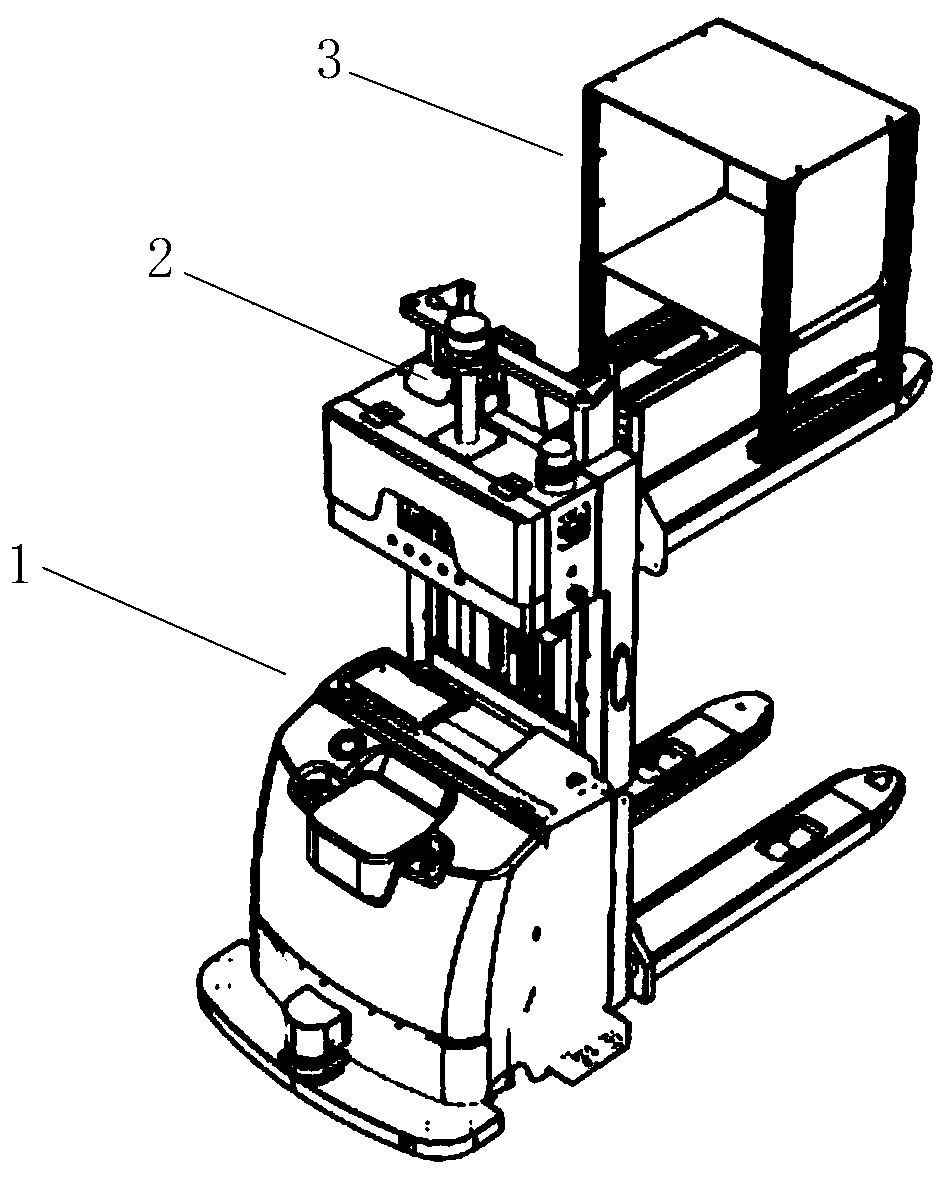

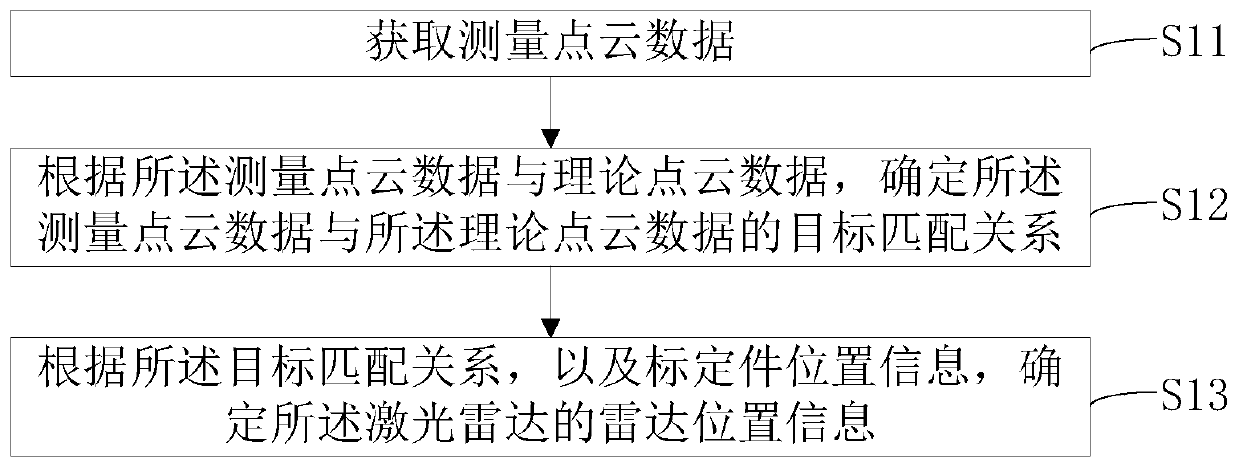

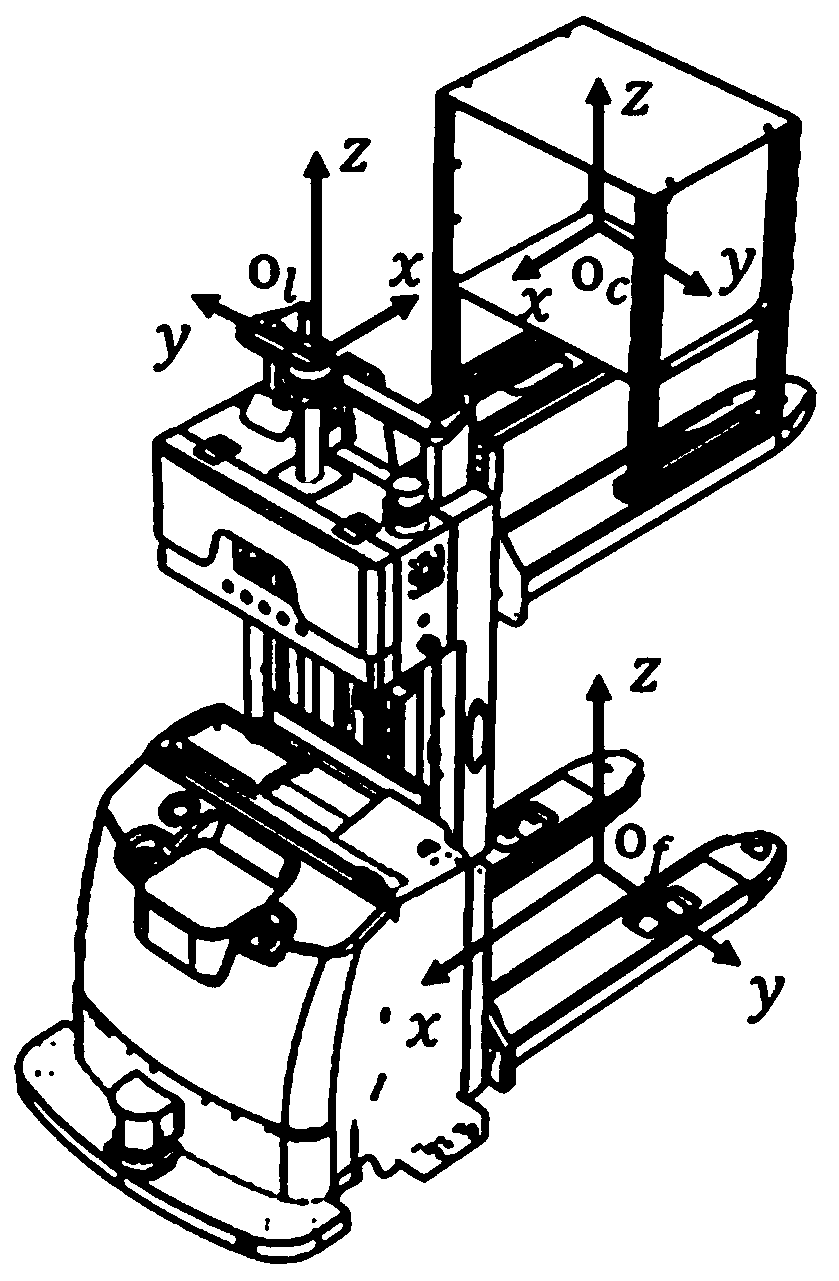

Laser radar position calibration method and system and data processing method and system thereof

InactiveCN110132130AAvoid improper guidanceImprove assembly processing efficiencyUsing optical meansEnvironmental geologyData processing

The invention provides a laser radar position calibration method and system and a data processing method and system thereof. The laser radar position calibration method comprises the following steps of: acquiring measurement point cloud data, wherein the measurement point cloud data is generated by scanning a calibration piece arranged on a vehicle by a laser radar arranged on the vehicle, the projection of the calibration piece on the horizontal plane is matched with the projection of the vehicle on the horizontal plane, and the height of the calibration piece after adjustment is matched withthe height of the laser radar; determining a target matching relation between the measurement point cloud data and the theoretical point cloud data according to the measurement point cloud data and the theoretical point cloud data; and determining radar position information of the laser radar according to the target matching relation and the position information of the calibration piece, whereinthe radar position information is used for representing the position of the laser radar relative to the AVG center. During AVG guiding, the laser radar position calibration method and system and the data processing method and system thereof are not influenced by factors such as machining precision, assembly tolerance, manual operation and the like during installation.

Owner:上海宾通智能科技有限公司

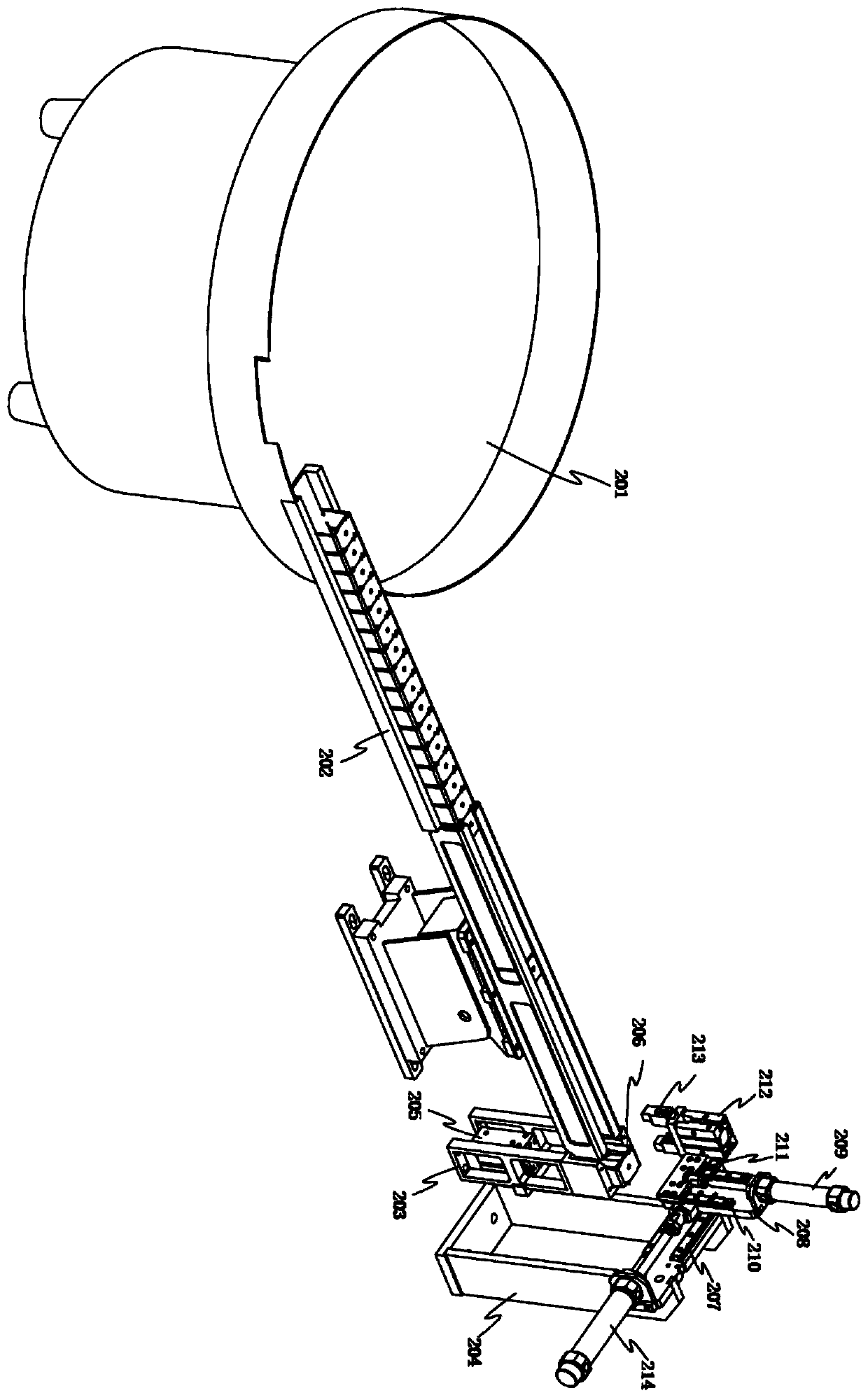

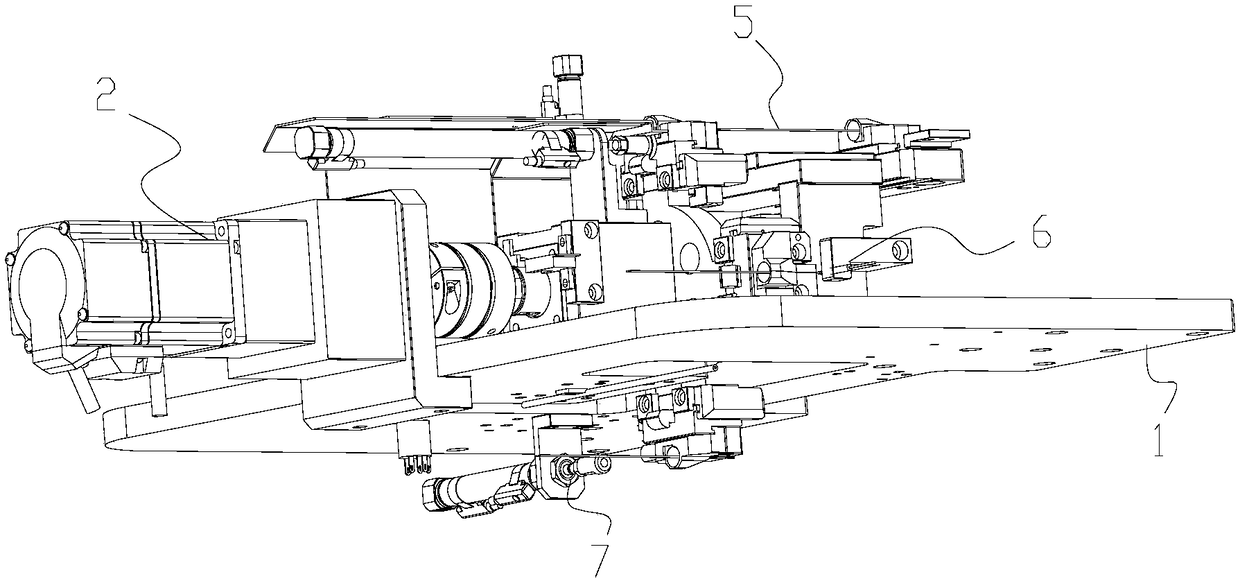

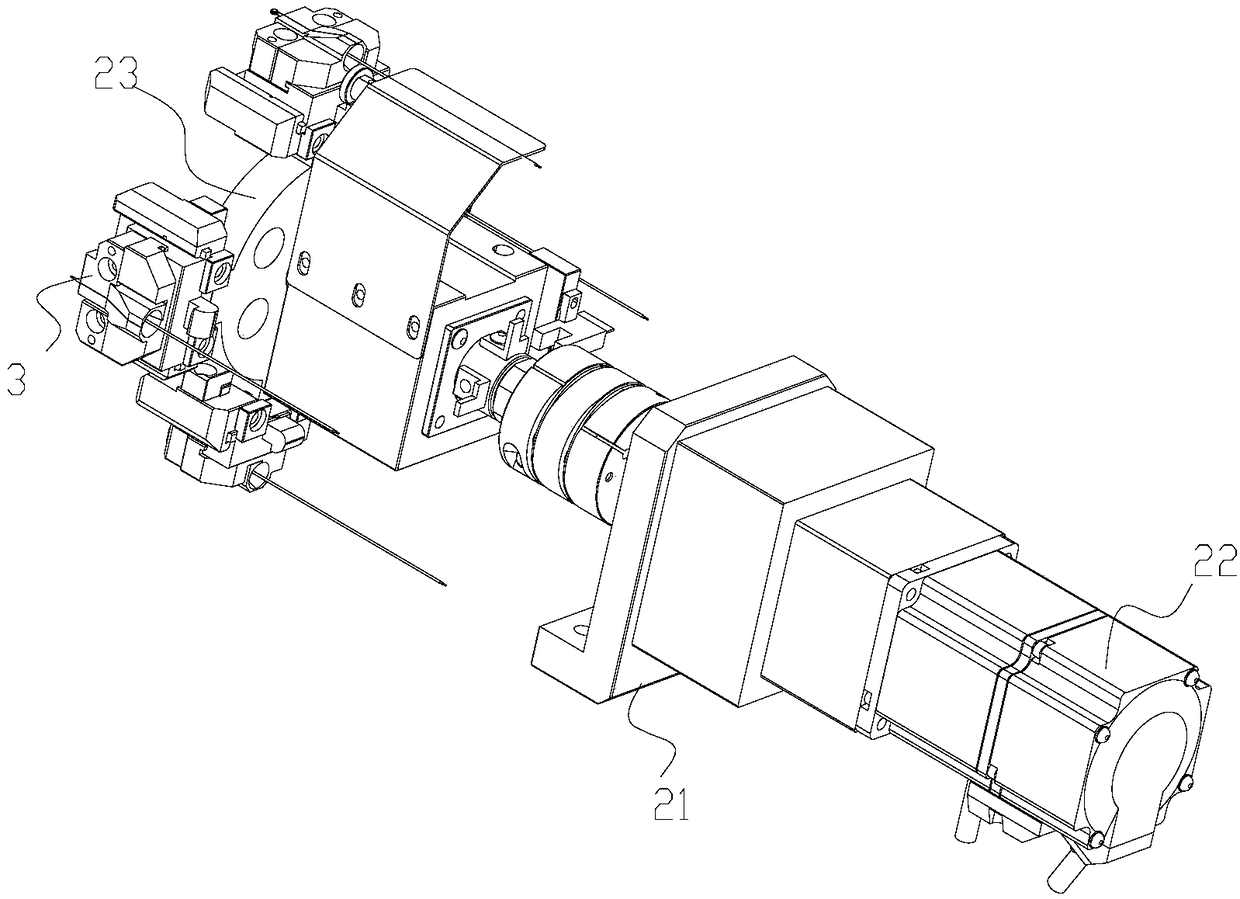

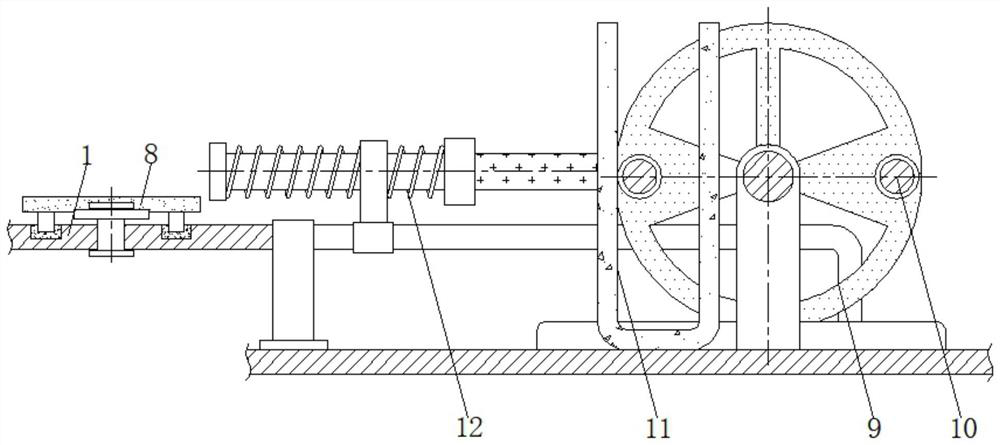

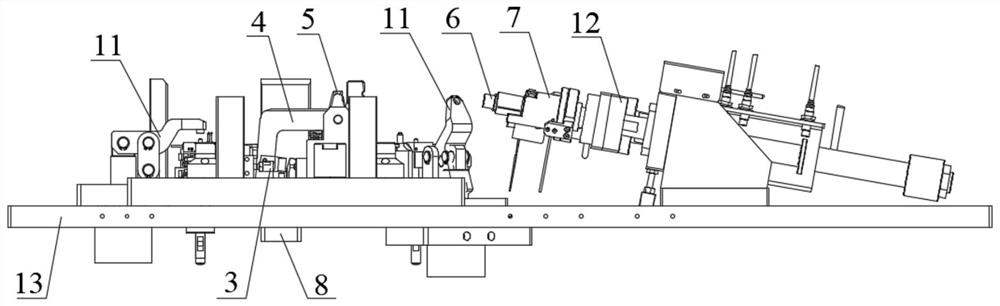

Full-automatic wire riveting machine and wire riveting method applying same

InactiveCN103701010AImprove assembly processing efficiencyReduce labor costsLine/current collector detailsDisplay deviceCam

The invention discloses a full-automatic wire riveting machine and a wire riveting method applying the same. The wire riveting machine is simultaneously provided with a feeding device, a display device, a material pulling device, a clamping device, a pay-off unit, a cam driving device, an upwards-pushing locating device, a wire pressing device, a material cutting device and a riveting device, wherein the feeding device and the material pulling device are cooperated so as to convey terminal material strips automatically according to a set locus; the clamping device is used for clamping and locating a main body part of a terminal at a wire riveting station; the pay-off unit is used for towing a wire to the neighborhood of the wire riveting station; the cam driving device is used for sequentially driving the upwards-pushing locating device, the wire pressing device, the material cutting device and the riveting device to operate; when a rotating shaft is rotated for a circle, all riveting and pressing operations can be finished. The full-automatic wire riveting machine disclosed by the invention can be used for realizing automatic operation of wire and terminal riveting assembly, replacing manual assembly, effectively improving the wire assembly processing efficiency, lowering the manpower cost and ensuring that wire assembly processing is simpler and easier.

