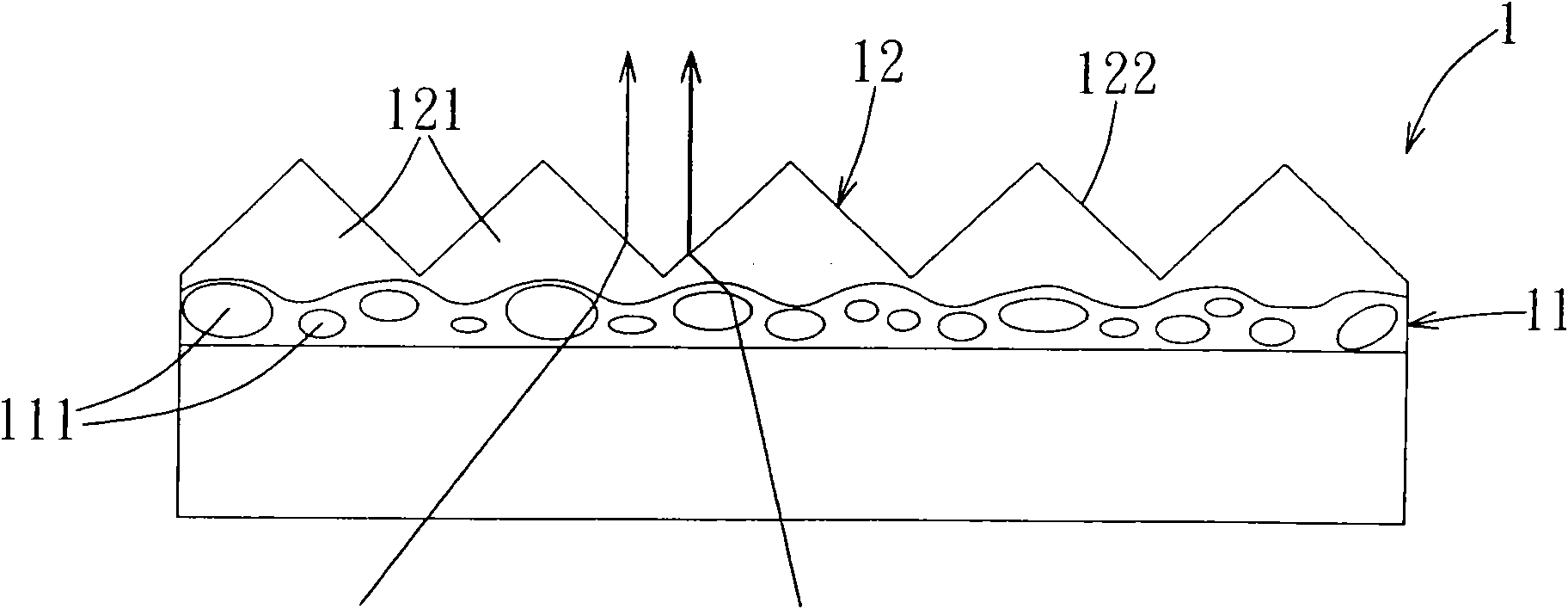

Composite optical film and manufacturing method thereof

A technology of optical film and light-gathering layer, which is applied in the field of optical film, can solve the problems of reducing the visual satisfaction of LCD users, and achieve the effects of mass production, excellent luminance performance, and consistent efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2

