An assembly machine for sheet metal connectors

A technology for connecting parts and assembling machines, which is applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low assembly and processing efficiency of sheet metal connectors, large differences in individual dimensions of sheet metal connectors, and low assembly efficiency. Achieve the effect of reducing labor cost input, improving assembly processing efficiency, and improving assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

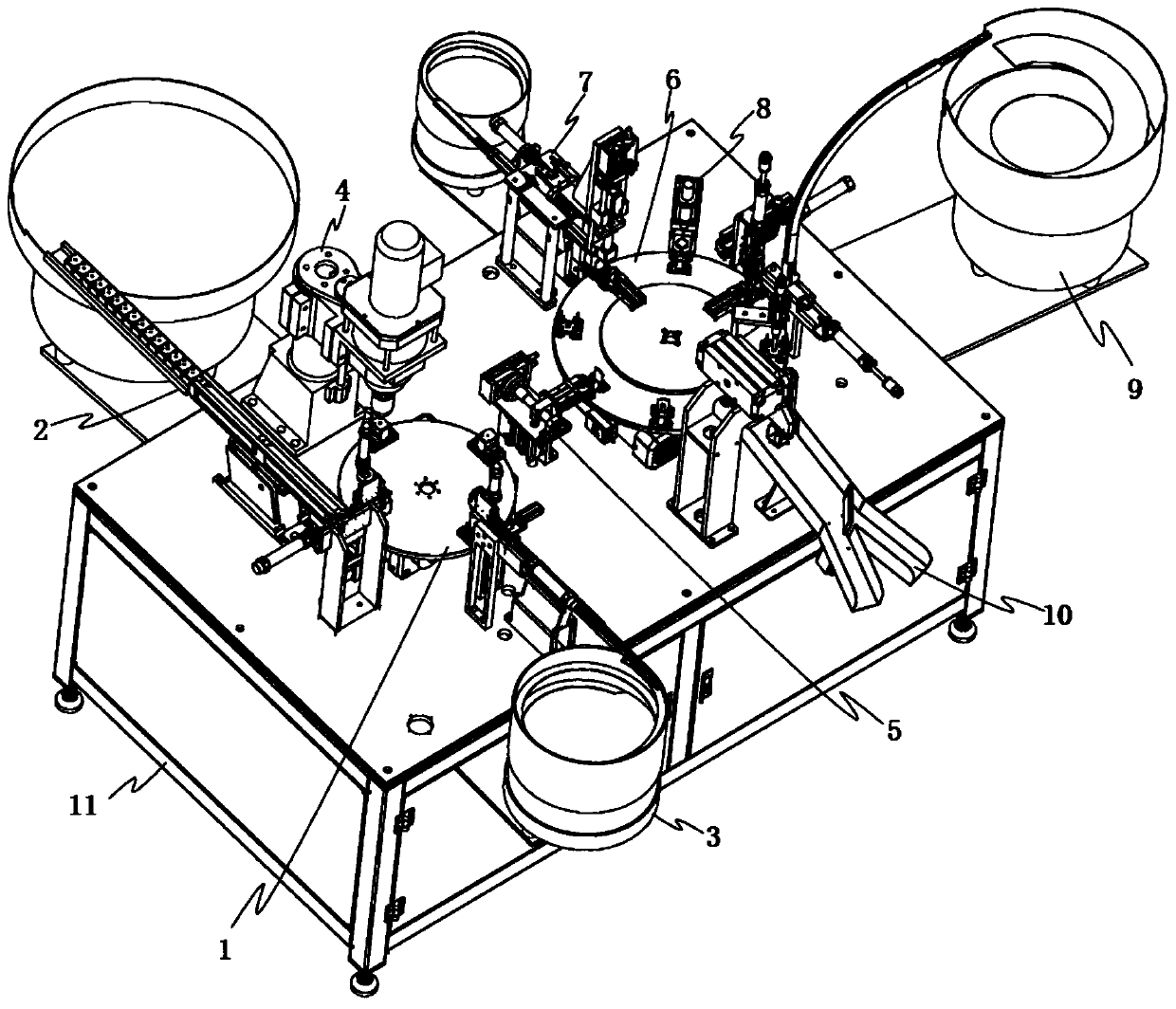

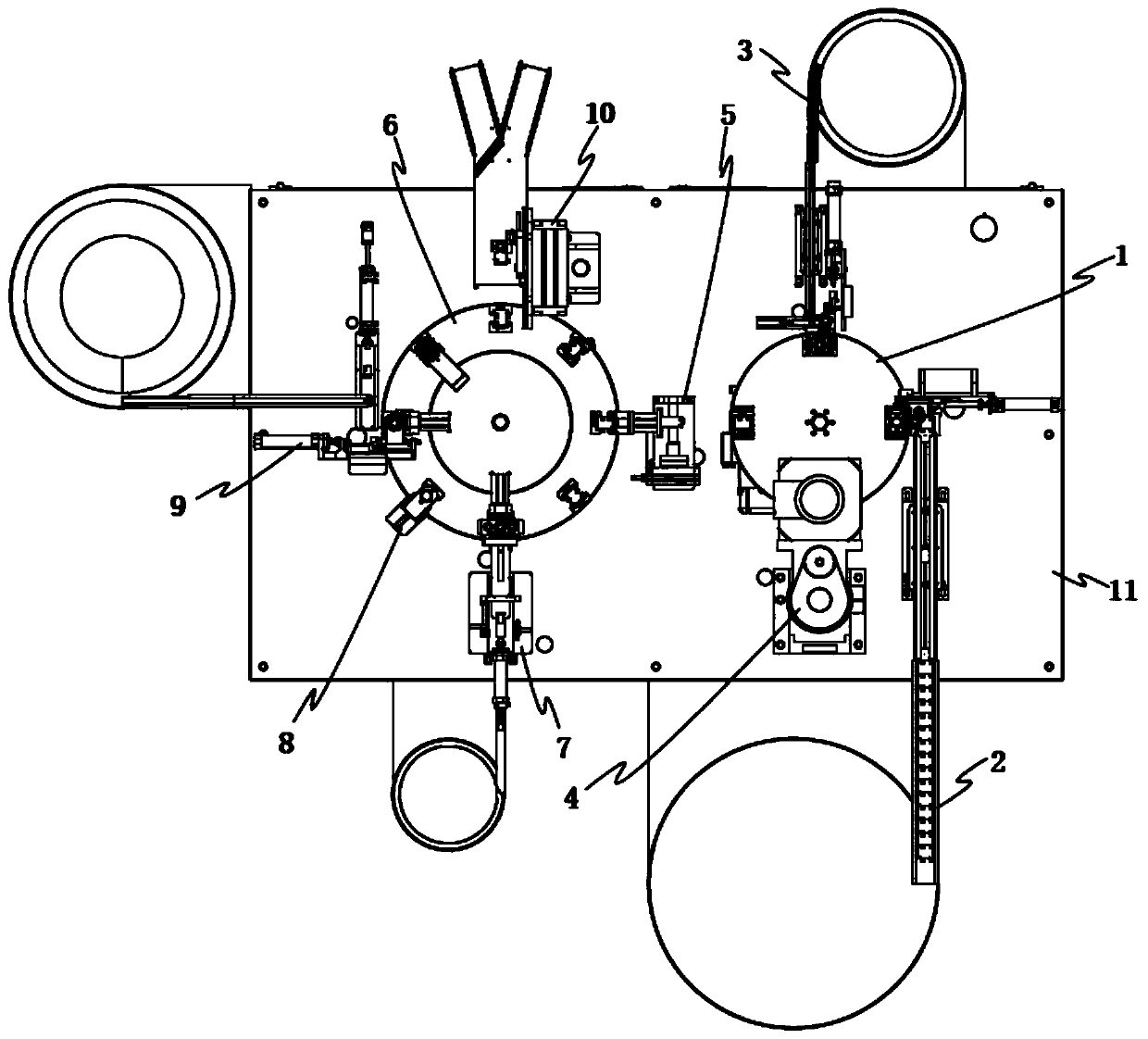

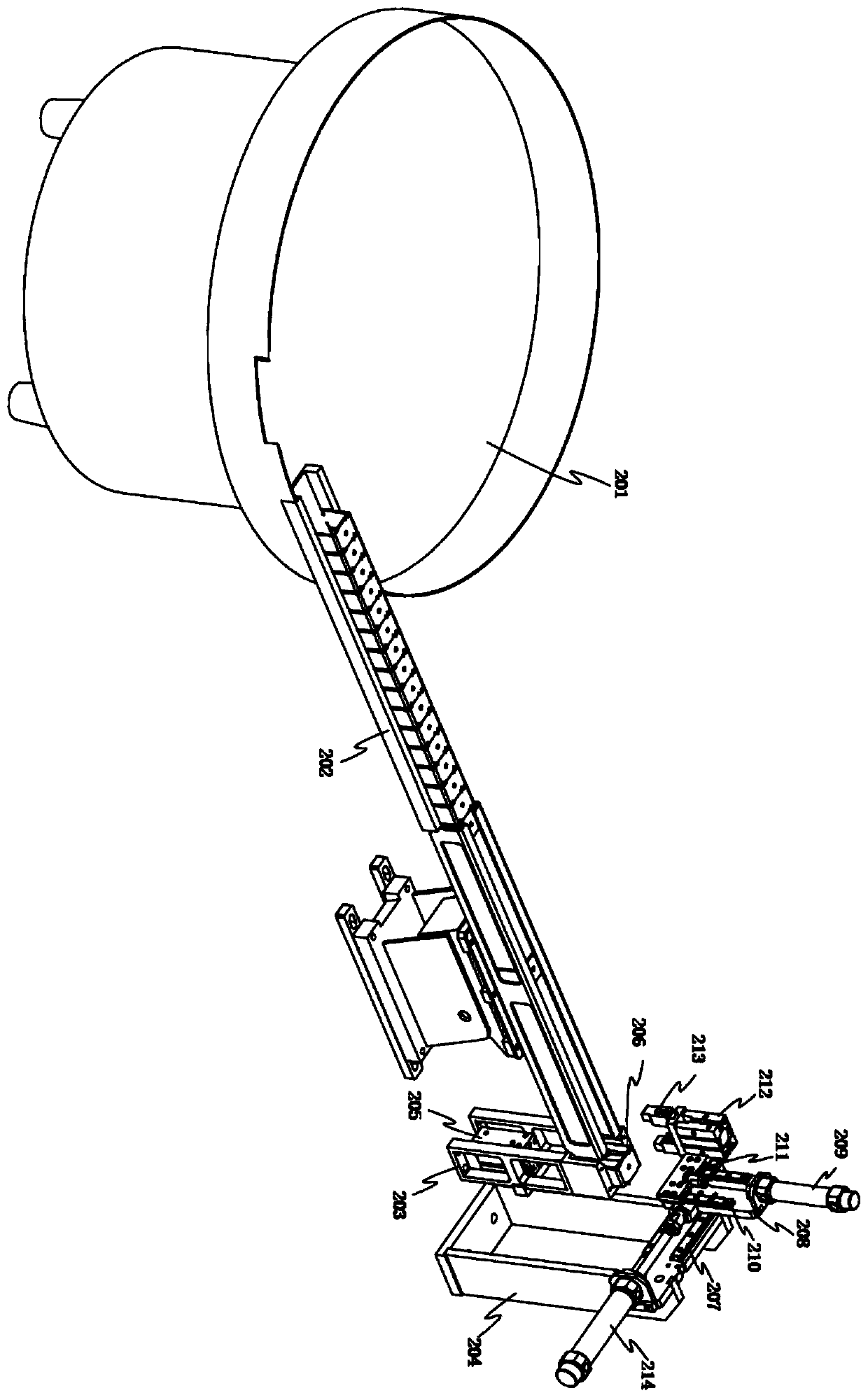

[0047] This assembly machine completes the first-stage assembly by the first turntable mechanism 1 and the small shaft input mechanism 3 around it, the sheet metal part input mechanism 2, and the riveting mechanism 4, and the second turntable mechanism 6 and the