Steel wire punching machine and method for machining aluminum block through steel wire punching machine

A stamping machine and steel wire technology, which is applied to the steel wire stamping machine with steel wire installed on the aluminum block and the processing field, can solve the problems of safety hazards, low assembly efficiency, and labor-intensive operators, and achieve the effect of reducing safety hazards and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

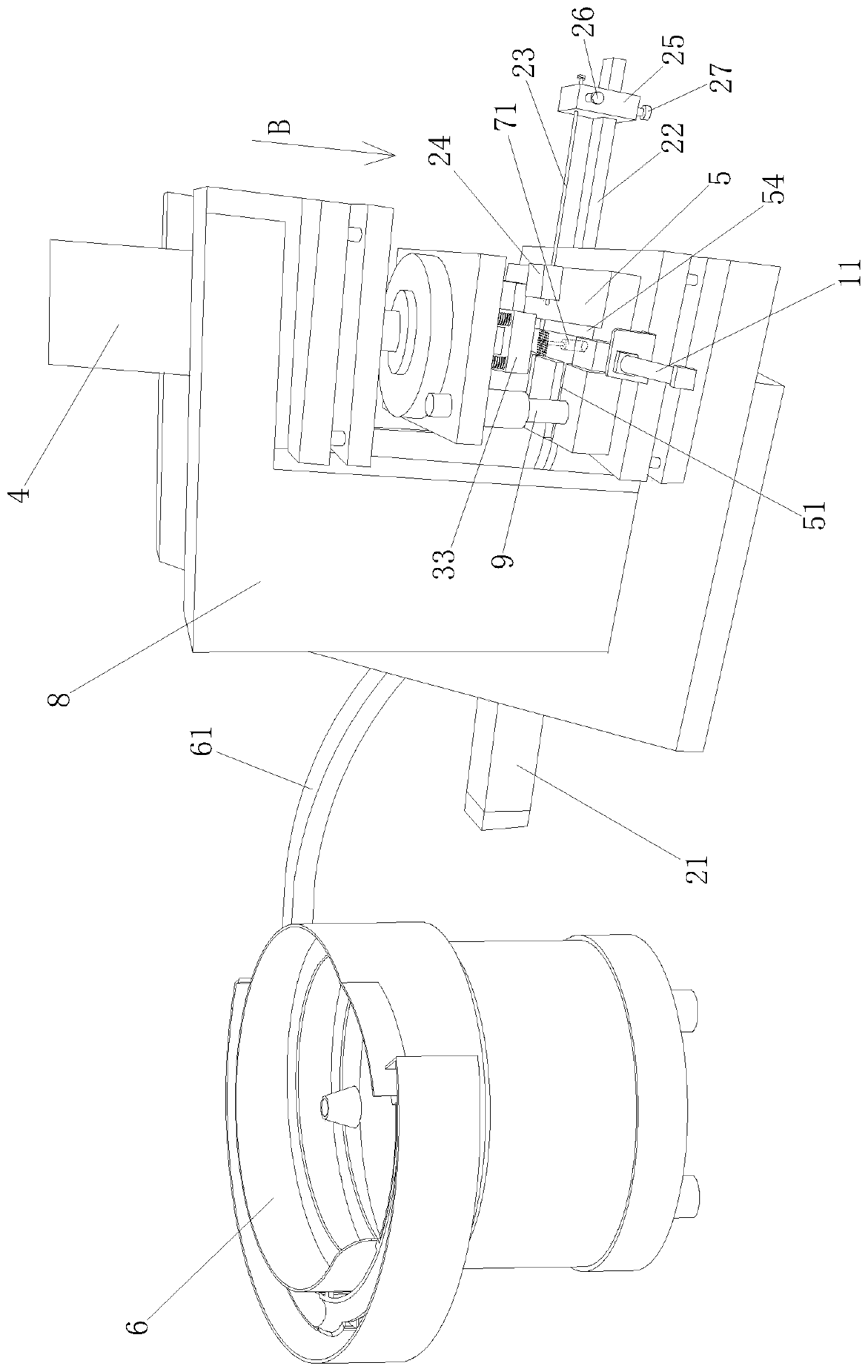

