Design method of chip breaking type milling cutter

A design method and milling cutter technology, which is applied to milling cutters, milling machine equipment, metal processing equipment, etc., can solve problems such as machine adjustment, low efficiency, and poor product quality consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

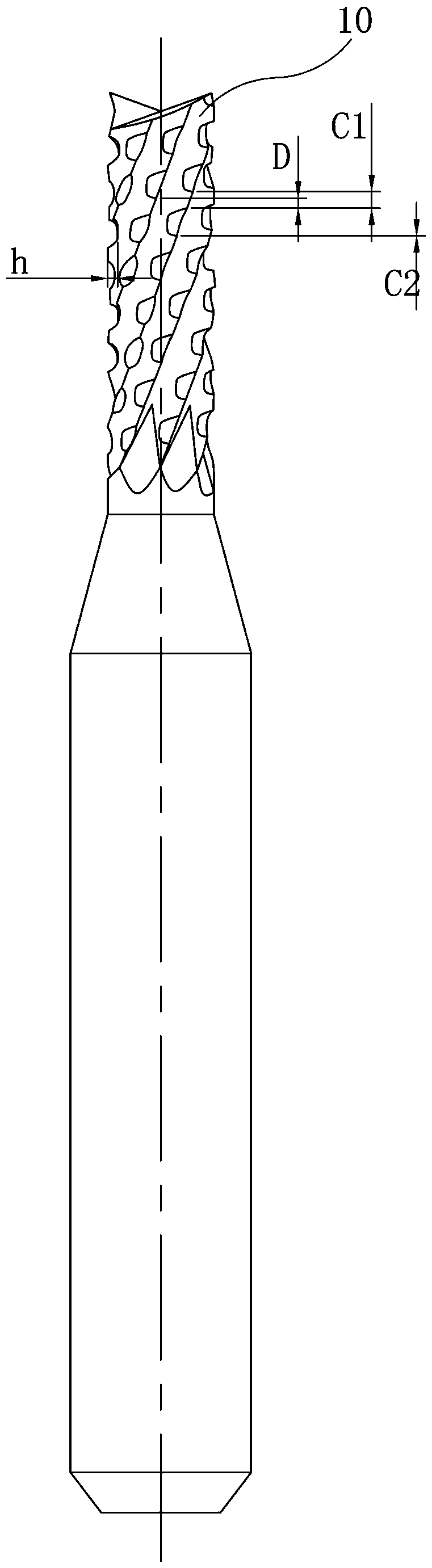

[0027] Such as figure 1 As shown, the present invention is a design method of a chip breaking type milling cutter, comprising the following steps:

[0028] Step (1): If figure 1 As shown, determine the target parameter requirement: the target parameter of RRC milling cutter 10 is: figure 1 The side groove depth h, the tooth width C1, the overlap D, and the groove length C2;

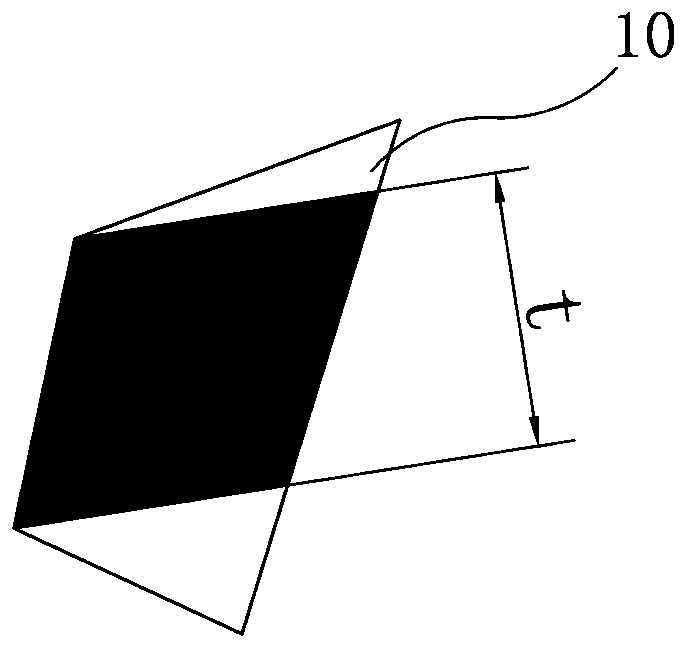

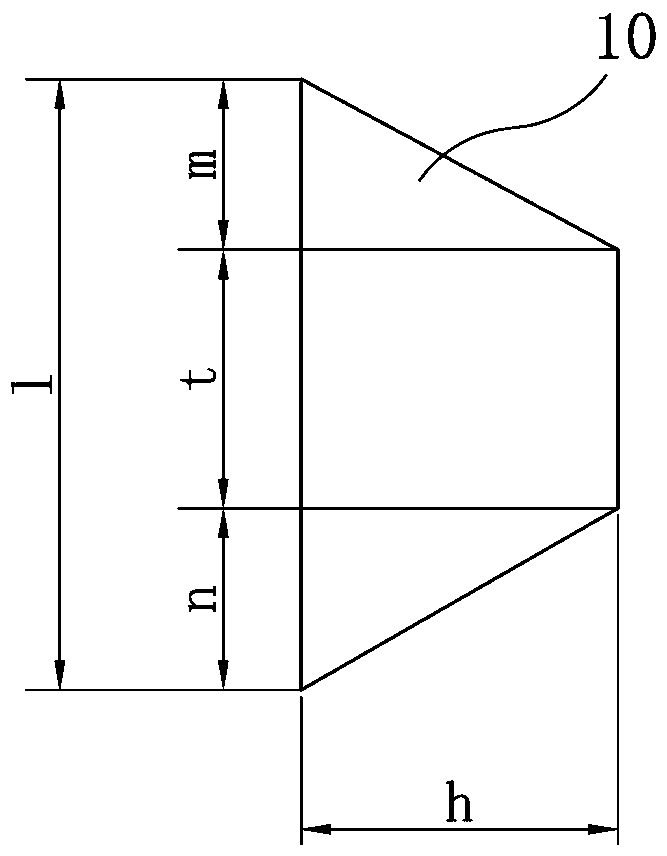

[0029] Step (2): According to the front view of the milling cutter 10 right-handed 2 grooves (such as figure 2 shown) and side view (as image 3 shown), and compare the cutting marks of the right-handed 2 grinding wheel on the groove: figure 2 Middle t is the width of the cutting area on the 0° face of the grinding wheel; image 3 Among them, h: depth of right-handed side groove; l: cutting width of grinding wheel in spiral direction; t: width of grinding wheel face at 0°; n: cutting width of grinding wheel at angle 1; m: cutting width of grinding wheel at angle 2;

[0030] Step (3): according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com