Polishing line setting and control method for helmet manufacturing

A control method and helmet technology, which is applied in the directions of automatic grinding control device, workpiece feed movement control, and tool manufacturing, can solve the problems of lower product yield, high labor intensity of employees, and large loss of tools and consumables, etc., to achieve Improve yield rate and quality consistency, reduce labor costs, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

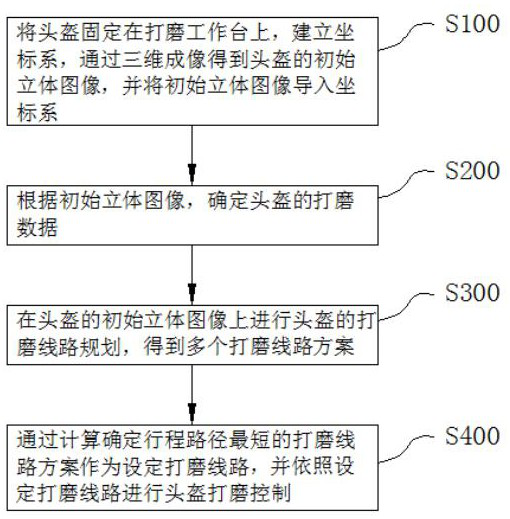

[0053] like figure 1 As shown, the embodiment of the present invention provides a polishing circuit setting and control method for helmet manufacturing, including the following steps:

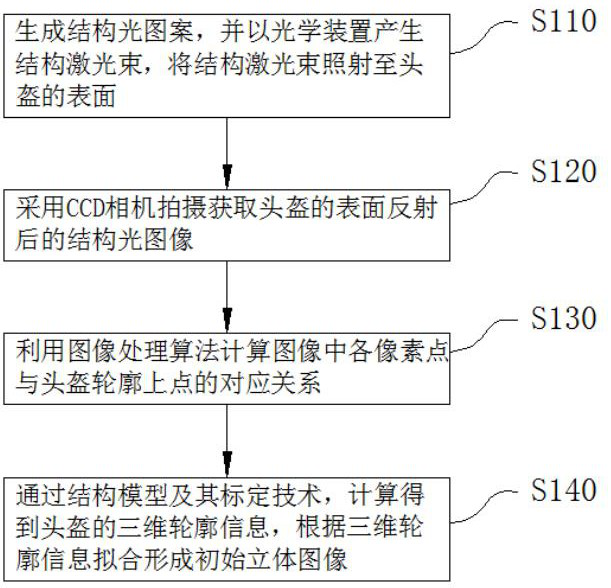

[0054] S100: Fix the helmet on the grinding table, establish a coordinate system, obtain the initial stereoscopic image of the helmet through three-dimensional imaging, and import the initial stereoscopic image into the coordinate system;

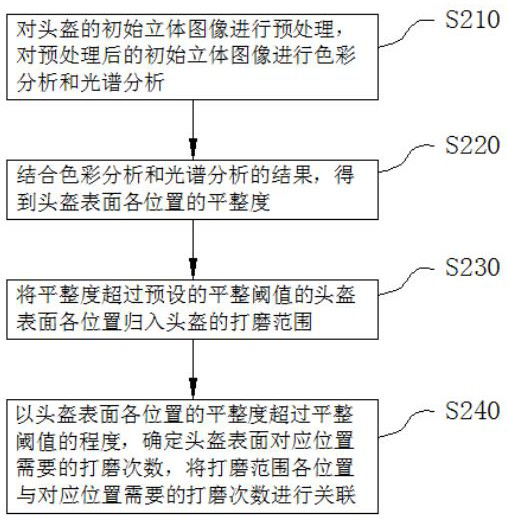

[0055] S200: Determine the polishing data of the helmet according to the initial stereo image;

[0056] S300: Plan the polishing route of the helmet on the initial stereo image of the helmet, and obtain multiple polishing route plans;

[0057] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com