Owner:东莞市星擎电子科技有限公司

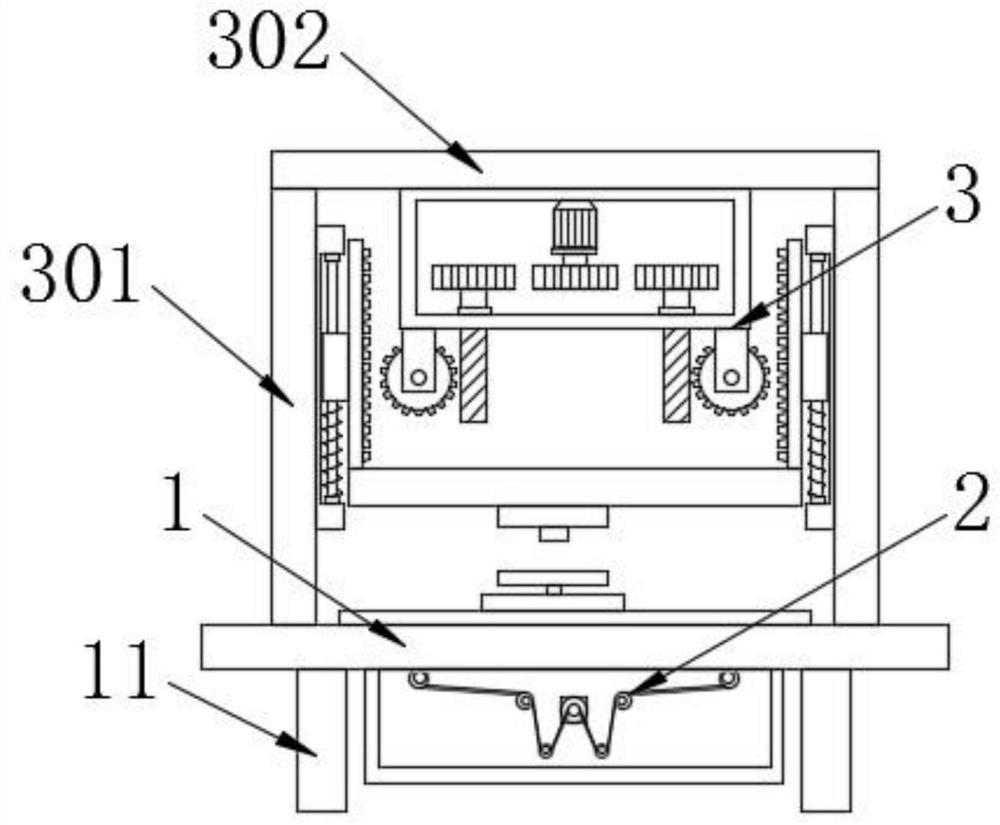

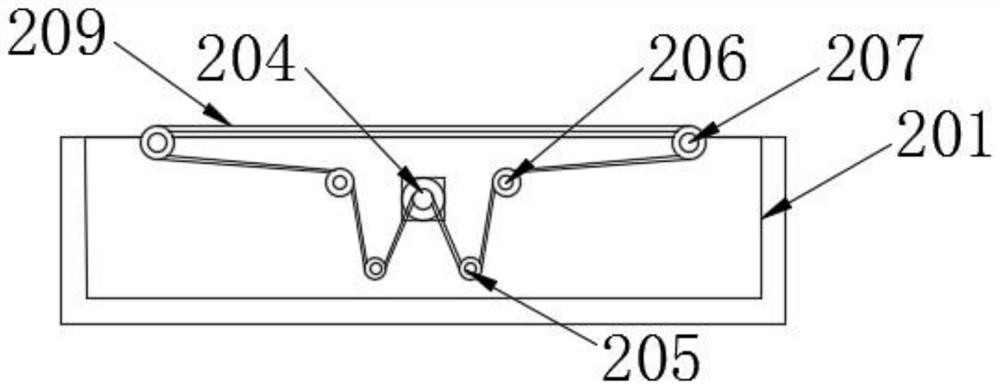

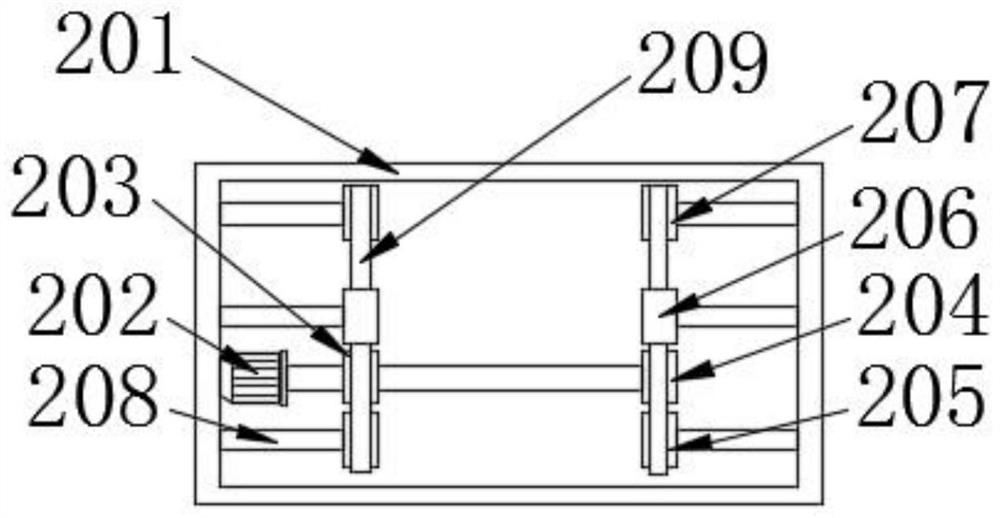

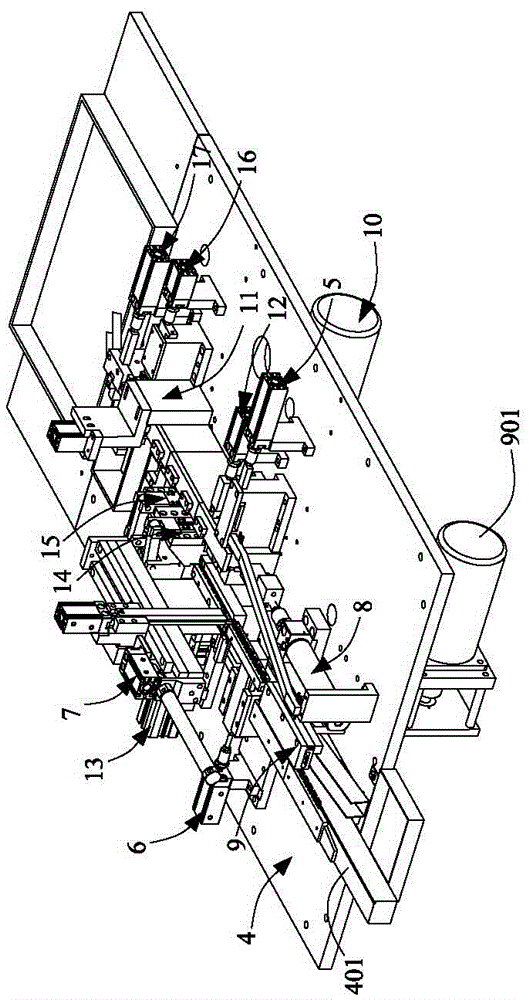

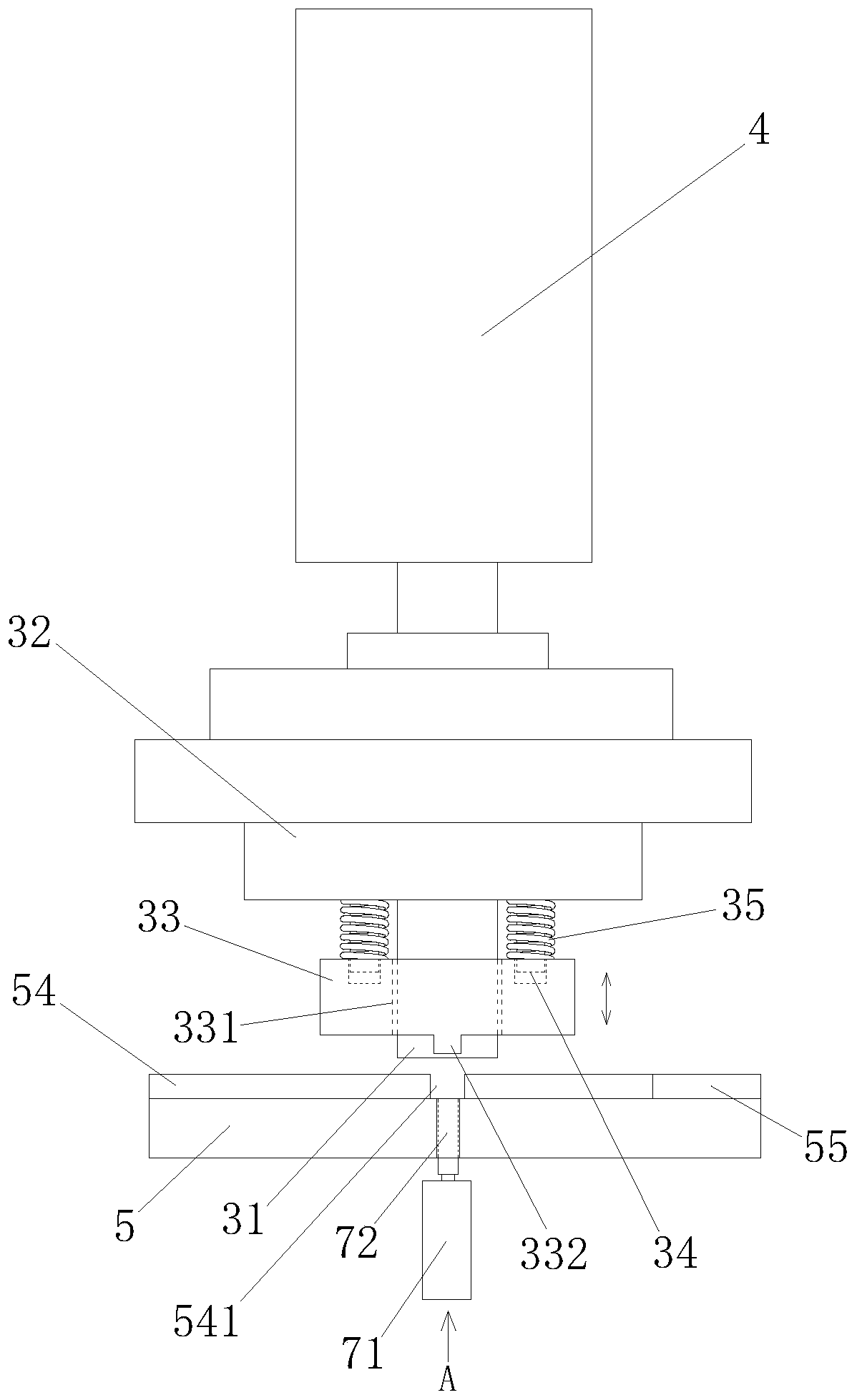

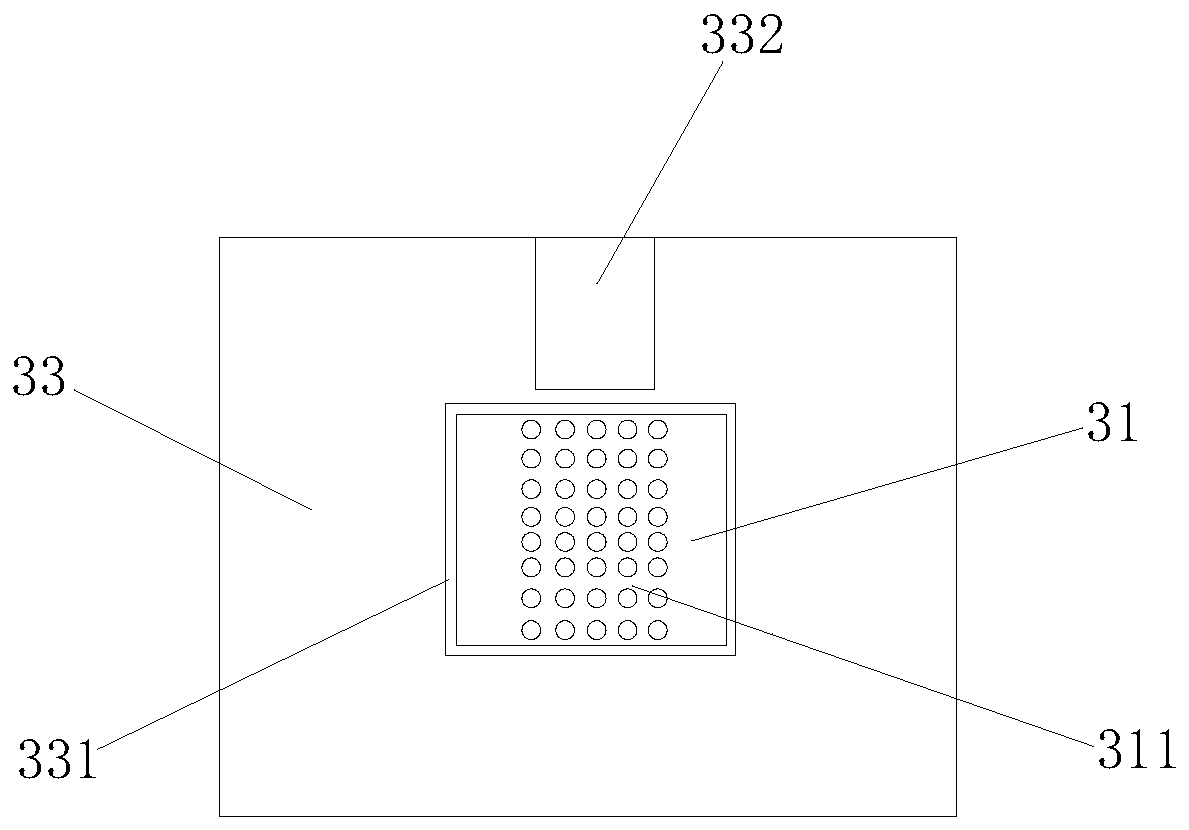

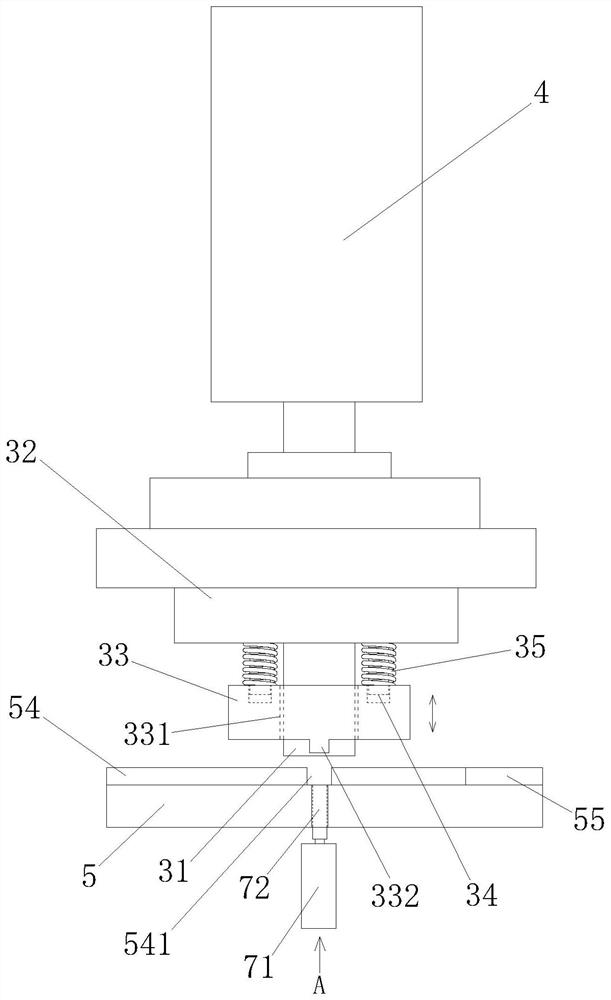

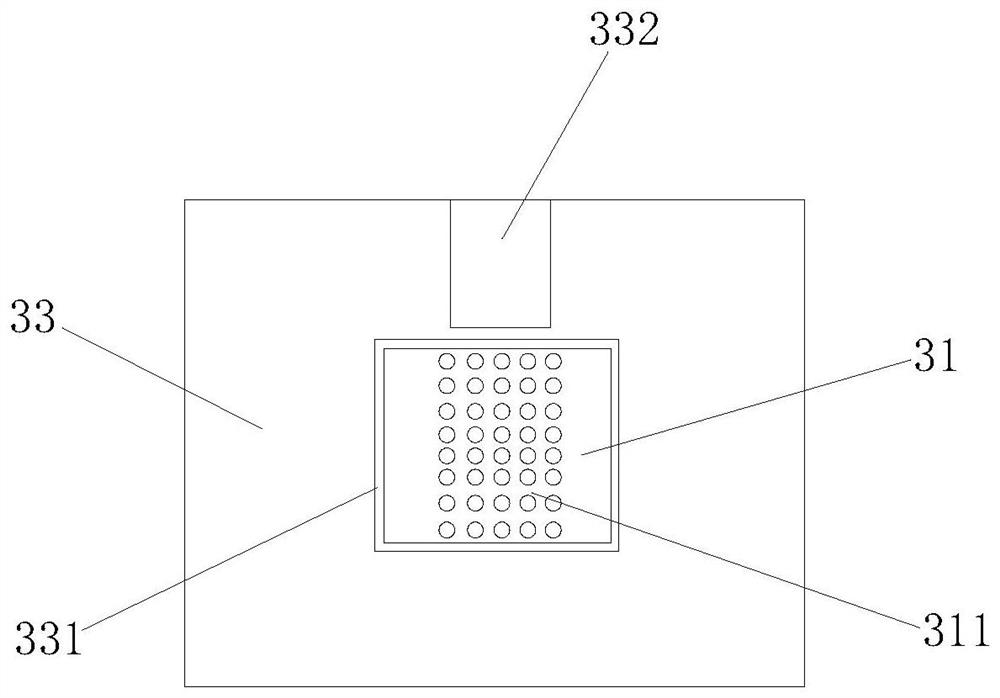

PCB assembling and processing equipment and working method thereof

ActiveCN112453896AGuaranteed stabilityAchieve movementAssembly machinesElectrical componentsProcess equipmentElectric machine

The invention discloses PCB assembling and processing equipment and a working method thereof. The PCB assembling and processing equipment comprises a workbench, wherein a conveying mechanism is arranged on the lower surface of the workbench and comprises a conveying chamber, the outer top end of the conveying chamber is fixed to the lower surface of the workbench, and a first motor is fixed to therear end wall of the interior of the conveying chamber; and a first belt wheel and a second belt wheel are fixed to the output end of the first motor and located at the rear end and the front end ofthe conveying chamber correspondingly. By arranging third belt wheels and fourth belt wheels, conveying belts are tensioned, so that the situation of insufficient power during conveying of the conveying belts is avoided, and the conveying stability of the conveying belts is guaranteed. Multiple support grooves are formed in a rotating table, so that continuous assembling of multiple PCBs is achieved, the automation degree is high, the continuity is high, and the assembling and processing efficiency is improved.