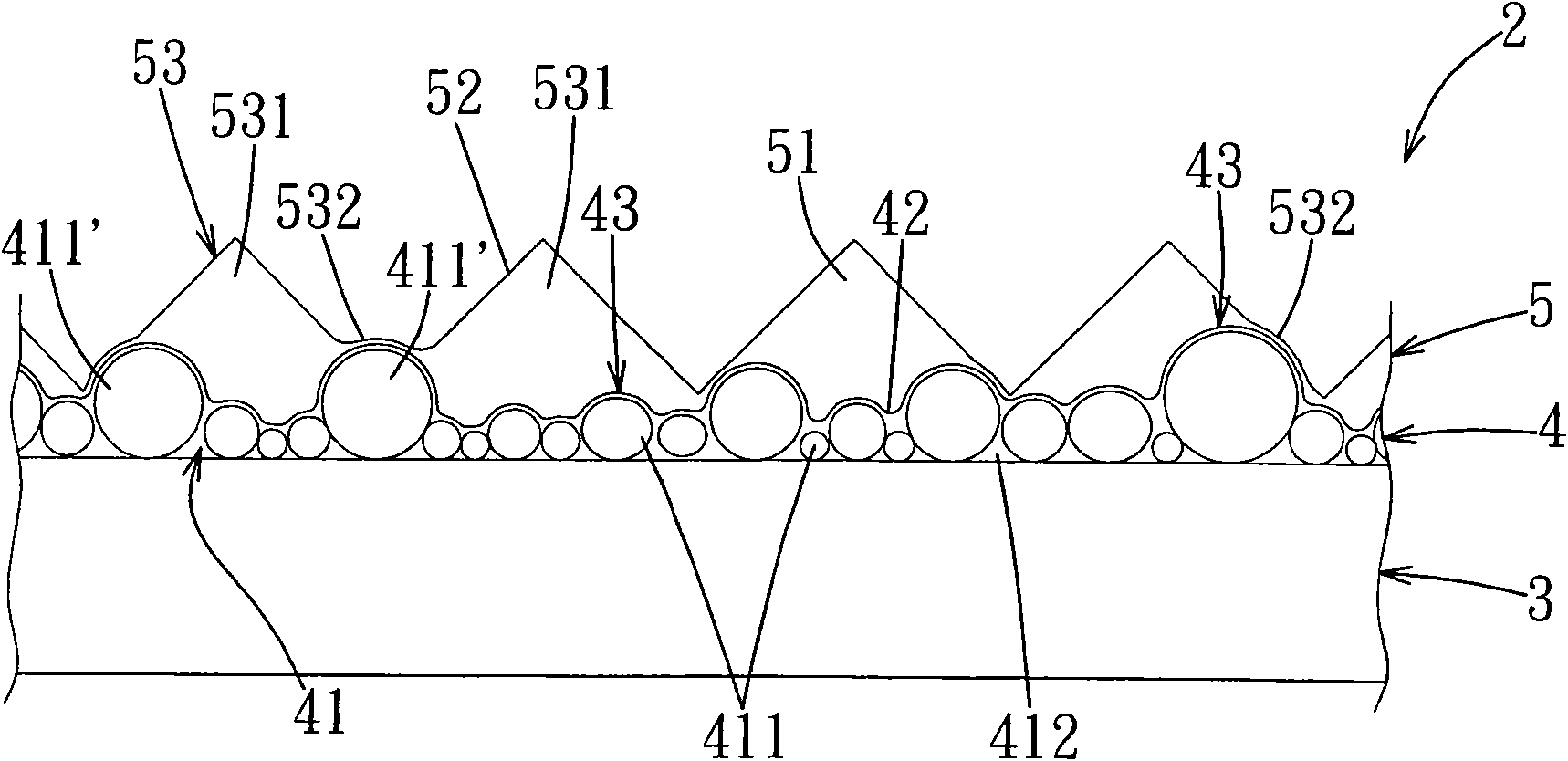

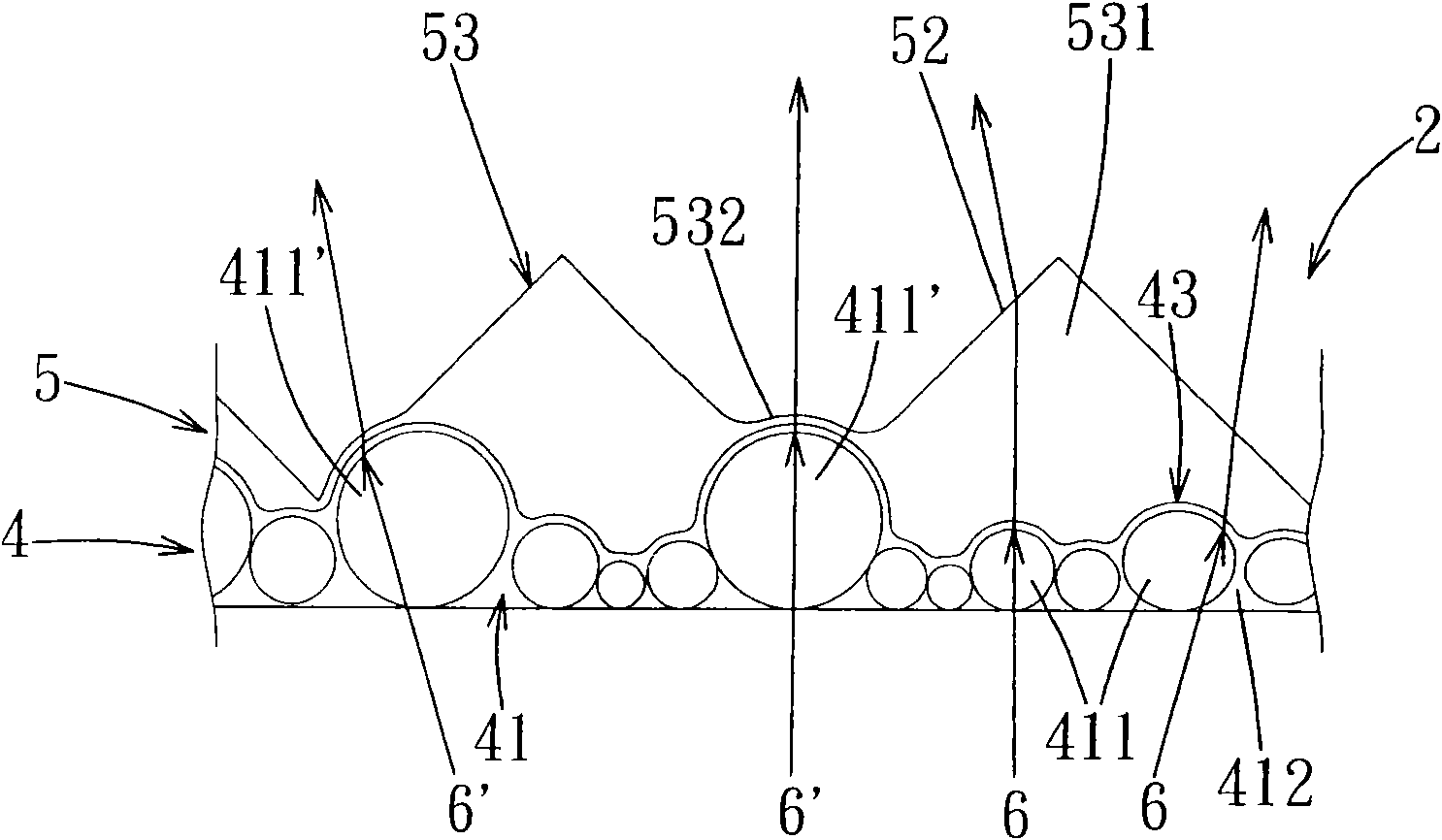

[0064] Embodiments 1 and 2 of the method of the present invention are carried out according to the various operating steps of the aforementioned preparation method of the present invention, and the coated diffusion layer (or light-gathering layer) resin solution is heated at 30 (or 6) m / min Under the traveling speed of , irradiate these solutions with ultraviolet light with a wavelength of 185nm and an irradiation intensity per unit area of 15mW / cm2 to cure the resin contained therein.

[0065] The various operating conditions are shown in Table 1 below. The optical film of the present invention that these two embodiments are made respectively, its section is then as follows figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com