Automatic injection molding system for semiconductor component packaging and working method of automatic injection molding system

A technology of injection molding system and working method, applied in coating and other directions, which can solve the problems of poor quality consistency and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

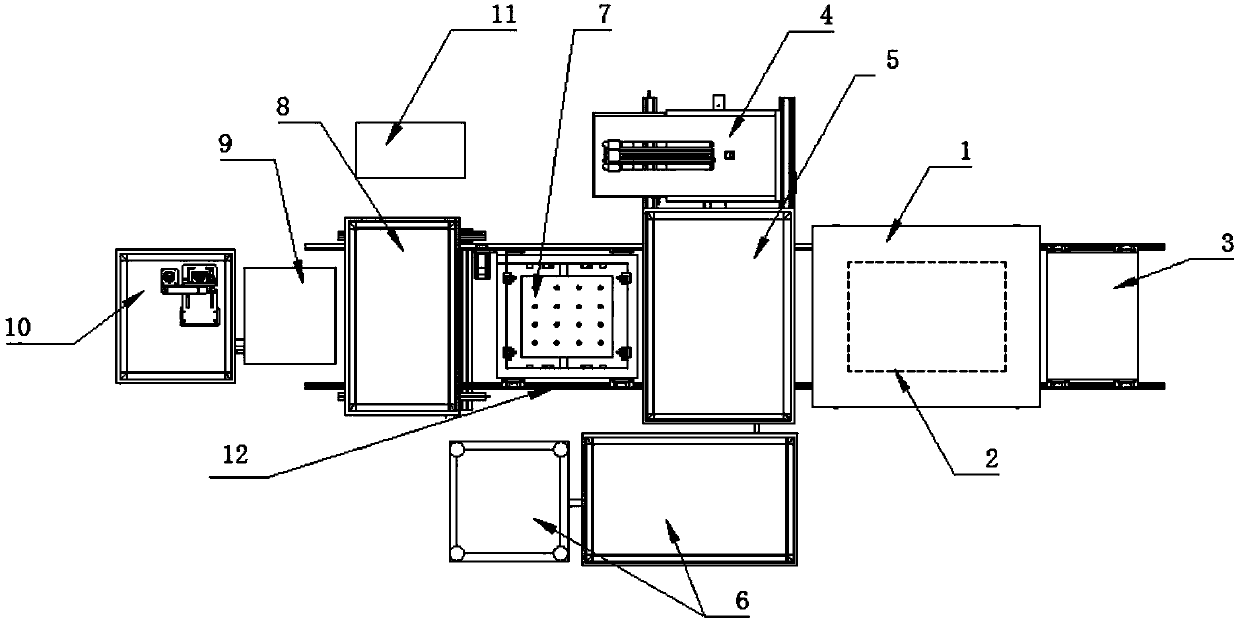

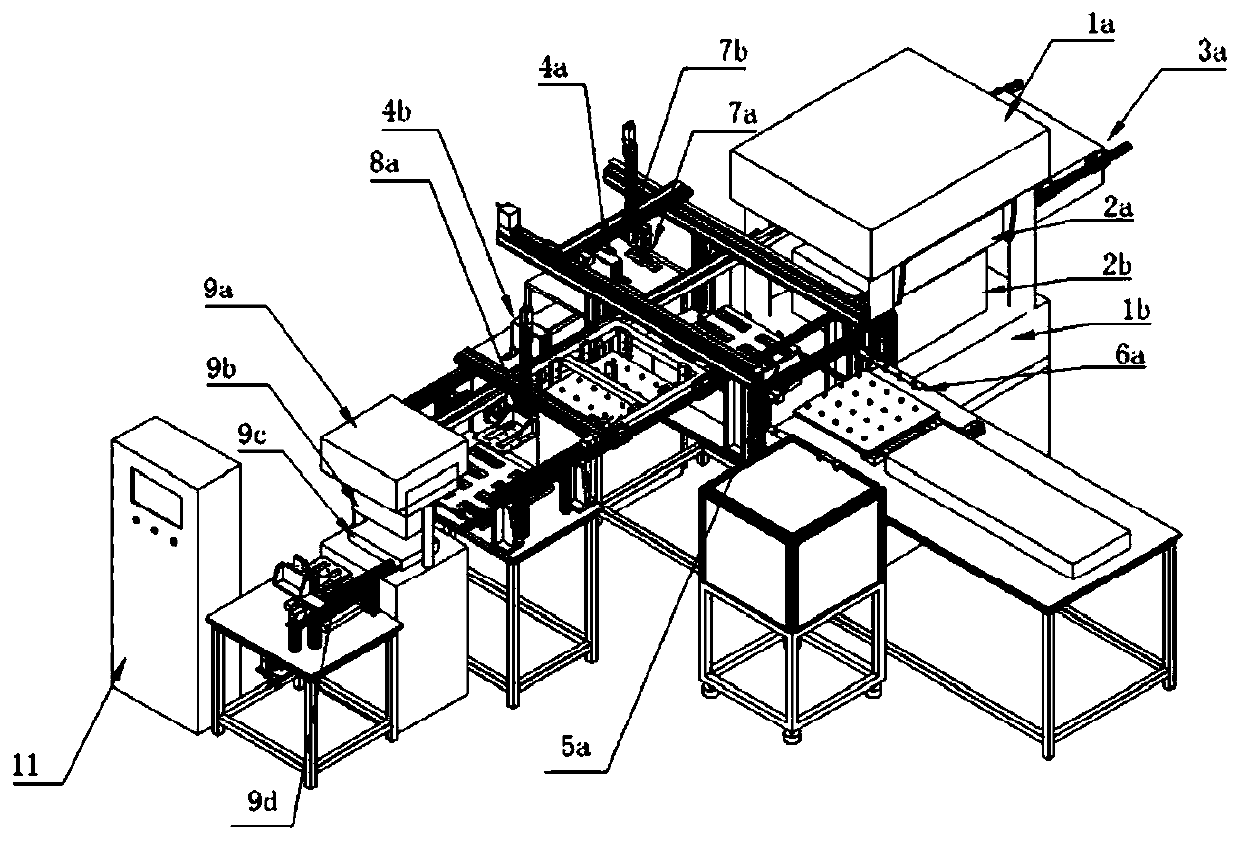

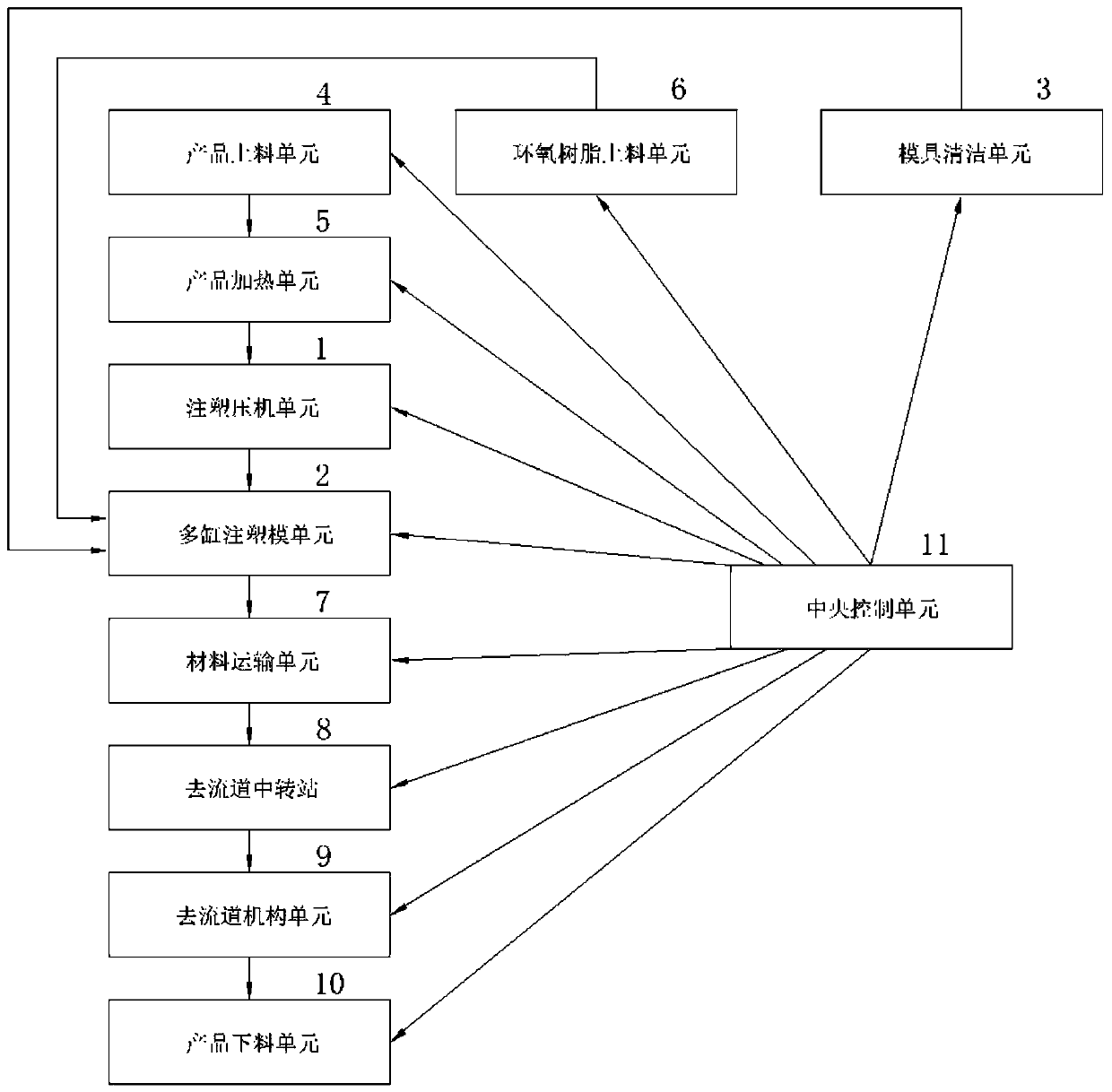

[0026] Such as figure 1 , figure 2 The semiconductor component packaging automatic injection molding system shown includes injection molding press unit 1, multi-cylinder injection mold unit 2, mold cleaning unit 3, product feeding unit 4, product heating unit 5, epoxy resin feeding unit 6, material The transportation unit 7, the transfer station 8 to the runner, the mechanism unit 9 to the runner, the product unloading unit 10, the central control unit 11 and the rack platform 12 required by each system.

[0027] The product loading unit 4 includes a material box transportation input device, a material box lifting control device 4a, a product pushing mechanism and a material box transportation output device 4b. Carry the material box full of products to the corresponding position of the product e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com