Owner:广德今腾电子科技有限公司

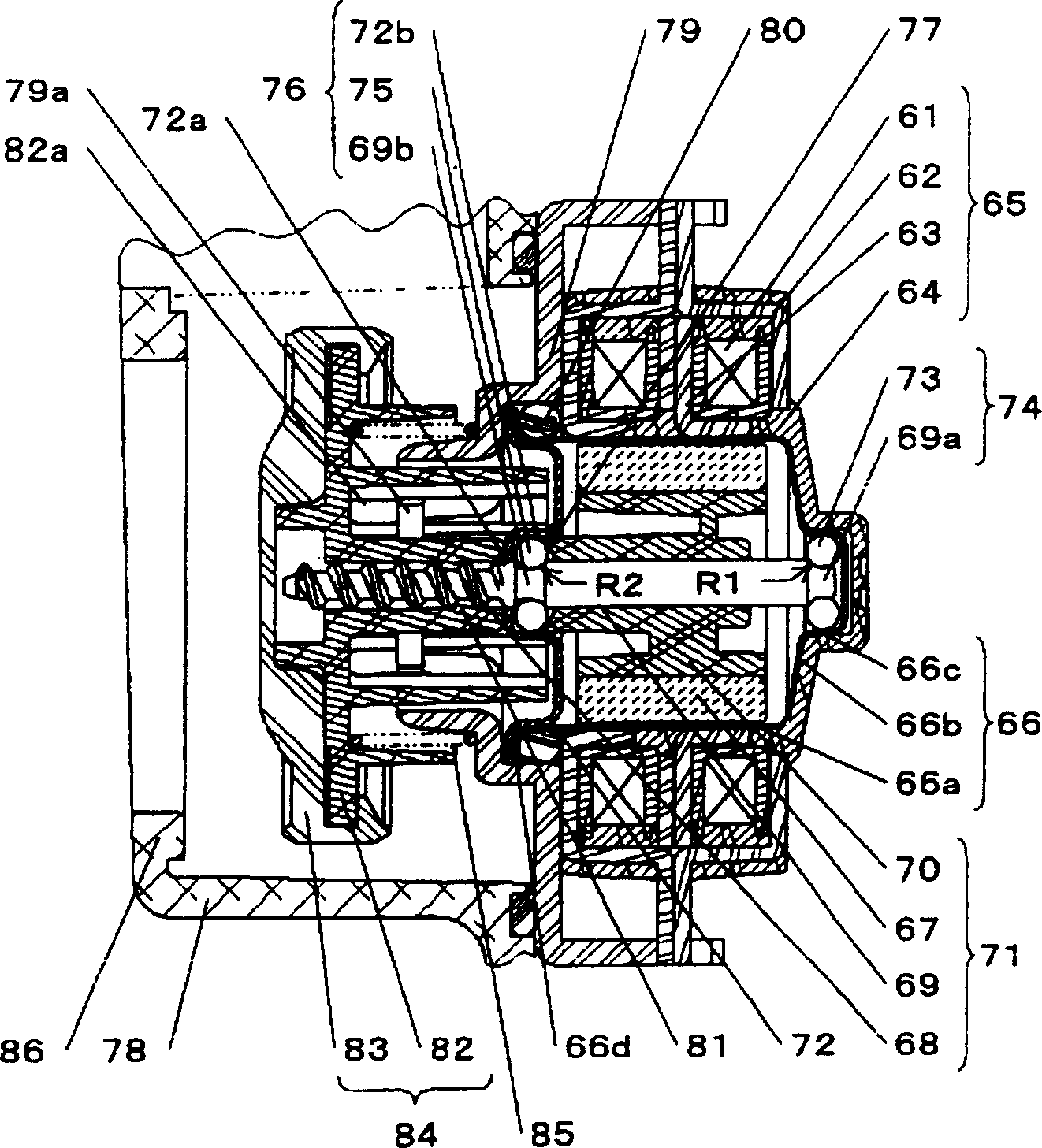

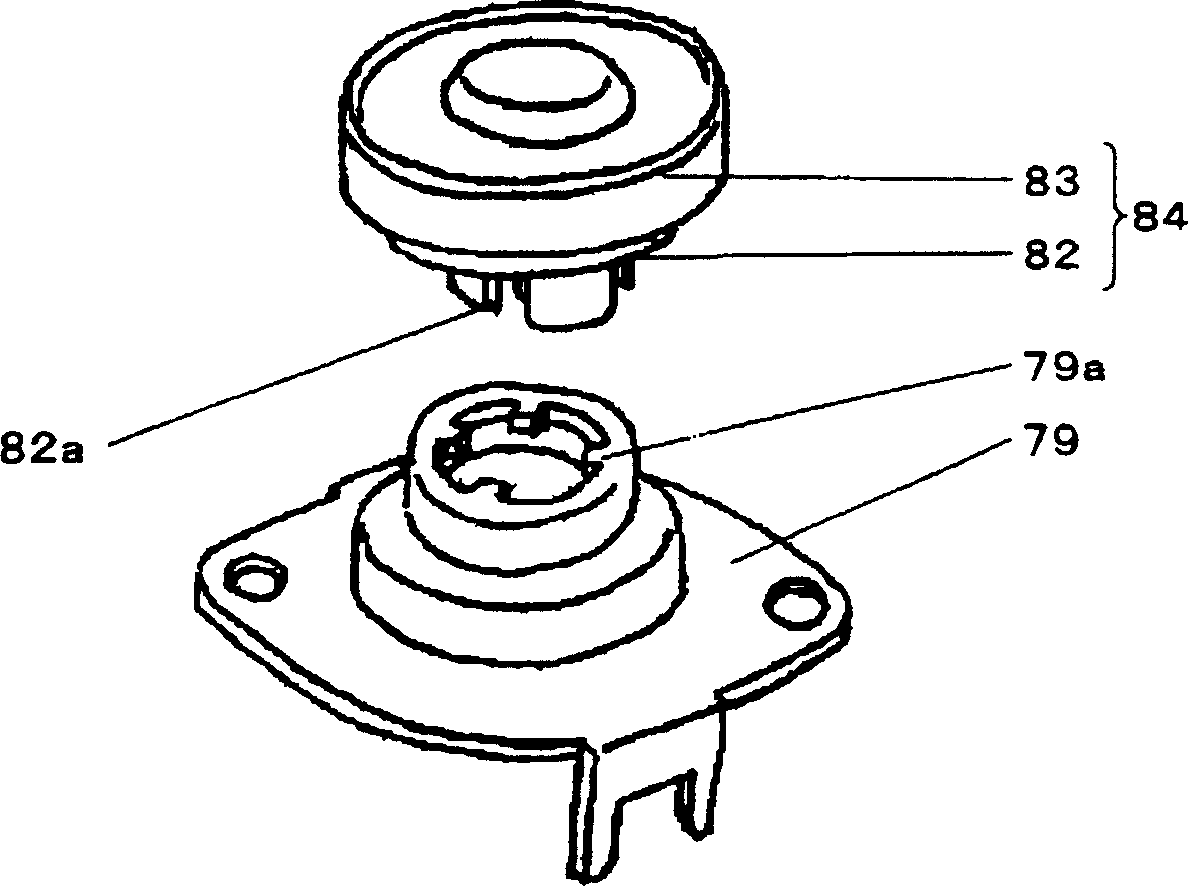

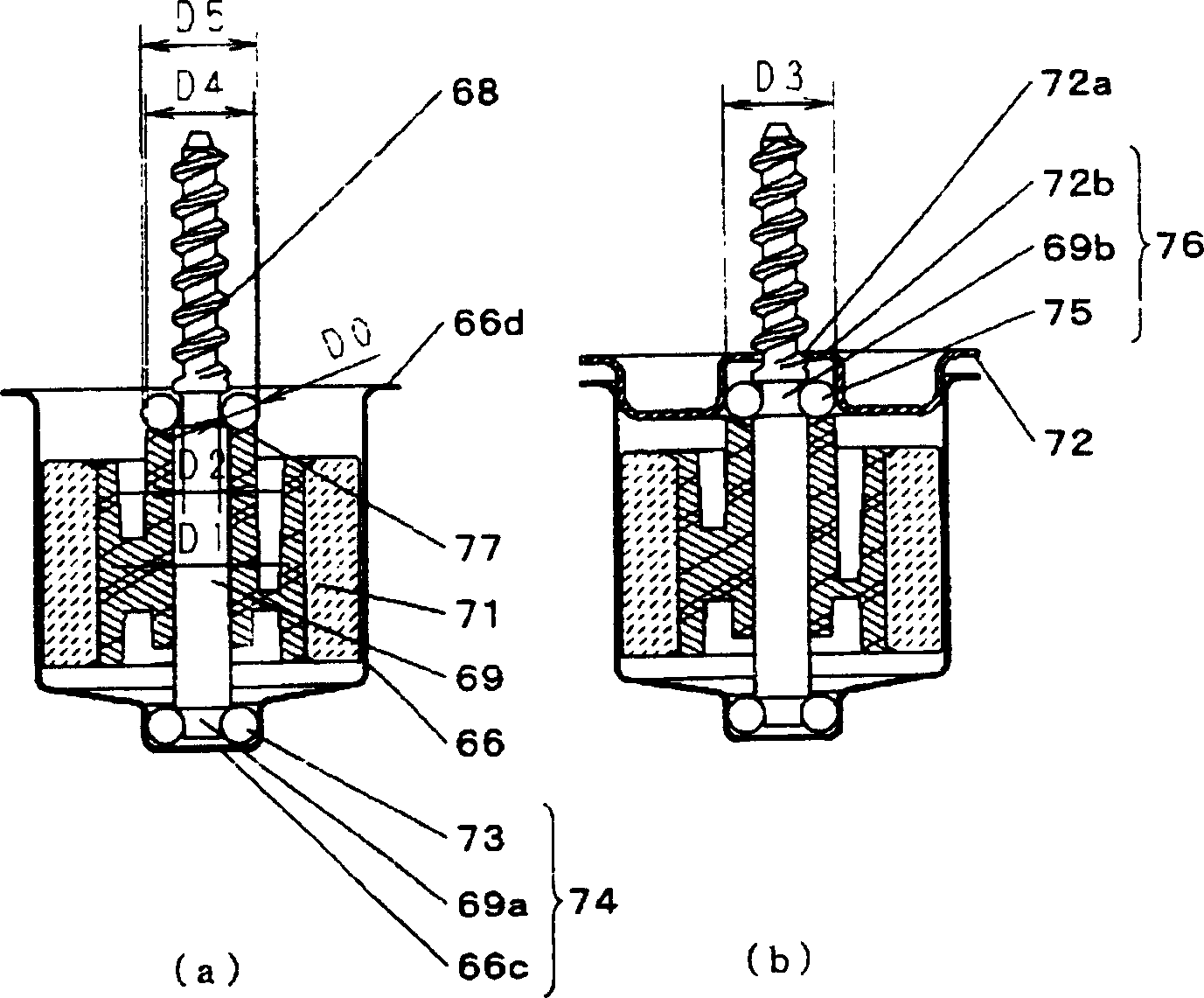

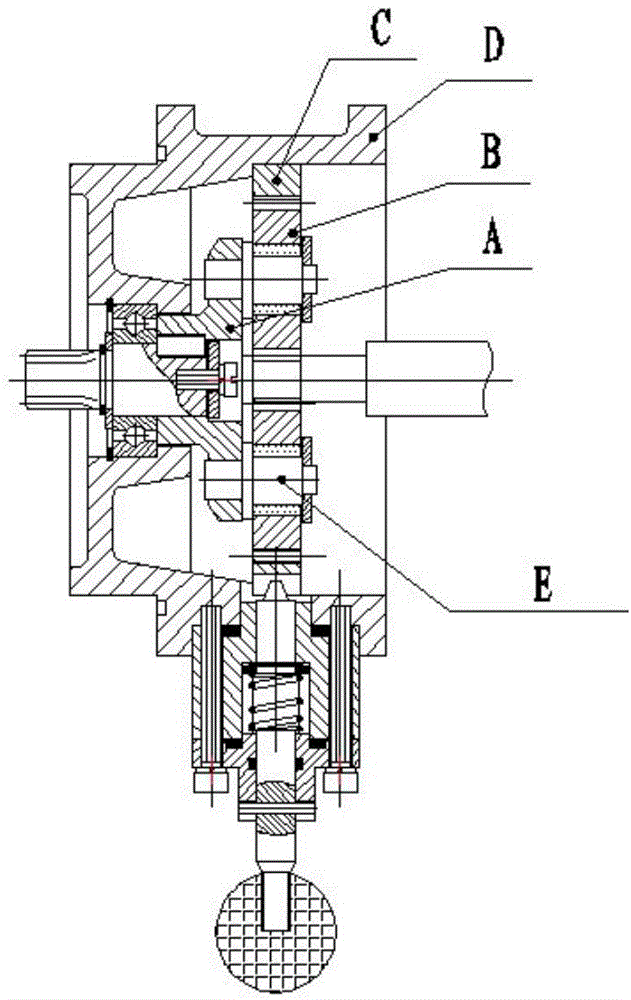

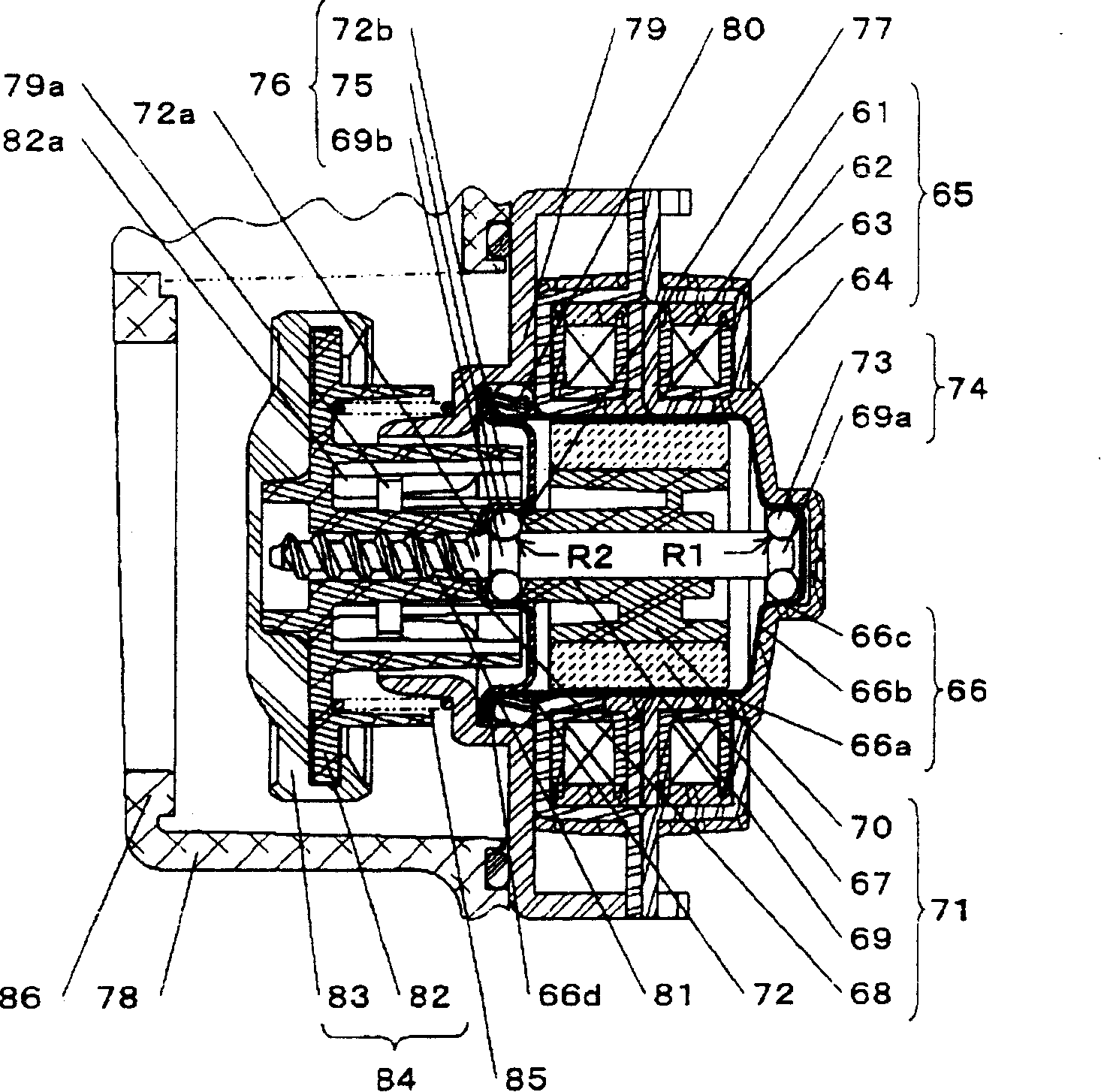

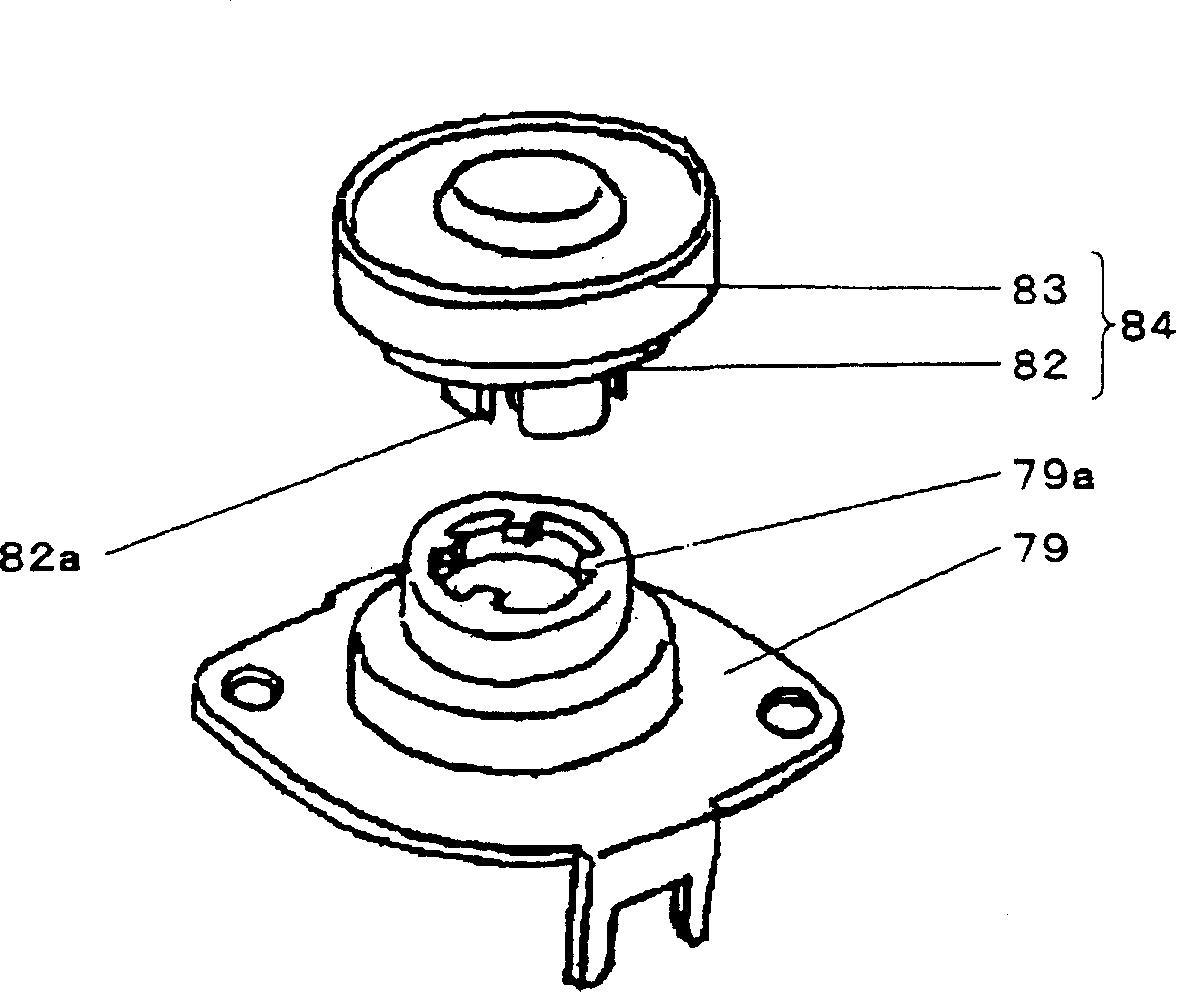

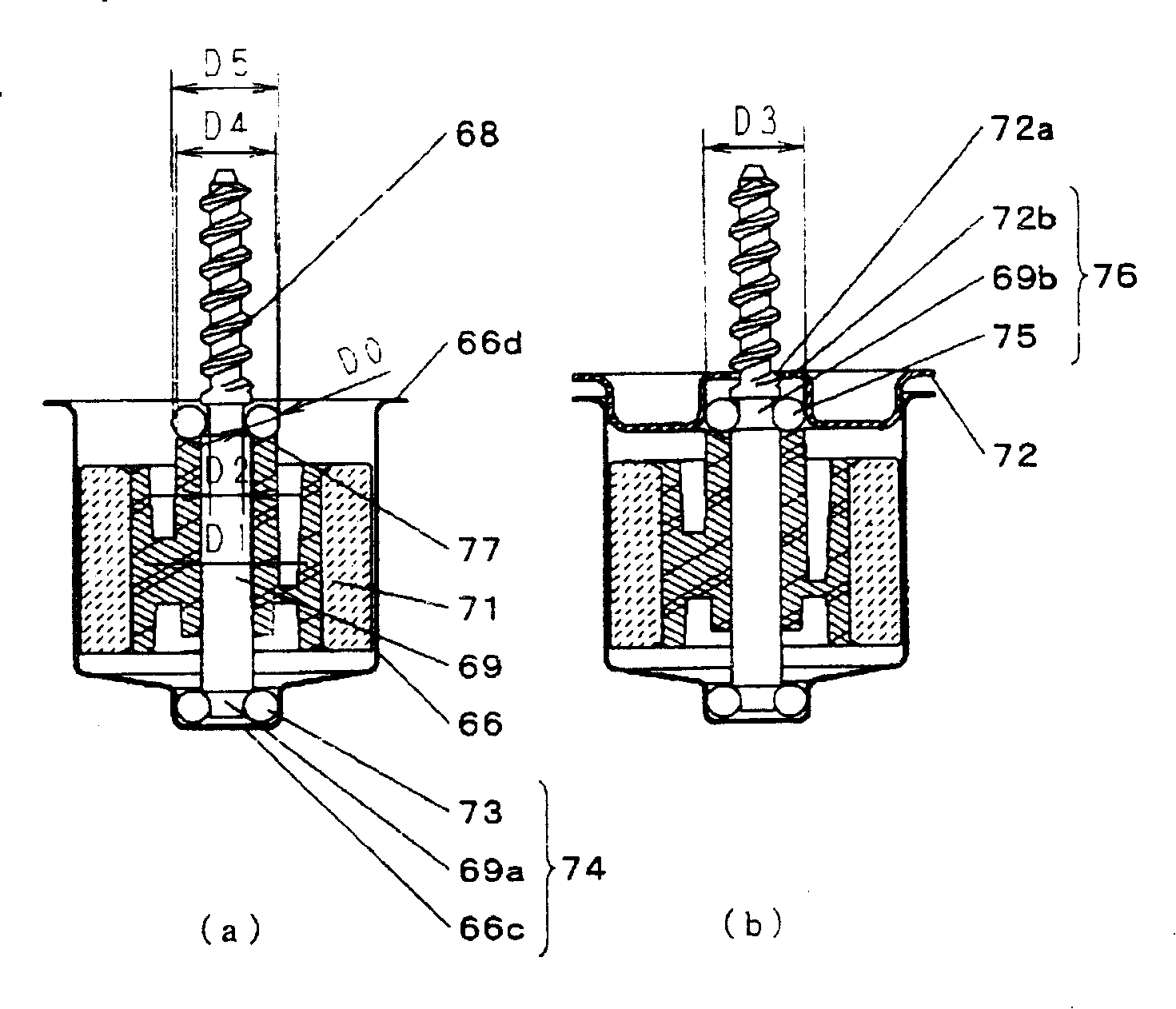

Break valve and its assembly method

InactiveCN1573189AReduce functionEliminate sliding contact partsOperating means/releasing devices for valvesPlastic/resin/waxes insulatorsRotational axisBall bearing

Provided is a cutoff valve which can simultaneously achieve highly reliable gas tightness, stable operation performance by small electric power, operation durability, and profitability. The inside pan shape portion of a metallic partition wall, a recessed portion formed on a lid made of a metal sheet, a tip end small diameter shaft and a small diameter groove formed on a metallic rotary shaft, and a plurality of metallic balls form rolling bearings for serving as both a radial bearing and a thrust bearing respectively, and hold the axis of a rotor. Because linear expansion coefficients of the rotary shaft and the holding member side are almost equal, possibility of the locking due to a temperature change is low, and the minimum radial clearance can be set. Because the accuracy of the axis of the rotor is high, stable operation performance can be achieved by small electric power, and high operation durability can be achieved by a rolling motion. Because the rolling bearings for serving as both the radial bearing and the thrust bearing are configured, high profitability can be achieved.

Owner:PANASONIC CORP

Automatic tin pick-up machine for intermediate frequence element

InactiveCN103578727ACompact structureSmall footprintInductances/transformers/magnets manufactureConveyor partsEngineeringSmall footprint

The invention discloses an automatic tin pick-up machine for an intermediate frequence element, which comprises a rack and a tin pick-up conveying mechanism, wherein the rack is sequentially provided with a coil skeleton input device, a conveying device, a screw feeding device, a screwing device, a tin pick-up mechanism and a control device; the control device is used for controlling each process in the assembling processing of the intermediate frequence element; the tin pick-up conveying mechanism is arranged on the rack and is positioned above the tin pick-up mechanism. The automatic tin pick-up machine for the intermediate frequence element has a compact structure, occupies a small area and can be used for completing a series of assembling processing steps of automatically feeding a screw, screwing down the screw, picking up tin, scraping dust, blanking and the like on a coil skeleton of the intermediate frequence element; labor intensity is reduced; cost is saved; assembling processing efficiency is improved.

Owner:XIAMEN JINGAO AUTOMATION TECH

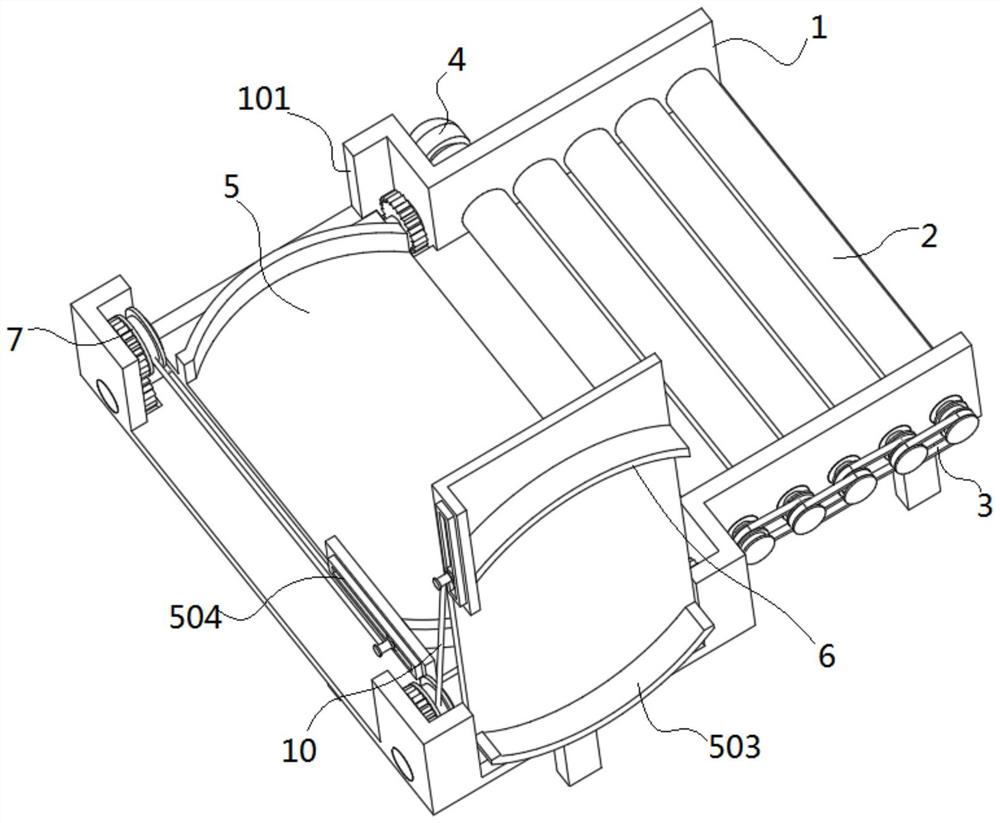

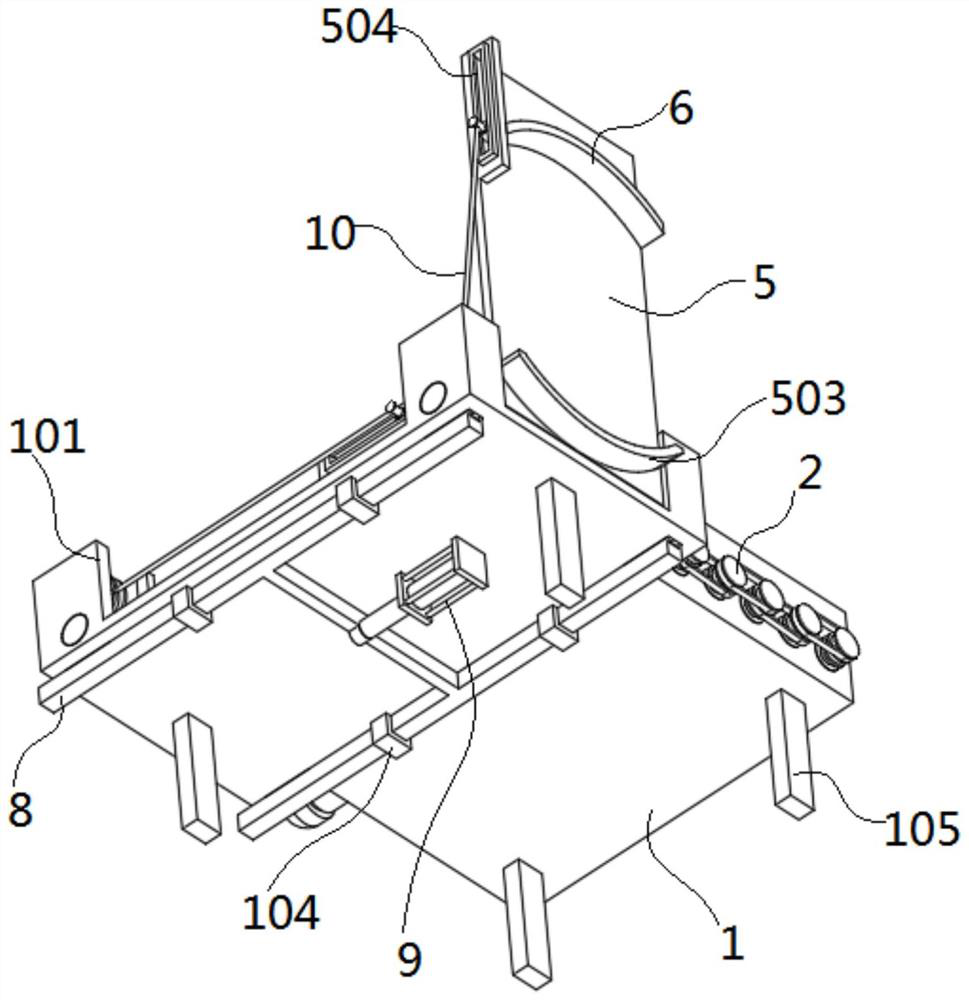

Glue spreading and fastening equipment for assembling automobile central control box, and working method thereof

ActiveCN112246560AGood sealingExtended service lifeLiquid surface applicatorsMaterial gluingElectric machineryEngineering

The invention discloses glue spreading and fastening equipment for assembling an automobile central control box, and a working method thereof. The glue spreading and fastening equipment comprises a tray, a glue spreading mechanism and a press fitting mechanism, and a clamping mechanism is arranged above one end of the tray; and a conveying disc is arranged below one end of the clamping mechanism.The glue spreading and fastening equipment has the beneficial effects that a lead screw III is driven by a motor VI to rotate, and a screw cylinder III, a motor VII and a glue nozzle are driven by thelead screw III to regulate and move right and left under the action of threads; a lead screw IV is driven by a motor VII on a sliding seat II to rotate, and a screw cylinder IV and the glue nozzle are driven by the lead screw IV to regulate and move front and back under the action of the threads; a rotating plate and a lower die frame are driven by the lead screw IV in cooperation with a second motor to rotate and regulate, and it is guaranteed that the glue nozzle can be rapidly moved to the position, where glue is required to spread, of the lower die frame; it is guaranteed that the movingrange of the glue nozzle is larger, and the glue spreading precision and efficiency of the equipment for the lower die frame are greatly improved; and the equipment is high in automation degree of glue spreading and fastening assembly of the automobile central control box, and easy to use.