surrounding sealing ring input The embedment mechanism 7, the oil injection mechanism 8, the sleeve input mechanism 9, and the finished product output mechanism 10 complete the second stage of assembly processing and output, in which the assembly parts on the first turntable mechanism 1 are transferred to the second turntable by the turning mechanism 5 Mechanism 6 carries out the assembly and processing at the same stage. First, the small shaft is vibrated by the input vibrating plate II 302 of the small shaft input mechanism 3, and is transported along the output guide bar II 303 to the push-out block 305 on the upper end surface of the support base I 301 at the front side of the front end. Then, the push cylinder I304...

Embodiment 2

[0049] When the sheet metal parts are assembled on the second turntable mechanism 6, the turntable II601 on the upper end of the reversing gearbox II610 is driven by the drive motor II609 of the second turntable mechanism 6 to rotate, and the workpiece station II603 on the turntable II601 and the sheet metal on it are rotated. The metal parts are transferred to the lower part of the sealing ring input embedded mechanism 7, and the sealing ring is input into the input vibration plate III701 of the embedded mechanism 7 to vibrate and output the sealing ring, and the sealing ring is transported to the upper end of the output guide frame 704 on the front side along the output guide bar III703, Then start the horizontal driving cylinder III706, and the sliding plate base I707 is driven by the horizontal driving cylinder III706 to slide forward along the horizontal slide rail II705 to the top of the output guide frame 704, then start the vertical driving cylinder III708 on the output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com