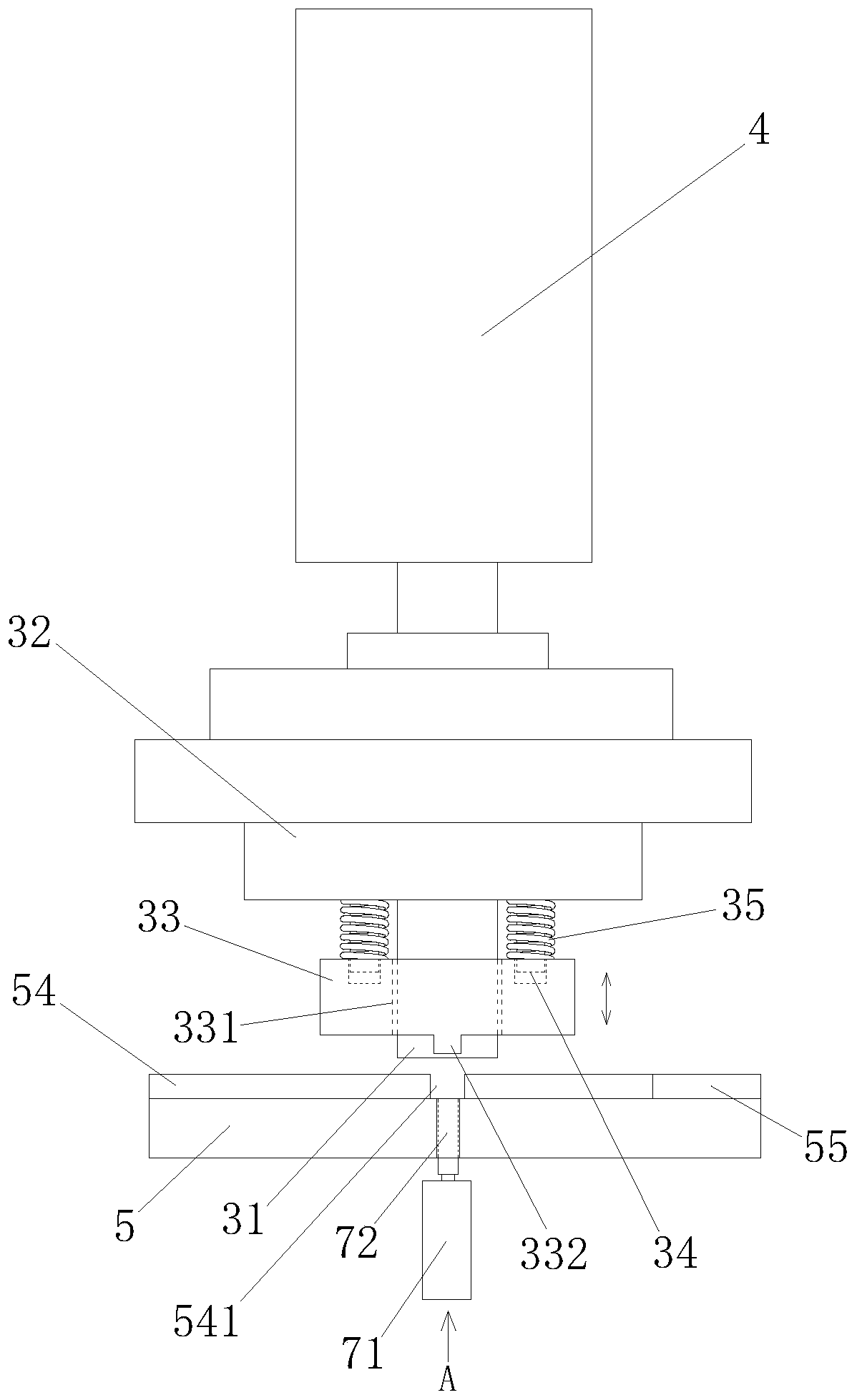

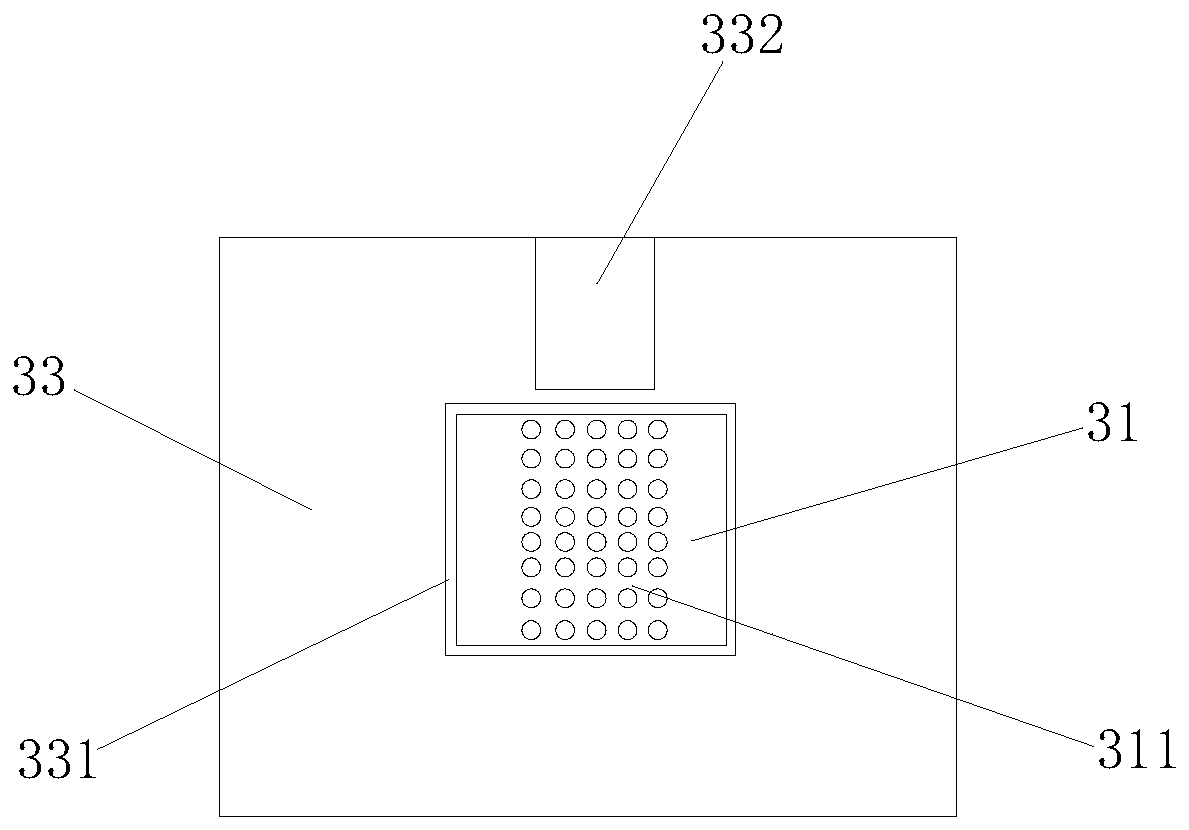

[0035] Figure 1 to Figure 5 Schematically shows the structure of a wire punching machine according to an embodiment of the present invention.

[0036] Such as Figure 1 to Figure 4 As shown, the steel wire stamping machine includes clamping parts, punching parts, pressing parts and driving parts 4 . In addition, the steel wire punching machine may also include a base 5 , a vibrating plate 6 , a mandrel component, a frame 8 and a guide column 9 .

[0037] Such as Figure 4 As shown, the base 5 is formed with a conveying channel A51, a conveying channel B52, and an accommodating channel 53. The conveying channel A51 communicates with the conveying channel B52 and is arranged vertically. The width of the channel A51 is slightly larger than the width of the aluminum block, and the longitudinal aluminum block is transported horizontally in the conveying channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com