Iron core group of magnetic offset type linear motor

A linear motor, core group technology, applied in the direction of magnetic circuit shape/style/structure, etc., can solve the problems of inability to improve manufacturing efficiency, increase manufacturing burden, increase difficulty in quality, etc., to simplify the assembly process, improve efficiency, and facilitate assembly. and processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

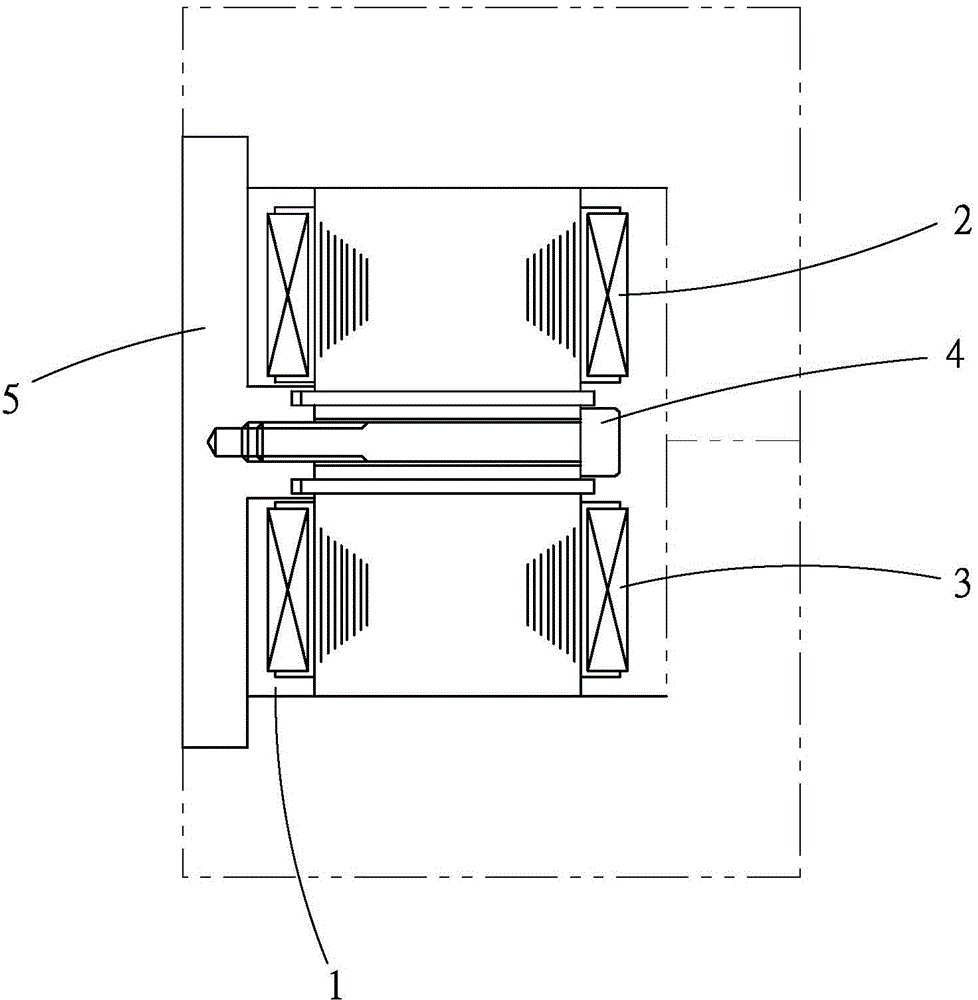

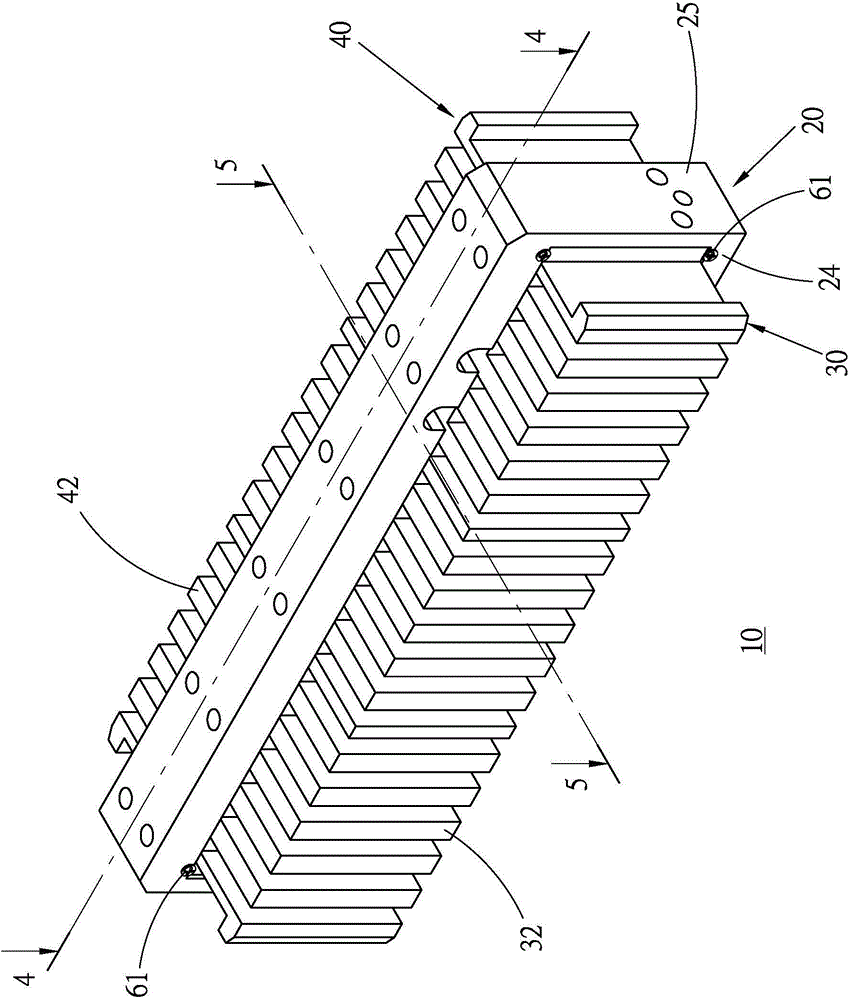

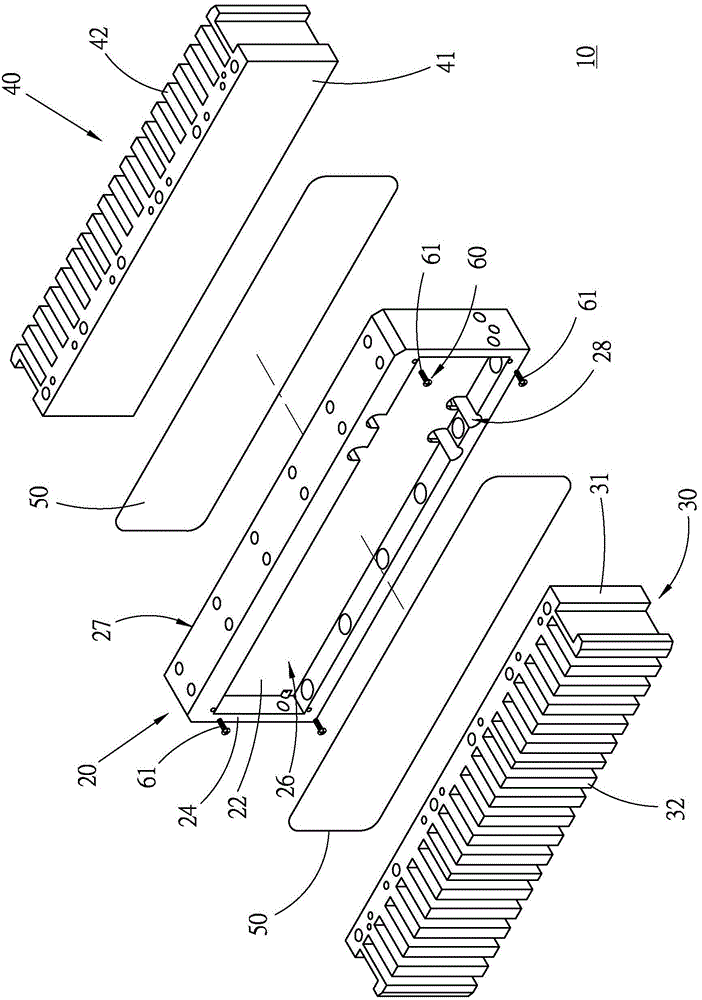

[0026] First, see Figure 2 to Figure 5 As shown, the core structure 10 of the magnetic phase braking linear motor provided in a preferred embodiment of the present invention mainly includes a base 20, a first core piece 30, a second core piece 40, and two heat conducting parts 50 and two fixing parts 60.

[0027] The base 20 is made of a non-magnetic material such as aluminum, and has a plate-shaped seat body 21 of appropriate thickness. The flat first end surface 22 and the second end surface 23 are respectively located on the opposite side plates of the seat body 21. On the side, a ring-shaped first positioning wall 24 protrudes from the first end surface 22 and corresponds to the position of the peripheral side plate end of the seat body 21, and a ring-shaped second positioning wall 25 is similar to the first end surface 22. The setting of a positioning wall 24 generally protrudes on the second end surface 23, so that the first positioning wall and 24 and the first end su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com