Break valve and its assembly method

A technology of circuit breaker and partition wall, which is applied in the direction of valve device, valve operation/release device, circuit, etc. It can solve the problems of grain interface corrosion, gas leakage, stress corrosion, etc., and achieve high economy and prevent material strength. Effect of drop, high operating durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

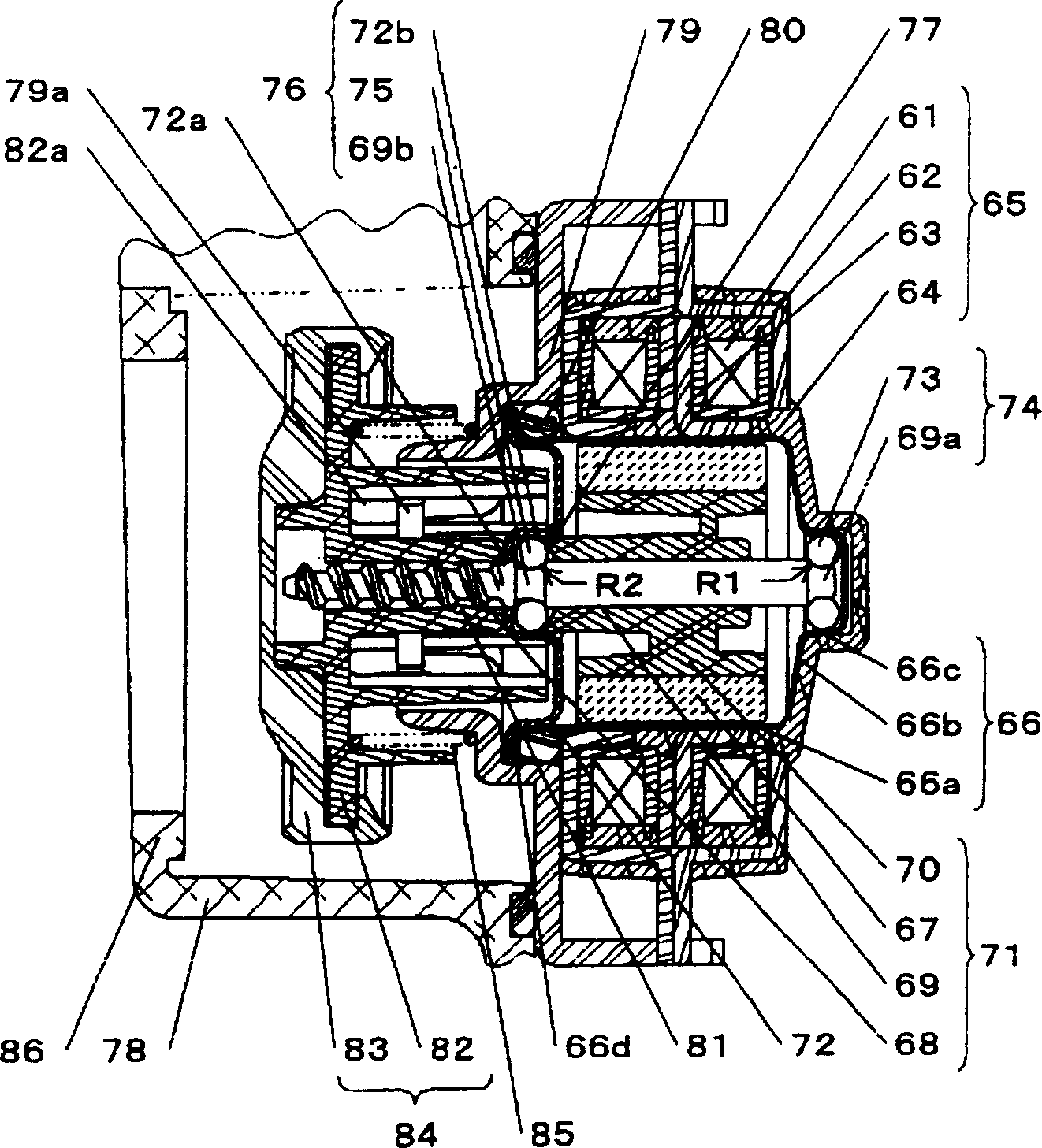

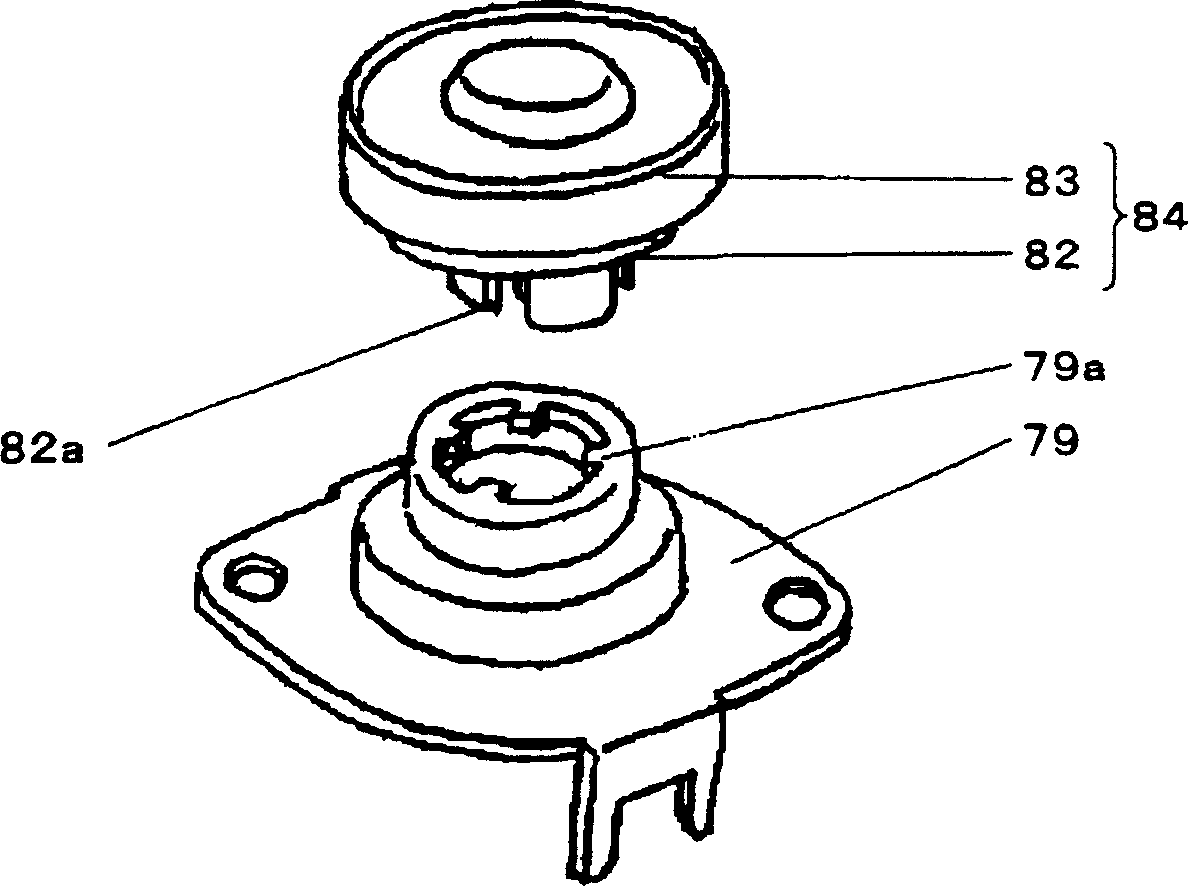

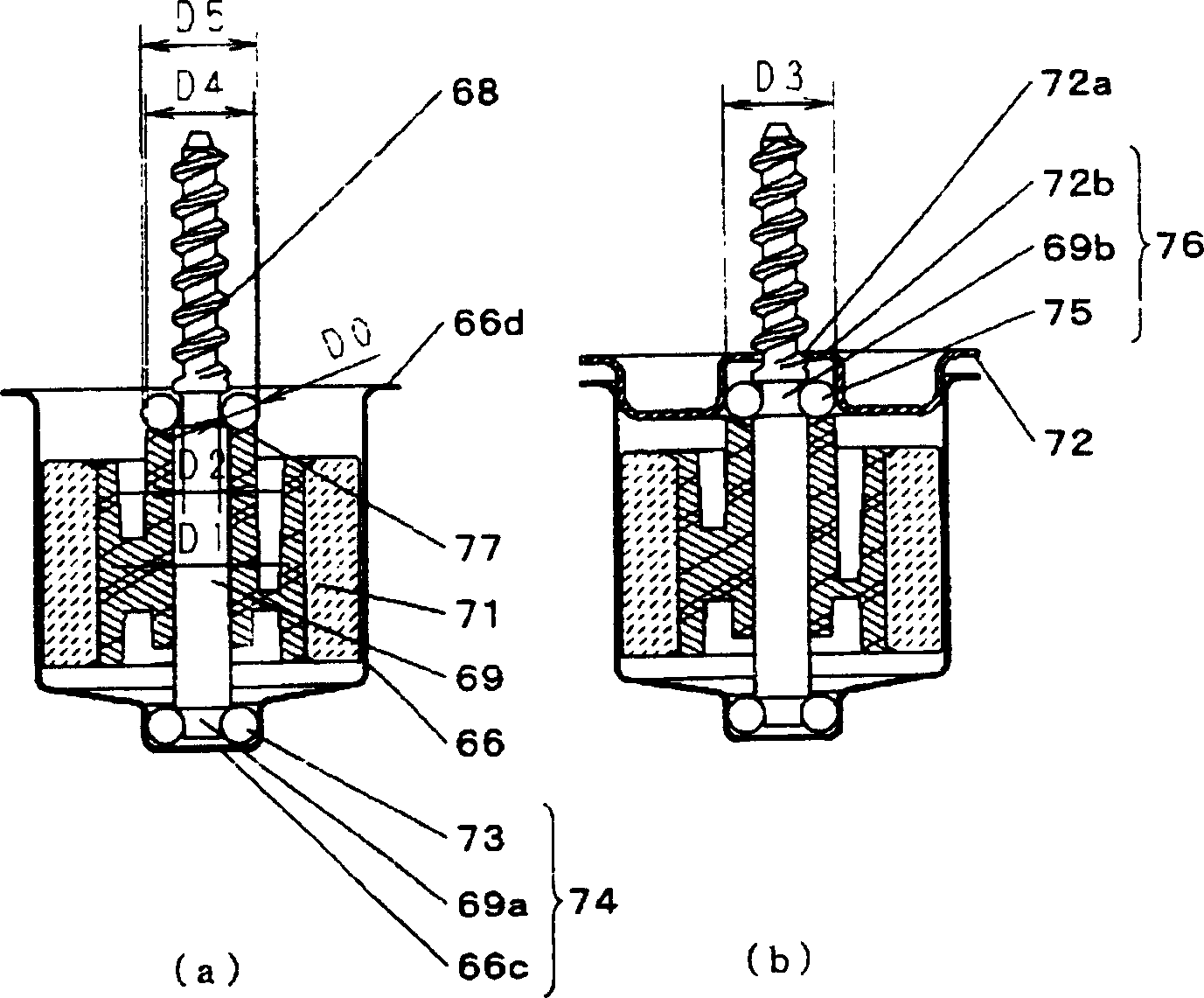

[0066] figure 1 It is a cross-sectional view of the shut-off valve in Embodiment 1 of the present invention in the valve-open state, figure 2 It is a perspective view of the flange and the valve body in the shut-off valve of Embodiment 1 of the present invention, image 3 shows a schematic diagram of the assembly process of the partition wall, the cover, the rotor, the radial / axial shared ball bearings on the opening end side and the bottom side of the partition wall in the circuit breaker valve according to Embodiment 1 of the present invention, wherein image 3 (a) is the assembly diagram before the cover is assembled, image 3 (b) is an assembly diagram of the cover in the insertion process, Figure 4 It is the partition wall, cover body, rotor, radial / axial shared ball bearings on the opening end side and the bottom surface side of the partition wall, valve body, spring and valve seat arranged in the flow path in the circuit breaker valve according to Embodiment 1 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com