HID (high intensity discharge) electronic ballast on-line tester

A technology of electronic ballasts and testers, applied in the direction of instruments, measuring electronics, measuring devices, etc., can solve problems that affect production efficiency, increase costs, and easily damage multiple components, so as to improve quality and product consistency, reduce The repair rate and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

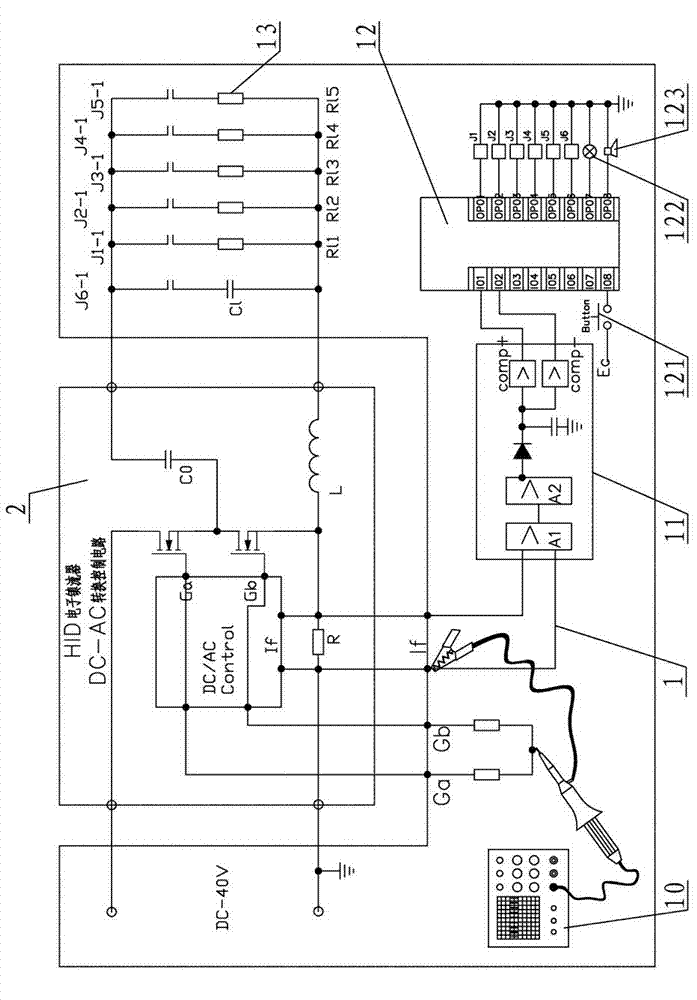

[0041] Such as figure 2 As shown, a HID electronic ballast online tester mainly detects the constant power control part in the DC-AC conversion circuit, including the main body of the tester and the test circuit 1 arranged on the main body of the tester. The test circuit 1 mainly includes an oscilloscope 10. Programmable controller 12, amplification / comparison circuit 11, dummy load 13 four parts.

[0042] Oscilloscope 10 is used to detect the output Ga and the waveform of Gb of the circuit on the constant power control board 2 under test; overlap or true.

[0043] The programmable controller 12 controls the entire detection process by the program of the programmable controller. The input end of the programmable controller 12 is provided with a program start button 121, and is also provided with a positive error out-of-tolerance signal I01 and a negative error out-of-tolerance signal I02; The output end of the programmable controller 12 is provided with an output execution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com