HDMI-CF electric coupler automatic assembling machine

A technology of HDMI-CF and automatic assembly machine, which is applied to the assembly/disassembly of contacts, etc., and can solve the problems of production equipment not realizing assembly line operation, low efficiency, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

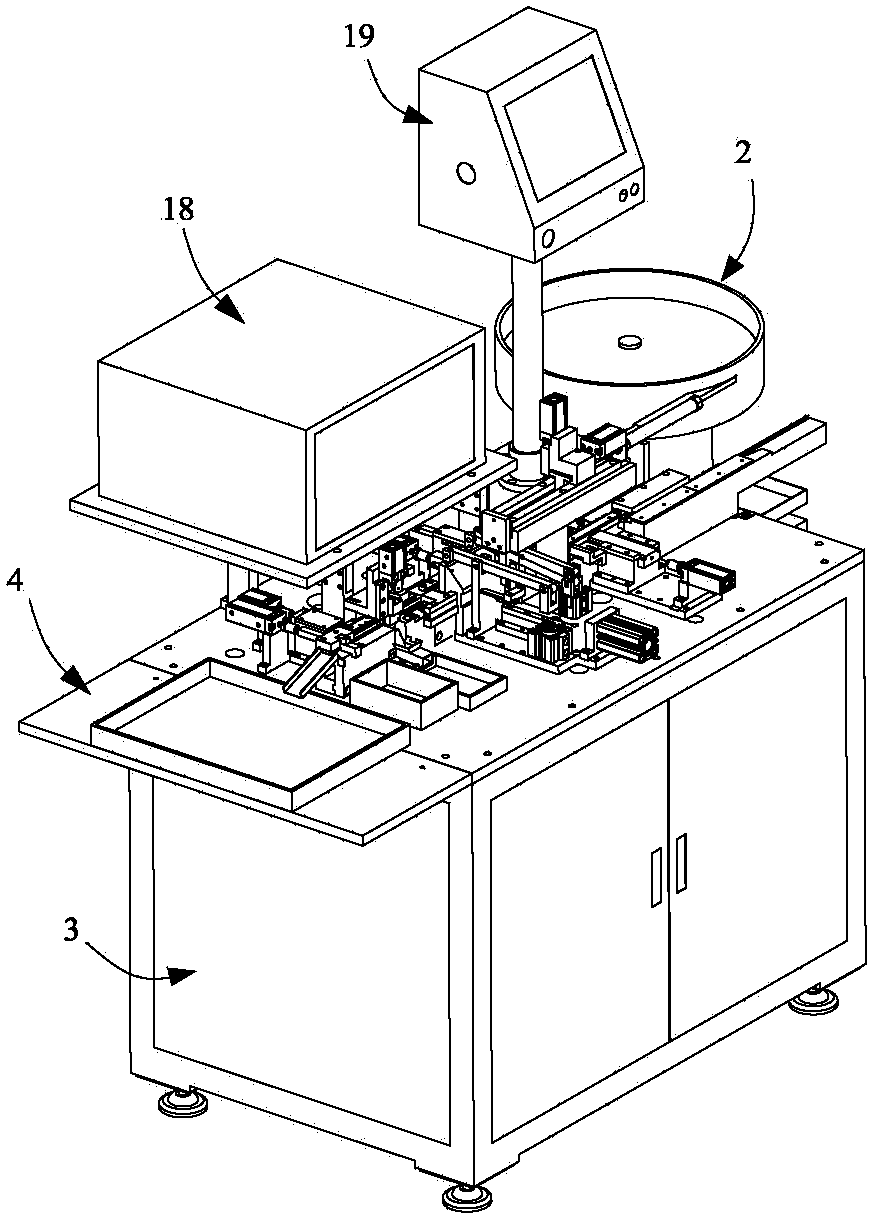

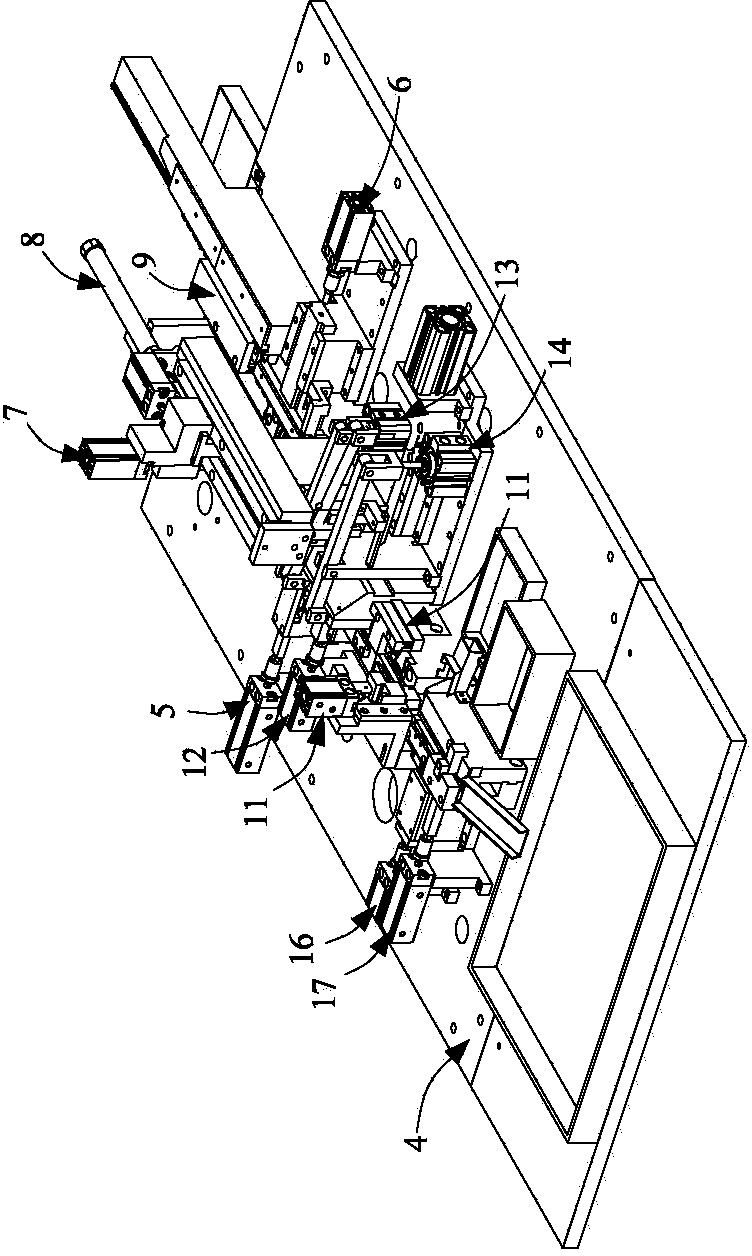

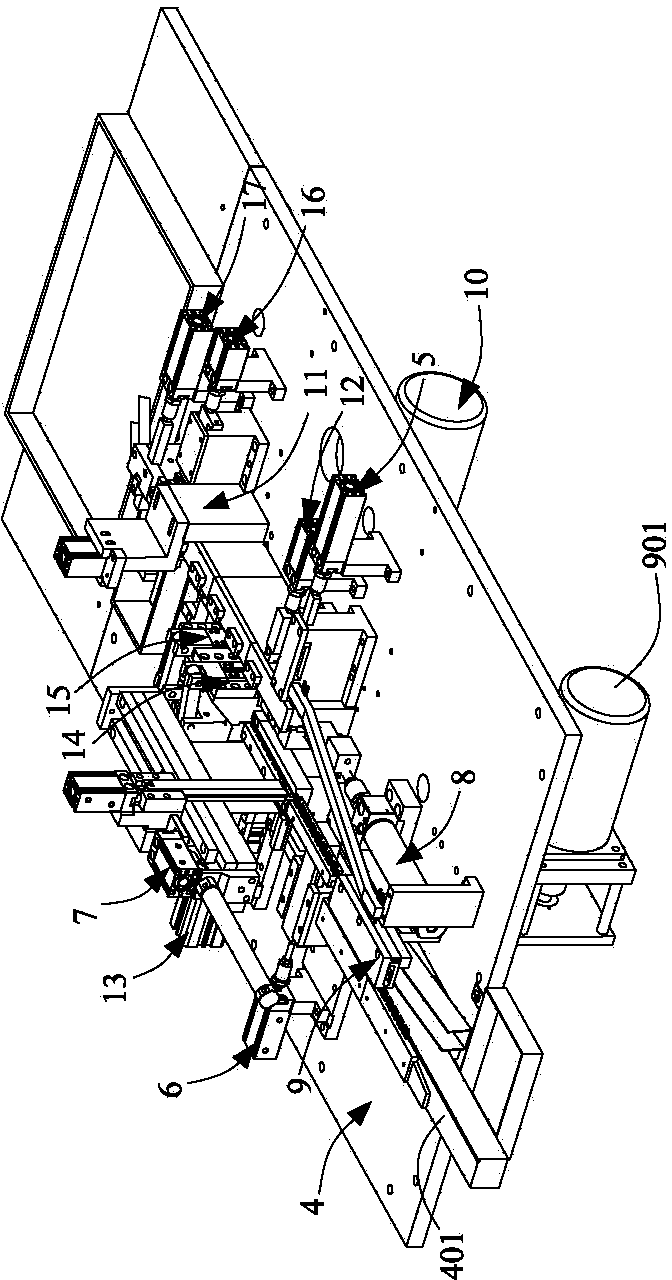

[0088] Please refer to Figure 1 to Figure 4 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a vibrating plate mounting frame 1, a vibrating plate 2 arranged on the vibrating basin mounting frame, a frame 3, and a working platform arranged on the frame 4. The first feeding mechanism 5, the second feeding mechanism 6, the third feeding mechanism 7 and the fourth feeding mechanism 8 installed on the working platform. The first feeding mechanism 5 is used to push the metal casing to realize automatic feeding of the metal casing; the second feeding mechanism 6 is used to push the rubber core material belt to realize automatic feeding of the rubber core material belt; the third feeding mechanism 7 will The rubber core material belt with the material in place is cut into single rubber core, and then continues to feed; and the fourth feeding mechanism 8 is used to push the finished product after the metal shell and the rubber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com