Automatic riveting machine matched wiring mechanism and wiring method

A riveting machine and matching assembly technology, applied in the direction of line/collector parts, electrical components, circuits, etc., can solve the problems of inconvenient processing, low operation efficiency, difficult to control processing quality, etc., to reduce labor costs, assemble and process Simple and easy, the effect of improving the efficiency of assembly and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is further described in conjunction with the following examples.

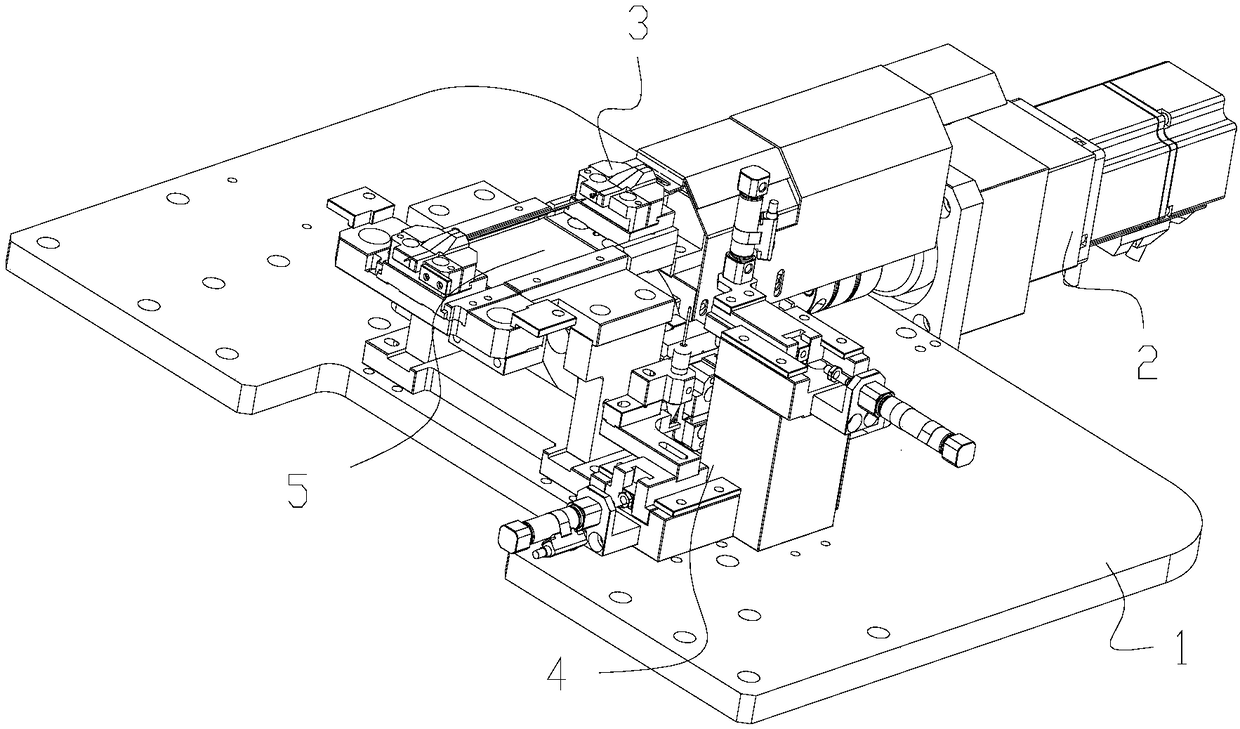

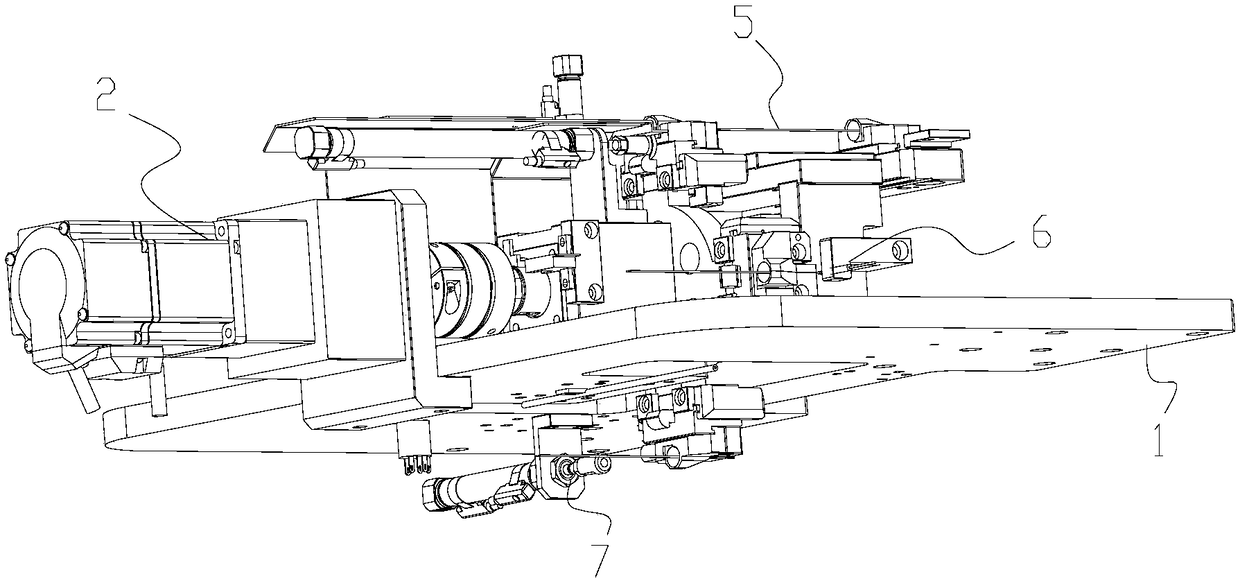

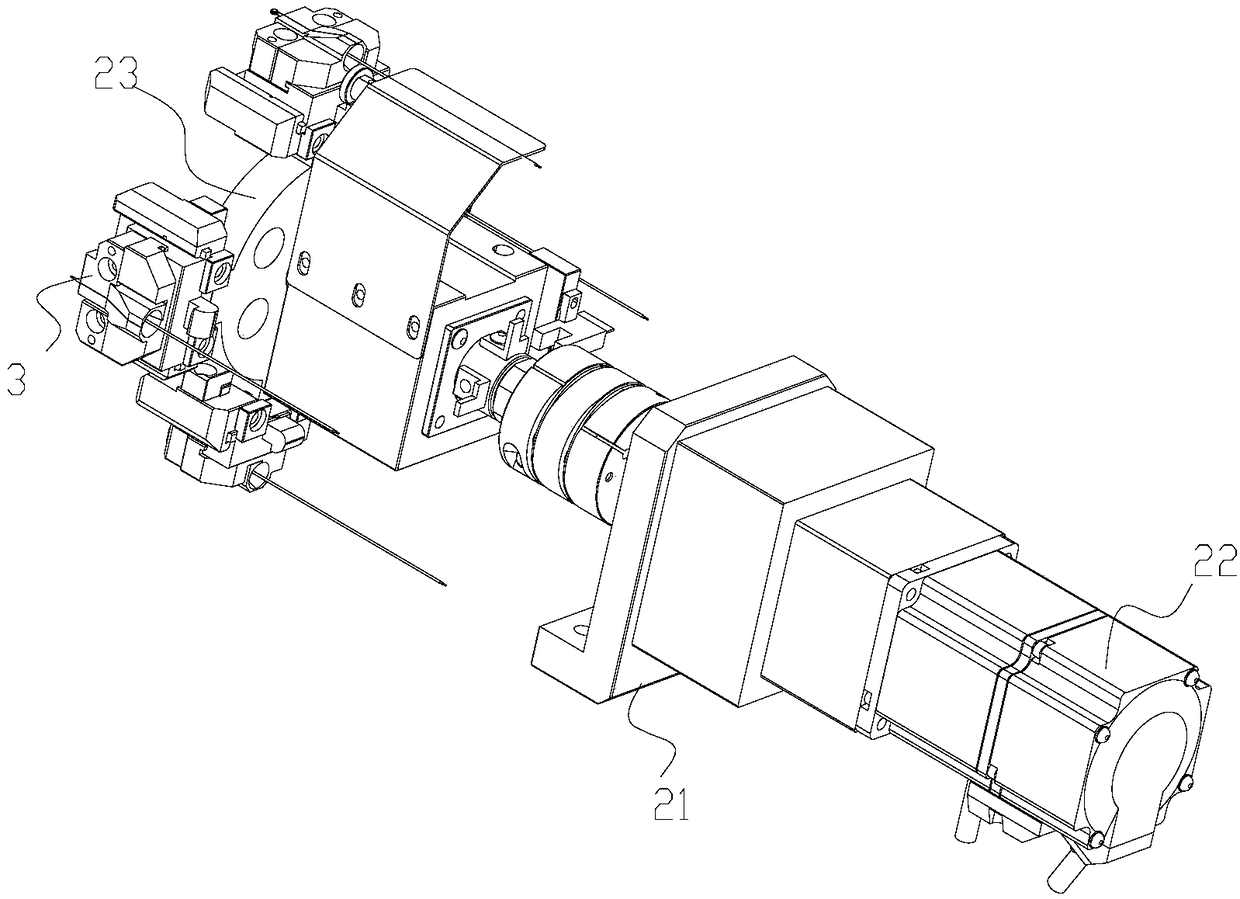

[0046] Depend on Figure 1 to Figure 10 It can be seen that the automatic riveting machine described in this embodiment is equipped with an assembly line mechanism, including a workbench 1; the workbench 1 is provided with a four-degree rotation device 2; the four-degree rotation device 2 is provided with a The clamping assembly 3 for clamping wires; the workbench 1 also includes:

[0047] The feeding device 4 is used to clamp the wire on the clamping assembly 3;

[0048] The pushing device 5 is used to push the wire on the clamping assembly 3 to the riveting station and the terminal cover for riveting;

[0049] The detection device 6 is used to detect the riveted wires on the clamp assembly 3;

[0050] The wire take-off device 7 is used to drop the detected wire on the clamping assembly 3;

[0051] The four-degree rotating device 2 drives the wire clamping assembly 3 to pass th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com