Novel section bar corner position pulling sheet, pulling set and novel section bar corner position system

A technology for pulling the code piece and horizontally pulling the code piece, which is applied in the field of profile corner position system and assembly accessories, can solve problems such as sealing, and achieve the effect of not easy to turn over.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

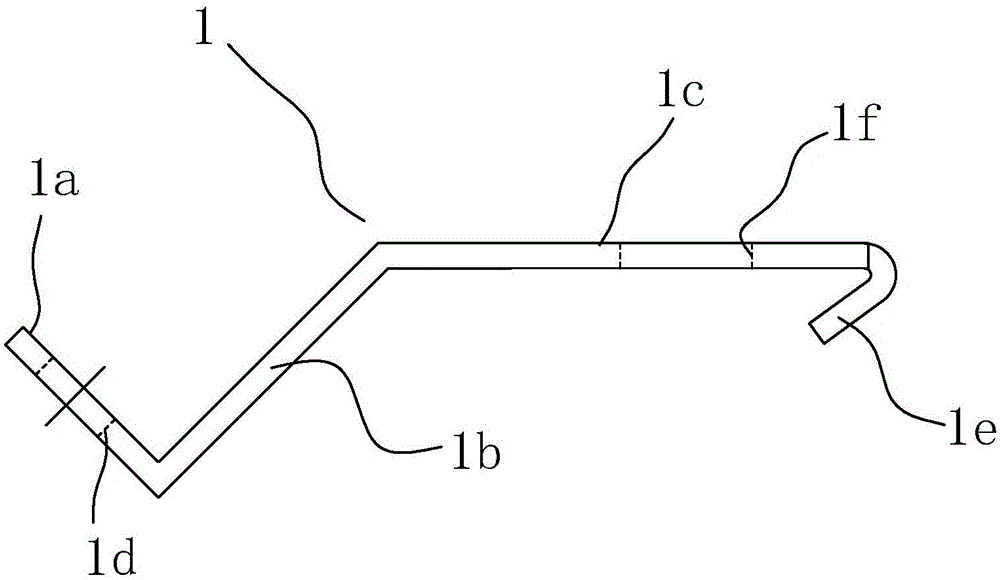

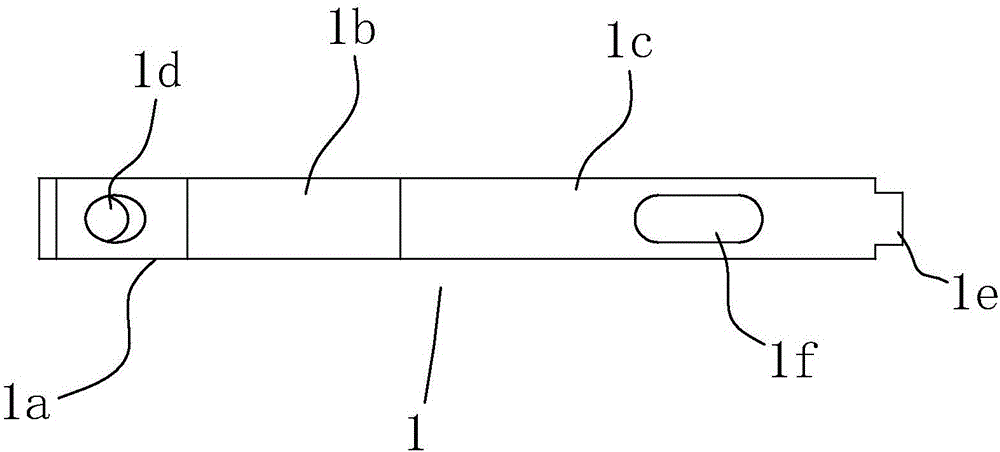

[0025] refer to figure 1 with figure 2 , a new type of profile corner pull piece, including a pull piece main body 1, the pull piece main body 1 is in the shape of a narrow and long strip as a whole, and is sequentially bent from the head end to the tail end to form a connecting section 1a, a transition section 1b, a hook pull Section 1c, connecting section 1a, transition section 1b, and hook section 1c are integrated, and the connecting section 1a has a connecting hole 1d. The direction of the head end of the pulling chip main body 1 is straight or bent, and the direction of the straight or bent direction of the pull hook 1e is opposite to the bending direction of the connecting section 1a. That is to say, if the inflection direction of the connecting section is taken as the upper direction, the drag hook extends obliquely downward. In this way, a structure convenient for tightening the screw and making the drag hook pull the profile can be conveniently constructed.

[002...

Embodiment 2

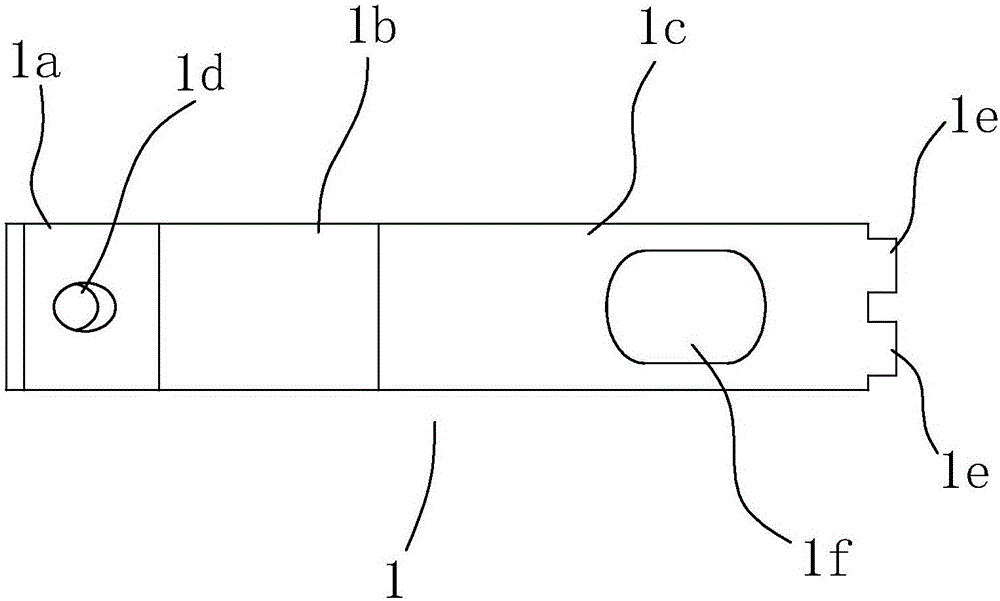

[0030] refer to image 3 , The shape and structure of the pulling piece of embodiment 2 is basically the same as that of embodiment 1, but the number of pulling hooks 1e is more than two, and they are arranged side by side at the end of the hook pulling section 1c. This kind of structure generally appears when the pull piece is wide. Since a single pull hook may not have enough pulling force, more than two pull hooks are designed to meet the tension balance requirements.

Embodiment 3

[0031] Embodiment 3 is about the specific implementation of the pull code group at the corner of the profile.

[0032] Example 3:

[0033] refer to Figure 4 , the profile corner pull code group includes a horizontal pull code 2 and a vertical pull code 3, and the horizontal pull code 2 is the above-mentioned new profile corner pull code, with the bottom surface of the horizontal pull code 2 connecting section It is a mirror image symmetry plane, the overall shape and structure of the vertical pull code sheet 3 is mirror image symmetrical to the horizontal pull code sheet 2, and a connecting screw 7 passes through the connecting hole of the horizontal pull code sheet 2 and the vertical pull code sheet 3 at the same time to connect the horizontal pull code sheet 2 Connect with the vertical pull code 3. Of course, after the connection, the connecting screw 7 locks the two pull code pieces, and there are multiple options for cooperating with nuts and directly processing threade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com