Automatic continuous preparation system for instant noodles seasoning oil

A technology for preparation system and seasoning oil, which is applied in the direction of edible oil/fat, food science, application, etc. It can solve the problems of few reports on the research of seasoning oil preparation system and key equipment, the functional configuration of the cooking pot can not meet the control requirements, and filter out Slag method and unreasonable equipment design, etc., to achieve special quality requirements, reduce labor intensity of employees, and avoid hot oil splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

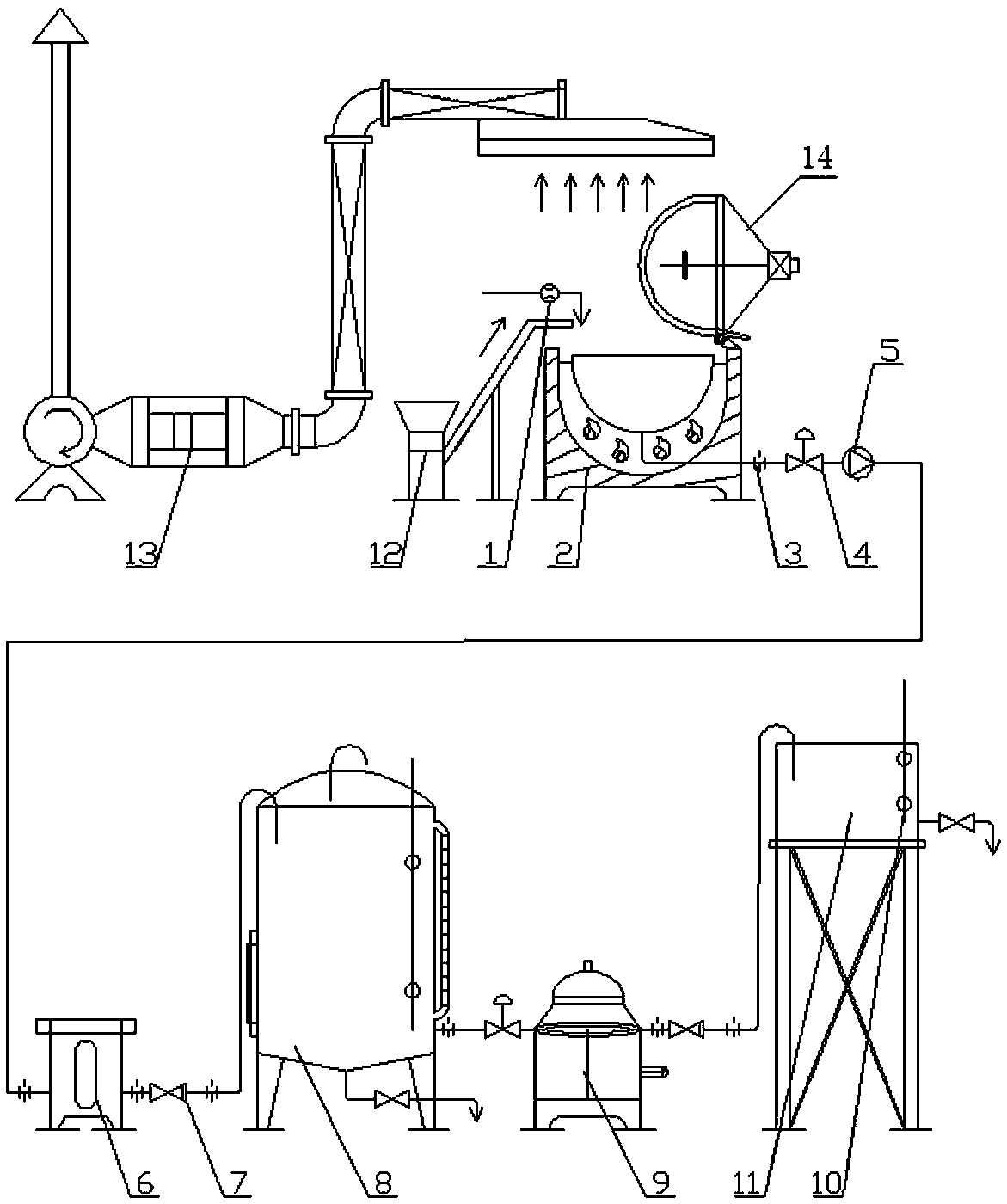

[0049] like figure 1 As shown, an automatic continuous preparation system for seasoning oil for instant noodles, comprising an edible oil quantitative flow device 1, a feeding machine 12, an oil boiling pot 2, a multi-layer filter 6, an oil storage tank 8, a centrifuge 9, and a finished oil tank 11 ,control unit,

[0050] The output end of the oil inlet pipe of the edible oil quantitative flow device 1 is located above the boiling oil pot 2, and the edible oil is quantitatively added to the boiling oil pot 2 by the control unit according to the set parameters, and the boiling oil pot 2 is ignited and boiled;

[0051] The output end of the feeder 12 is located above the boiling oil pot 2, and an overturning sieve mechanism 14 is set in the boiling oil pot 2, which is set by the control unit according to the temperature. When the oil temperature in the boiling oil pot 2 reaches the set condition, Spices are sent into the overturning sieve mechanism 14 in the frying pan 2;

[0...

Embodiment 2

[0058] As an optimized structure of Embodiment 1, a multi-point natural gas burner is arranged below the pot body of the oil boiling pot 2, and an overturning sieve mechanism 14 is set on the oil boiling pot, and the overturning sieve mechanism 14 includes a container type screen, a stirring Shaft, stirring motor, reducer, frequency converter, the frequency converter is connected to the stirring motor, the output shaft of the stirring motor is connected to the reducer, and the stirring shaft is connected to the reducer. They are located in the container-type screen, and the residue is removed in time by turning over the screen.

[0059] Boiling oil pot 2 is heated by natural gas burner multi-point combustion method, with fast heating, uniform heating, high thermal efficiency, no deformation of the bottom of the pot, and automatic temperature control; equipped with a hydraulic tilting screen mechanism, the container screen, stirring shaft and stirring The shaft reducer is integr...

Embodiment 3

[0064] As a further optimization of Example 1, the centrifugal separator 9 is a butterfly separator. There are many liquid-solid separation equipment, but we found that the butterfly separator has a strong separation ability for tiny solids and flocs suspended in the liquid, and the equipment is small in size, easy to operate, high in production efficiency, and easy to use. Realize automatic control.

[0065] A reed switch float level gauge 10 is installed in the finished oil tank 11 and the oil storage tank 8, and the reed switch float level gauge 10 is connected to the control unit, and the reed switch float level gauge 10 in the finished product oil tank 11 When the oil level reaches the set low level or in the process of continuous packaging and outputting oil, the control unit detects that the reed switch float level gauge 10 in the oil storage tank 8 is not at the set low level, and opens the control valve and the centrifuge 9.

[0066] The reed switch float level gauge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com