Noise-reducing planetary reducer

A planetary reducer and planetary technology, applied in the field of noise reduction planetary reducer, can solve the problems of reducing assembly processing efficiency, shortening the service life of gears, low qualification rate, etc., to improve assembly processing efficiency, reduce eccentric weight and processing cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

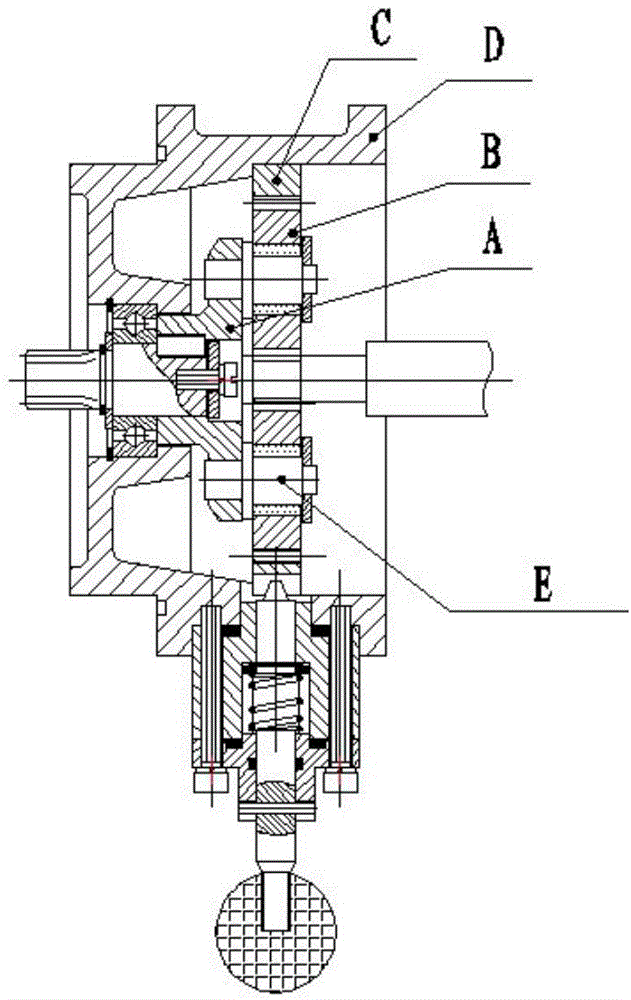

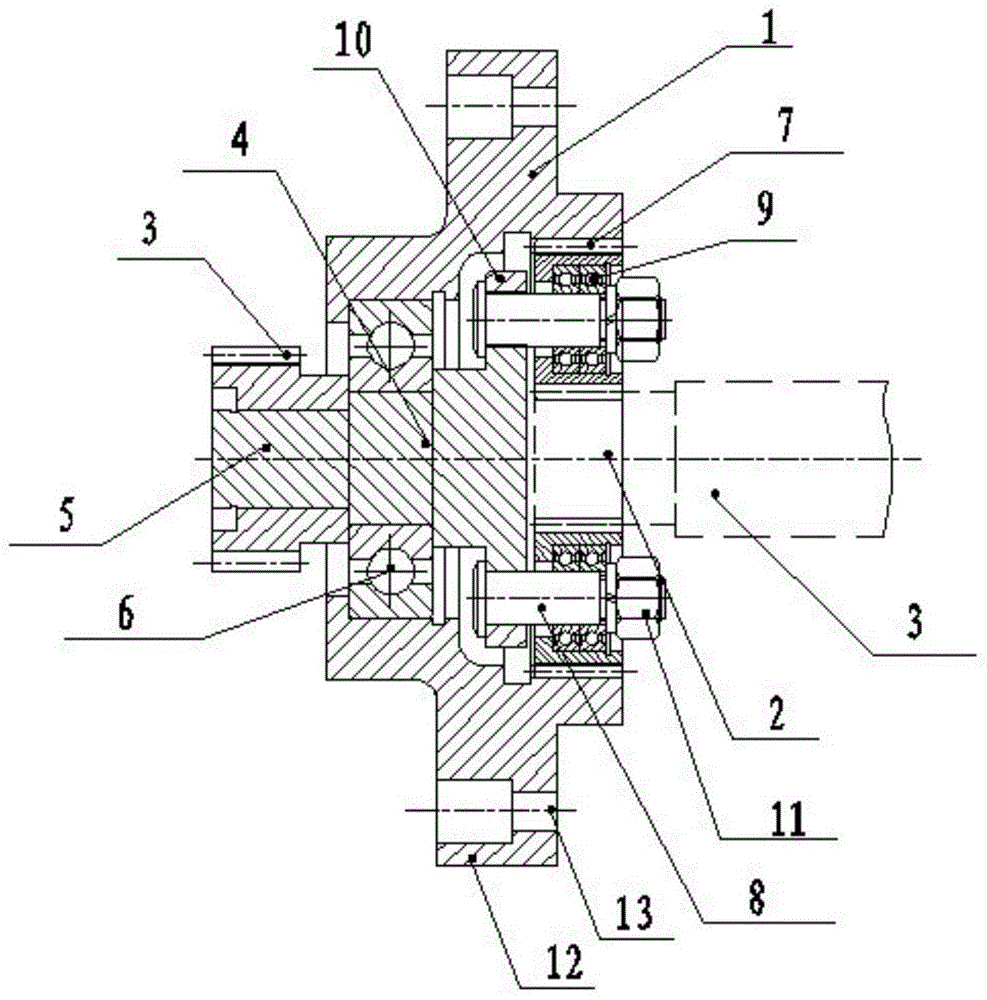

[0022] After many tests, it was found that the noise of the reducer is mainly generated by the meshing of the gears, and the meshing parts of the floating planetary disc, the internal gear and the planetary box.

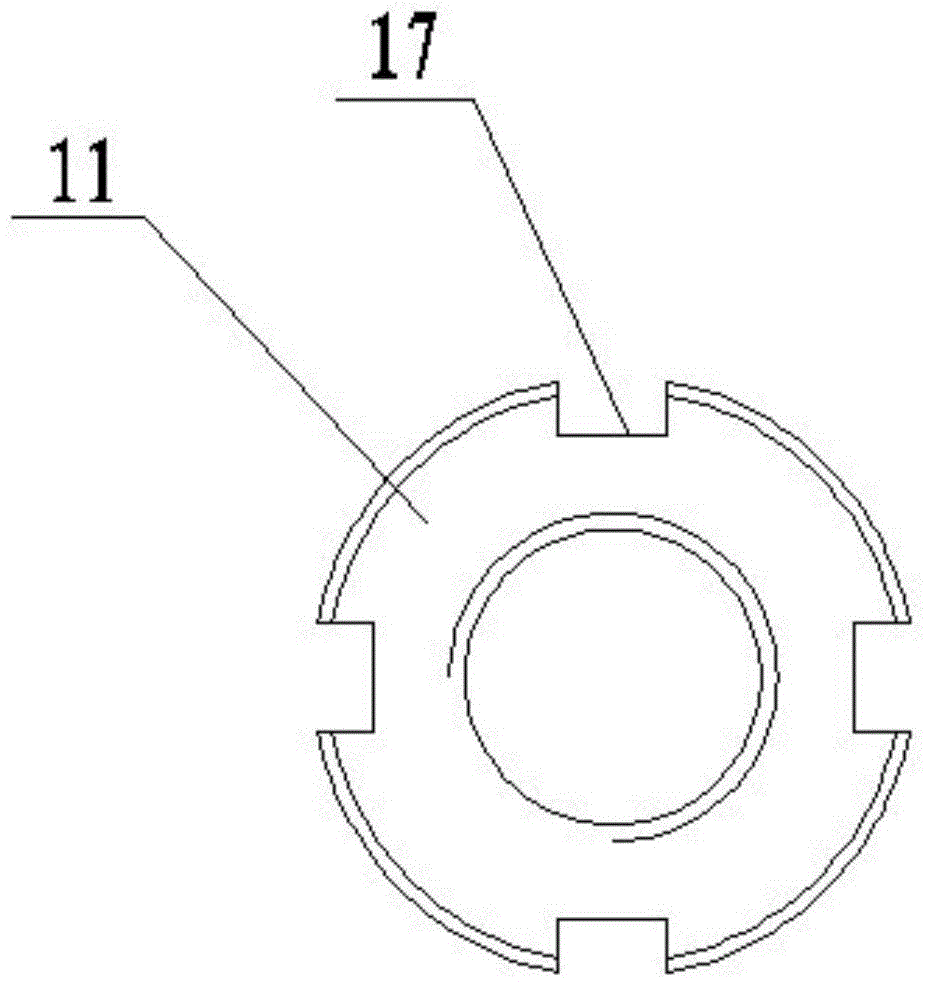

[0023] like Figure 2-4 As shown, the technical solution of the present invention is: a noise-reducing planetary reducer, including a planetary box 1, a planetary assembly, a planetary input gear 2 and a planetary output gear 3, and the planetary box 1 is sequentially arranged from left to right A planetary disc 4 and a planetary assembly are provided. The left end of the planetary disc 4 is connected to a planetary output shaft 5. The planetary disc 4 and the planetary output shaft 5 are integrally structured. The planetary output gear 3 is located on the planetary output On the shaft 5, a bearing 6 is arranged between the outside of the left end of the planetary disc 4 and the inside of the planetary box body 1. The planetary assembly is meshed with the inner gear,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com