Owner:马鞍山贺辉信息科技有限公司

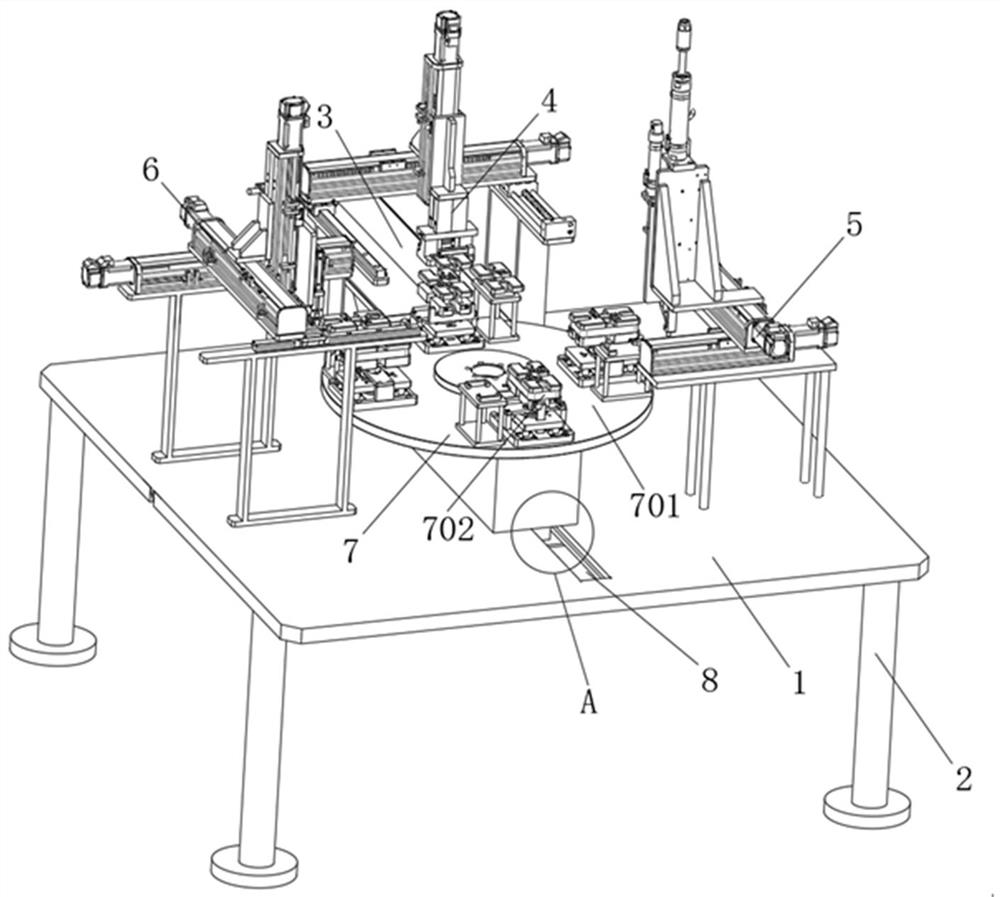

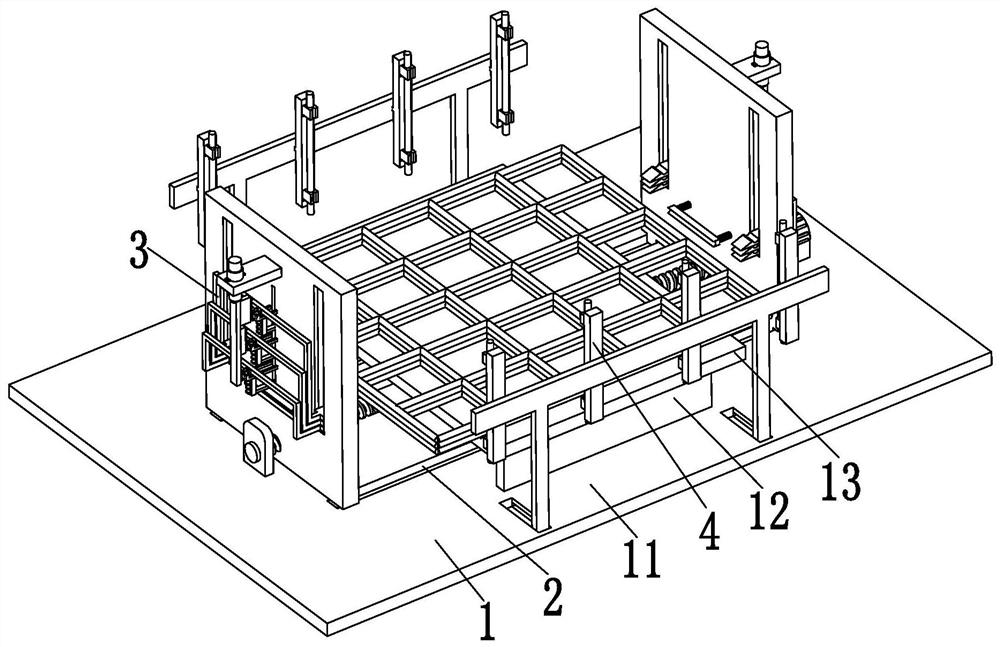

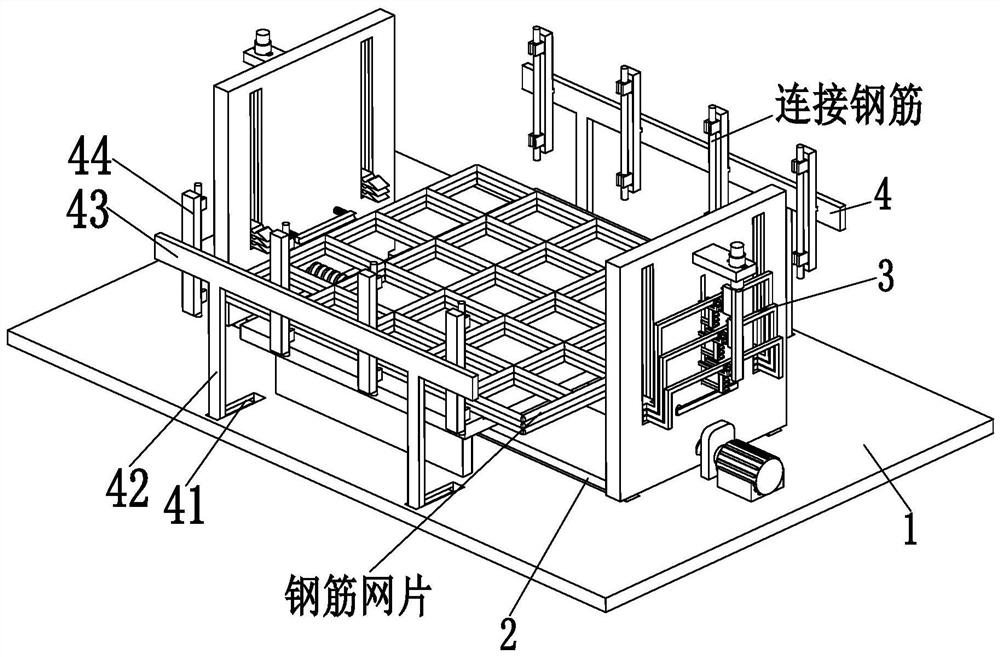

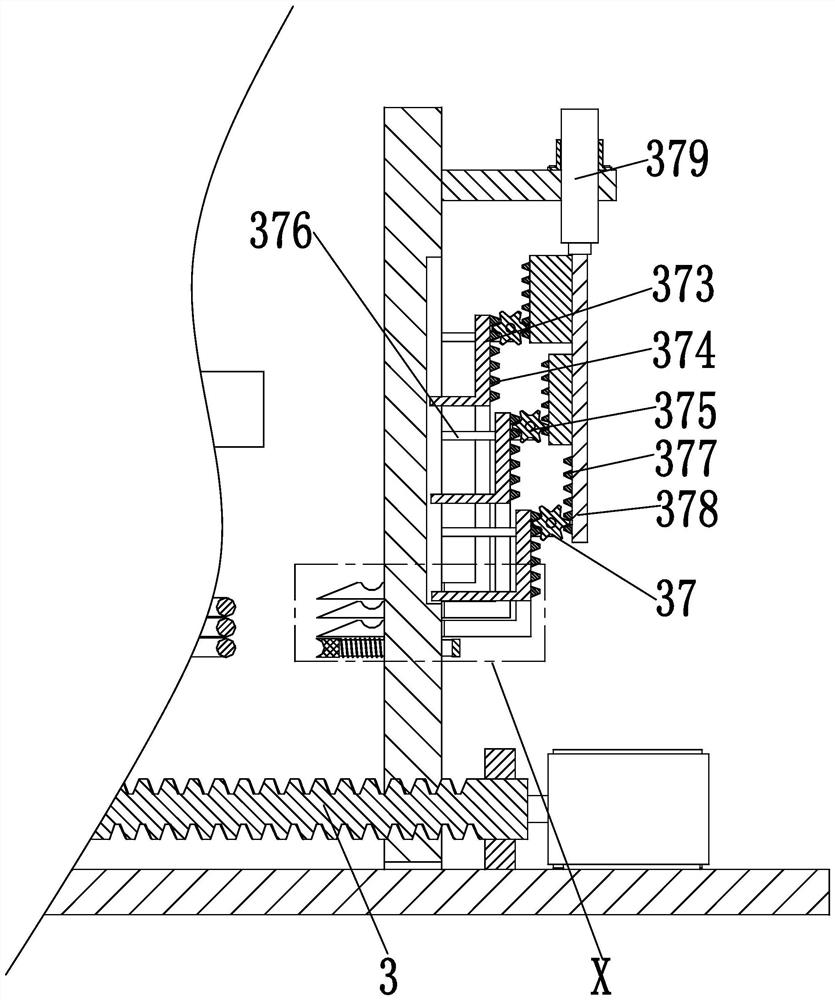

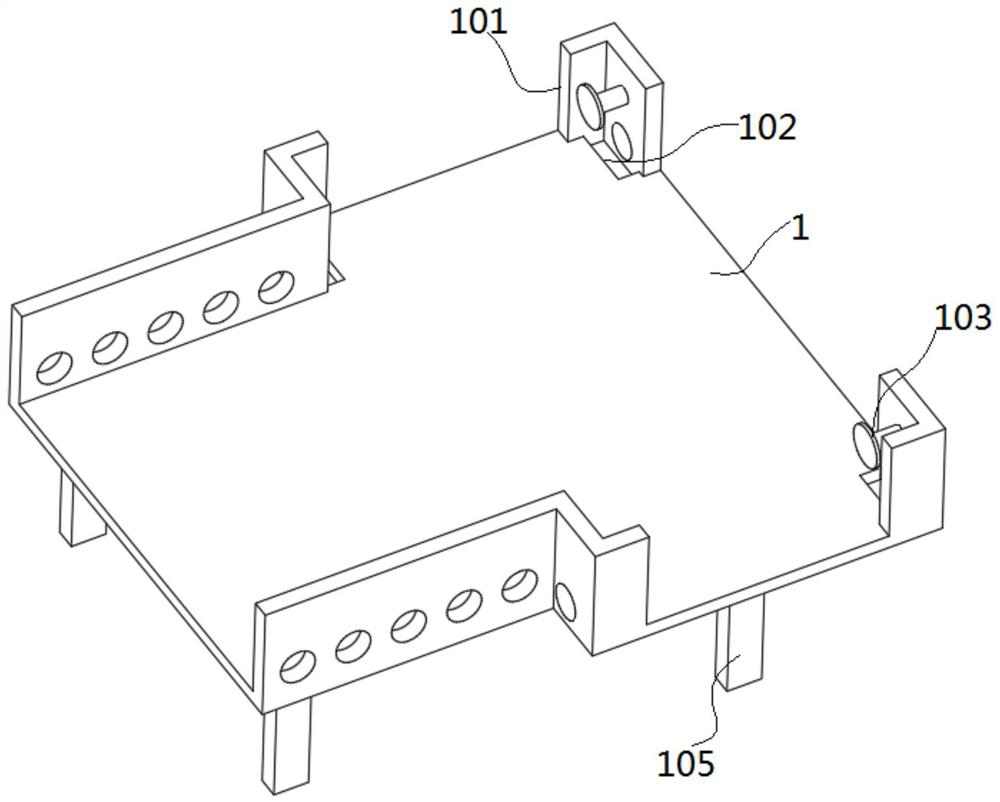

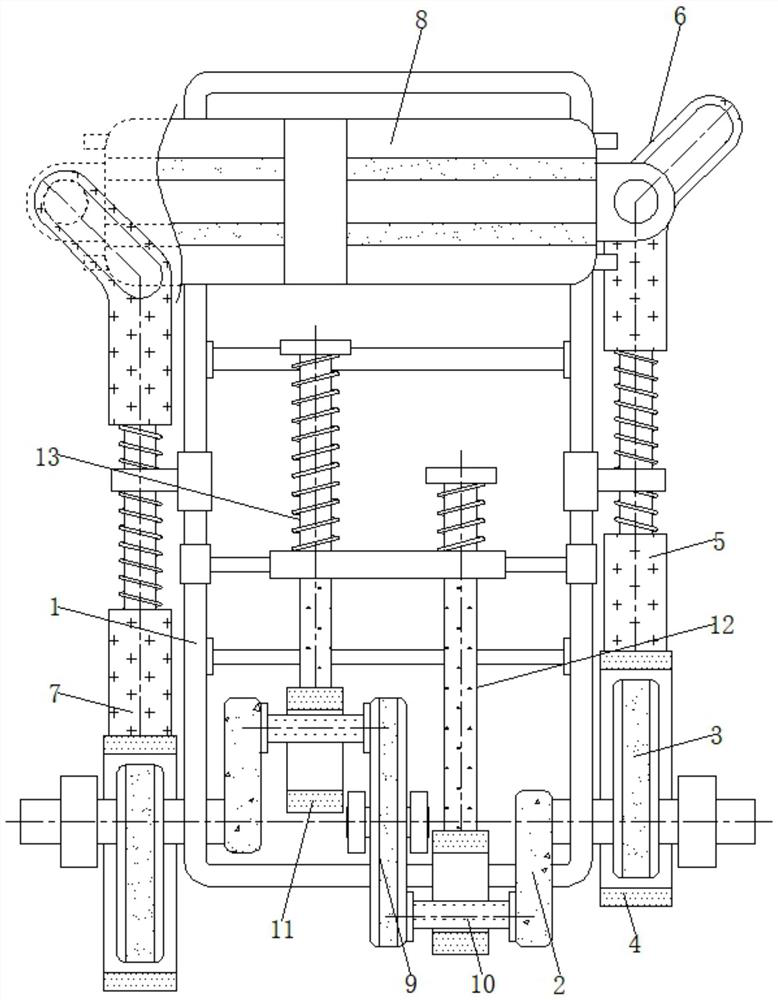

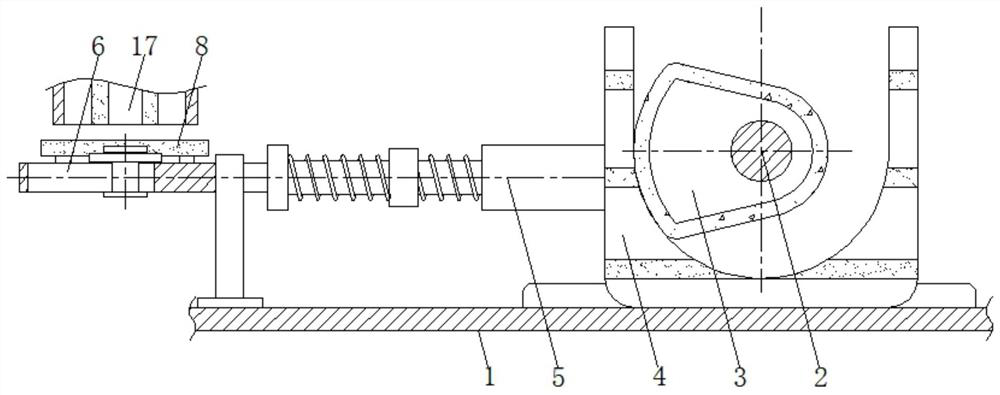

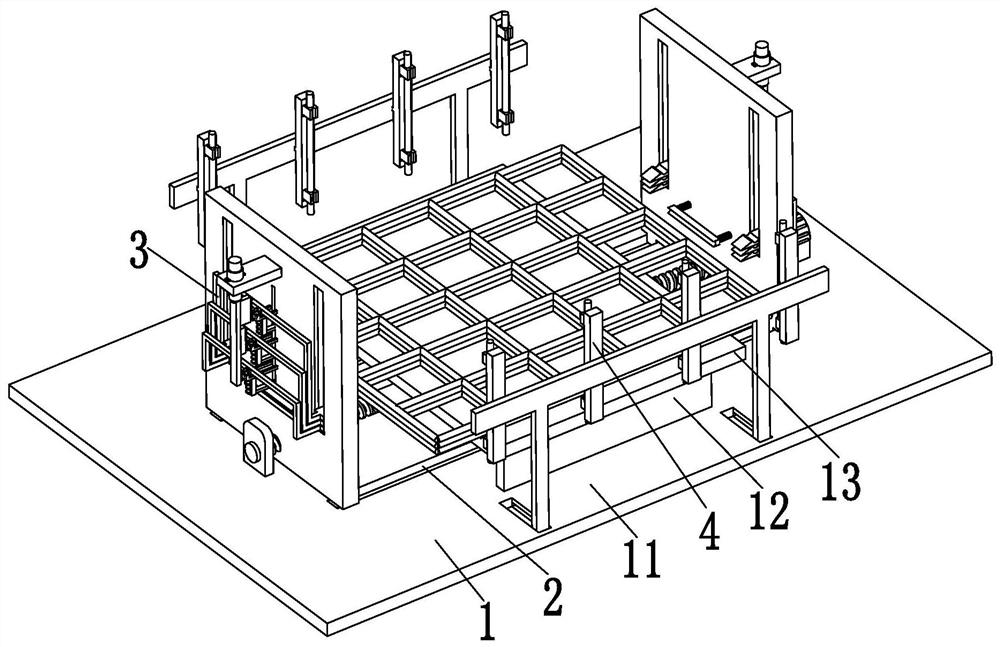

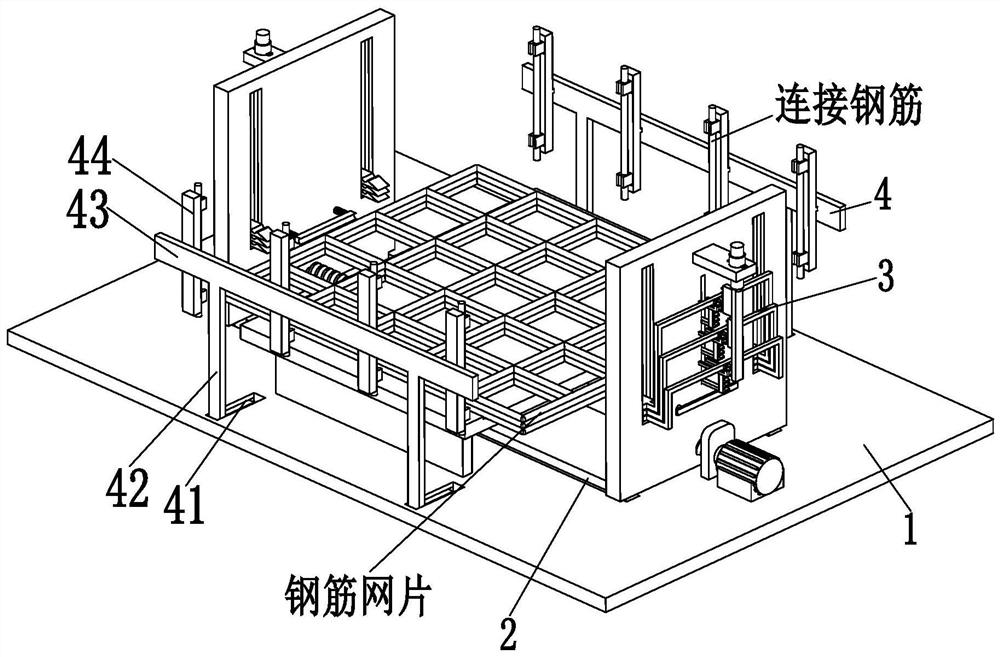

Assembly system for making reinforcing meshes from autoclaved aerated concrete slabs

ActiveCN113059682AImprove assembly processing efficiencyReduce duplicationAuxillary shaping apparatusMesh reinforcementMaterial resources

The invention relates to an assembly system for making reinforcing meshes from autoclaved aerated concrete slabs. The assembly system comprises a fixed base, limiting sliding chutes, positioning devices and assembly devices, wherein the limiting sliding chutes are symmetrically formed in the front side and the rear side of the upper end face of the fixed base; the positioning devices are arranged in the limiting sliding chutes; and the assembly devices are symmetrically arranged on the front side and the rear side of the upper end face of the fixed base. According to the assembly system, the problem of lowering of the quality of an assembled three-dimensional structure since manual assistance is generally needed for movement to guarantee position alignment, the mechanization degree is low, the labor intensity of workers is increased and the manual assistance stability is poor when traditional reinforcing meshes are assembled into the three-dimensional structure, and the problem of waste of manpower and material resources since a certain number of reinforcing meshes need to be assembled and formed, one-time assembly is difficult to succeed and the step needs to be repeated for assembly after one reinforcing mesh is assembled when the traditional reinforcing meshes are assembled into the three-dimensional structure can be solved.

Owner:山东国厦新型建材有限公司

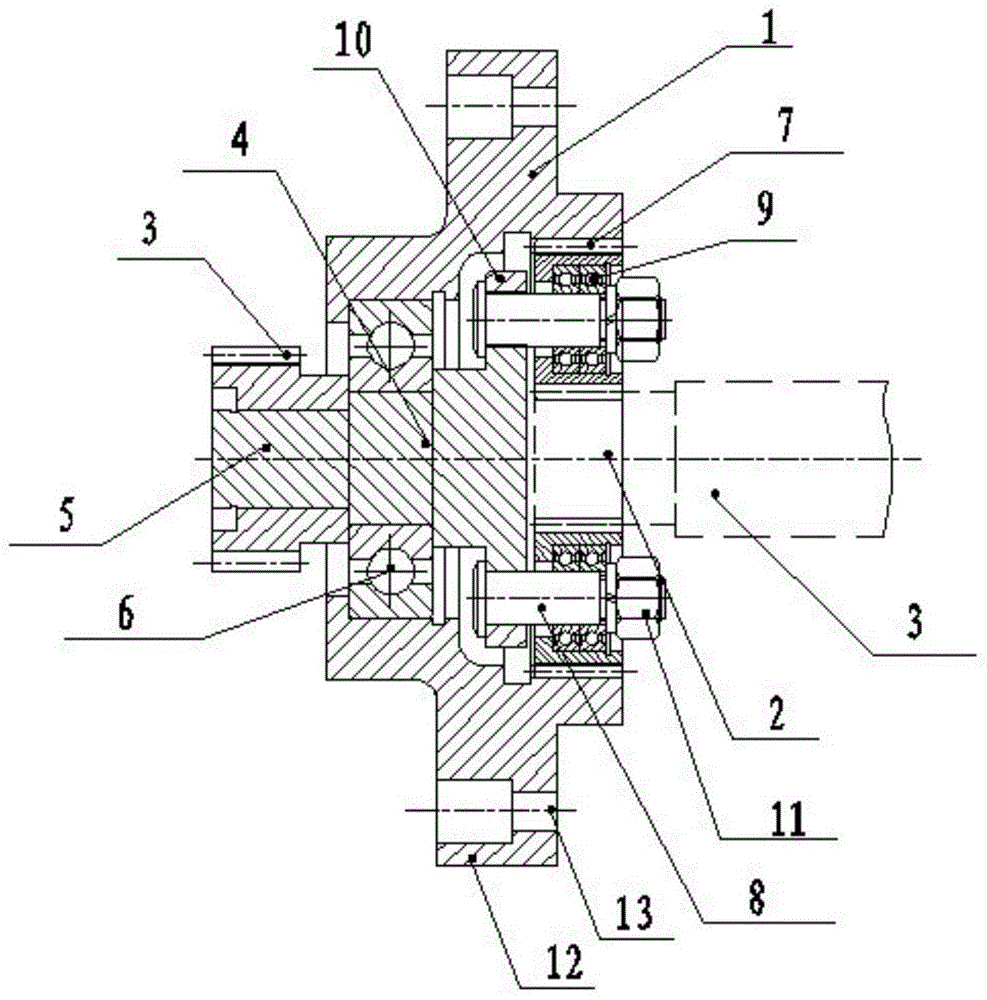

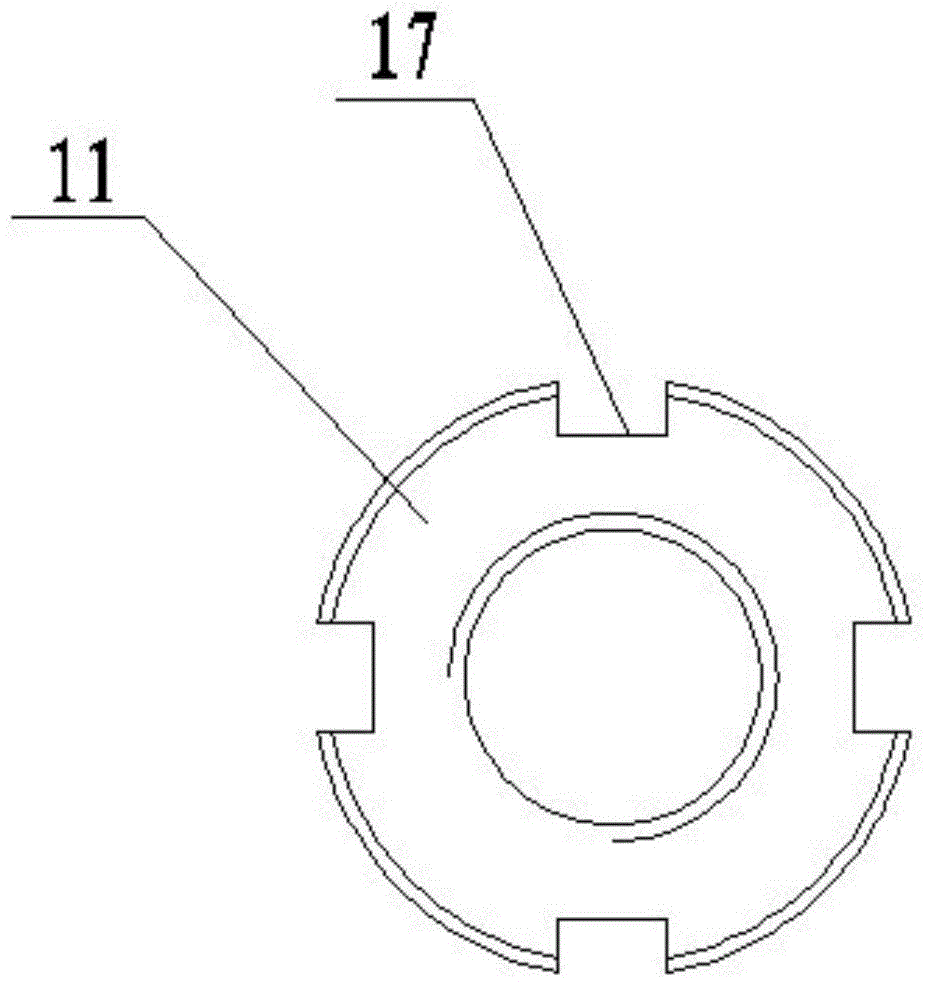

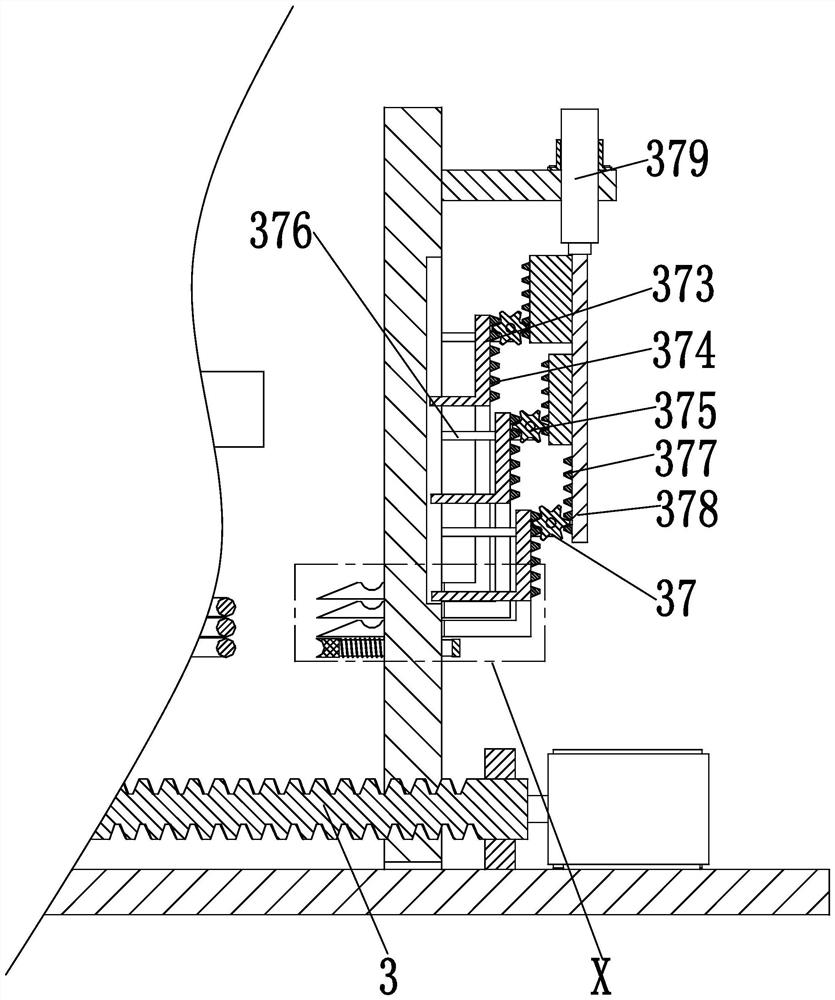

Noise-reducing planetary reducer

InactiveCN104879477AReduce eccentricityImprove verticalityToothed gearingsCouplings for rigid shaftsReducerOverlap ratio

The invention provides a noise-reducing planetary reducer. The noise-reducing planetary reducer comprises a planetary case body, a planetary assembly, a planetary input gear and a planetary output gear, wherein a planetary plate and the planetary assembly are sequentially arranged in the planetary case body from left to right; the left end of the planetary plate is connected with a planetary output shaft; the planetary output gear is arranged on the planetary output shaft; the planetary assembly comprises three planetary gears which are mutually in 120-degree arrangement; connecting shafts are arranged in the planetary gears in a sleeving way; the convex edges of the left ends of the connecting shafts are arranged in raised round holes in the right end of the planetary plate in a clamping way; the right ends of the connecting shafts are connected with nut locking structures. The noise-reducing planetary reducer provided by the invention has the beneficial effects that the planetary plate and the planetary output shaft are of an integrated structure, bearings I are additionally arranged in the outer diameter positions of the planetary plate, eccentricity and lopsidedness of the planetary plate are reduced, and the noise is reduced; the locking nut structures are locking structures which are additionally arranged on the basis of common nuts, the overlap ratio of the planetary gears and an inner gear is increased, the assembling and machining efficiency is greatly increased, and the cost is reduced.

