Close-fitting underwear and production method thereof

A production method and technology for underwear, which can be applied to brassieres, clothing, brassieres, etc., can solve the problems of women’s underwear wearing discomfort, and achieve the effects of high product quality consistency, not easy to deform, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

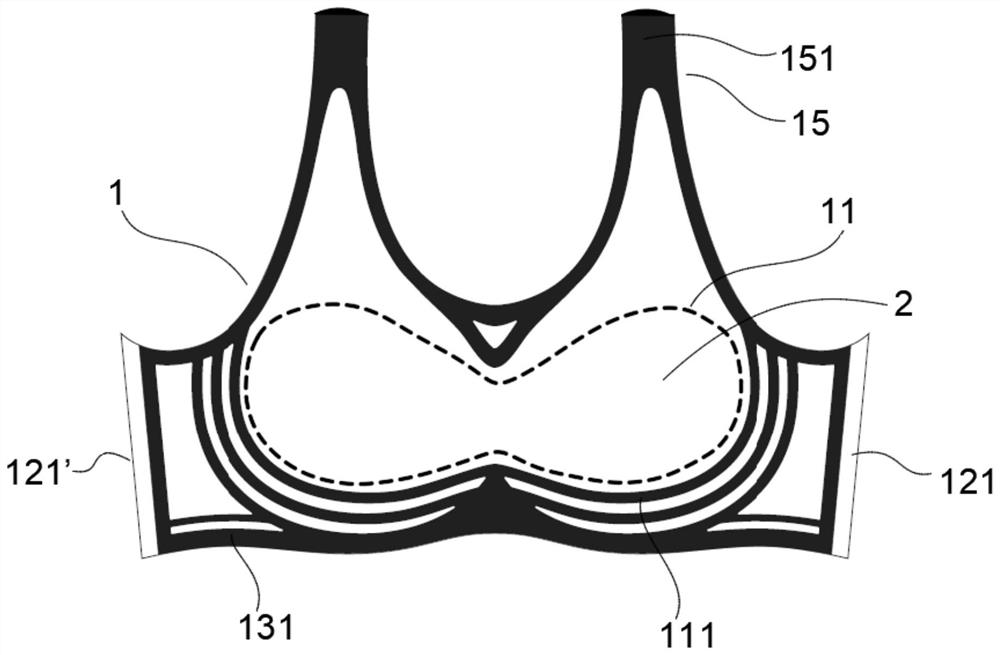

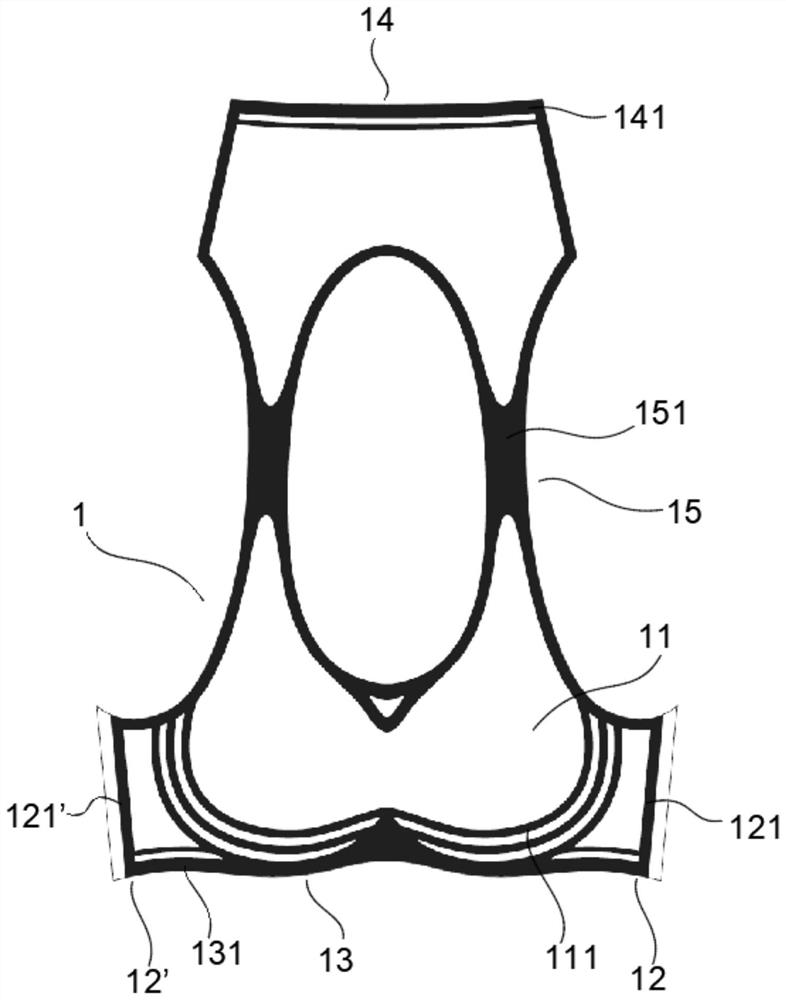

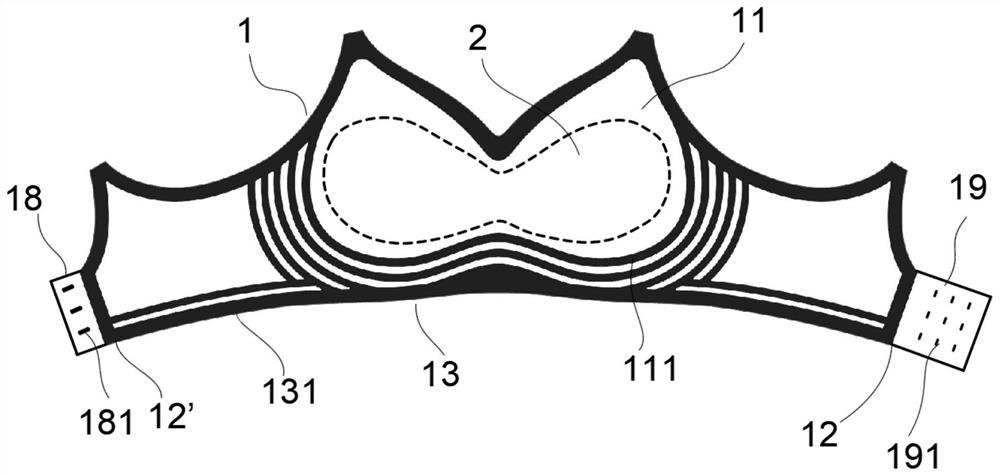

[0045] The production method of tight underwear provided in this embodiment includes the following steps:

[0046] 1) Spraying rubber material: prepare the first cloth layer 16, and spray liquid rubber material on the first cloth layer 16 along the outer circumference of the finished chest pad installation position, side breast position, front lower circumference, rear lower circumference and shoulder position. The glue layer 161, the liquid glue material includes the following raw materials in terms of mass percentage: 65% TPU and 35% TPE. Then, a second cloth layer 17 is covered on the first cloth layer 16. The first cloth layer 16 and the second cloth layer 17 include the following raw materials by mass percentage: 62% nylon and 38% spandex.

[0047] 2) Hot pressing: The first cloth layer 16 and the second cloth layer 17 are hot pressed for 8 seconds in an environment with a temperature of 115° C. and a pressure of 2.5 atmospheres to prepare semi-finished products.

[0048] 3) P...

Embodiment 2

[0050] 1) Spraying rubber material: prepare the first cloth layer 16, and spray liquid rubber material on the first cloth layer 16 along the outer circumference of the finished chest pad installation position, side breast position, front lower circumference, rear lower circumference