Electric saw chain machining platform with protection mechanism

A protection mechanism and processing platform technology, applied in the direction of metal processing equipment, manufacturing tools, metal sawing equipment, etc., can solve the problems of operator cuts, safety accidents, complicated procedures, etc., to reduce safety hazards, reduce contact, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

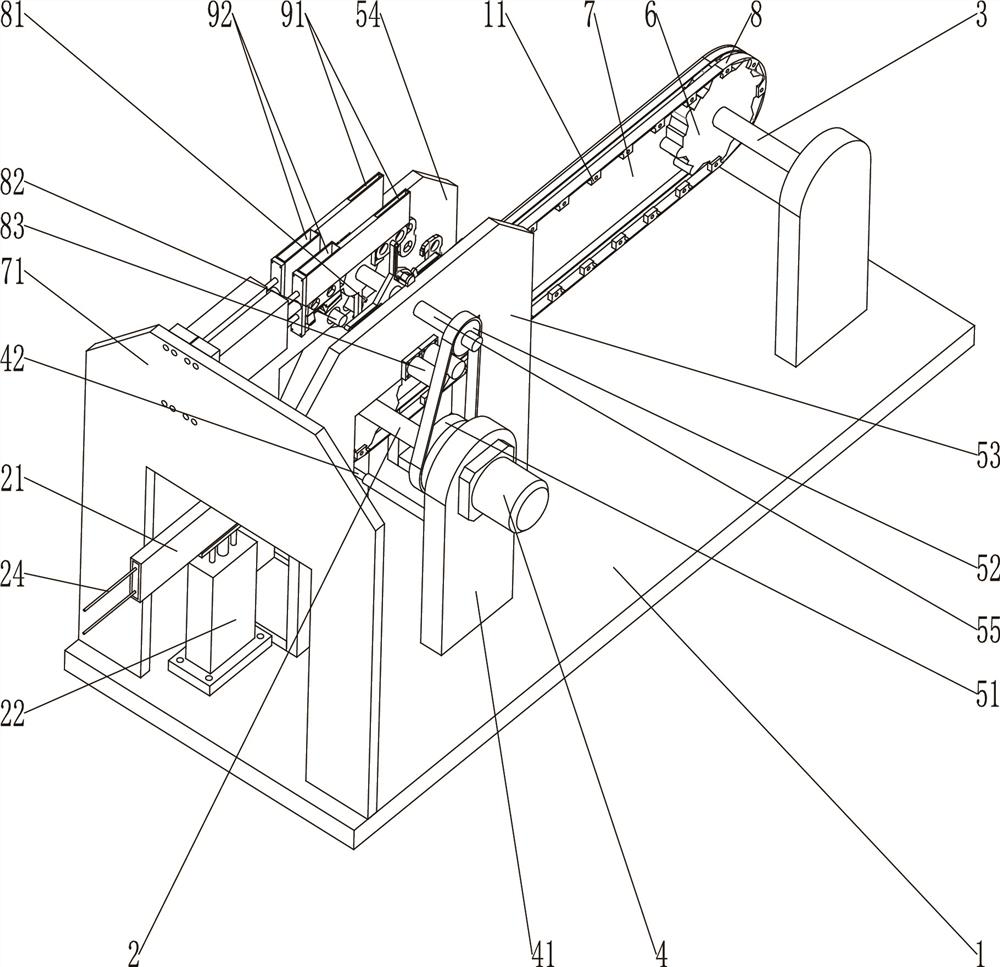

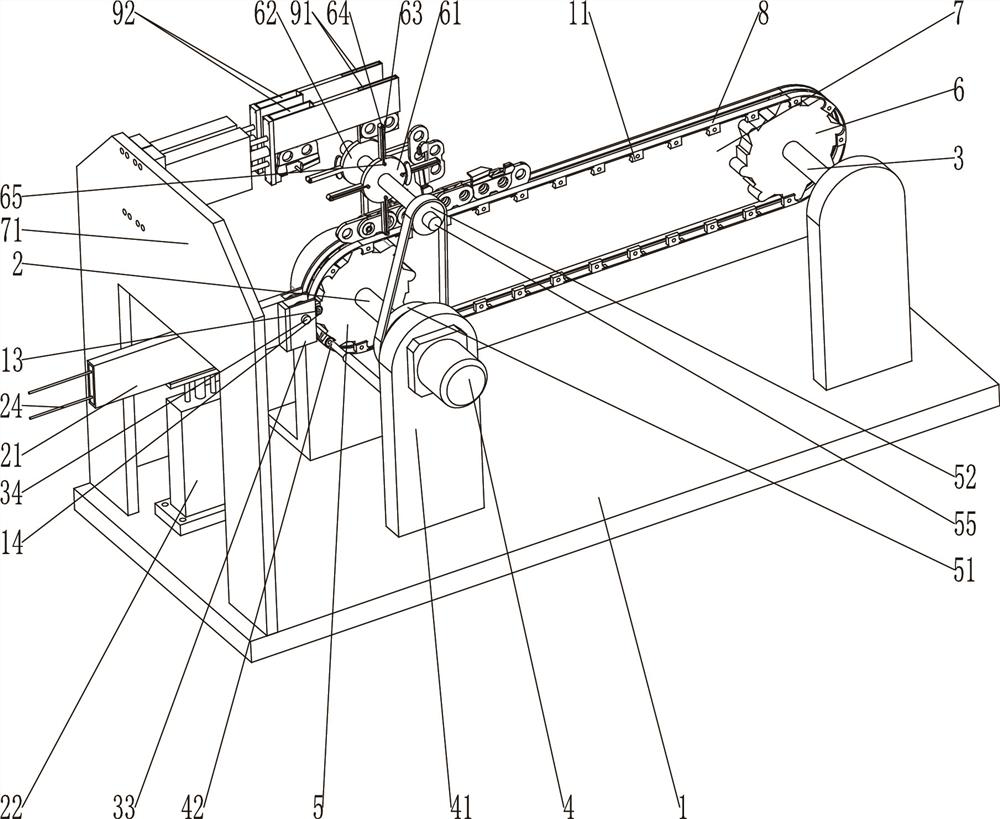

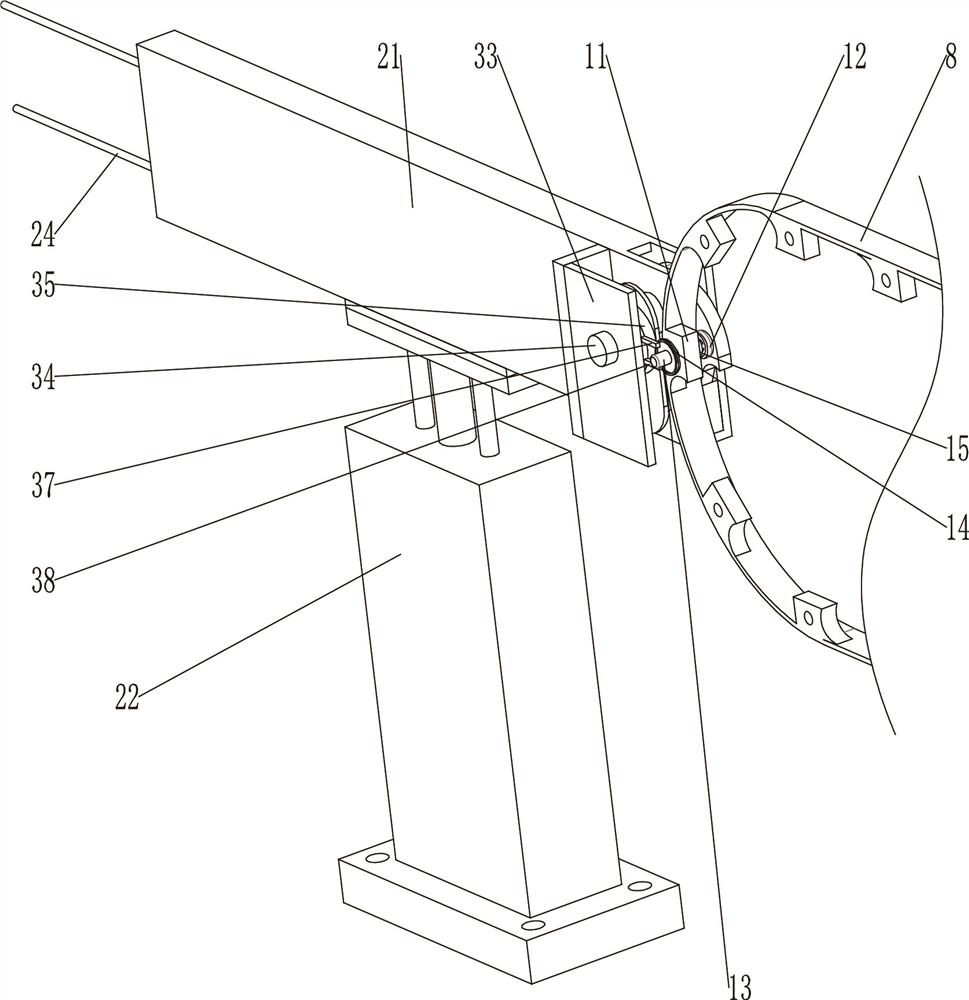

[0022] Embodiment 1: An electric saw chain processing platform with a protective mechanism, including a frame 1, the frame 1 is provided with a driving shaft 2 and a driven shaft 3, and the driving shaft 2 is connected with a stepping motor 4, so The driving shaft 2 is used to install the driving sprocket 5 of the electric saw, and the driven shaft 3 is used to install the driven sprocket 6 of the electric saw. When assembling, the driving sprocket 5 and the driven sprocket 6 side The side chain plate 7 is installed first, and then the driving sprocket 5 and the driven sprocket 6 are integrally installed on the driving shaft 2 and the driven shaft 3 .

[0023] Described stepper motor 4 rotates once, then drives driving sprocket 5 and rotates a tooth, is provided with the auxiliary chain 8 that cooperates with it between described driving sprocket 5 and driven sprocket 6; 8 and the side chain plate 7 are arranged on both sides of the driving sprocket 5, and the inner side of th...

Embodiment 2

[0039] Embodiment 2: A chainsaw chain processing platform with a protective mechanism, including a frame 1, the frame 1 is provided with a driving shaft 2 and a driven shaft 3, and the driving shaft 2 is connected with a stepping motor 4, so The driving shaft 2 is used to install the driving sprocket 5 of the electric saw, and the driven shaft 3 is used to install the driven sprocket 6 of the electric saw. When assembling, the driving sprocket 5 and the driven sprocket 6 side The side chain plate 7 is installed first, and then the driving sprocket 5 and the driven sprocket 6 are integrally installed on the driving shaft 2 and the driven shaft 3 .

[0040] The drive shaft 2 is fixed with a first transmission wheel 51, the frame 1 is provided with a second transmission wheel 52 matching the first transmission wheel 51, and the frame 1 is symmetrically provided with a first vertical wheel. plate 53 and the second vertical plate 54, the first vertical plate 53 and the second verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com