Owner:TIANJIN JINDA ACTUATOR CO LTD

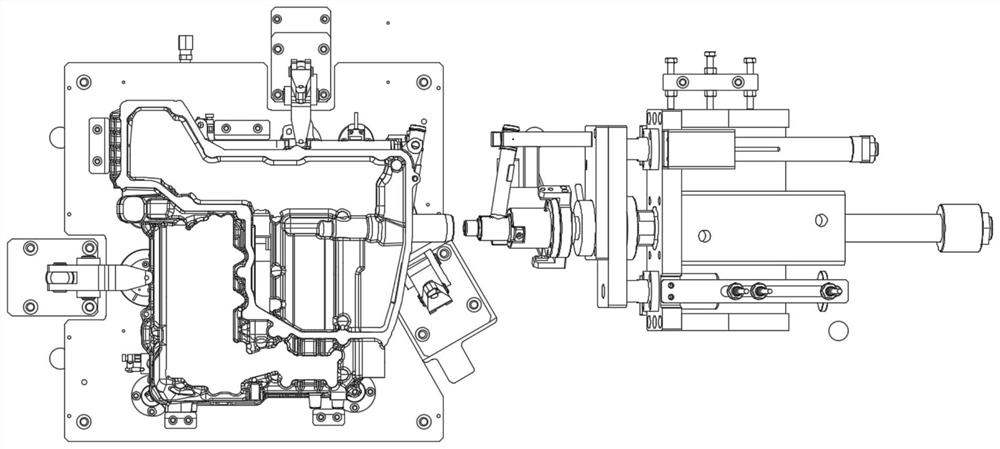

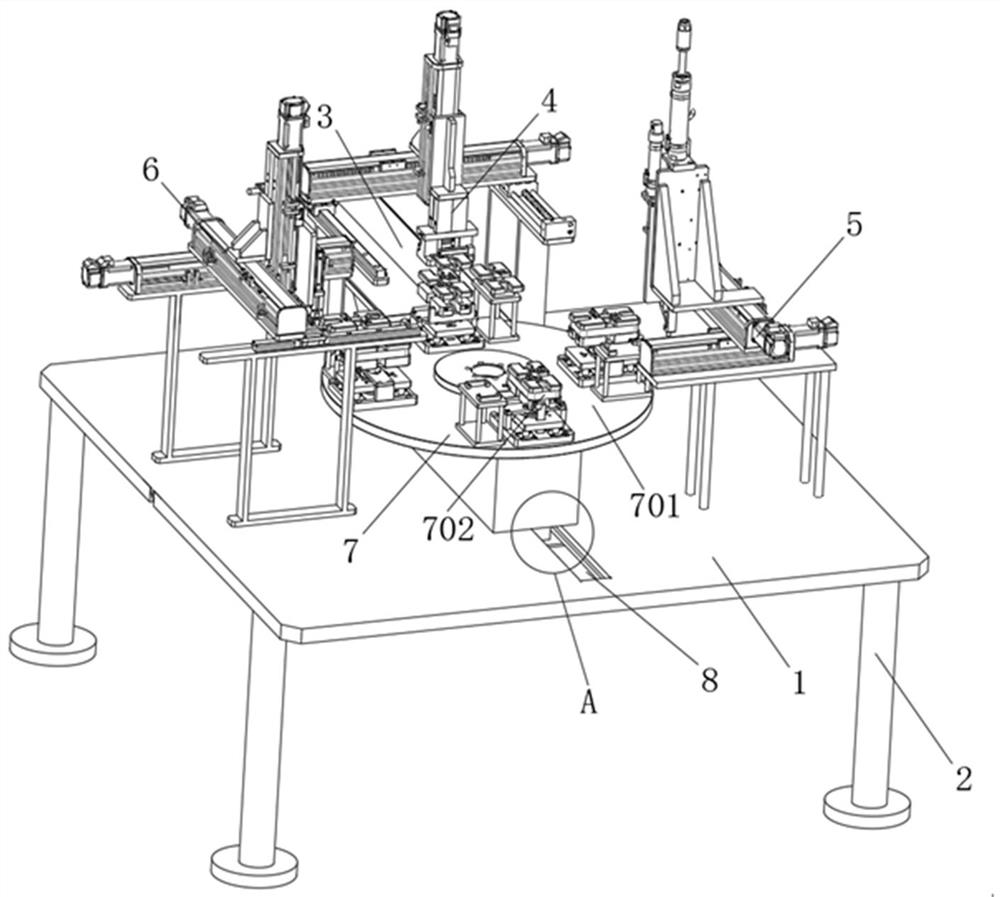

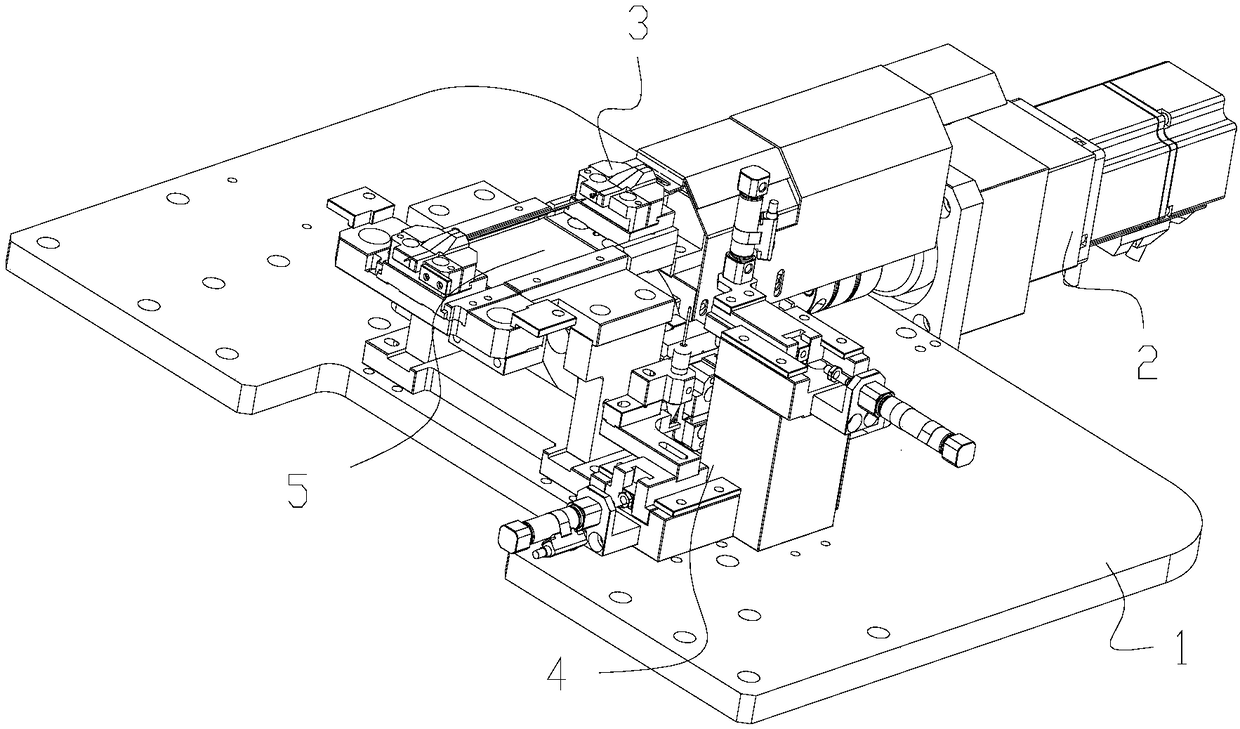

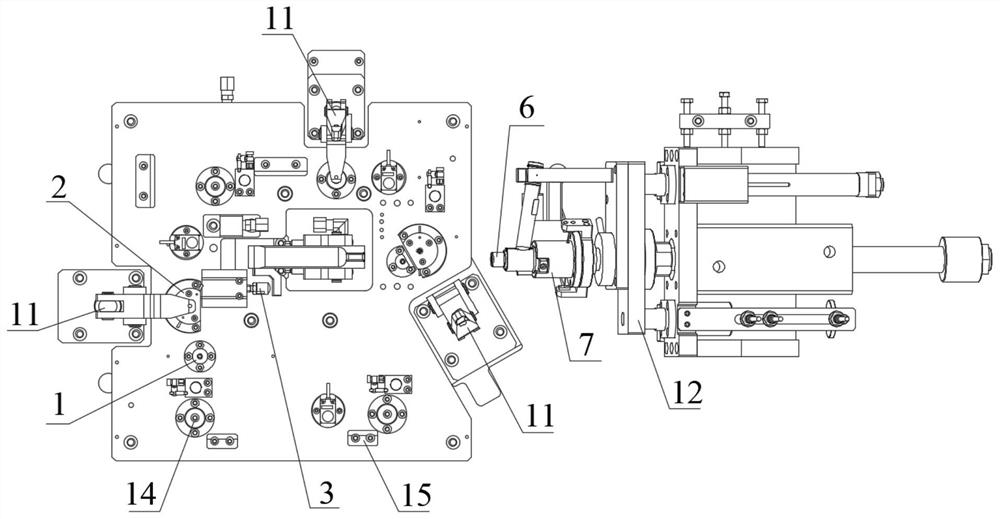

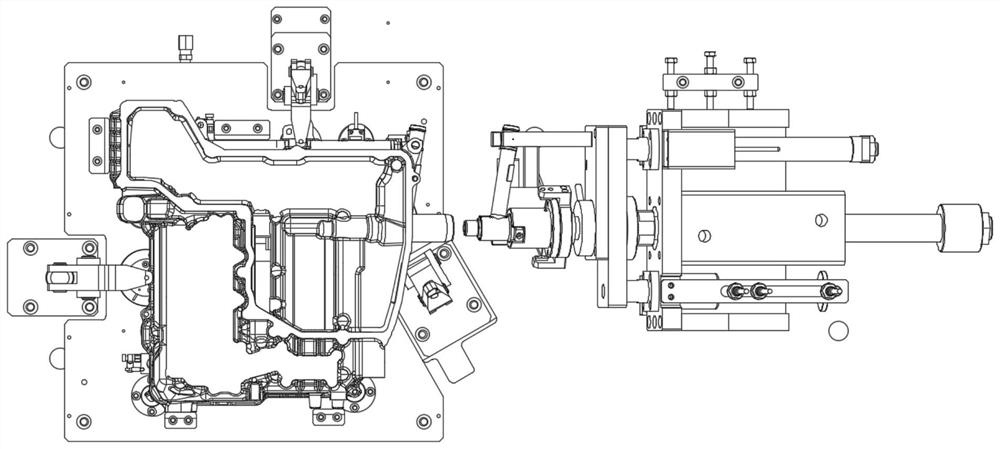

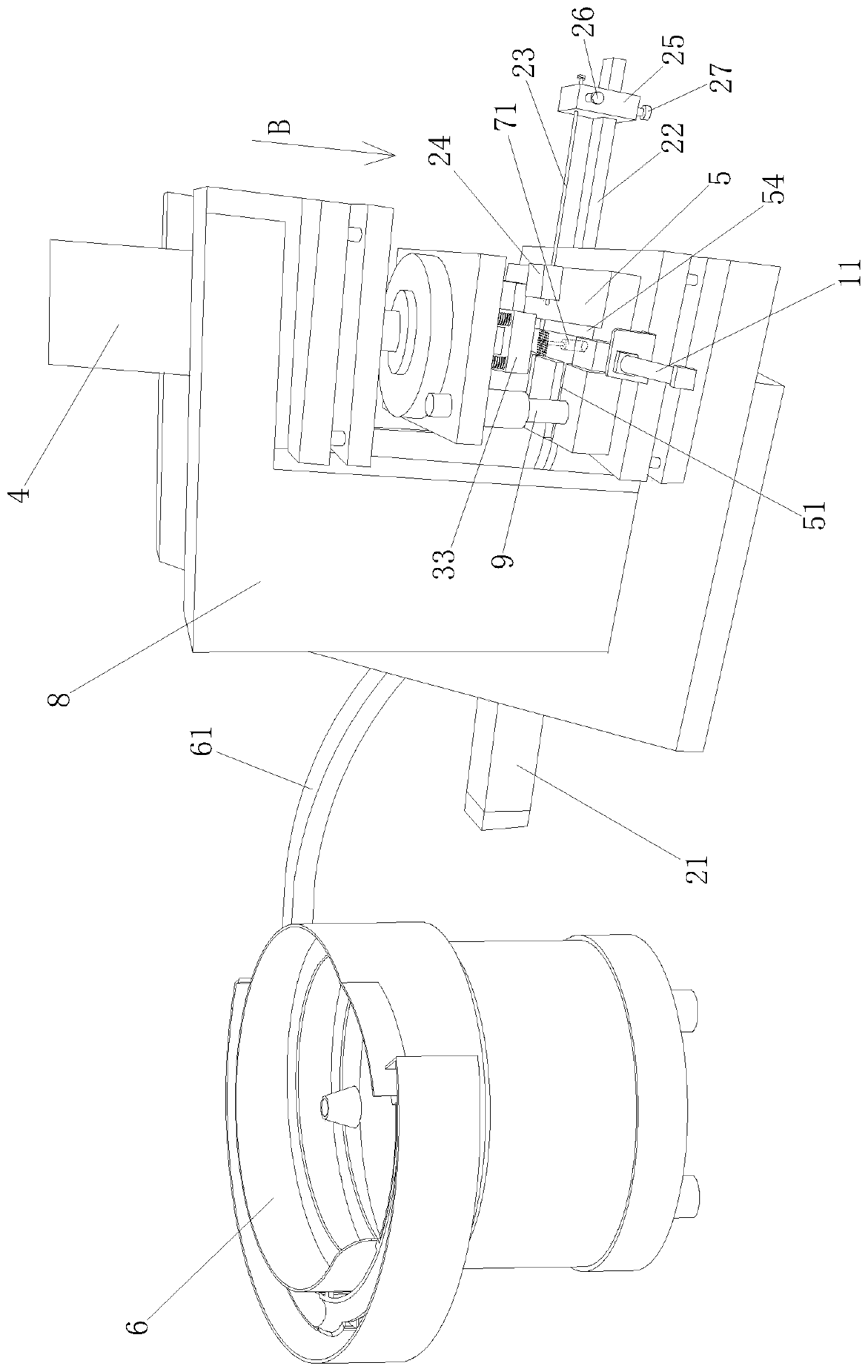

Machining device suitable for assembling inverter shell and machining method

ActiveCN111872657AAchieve positioningRealize clampingWork holdersMetal working apparatusPipe fittingNew energy

The invention discloses a machining device suitable for assembling an inverter shell and a machining method, and belongs to the technical field of inverter machining. According to the machining device, a positioning block, a force bearing block, a pressing claw, a pin mounting unit and a pipe fitting assembling assembly are arranged on the positions, corresponding to the inverter shell to be assembled, on a workbench. By means of corresponding arrangement and mutual matching of the number and the positions of all the components, accurate positioning and clamping of workpieces can be rapidly achieved, and then sequential assembling of pins and pipe fittings is achieved. The machining device suitable for assembling the inverter shell is simple in structure and convenient to assemble and operate, the machining method for assembling through the machining device is simple and convenient, accurate positioning and reliable clamping of the inverter shell can be achieved, pin assembling and pipe fitting assembling are automatically and rapidly completed after positioning and clamping are completed, the assembling precision and the assembling efficiency of the inverter shell of a new energyautomobile are effectively improved, the assembling cost of the inverter shell is reduced, and good application prospects and popularization value are achieved.

Owner:广东鸿图武汉压铸有限公司 +1

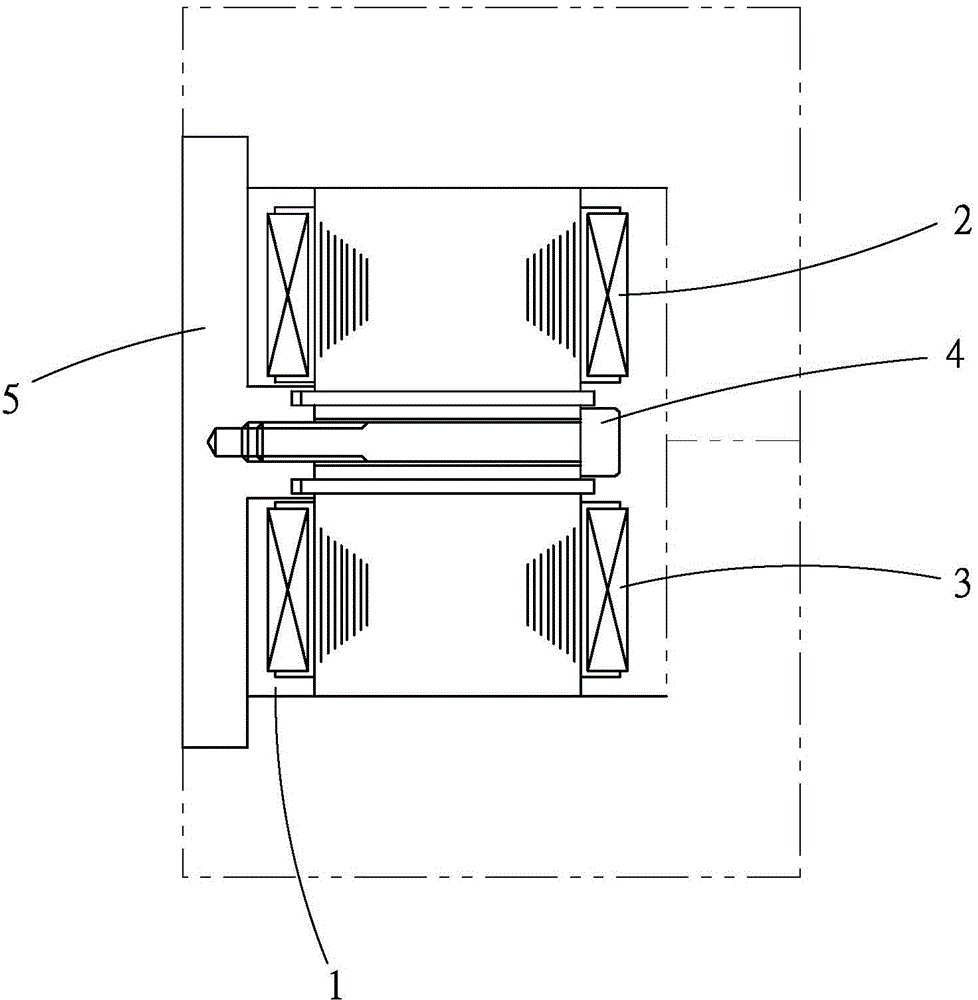

Tire assembling, overturning and clamping mechanism for automobile production line

PendingCN114406939AShorten the timeImprove assembly processing efficiencyWork benchesMetal-working hand toolsProduction lineControl theory

The invention discloses a tire assembly overturning and clamping mechanism for an automobile production line, and relates to the technical field of tire assembly. The tire turnover device comprises a conveying rack, and tire turnover plates are rotationally connected between the opposite faces of the two inner sides of one end of the conveying rack; a movable clamping plate is in sliding fit with the surface of one end of the turnover frame; the two inner side faces of one end of the conveying rack are both rotationally connected with take-up cylinders which are in meshing transmission with the tire overturning plates. The take-up cylinder is connected with the movable clamping plate through a pull wire. The lower surface of the conveying rack is sleeved with a movable guide frame meshed with the two tire overturning plates. A telescopic cylinder is fixed on the lower surface of the conveying rack; the end of a piston rod of the telescopic cylinder is fixedly connected with the movable guide frame. By adopting double-station overturning clamping, when the telescopic air cylinder stretches out and draws back, the movable guide frame and the two tire overturning plates are driven to be switched and overturned mutually, so that the time for tire assembling operation is shortened, the tire assembling and machining efficiency is improved, and the actual production requirement is met.

Owner:江苏汉邦车业有限公司

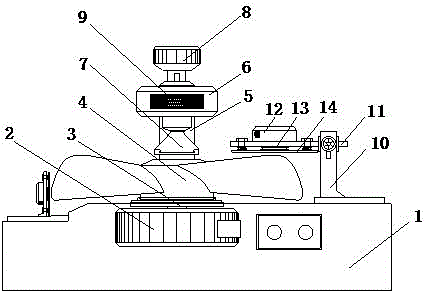

Quality detection device for fan blade

InactiveCN106092030AImprove assembly processing efficiencyEasy to chooseMeasurement devicesEngineeringWorkload

The invention discloses a quality detection device for a fan blade, and the device comprises a base and moving frame bodies. Two ends of the top of the base are respectively provided with a moving frame body, and the inner cavities of the moving frame bodies are provided with a bearing plate. The top of the bearing plate is provided with a data analysis processor, and the bottom of the bearing plate is provided with a jump sensor. The bottom of the jump sensor is provided with a detection board. The device provided by the invention is simple in structure, is convenient to use, can achieve the effective detection of the offset of a blade angle and the spacing of the blades through the arrangement of the jump sensor, the data analysis processor and the detection board, brings convenience to a worker for sorting out an unqualified blade, and avoids a phenomenon that a blade collides with a protection cover after the fan is assembled, thereby improving the assembly and processing efficiency of a fan, and effectively reducing the workload of the worker.

