Novel chemical fiber equipment spare part cleaning machine

A technology for parts and cleaning machines, applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using liquids, etc., can solve problems such as inability to remove chemical fibers, affect the working status of chemical fiber equipment, and affect the production efficiency of chemical fiber equipment. Achieve the effects of simple mechanical structure design, easy repair and post-maintenance, and improved cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

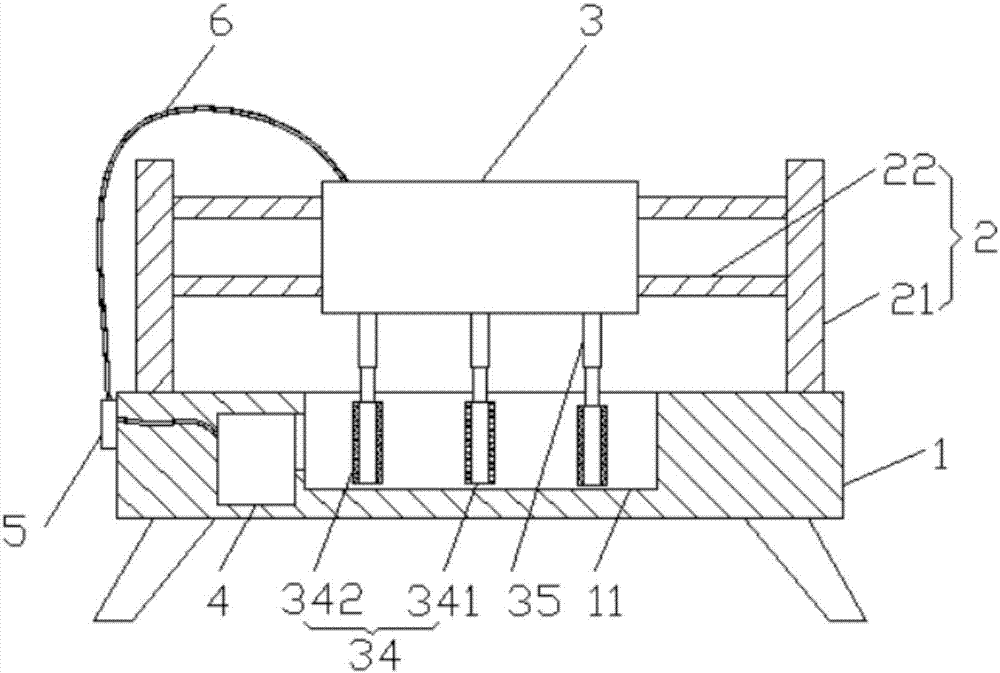

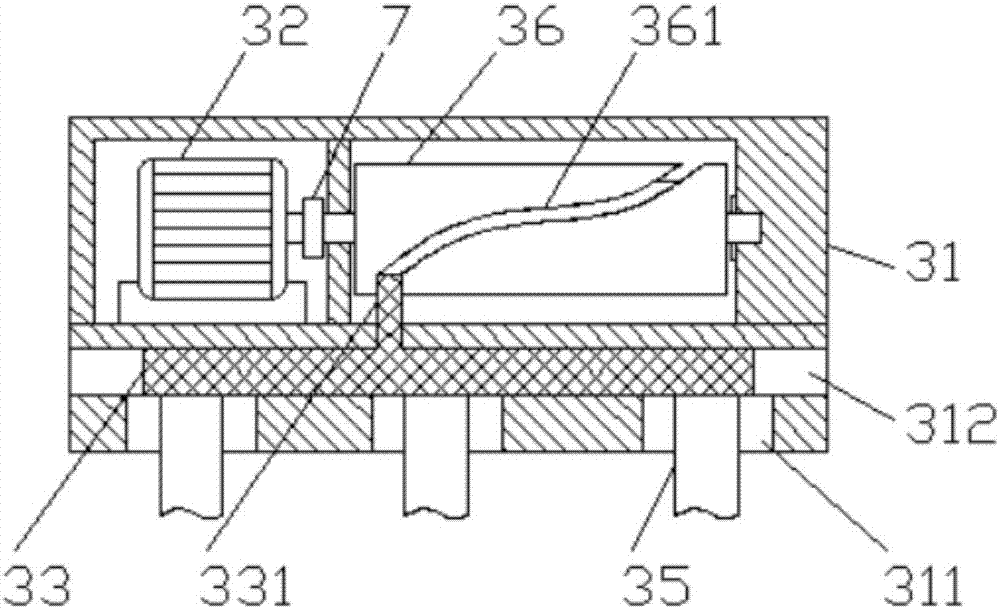

[0017] see Figure 1-2 The present invention provides a technical solution: a novel cleaning machine for parts of chemical fiber equipment, comprising a base 1, a bracket 2, a cleaning device 3 and an ultrasonic generator 4, the center of the base 1 is provided with a cleaning groove 11, and the bracket 2 is fixed on the upper surface of the base 1, the bracket 2 includes a fixed rod 21 and a connecting rod 22, the two ends of the connecting rod 22 are vertically fixedly connected with the fixed rod 21, the cleaning device 3 is fixedly connected with the bracket 2, the cleaning The device 3 includes a casing 31, a motor 32, a movable rod 33, a cleaning brush head 34, a telescoping rod 35 and a rotating column 36. The output end of the motor 32 is fixedly connected to the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com