Automatic roughing device for midsoles of sports shoes

A sports shoe, automatic technology, applied in the direction of shoe soles, footwear, applications, etc., can solve the problems of high labor intensity, high worker mobility, high worker wages, etc., to reduce operating personnel, low technical requirements, and improve corporate interests Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

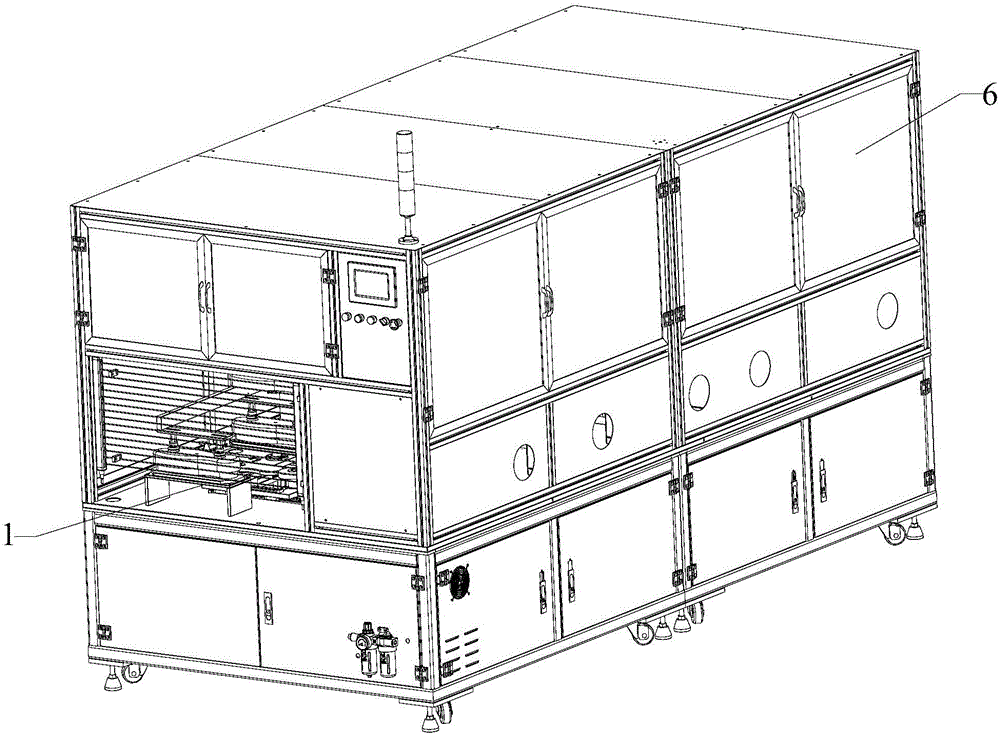

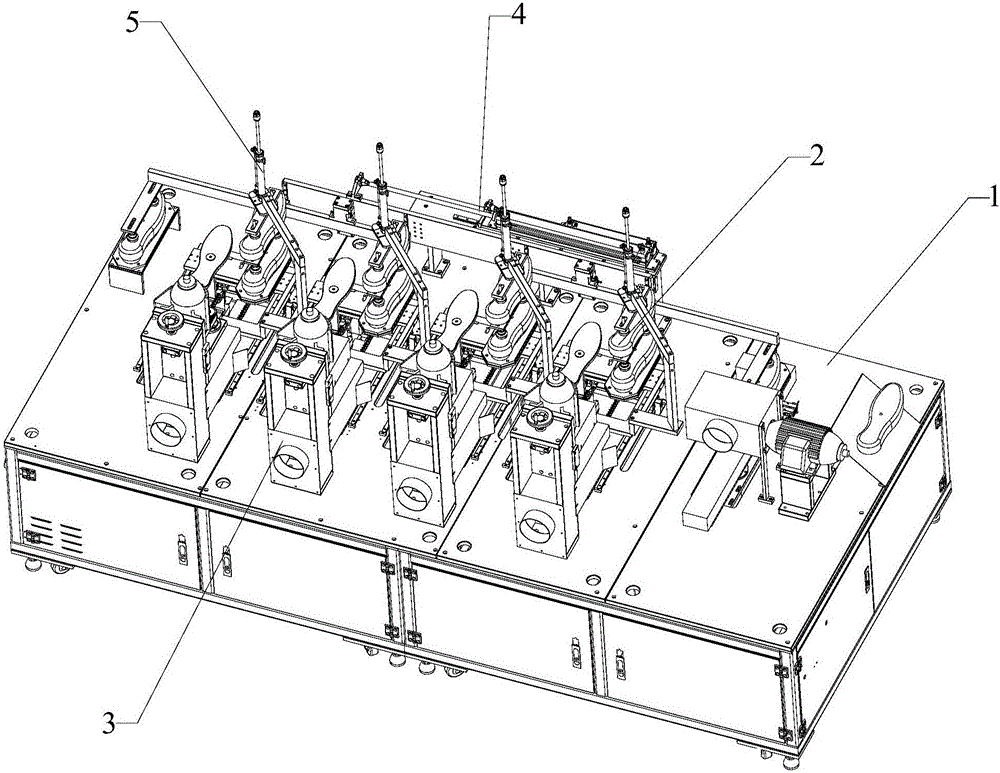

[0037] Please refer to Figure 1 to Figure 5 Shown, embodiment one of the present invention is:

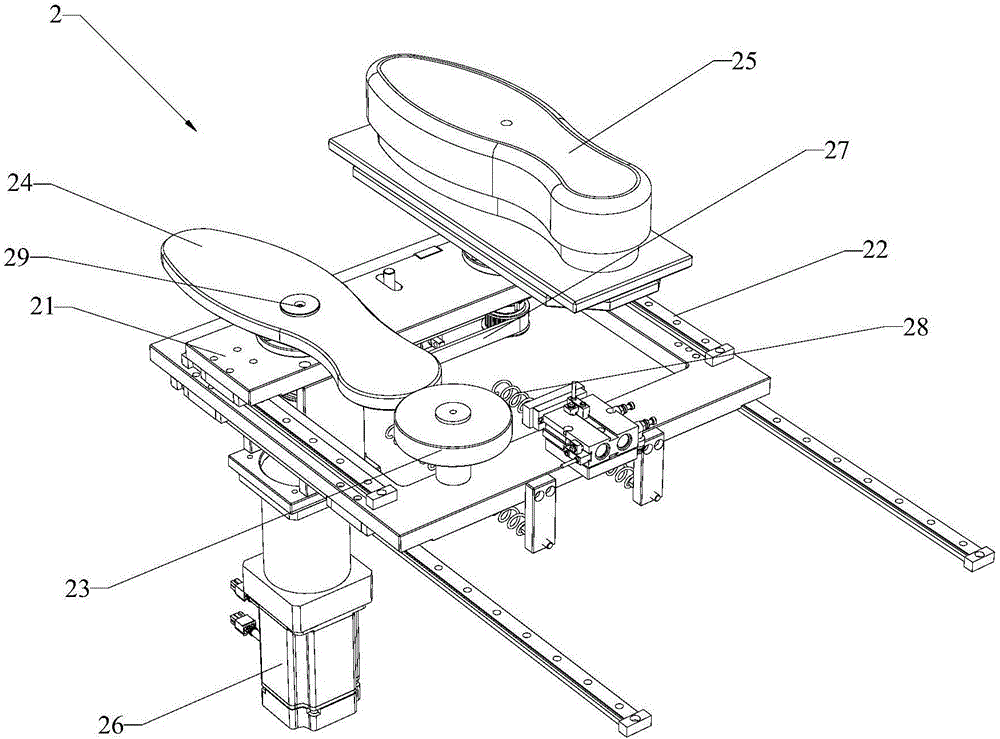

[0038] A kind of equipment for roughing the bottom of sports shoes automatically, comprising a frame 1 and a movement mechanism 2 and a roughening mechanism 3 installed on the frame 1; the movement mechanism 2 includes a slide block 21, a slide rail 22, a roller 23, Shaped wheel 24, midsole mount 25, servo motor 26, synchronous belt 27 and spring 28, described slide rail 22 and roller 23 are installed on the frame 1, and described slide block 21 is slidably installed on slide rail 22 , the slider 21 is vertically provided with two rotating shafts 29, the two rotating shafts 29 are connected to each other through a synchronous belt 27, the servo motor 26 drives the rotating shaft 29 to rotate, the profiling wheel 24 and the middle Bottom mounts 25 are respectively installed on the tops of two rotating shafts 29, the rollers 23 abut against the profiling wheels 24, one end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com