Owner:WUXI ZUNBAO ELECTRIC VEHICLE CO LTD

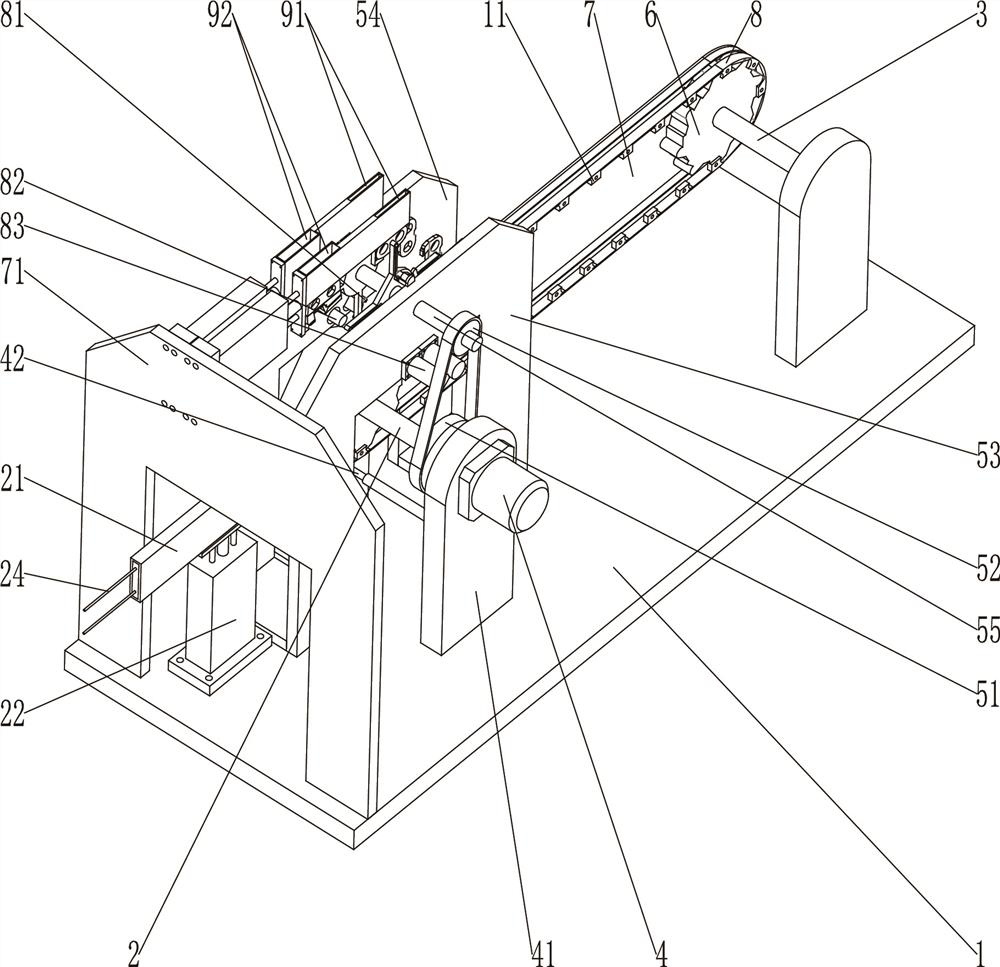

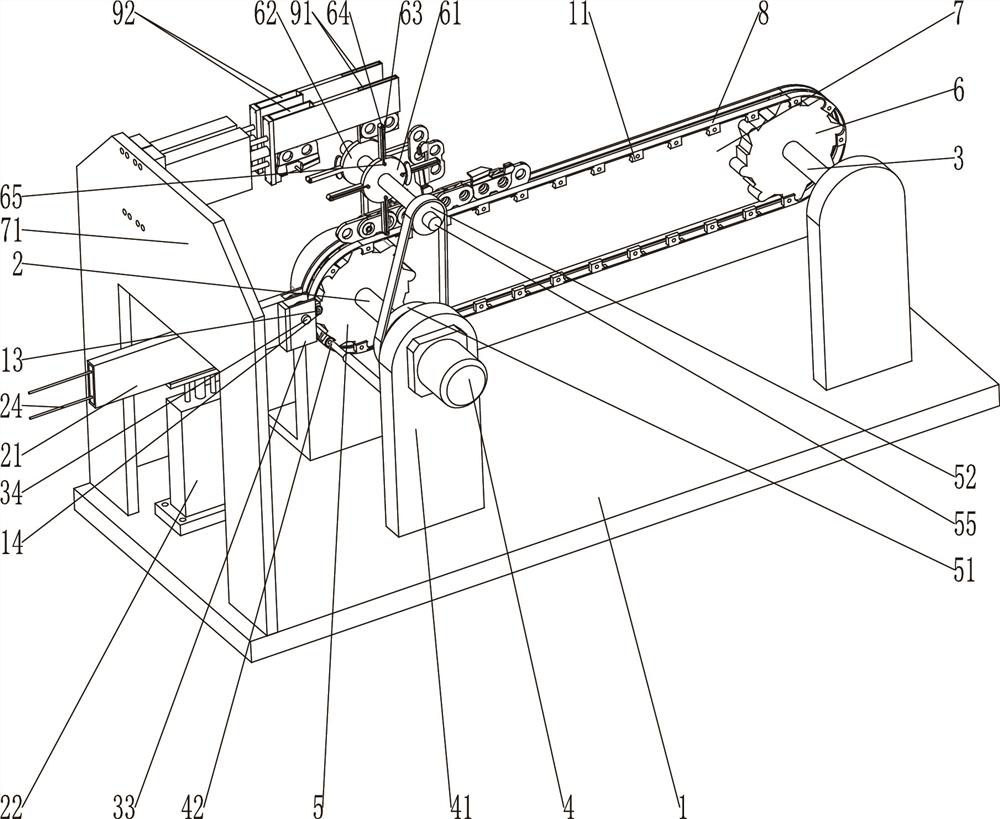

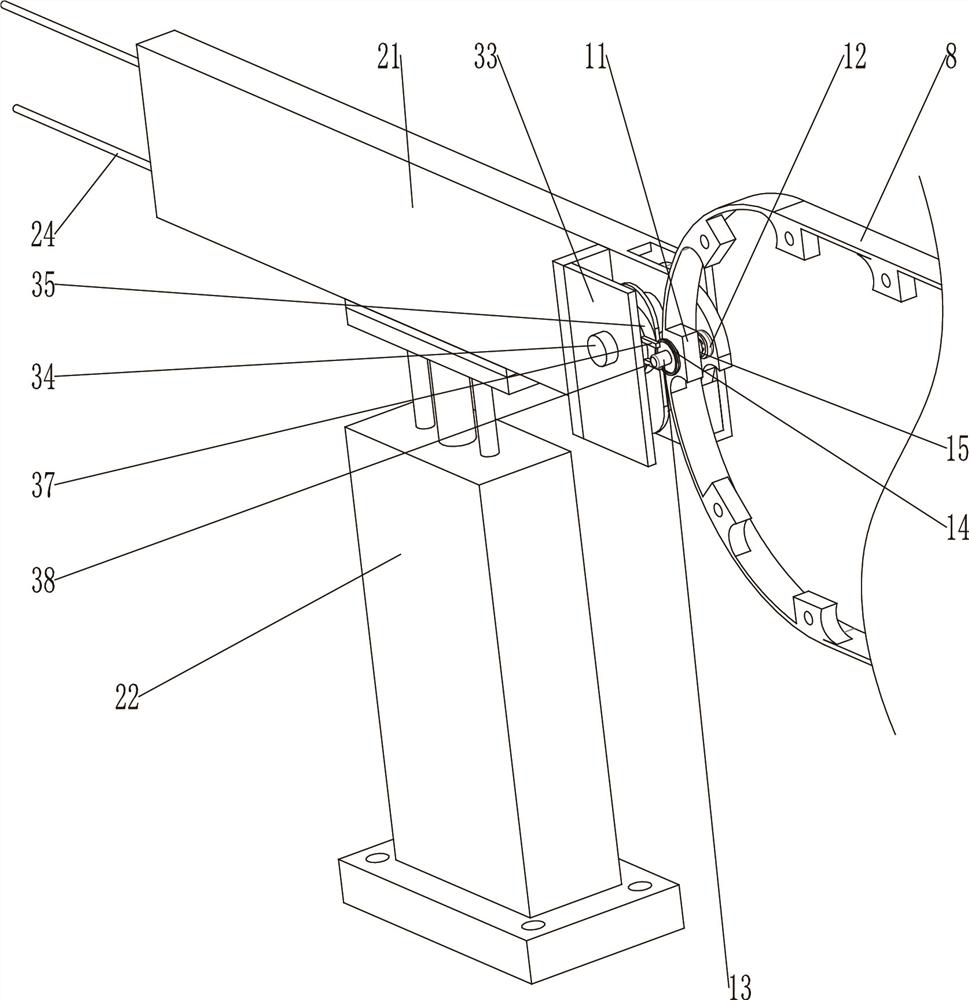

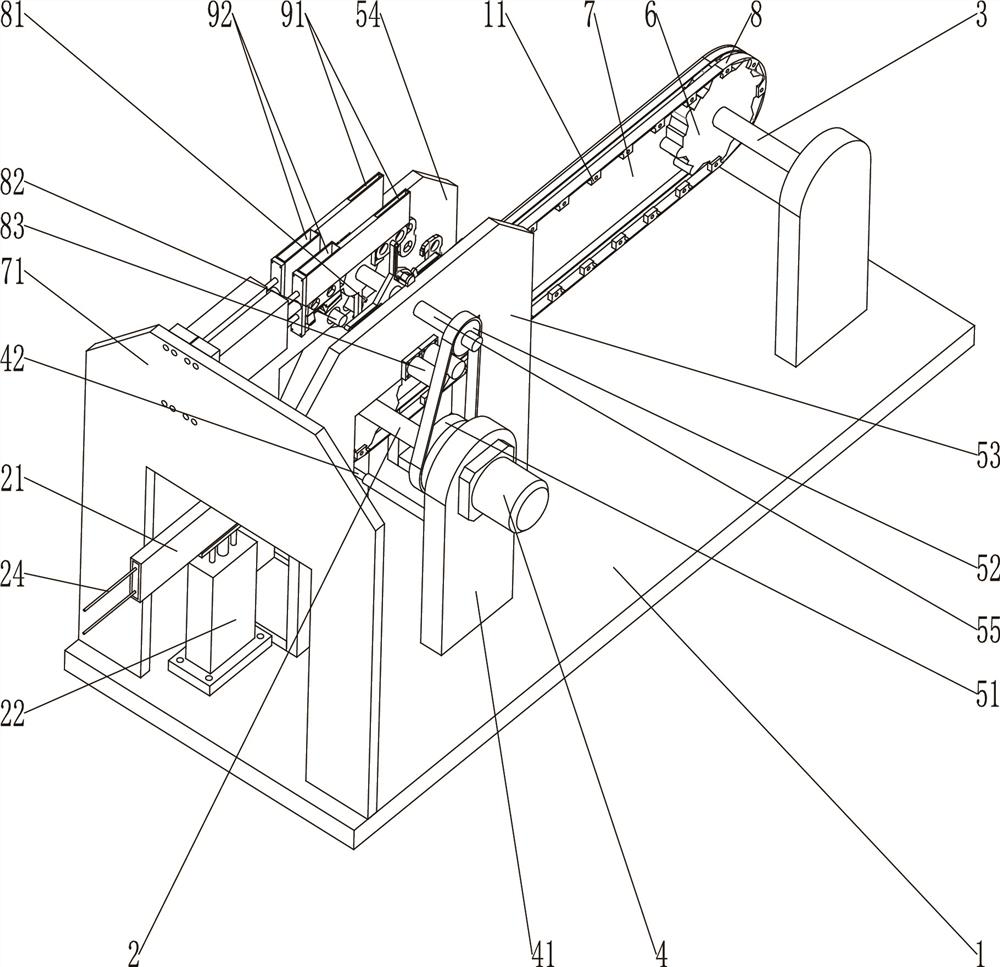

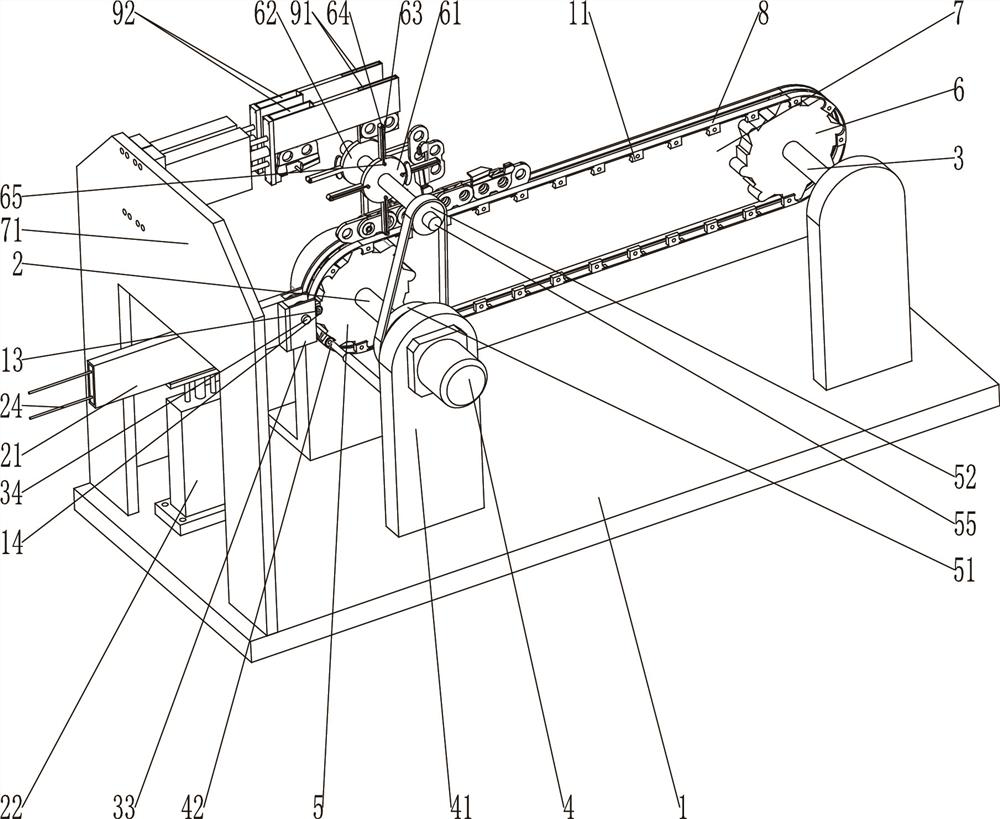

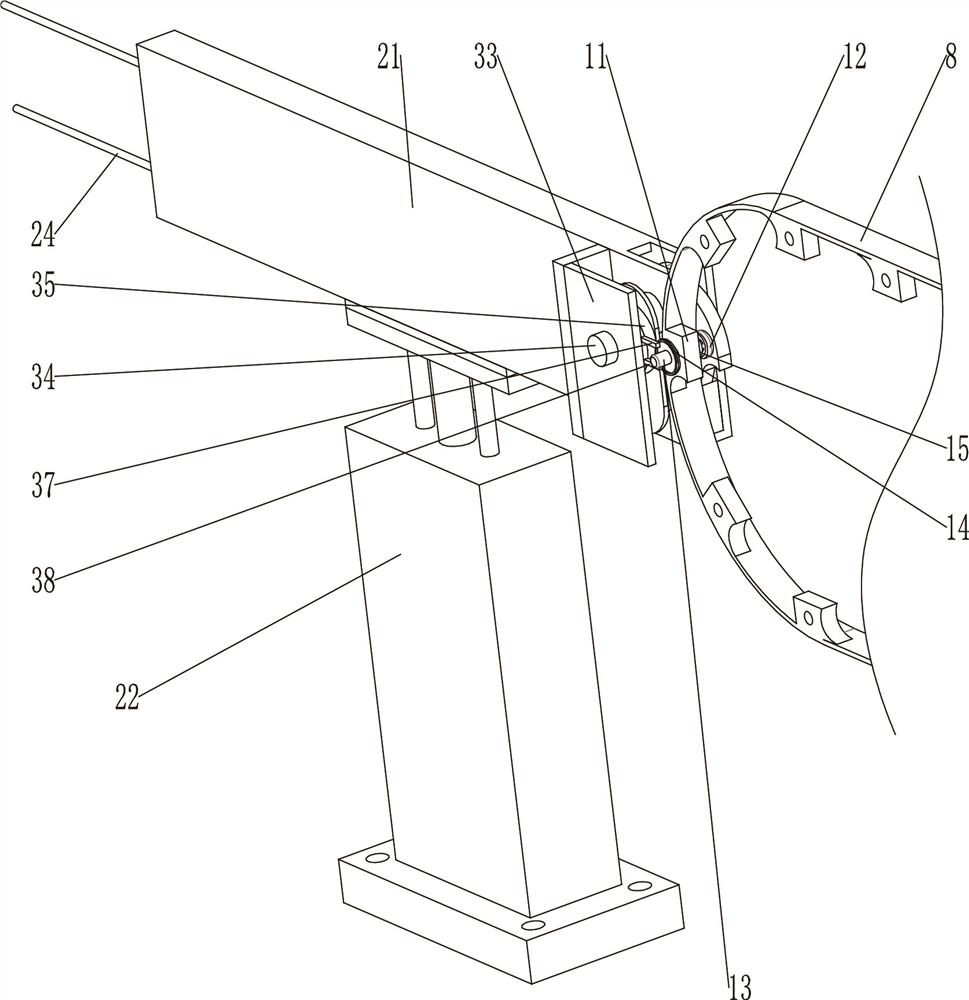

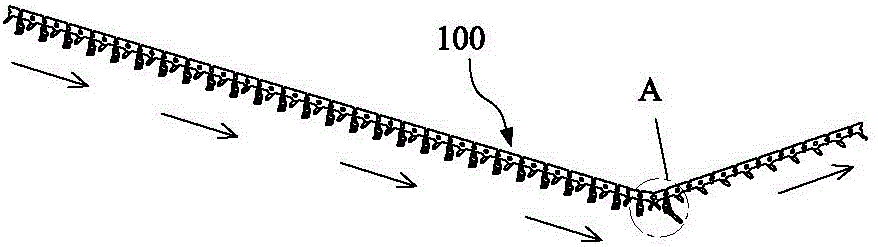

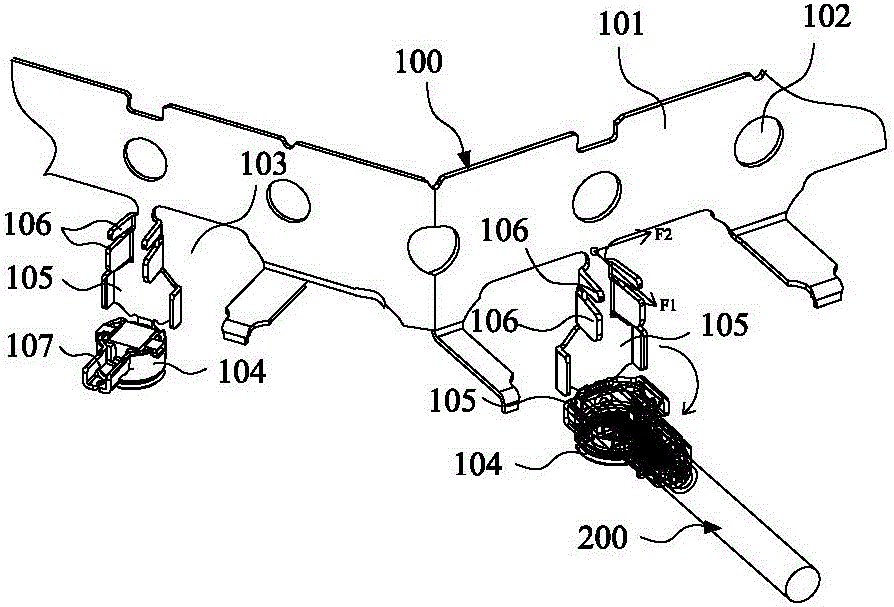

An assembly machine for sheet metal connectors

ActiveCN109570998BSame sizeRealize mechanical automation assemblyAssembly machinesEngineeringMachine

Owner:李广

A glue-applied crimping device and its working method for the assembly of automobile central control box

ActiveCN112246560BExpand the scope of activitiesImprove mobile productivityLiquid surface applicatorsMaterial gluingElectric machineryEngineering

The invention discloses a glue-applying and pressing-buttoning device for assembling a central control box of an automobile and a working method thereof, comprising a tray, a glue-applying mechanism and a press-fitting mechanism. A transmission plate is arranged under one end of the mechanism. The beneficial effect of the present invention is: motor six drives lead screw three to rotate, and lead screw three drives screw cylinder three, motor seven and glue nozzle to adjust and move left and right through thread action, and motor seven on sliding seat two drives lead screw four to rotate, and the screw Lever 4 drives screw barrel 4 and glue nozzle to adjust and move back and forth through the action of thread, and cooperates with motor 2 to drive rotary plate and lower mold frame to rotate and adjust, so as to ensure that the glue nozzle can be quickly moved to the position where glue needs to be applied on the lower mold frame, and the glue is guaranteed The nozzle can move in a wider range, which greatly improves the accuracy and efficiency of the equipment for gluing the lower mold frame. The equipment has a high degree of automation for the gluing and pressing assembly of the automobile central control box, and is very convenient to use.

Owner:马鞍山贺辉信息科技有限公司

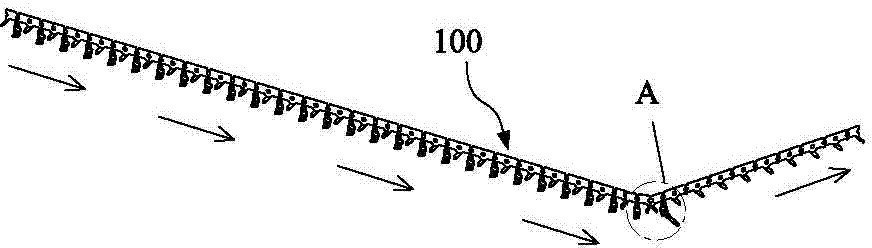

Chainsaw chain processing platform with protective mechanism

The invention discloses an electric saw chain processing platform with a protective mechanism, comprising a frame, a driving sprocket, a driven sprocket and a side chain plate, and the frame is provided with a first turntable for conveying saw blades and side chain links and the second turntable, the first turntable and the second turntable have the same structure and are mirror-symmetrically arranged on both sides of the drive sprocket, a number of transmission rods are uniformly arranged on the first turntable and the second turntable, and the transmission rods are provided with There is a second electromagnet for absorbing the saw blade and the side chain link. The frame is provided with a first delivery box and a second delivery box matched with the delivery rod. The first delivery box and the second delivery box pass through The first cylinder and the second cylinder are arranged on the frame. The invention provides a chainsaw chain processing platform on which side chain links and left and right saw blades can be installed alternately, which greatly improves the assembly and processing efficiency of the chainsaw chain and reduces labor costs. The contact with the saw blade reduces the potential safety hazard of the saw blade to human beings during installation and improves the production efficiency.

Owner:金华宏景工具制造有限公司

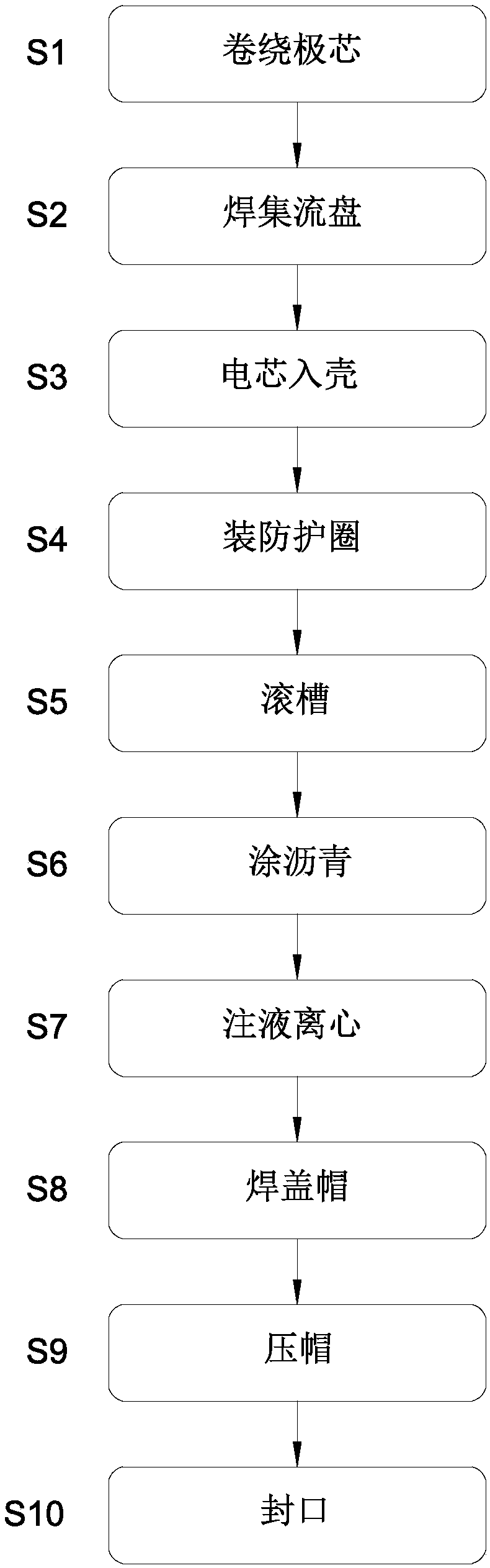

Assembly processing method of SC battery

InactiveCN108232274AGuaranteed performanceStable structureFinal product manufactureCylindrical casing cells/batteryCentrifugationEngineering

The invention provides an assembly processing method of an SC battery. The assembly processing method sequentially comprises the following steps of winding a pole shank; welding a collector plate, wherein the concentricity of the pole shank and the collector plate is within 0.2mm, welding points are 8 to 12, and the welding tension is not less than 20N; loading the pole shank into a shell; mounting a protective ring: embedding, by a manipulator, the protective ring between the battery shell and the collector plate; slot rolling: wherein the width of a groove is 3mm to 5mm, and the depth of thegroove is 1.2mm to 1.6mm; asphalt coating; electrolyte injection and centrifugation: injecting an electrolyte into the battery shell and realizing centrifugal operation by an electrolyte injection and centrifugation device; cap welding, wherein the welding tension is not less than 15N; cap pressing; sealing. The assembly processing method can be used for preventing the collector plate and the battery shell from generating a short circuit; thus, the performance of the SC battery is effectively ensured; the made SC battery is stable in structure and high in sealability, and further, has higherresistance; the service life of the battery is long; the assembly processing efficiency is high, and the quality consistency of SC batteries made in a batch manner is high.

Owner:东莞市朗泰通实业有限公司

Electric saw chain machining platform with protection mechanism

The invention discloses an electric saw chain machining platform with a protection mechanism. The electric saw chain machining platform comprises a rack, a driving chain wheel, a driven chain wheel and a side chain plate, wherein the rack is provided with a first rotating disc and a second rotating disc which are used for conveying saw blades and side chain links, and the first rotating disc and the second rotating disc are the same in structure and are arranged on the two sides of the driving chain wheel in a mirror symmetry mode; a plurality of conveying rods are evenly arranged on the first rotating disc and the second rotating disc, and second electromagnets used for attracting the saw blades and the side chain links are arranged on the conveying rods; and a first conveying box and a second conveying box which are matched with the conveying rods are arranged on the rack, and the first conveying box and the second conveying box are arranged on the rack through a first air cylinder and a second air cylinder. According to the electric saw chain machining platform, the side chain links, the left saw blade and the right saw blade can be arranged in a staggered mode, so that the assembling and machining efficiency of an electric saw chain is greatly improved, manual contact with the saw blades is reduced, therefore, potential safety hazards to workers during installation of the saw blades are reduced, and production efficiency is improved.

Owner:金华宏景工具制造有限公司

Break valve

InactiveCN100386548CPrevent difficultyReduce intensityOperating means/releasing devices for valvesPlastic/resin/waxes insulatorsRotational axisBall bearing

Provided is a cutoff valve which can simultaneously achieve highly reliable gas tightness, stable operation performance by small electric power, operation durability, and profitability. The inside pan shape portion of a metallic partition wall, a recessed portion formed on a lid made of a metal sheet, a tip end small diameter shaft and a small diameter groove formed on a metallic rotary shaft, and a plurality of metallic balls form rolling bearings for serving as both a radial bearing and a thrust bearing respectively, and hold the axis of a rotor. Because linear expansion coefficients of the rotary shaft and the holding member side are almost equal, possibility of the locking due to a temperature change is low, and the minimum radial clearance can be set. Because the accuracy of the axis of the rotor is high, stable operation performance can be achieved by small electric power, and high operation durability can be achieved by a rolling motion. Because the rolling bearings for serving as both the radial bearing and the thrust bearing are configured, high profitability can be achieved.

