Silica gel preparation method

A technology of silicone gel and raw materials, applied in chemical instruments and methods, colloidal chemistry, colloidal chemistry, etc., can solve the problem that it is difficult to meet the consistent performance indicators of large-scale products, good repeatability, reliable quality, and can not meet the consistency of IGBT module products. requirements, affecting the efficiency of industrialized mass production, etc., to achieve the effect of improving potting efficiency, consistent performance indicators, and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] Still taking the material preparation method of AB component silicone gel described above as an example, the material preparation process provided by the present invention will be described in detail.

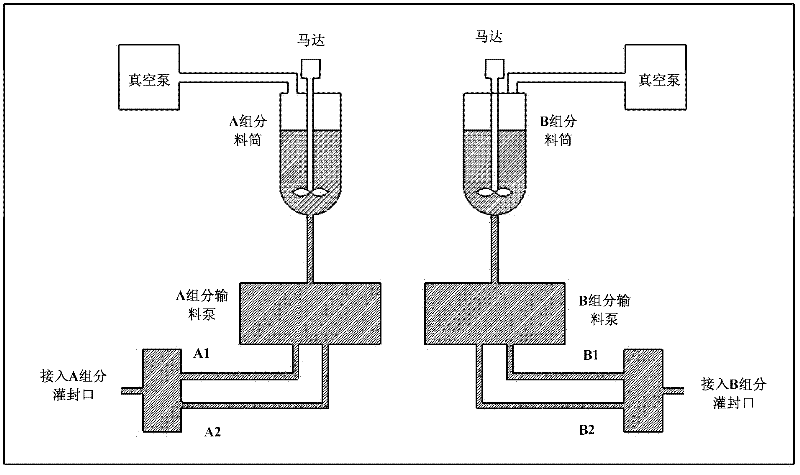

[0035] refer to figure 1 As shown, the AB components used to prepare the silicone gel after aging were placed in the A and B component material preparation barrels equipped with a stirring mechanism, and the vacuum pump was started to maintain a vacuum of 50mbar. Vacuum defoaming treatment is carried out separately, and the vacuum defoaming time is maintained at about 4 hours. At the same time, the control motor drives the stirring paddle located in the barrel to intermittently stir the raw material components. The stirring rate is 800-1600rad / min, and the stirring time interval 10-20min. It can be observed that no new bubbles are generated during this process, and the components of the silicone gel can flow evenly, which can confirm that the bubble removal is complete....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com