and shoulder position. The glue layer 161, the liquid glue material includes the following raw materials in terms of mass percentage: 70% TPU and 30% TPE. Then, a second cloth layer 17 is covered on the first cloth layer 16. The first cloth layer 16 and the second cloth layer 17 include the following raw materials in terms of mass percentage: 63.1% nylon and 36.9% spandex.

[0051] 2) Hot pressing: The first cloth layer 16 and the second cloth layer 17 are hot pressed for 10 seconds in an environment with a temperature of 120° C. and a pressure of 2 atmospheres to prepare semi-finished products.

[0052] 3) Punching and stitching: the semi-finished product is punched out on a knife die to form a produc...

Embodiment 3

[0054] 1) Spraying rubber material: prepare the first cloth layer 16, and spray liquid rubber material on the first cloth layer 16 along the outer circumference of the finished chest pad installation position, side breast position, front lower circumference, rear lower circumference and shoulder position. The glue layer 161, the liquid rubber material includes the following raw materials in terms of mass percentage: 75% TPU and 25% TPE. Then, a second cloth layer 17 is covered on the first cloth layer 16. The first cloth layer 16 and the second cloth layer 17 comprise the following raw materials in terms of mass percentage: 64% nylon and 36% spandex.

[0055] 2) Hot pressing: The first cloth layer 16 and the second cloth layer 17 are hot pressed for 12 seconds in an environment with a temperature of 125° C. and a pressure of 1.5 atmospheres to prepare semi-finished products.

[0056] 3) Punching and stitching: the semi-finished product is punched out on a knife die to form a produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com