Owner:PANASONIC CORP

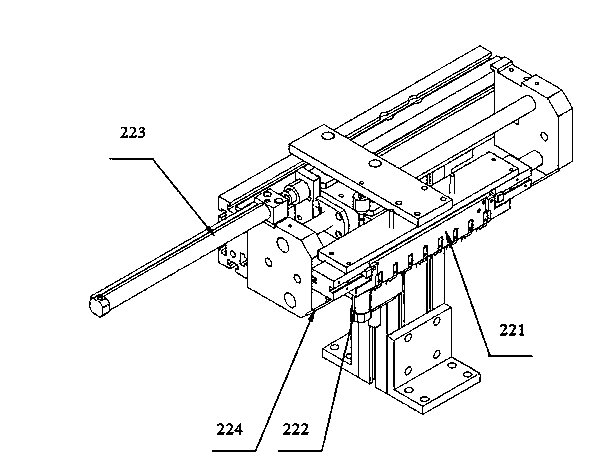

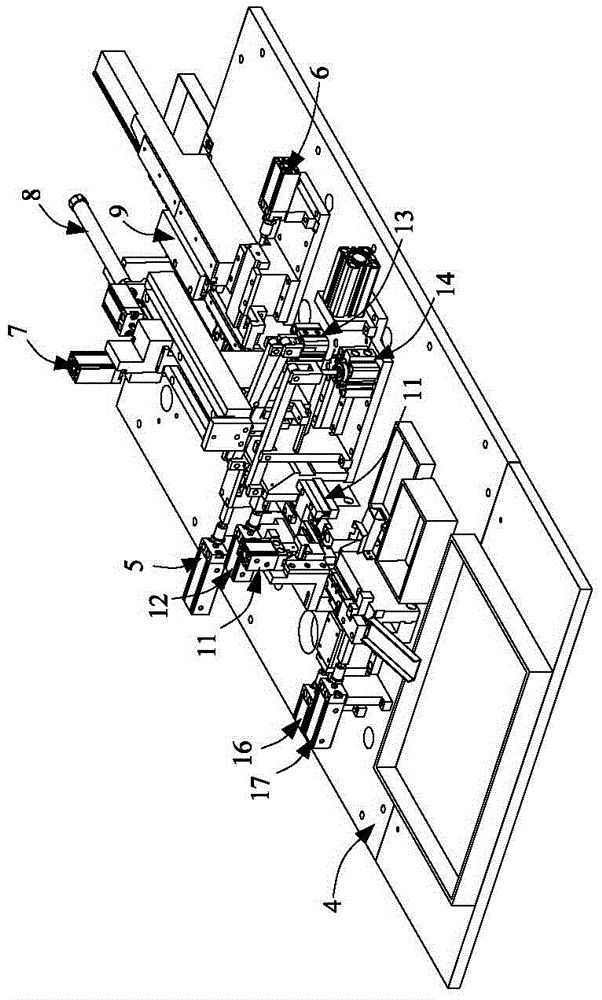

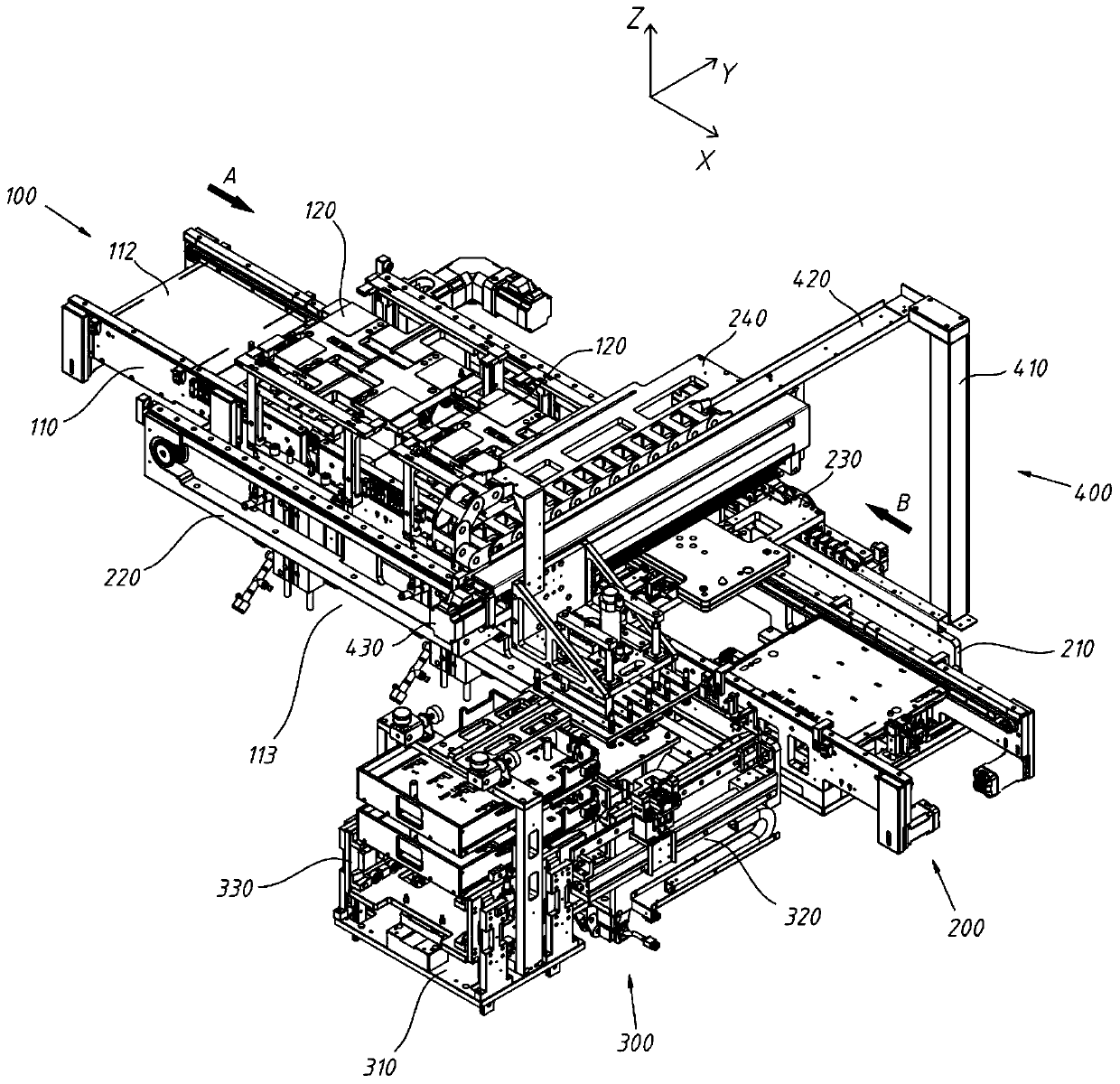

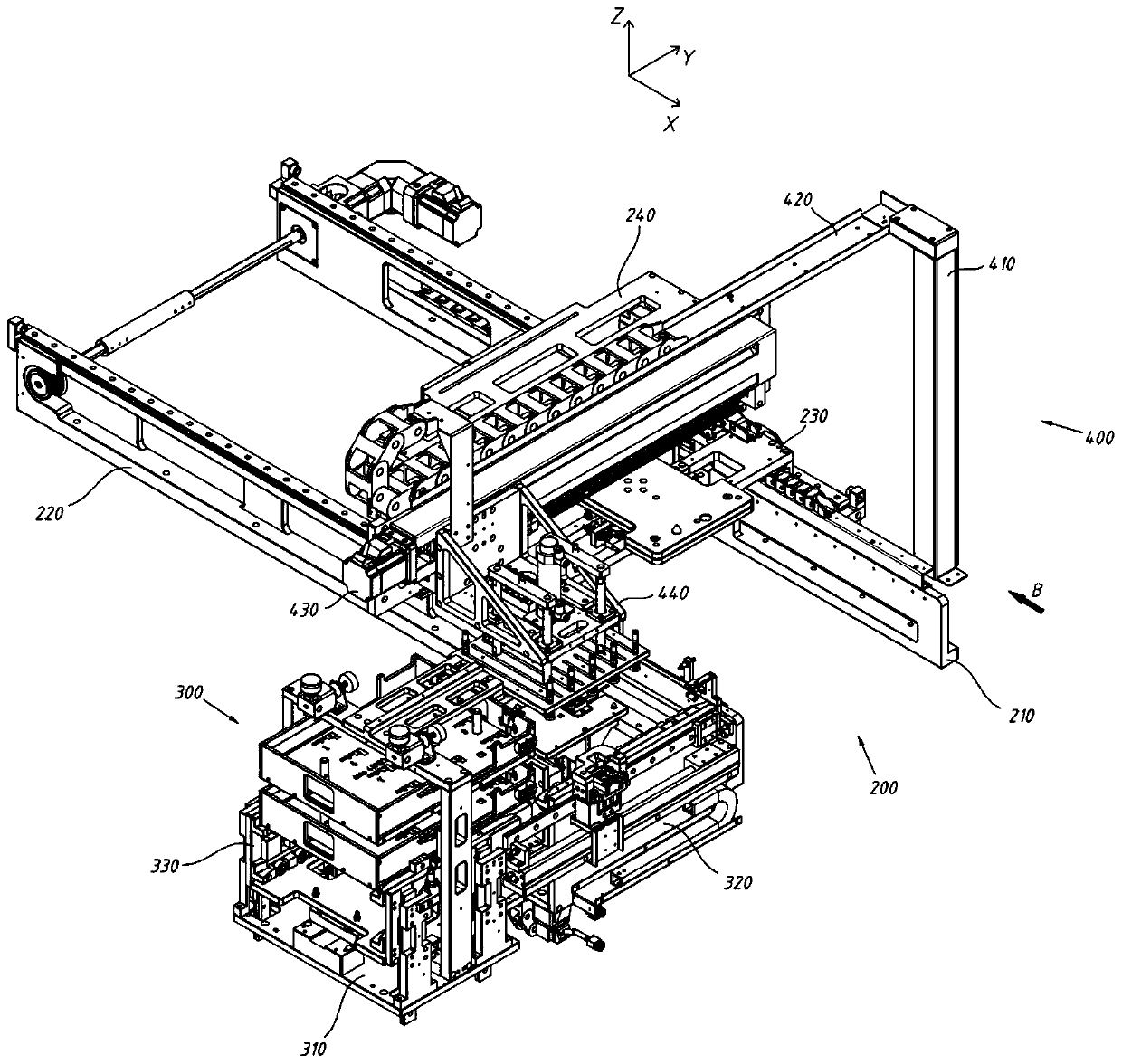

Automatic riveting machine matched wiring mechanism and wiring method

PendingCN108365498AImprove assembly processing efficiencyEasy processing and assemblyLine/current collector detailsEngineeringMechanical engineering

The invention discloses an automatic riveting machine matched wiring mechanism. The automatic riveting machine matched wiring mechanism comprises a working table, a feeding apparatus, a pushing apparatus, a detection apparatus and a wire releasing and collecting apparatus, wherein the working table is provided with a four-scale-division rotary apparatus; the four-scale-division rotary apparatus isprovided with a wire clamping assembly for clamping a wire; the feeding apparatus is used for clamping the wire on the wire clamping assembly; the pushing apparatus is used for riveting the wire on the wire clamping assembly; the detecting apparatus is used for detecting the riveted wire on the wire clamping assembly; the wire releasing and collecting apparatus is used for enabling the wire detected on the wire clamping assembly to fall off; and the four-scale-division rotary apparatus drives the wire clamping assembly to pass through the feeding apparatus, the pushing apparatus, the detection apparatus and the wire releasing and collecting apparatus in sequence. By virtue of setting of the feeding apparatus, the pushing apparatus, the detection apparatus, the wire releasing and collecting apparatus and the four-scale-division rotary apparatus, quick operation of wire feeding is realized, the problems of difficulty in manual wire feeding and low efficiency are solved, the wire material assembling and processing efficiency is improved, human cost is lowered, and wire material assembling and processing can be simpler and easier.

Owner:东莞市星擎电子科技有限公司

Efficient diode feeding device based on intelligent manufacturing technology

PendingCN113879783AAvoid staggeringImprove the delivery effectConveyor partsRotary conveyorsManufacturing technologySemiconductor technology

The invention relates to the technical field of semiconductors, and discloses an efficient diode feeding device based on intelligent manufacturing technology. The efficient diode feeding device comprises a machine body, wherein a crankshaft is arranged in the machine body, and a convex block is arranged on the surface of the crankshaft; a first push plate is arranged on the surface of the convex block, and a first push rod is arranged on the surface of the first push plate; a push ring is arranged at the end, away from the first push plate, of the first push rod, and a second push rod is arranged on the surface of the first push plate; a material conveying plate is arranged on the surface of the machine body, and a rotating ring is arranged on the surface of the crankshaft; and a shaft rod is arranged on the surface of the rotating ring. According to the efficient diode feeding device based on the intelligent manufacturing technology, through cooperative use of a conveying device and a material conveying disc, cooperative use of the material conveying disc and a material conveying pipe and cooperative use of the material conveying pipe and the material conveying plate, diodes can be continuously and singly conveyed, so that staggering of the diodes can be prevented, the diode conveying effect is good, and feeding and conveying of the diodes are facilitated.

Owner:高德庆

A hdmi-cf electrical connector automatic assembly machine

InactiveCN103855592BImprove assembly processing efficiencyTo achieve the purpose of automated productionContact member assembly/disassemblyHDMIEngineering

The invention discloses an HDMI-CF electric coupler automatic assembling machine. A vibration disk is arranged and a first feeding mechanism is arranged on an operating platform, so automatic feeding of metal shells can be achieved; a second feeder and a third feeder are arranged on the operating platform, so automatic feeding of rubber core material strips can be achieved; in addition, when the rubber core material strips are fed, a first material cutting mechanism can cut off wastes at head ends of the rubber core material strips; through a metal shell fixing mechanism and a rubber core inserting mechanism, rubber cores can be inserted into the metal shells; a rubber core correcting mechanism is arranged subsequently, so the rubber cores can be corrected; a clamping point riveting mechanism can rivet clamping points of the metal shells and enable the rubber cores not to retreat; a material strip pre-cutting mechanism works in cooperation with a second material cutting mechanism to cut off the material strips at the back ends of the rubber cores to obtain finished products; the finished products are conveyed to a detection mechanism for automatic quality and performance detection, qualified products can be used for feeding directly, unqualified products can be conveyed to an unqualified product collection box through a sorting mechanism, so full-automatic production of the rubber cores and the metal shells can be achieved.

Owner:DONGGUAN KECHENDA ELECTRONICS TECH

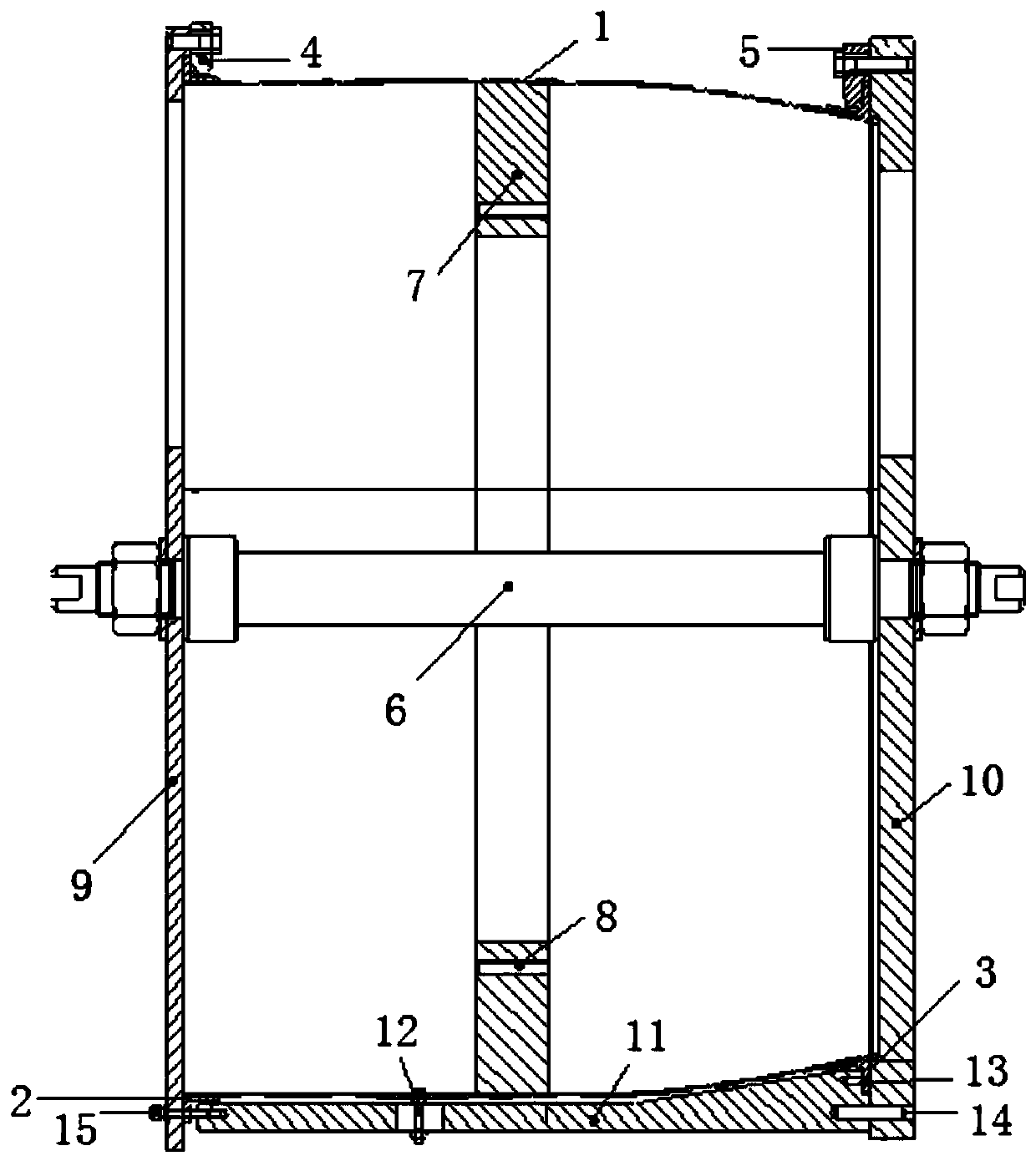

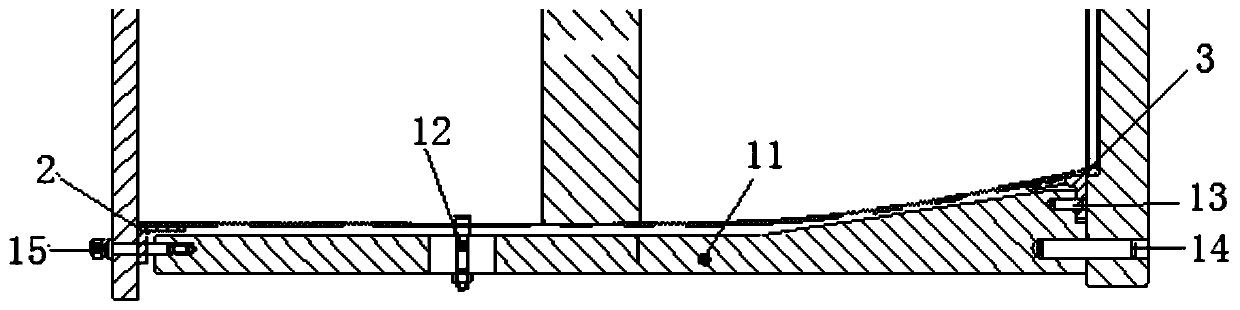

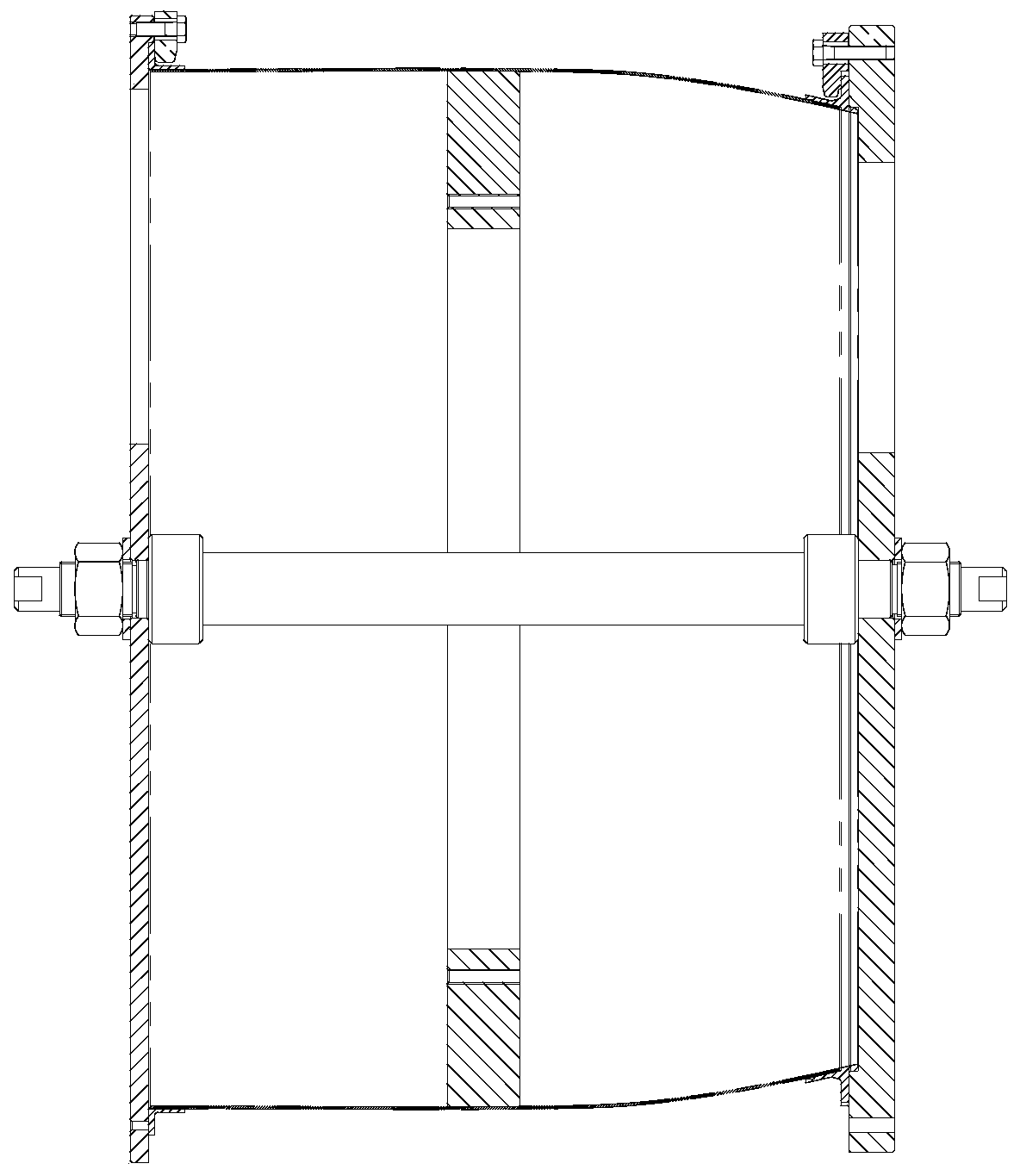

A clamping device for riveting assembly of large thin-walled components

The invention discloses a clamping device for riveting assembling of a large thin-walled assembly. The clamping device comprises a mandrel shaft, an angular positioning assembly, a left plugging disc,a right plugging disc, a left pressing plate and a right pressing plate. Peripheral equipment is a to-be-clamped barrel, a left flange and a right flange. The left flange is connected to the left plugging disc through the left pressing plate. The right flange is connected to the right plugging disc through the right pressing plate. The inner side faces of the left plugging disc and the right plugging disc are attached to the two end faces of the barrel. The mandrel shaft penetrates through center holes of the left flange and the right flange to fix the barrel, the left flange and the right flange together. The angular positioning assembly achieves angular positioning between the left flange, the right flange and the barrel by being matched with pin holes in the left flange, the right flange and the barrel. After the angular positioning assembly is disassembled, machining of each rivet hole of an outer ring of the assembly and the mounting seat position is completed, and the double functions of assembling positioning and mechanical machining clamping are achieved. The clamping device can solve the problems that positioning during assembling of the large thin-walled part is not accurate, and the quality uniformity is not high.

Owner:BEIJING POWER MACHINERY INST

A fully automatic thread riveting machine and a thread riveting method using the automatic thread riveting machine

InactiveCN103701010BImprove assembly processing efficiencyReduce labor costsLine/current collector detailsDisplay deviceEngineering

The invention discloses a full-automatic wire riveting machine and a wire riveting method applying the same. The wire riveting machine is simultaneously provided with a feeding device, a display device, a material pulling device, a clamping device, a pay-off unit, a cam driving device, an upwards-pushing locating device, a wire pressing device, a material cutting device and a riveting device, wherein the feeding device and the material pulling device are cooperated so as to convey terminal material strips automatically according to a set locus; the clamping device is used for clamping and locating a main body part of a terminal at a wire riveting station; the pay-off unit is used for towing a wire to the neighborhood of the wire riveting station; the cam driving device is used for sequentially driving the upwards-pushing locating device, the wire pressing device, the material cutting device and the riveting device to operate; when a rotating shaft is rotated for a circle, all riveting and pressing operations can be finished. The full-automatic wire riveting machine disclosed by the invention can be used for realizing automatic operation of wire and terminal riveting assembly, replacing manual assembly, effectively improving the wire assembly processing efficiency, lowering the manpower cost and ensuring that wire assembly processing is simpler and easier.

