Universal slide rail for automobile seat

A technology of car seats and slide rails, which is applied in the field of auto parts, can solve the problems of complex forming process and inconvenient assembly of sliding core and chute, and achieve the effect of simple structure, convenient later maintenance and repair, and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described.

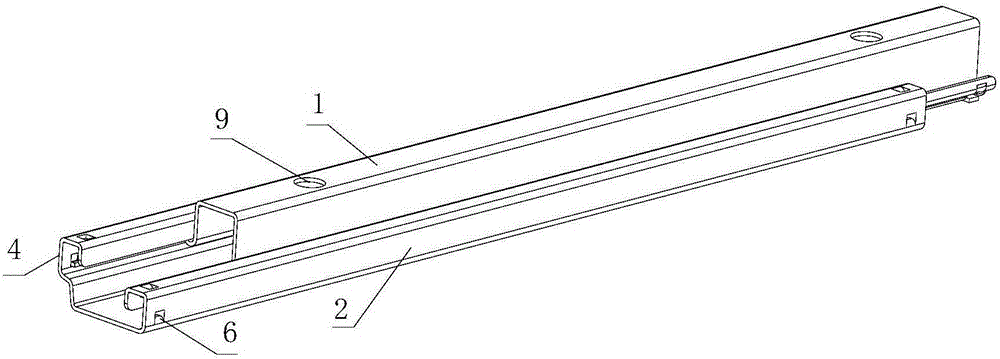

[0019] Such as figure 1 As shown, a kind of universal slide rail for car seats comprises an upper slide rail 1 and a lower slide rail 2. The upper end surface of the upper slide rail 1 is provided with mounting holes 9 front and rear. The size and type of the mounting holes 9 can be determined according to different vehicle models. Different types of seat adjusters are machined. The upper slide rail 1 can slide on the lower slide rail 2, thereby adjusting the distance between the front and back of the seat.

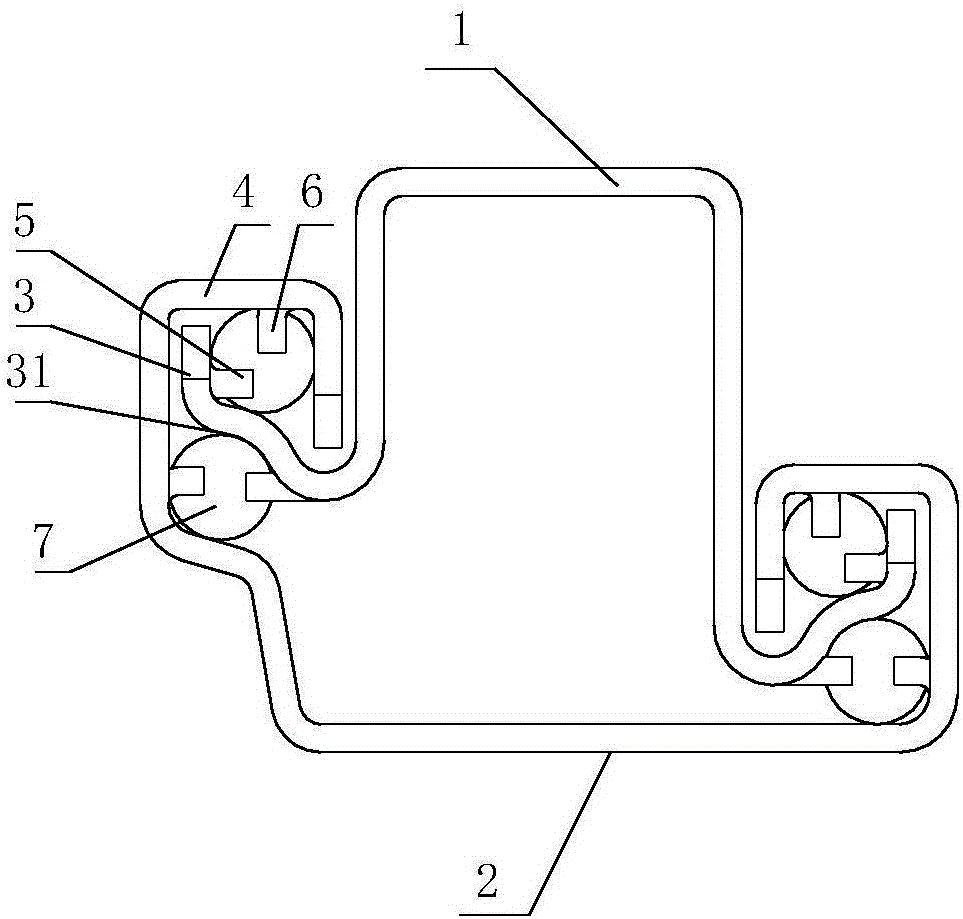

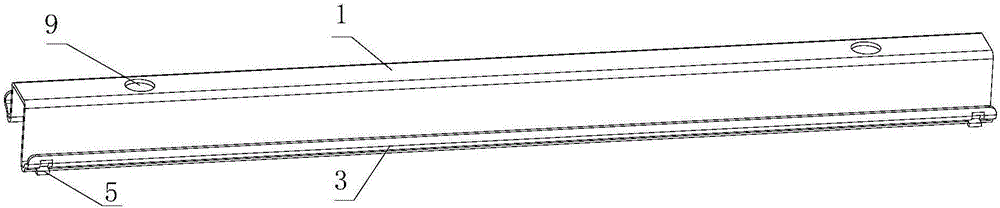

[0020] Such as Figure 3-4 As shown, the upper slide rail 1 is a U-shaped structure with a downward opening, the upper end surface is flat, and the ends of both sides are curled outwards and upwards to form a sliding core 3, and the heights of the sliding cores 3 formed by the two sides of the upper sliding rail 1 are not equal , the height of the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com