Owner:东莞市星擎电子科技有限公司

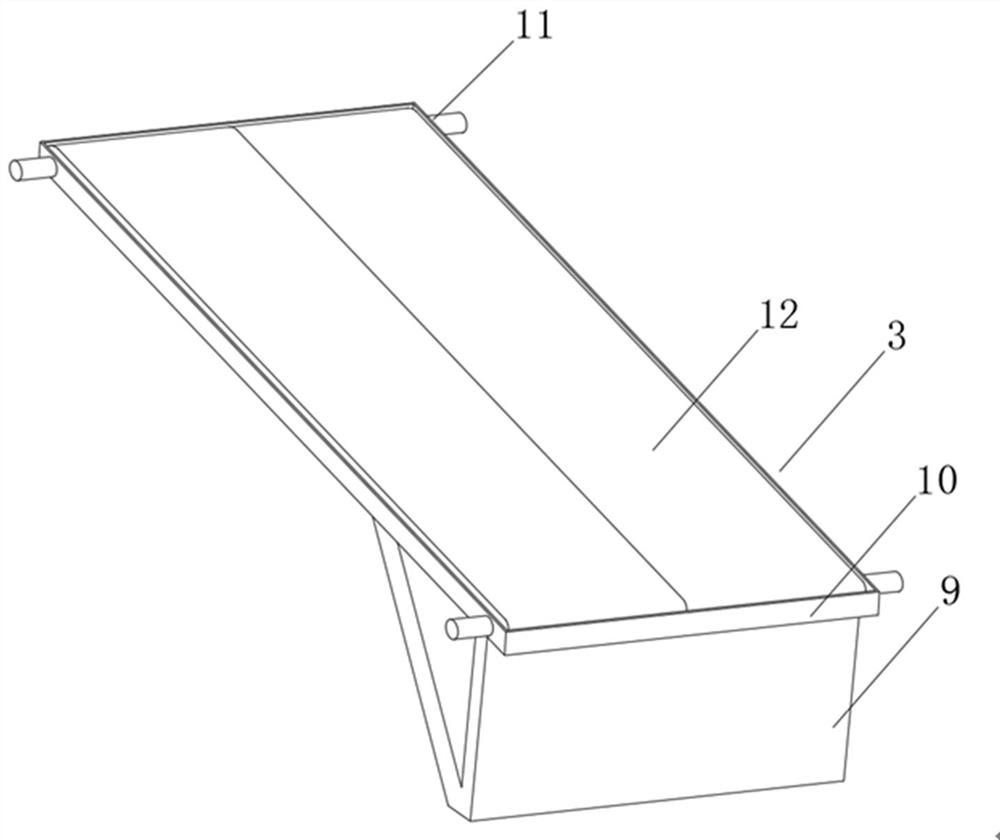

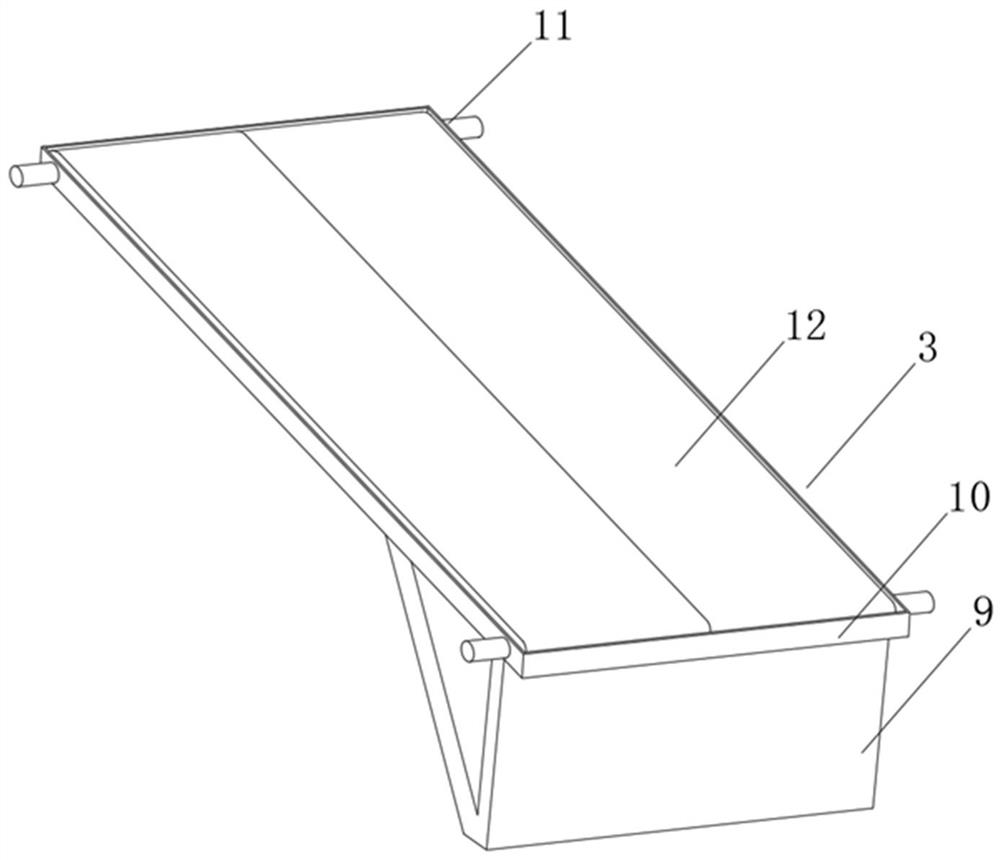

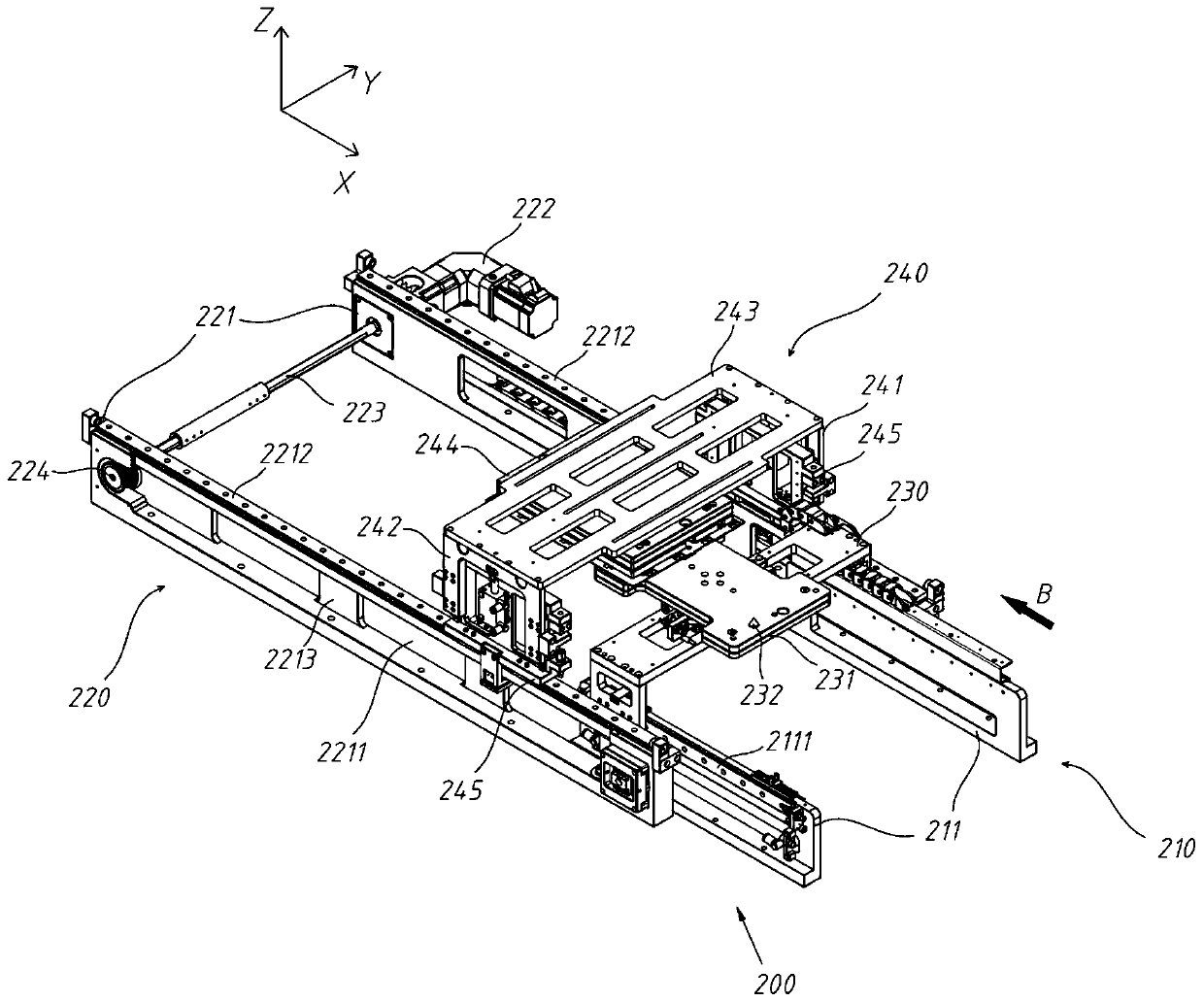

Circulation type bidirectional assembly line

PendingCN110775558AReduce the handling processSmall footprintMetal working apparatusMechanical conveyorsBidirectional transmissionEngineering

The invention discloses a circulation type bidirectional assembly line. The line comprises an assembly line, a carrying line and a circulation type feeding device arranged beside the carrying line, wherein projection parts, on a horizontal plane, of the assembly line and the conveying line are partially or overall overlapped, the conveying direction of the assembly line is opposite to the carryingdirection of the carrying line, a transferring device is arranged between the carrying line and the circulation type feeding device, and the transferring device comprises a transferring rack erectedon the carrying line and a transferring mechanism periodically reciprocating between the circulation type feeding device and the carrying line. According to the assembly line, a bidirectional conveying mode is adopted, the occupied area of equipment is reduced, a material carrying stroke is shortened, the assembling / machining efficiency is improved, the interval of successive two-time assembling / machining is shortened, the assembling / machining efficiency is further improved, and the problem that the occupied area of an empty material plate or tray is large is solved by adopting a circulation type feeding mode.

Owner:BOZHON PRECISION IND TECH CO LTD

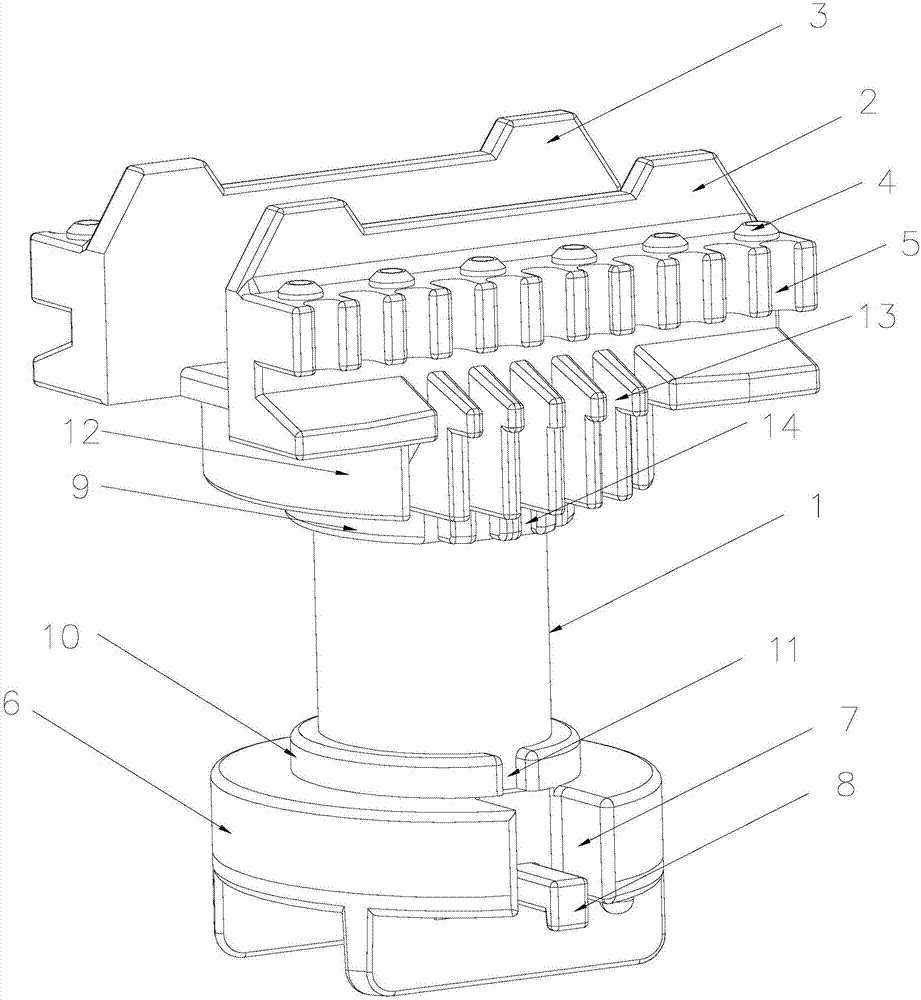

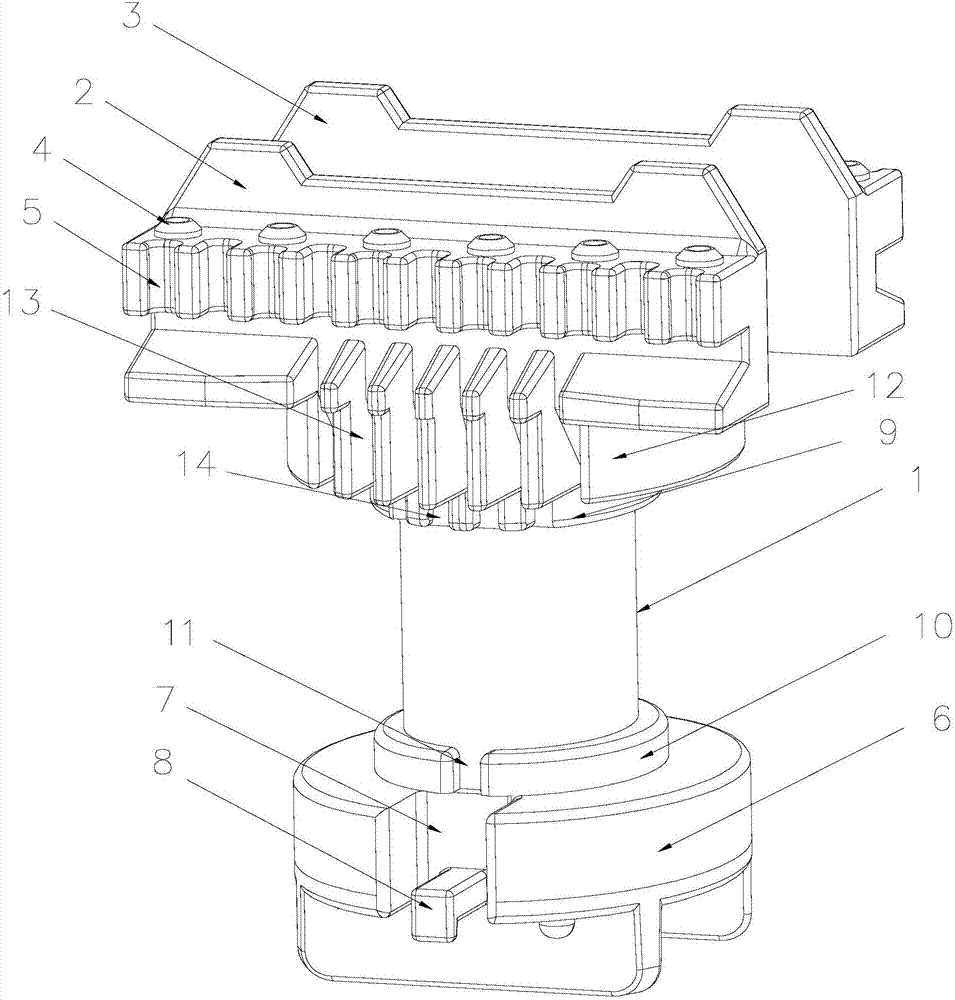

Transformer winding bobbin

InactiveCN106876117AImprove securityNot easy to short circuitTransformers/inductances coils/windings/connectionsBobbinEngineering

The invention discloses a transformer winding bobbin. The transformer winding bobbin comprises a primary end, a secondary end and a winding shaft, wherein the primary end and the secondary end are fixed on two opposite sides of the upper end of the winding shaft respectively; a plurality of PIN seats are fixed to each of the primary end and the secondary end; a plurality of first lead wire grooves are formed in the outer surface of each of the primary end and the secondary end; a lower baffle is arranged at the lower end of the winding shaft; a tail wire lead-down groove is formed in the lower baffle; a hook block is arranged in the tail wire lead-down groove; a tail wire of a wire group is pulled out of the tail wire lead-down groove formed in the lower baffle; and the tail wire is wound around the hook block to be fixed, so that the tail wire does not need to be buried in a copper coil, a short circuit is difficultly caused, the safety performance of the wire group is improved, a winding mode is improved, automated winding can be realized, and the assembling processing efficiency is improved.

Owner:ZHUHAI LIMING YUNLU NEW ENERGY TECH

A processing device and processing method suitable for inverter shell assembly

ActiveCN111872657BAchieve positioningRealize clampingWork holdersMetal working apparatusPipe fittingNew energy

The invention discloses a processing device and a processing method suitable for inverter shell assembly, which belong to the technical field of inverter processing. Positioning blocks and force bearings are arranged on the workbench corresponding to the inverter shell to be assembled. Blocks, pressing claws, pin installation units and pipe fitting assembly components can quickly realize accurate positioning and clamping of workpieces, and then realize the sequential assembly of pins and pipe fittings by using the corresponding settings and mutual matching of the number and position of each part. The processing device suitable for inverter casing assembly of the present invention has simple structure, convenient assembly and operation, and the processing method for assembly is simple and convenient, and can realize accurate positioning and reliable clamping of the inverter casing, and After completing the positioning and clamping, the assembly of pins and pipe fittings is automatically and quickly completed, which effectively improves the assembly accuracy and efficiency of the inverter shell of new energy vehicles, reduces the assembly cost of the inverter shell, and has a relatively high performance. Good application prospects and promotion value.

Owner:广东鸿图武汉压铸有限公司 +1

A kind of autoclaved aerated concrete plate to make steel mesh assembly system

ActiveCN113059682BImprove assembly processing efficiencyReduce duplicationAuxillary shaping apparatusClassical mechanicsMesh reinforcement

The invention relates to an autoclaved aerated concrete plate to make a steel mesh assembly system, comprising a fixed base, a limit chute, a positioning device and an assembly device. The front and rear sides of the upper end face of the fixed base are symmetrically provided with limit chute , a positioning device is arranged in the limit chute, and an assembly device is symmetrically arranged on the front and rear sides of the upper end face of the fixed base. The invention can solve the problem that when the traditional steel mesh is assembled into a three-dimensional structure, it usually needs to be manually assisted to ensure its position alignment, the degree of mechanization is low, the labor intensity of workers is increased, and the stability of manual assistance is poor, resulting in assembly. The quality of the resulting three-dimensional structure decreases, and when the traditional steel mesh is assembled into a three-dimensional structure, it needs to be assembled from a certain number of steel meshes, which is difficult to assemble successfully at one time. Steps to assemble, waste manpower and material resources and other problems.

Owner:山东国厦新型建材有限公司

Steel wire punching machine and method for machining aluminum block through steel wire punching machine

The invention discloses a steel wire punching machine and a method for machining an aluminum block through the steel wire punching machine. The steel wire punching machine and the method for machiningthe aluminum block through the steel wire punching machine comprise a clamping part, a top punching part, a pressing part and a driving part; the clamping part can clamp and position the aluminum block under the pressing part, and the steel wire is placed between the aluminum block and the top punching part; the steel wire can be bent and inserted into the aluminum block through the top punchingpart; the pressing part moves downwards to be pressed on the aluminum block, and the aluminum block is deformed and extruded on the periphery of the steel wire, so that the steel wire is connected with the aluminum block; and the bending part of the steel wire extends out of the aluminum block to form a hanging ring pattern so as to be used for installing a spring in a folding crank arm. The assembling operation of the aluminum block and the steel wire is simple, and an operator only needs to place the steel wire between the aluminum block and the top punching part without manual bending of the steel wire; and the aluminum block inserted with the steel wire is not required to be transferred to a press bed manually, thus greatly improving the assembling efficiency and saving time and labor.

Owner:佛山市南海三力阳蓬有限公司

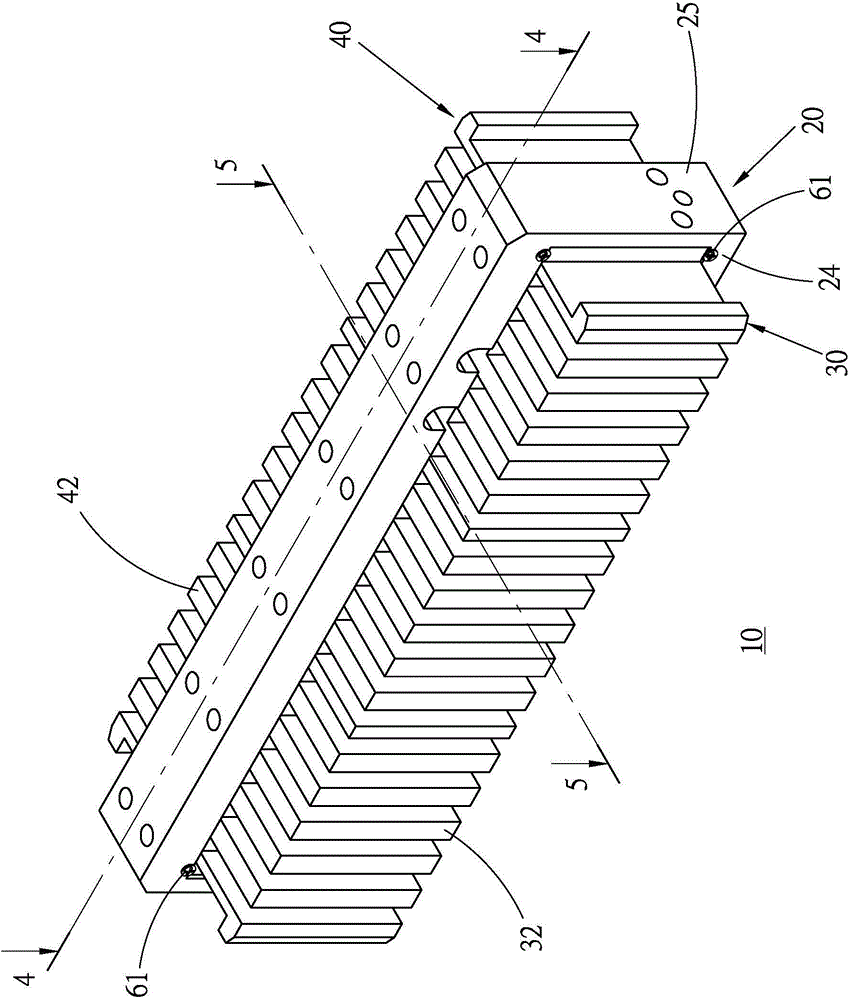

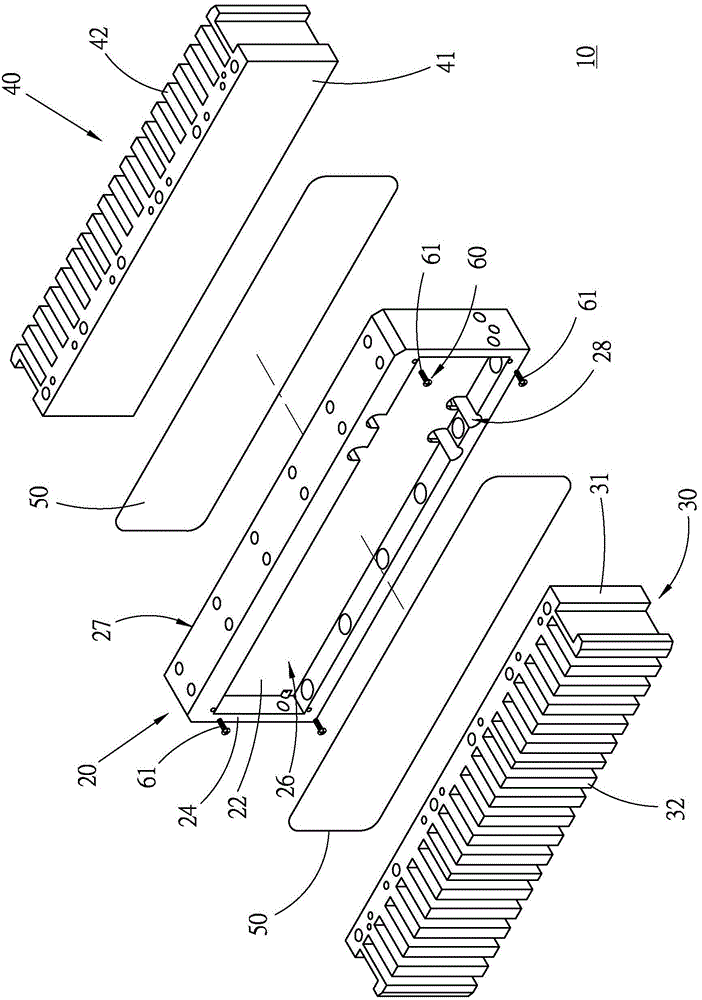

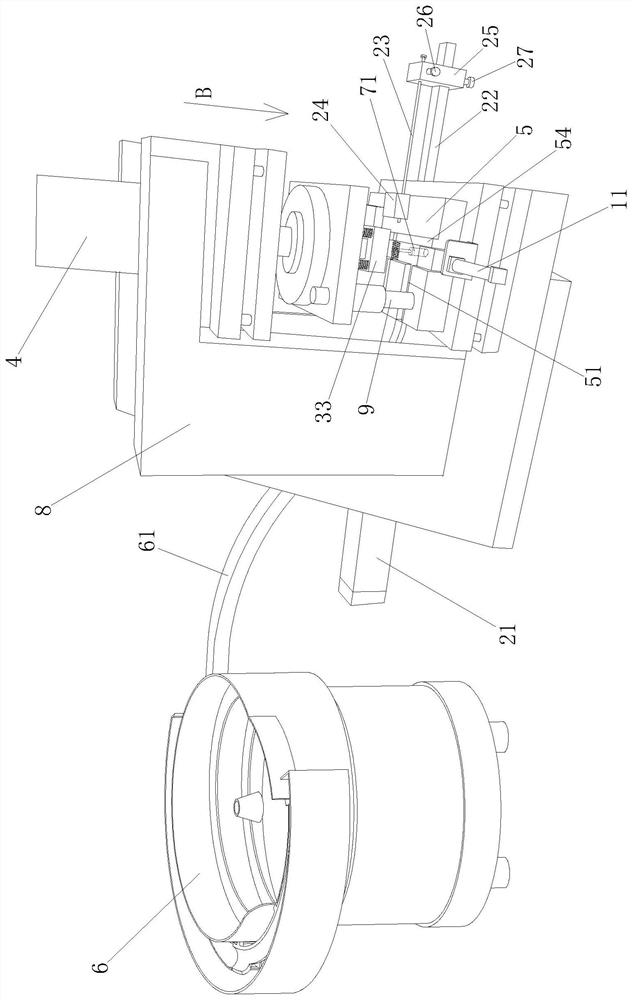

Iron core group of magnetic offset type linear motor

InactiveCN105576855AEasy to assembleEasy to processMagnetic circuit shape/form/constructionMagnetic tension forceCore component

The invention provides an iron core group of a magnetic offset type linear motor. The iron core group includes a base which is provided with a first end surface and a second end surface which backs onto the first end surface, a first iron core component which is fixedly arranged on the first end surface, and a second iron core component which is fixedly arranged on the second end surface; the base is provided with a base body; the first end surface is formed at one side base surface; a first ring-shaped positioning wall, protruding out from the first end surface, is arranged on the first end surface, and surrounds the peripheral side of the first iron core component; the first iron core component is provided with a first bottom portion which is attached to the first end surface at one side end surface, so that the peripheral side of the first iron core component can abut against the first positioning wall; and the first iron core component is also provided with a plurality of teeth which are distributed in a gridded manner and are arranged on the other side end surface of the first bottom portion and protrude out from the other side end surface of the first bottom portion. With the iron core group of the invention adopted, the efficiency of assembly and processing can be improved. The overall mechanical strength of the iron core group can be increased.

Owner:HIWIN MIKROSYST

Steel wire stamping machine and method for processing aluminum block by steel wire stamping machine

The invention discloses a steel wire punching machine and a method for machining an aluminum block through the steel wire punching machine. The steel wire punching machine and the method for machiningthe aluminum block through the steel wire punching machine comprise a clamping part, a top punching part, a pressing part and a driving part; the clamping part can clamp and position the aluminum block under the pressing part, and the steel wire is placed between the aluminum block and the top punching part; the steel wire can be bent and inserted into the aluminum block through the top punchingpart; the pressing part moves downwards to be pressed on the aluminum block, and the aluminum block is deformed and extruded on the periphery of the steel wire, so that the steel wire is connected with the aluminum block; and the bending part of the steel wire extends out of the aluminum block to form a hanging ring pattern so as to be used for installing a spring in a folding crank arm. The assembling operation of the aluminum block and the steel wire is simple, and an operator only needs to place the steel wire between the aluminum block and the top punching part without manual bending of the steel wire; and the aluminum block inserted with the steel wire is not required to be transferred to a press bed manually, thus greatly improving the assembling efficiency and saving time and labor.

Owner:佛山市南海三力阳蓬有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com